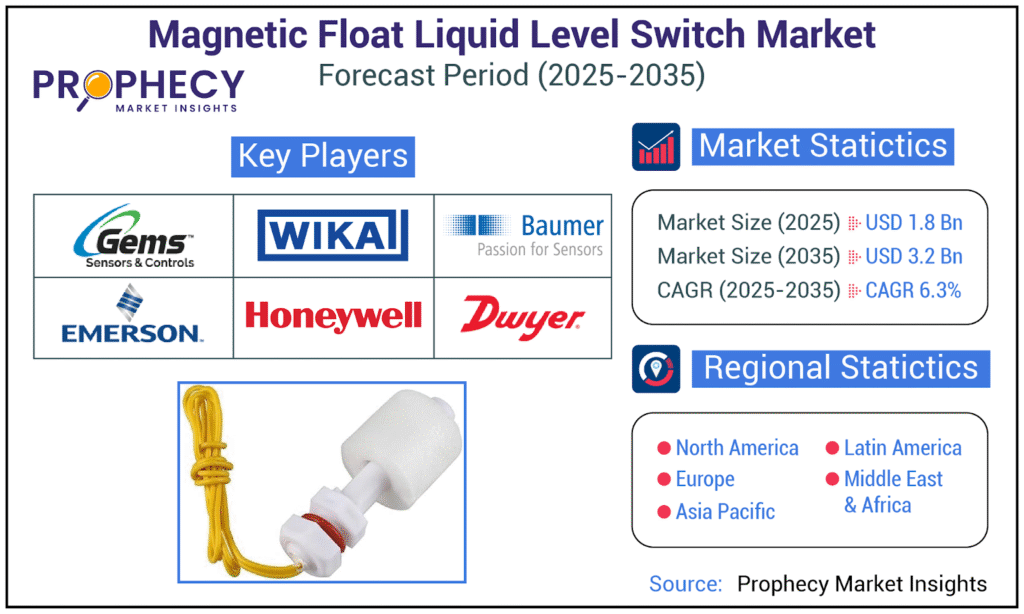

In the intricate world of industrial automation and process control, precise liquid level management is paramount for safety, efficiency, and operational integrity. A key component enabling this precision is the magnetic float liquid level switch. This essential market is currently experiencing steady expansion, driven by its robust reliability and diverse applications across various industries. According to the latest analysis, the global Magnetic Float Liquid Level Switch Market, valued at USD 1.7 Billion in 2024, is contemplated to enlarge at a valuation of USD 3.2 Billion by 2035, developing at a Compound Annual Growth Rate (CAGR) of 6.3%. This Q&A explores the dynamics behind this consistent growth.

Understanding the Market: Essential Questions Answered

Q1: What exactly is a Magnetic Float Liquid Level Switch, and why is it important?

A1: A magnetic float liquid level switch is a device used to detect the level of liquid in a tank or container. It operates on a simple yet highly reliable principle: a float containing a magnet moves freely along a stem or guide as the liquid level changes. When the float reaches a predetermined level, its internal magnet activates a reed switch (a type of electrical switch that uses a magnetic field to open or close a circuit) housed within the non-magnetic stem. This activation then sends a signal to a control system, triggering an action such as starting/stopping a pump, activating an alarm, or opening/closing a valve.

These switches are critical because they provide a simple, cost-effective, and durable solution for automated liquid level control, preventing overflows, dry-running of pumps, ensuring optimal fill levels, and enhancing overall operational safety in various industrial processes.

Q2: What is the current size and projected growth of this market?

A2: The global Magnetic Float Liquid Level Switch Market is experiencing consistent and reliable growth.

- In 2024, the market valuation was USD 1.7 Billion.

- By 2035, the market size is contemplated to enlarge at a valuation of USD 3.2 Billion.

- The market is developing at a Compound Annual Growth Rate (CAGR) of 6.3%.

This steady growth highlights the indispensable role these switches play across numerous industries and their continued adoption in new and existing applications.

Q3: What are the primary factors driving the growth of the Magnetic Float Liquid Level Switch Market?

A3: Several key drivers are contributing to the market’s expansion:

- Industrial Automation and Digitization: The global push towards industrial automation, IoT integration, and smart manufacturing demands precise and reliable sensing solutions, where magnetic float switches are foundational.

- Growing Demand from Process Industries: Sectors such as oil & gas, chemical processing, water & wastewater treatment, food & beverage, and pharmaceuticals heavily rely on accurate liquid level control for production efficiency and safety. The expansion of these industries directly fuels demand.

- Emphasis on Safety and Environmental Compliance: Preventing spills, overflows, and equipment damage is critical for safety and meeting environmental regulations. Magnetic float switches offer a proven solution for these concerns.

- Cost-Effectiveness and Reliability: Compared to some more complex level sensing technologies, magnetic float switches are generally robust, require minimal maintenance, and offer a cost-efficient solution, making them attractive for various applications.

- Increasing Infrastructure Development: Investments in new industrial plants, power generation facilities, and municipal water treatment projects globally create new installation opportunities for these switches.

“For in-depth analysis tailored to your specific business needs and strategic objectives, request a customized version of this report here.”

Q4: Are there any challenges or restraints facing the market?

A4: While the market demonstrates consistent growth, certain factors can act as restraints:

- Emergence of Alternative Technologies: Ultrasonic, radar, and capacitance level sensors offer non-contact or more advanced features, potentially diverting some demand, especially in highly specialized or corrosive environments.

- Material Compatibility Limitations: Magnetic float switches rely on direct contact with the liquid. In applications involving highly corrosive, viscous, or sludgy liquids, material compatibility and potential for fouling can be a challenge.

- Sensitivity to Contamination: Buildup of debris or residue on the float can affect its movement and accuracy over time, requiring periodic cleaning.

- Temperature and Pressure Limitations: While robust, extreme temperatures or pressures can impact the performance or material integrity of certain float switch designs.

Q5: What significant opportunities exist for growth and innovation in this market?

A5: Opportunities abound for market expansion and technological advancement:

- Integration with IIoT and Smart Systems: Developing smart float switches with integrated communication protocols (e.g., Modbus, IO-Link) for seamless data transfer to Industrial Internet of Things (IIoT) platforms and SCADA systems.

- Development of Specialized Materials: Innovations in corrosion-resistant and chemically inert materials for the float and stem can expand applications into more aggressive environments.

- Miniaturization and Customization: Creating smaller, more compact designs for space-constrained applications, and offering highly customizable solutions for niche industrial requirements.

- Remote Monitoring and Diagnostics: Enhancing switches with capabilities for remote diagnostics, predictive maintenance alerts, and wireless connectivity to reduce manual checks and optimize operations.

- Growth in Renewable Energy and New Industries: Expanding applications in sectors like renewable energy (e.g., solar thermal, hydrogen production), battery manufacturing, and advanced material processing.

Q6: How is the market segmented, and which segments are dominant?

A6: The Magnetic Float Liquid Level Switch Market is segmented to cater to diverse industrial needs:

- By Type/Principle:

- Vertical Mounted: Most common, with the float moving along a vertical stem.

- Horizontal Mounted: Used for side-entry applications or specific tank designs.

- By Material:

- Stainless Steel: Widely used due to its corrosion resistance and durability.

- Plastics (e.g., Polypropylene, PVDF): Preferred for corrosive liquids or those requiring high purity.

- Others: Includes brass, titanium, etc., for specific applications.

- By Application/End-Use Industry:

- Oil & Gas: Crucial for storage tanks, separators, and process vessels.

- Water & Wastewater Treatment: Essential for monitoring levels in clarifiers, sumps, and reservoirs.

- Chemical Processing: Used in reactors, storage tanks, and mixing vessels, often with specialized materials.

- Food & Beverage: For level control in mixing tanks, fermenters, and storage.

- Pharmaceuticals: Demands high-purity materials for sterile applications.

- Power Generation: In cooling systems, fuel tanks, and lubrication systems.

- HVAC: In chillers, boilers, and condensate pans.

- Automotive: In fluid reservoirs and fuel tanks.

- Others: Includes marine, aerospace, and general manufacturing.

- By End-User:

- OEMs (Original Equipment Manufacturers): Integrating switches into their machinery.

- System Integrators: Designing and implementing control systems.

- Direct Industrial Users: For plant maintenance and upgrades.

The Oil & Gas, Water & Wastewater Treatment, and Chemical Processing industries are typically the dominant application segments due to their inherent reliance on precise liquid level control.

Q7: Who are the key players in the Magnetic Float Liquid Level Switch Market?

A7: The market is competitive, with both established industrial control companies and specialized sensor manufacturers. Key players focus on product reliability, material science innovation, and global distribution.

Leading companies in this market include:

- SICK AG (Germany)

- Emerson Electric Co. (U.S.)

- ABB Ltd. (Switzerland)

- Endress+Hauser Group Services AG (Switzerland)

- Honeywell International Inc. (U.S.)

- OMEGA Engineering Inc. (U.S.)

- Dwyer Instruments, Inc. (U.S.)

- WIKA Alexander Wiegand SE & Co. KG (Germany)

- Gems Sensors & Controls (U.S.)

- BinMaster (U.S.)

- Trafag AG (Switzerland)

- (And various other regional and niche manufacturers).

These companies are continually innovating to offer more robust, versatile, and intelligent solutions to meet the evolving demands of industrial automation.

Author:

Authored by Shweta.R, Business Development Specialist at Prophecy Market Insights. This comprehensive analysis is grounded in an extensive blend of primary interviews, industry expert consultations, and in-depth secondary research. It provides strategic insights into the evolving dynamics, competitive landscape, and emerging opportunities within the Magnetic Float Liquid Level Switch Market

About Us:

Prophecy Market Insights is a leading provider of market research services, offering insightful and actionable reports to clients across various industries. With a team of experienced analysts and researchers, Prophecy Market Insights provides accurate and reliable market intelligence, helping businesses make informed decisions and stay ahead of the competition. The company’s research reports cover a wide range of topics, including industry trends, market size, growth opportunities, competitive landscape, and more. Prophecy Market Insights is committed to delivering high-quality research services that help clients achieve their strategic goals and objectives.

Contact Us:

Prophecy Market Insights

Website- https://www.prophecymarketinsights.com