Tech News

What Are the Advantages of 3D Printing Technology?

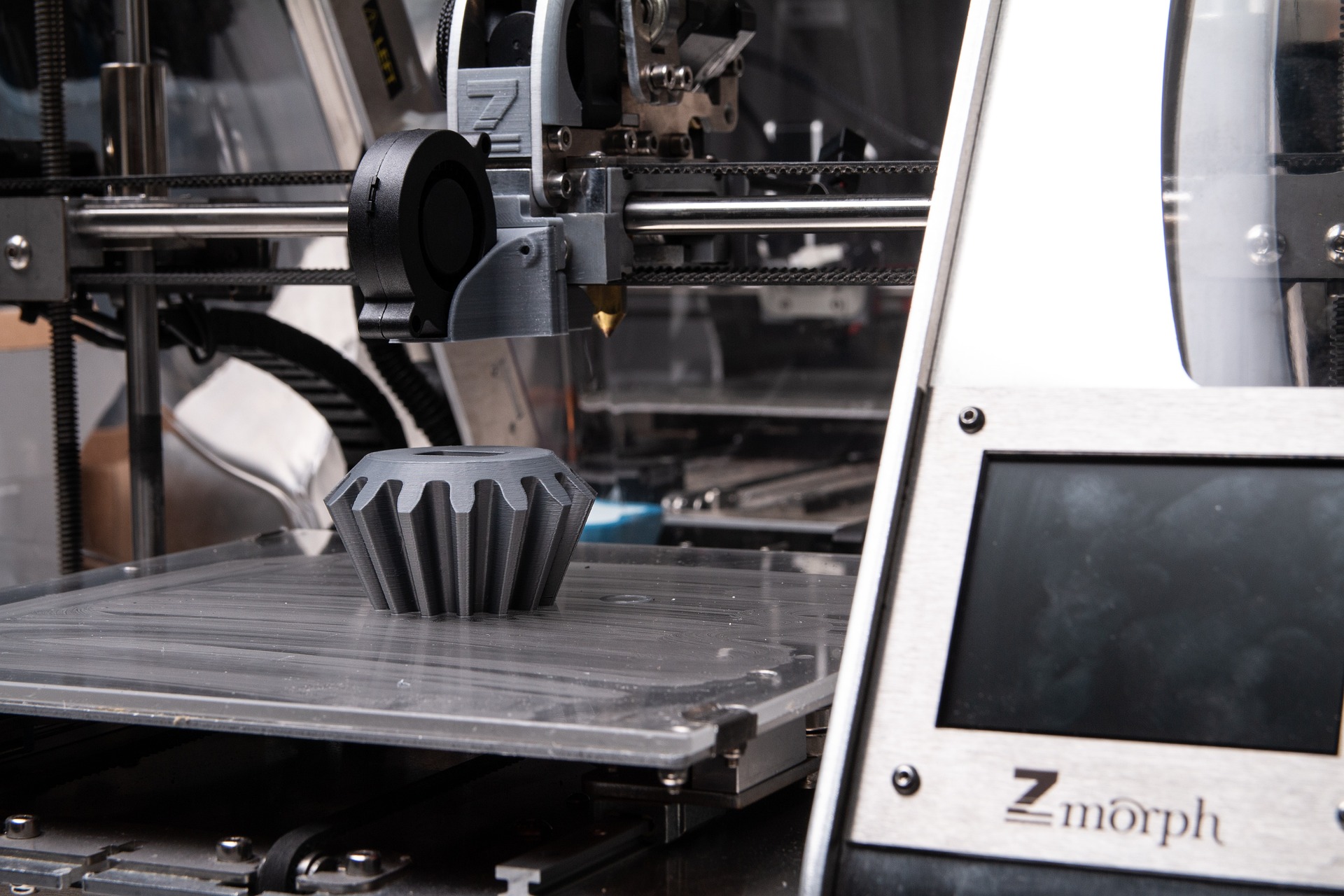

3D printing technology is a unique manufacturing method that layer by layer builds parts from materials such as plastics and metals, enabling it to quickly prototype complex objects without incurring high setup costs or lead time delays.

Innovative production takes the concept of just-in-time to a whole new level by eliminating warehousing costs, decreasing inventory levels, and cutting logistics costs.

Cost

3D printing technology enables for much quicker prototyping than traditional methods and can reduce manufacturing costs in the long run while increasing product quality and strength.

However, it is essential to comprehend the costs associated with 3D printing. While an initial investment can help get things underway, each machine requires specific print materials and post-processing technologies in order to operate at maximum potential.

Additionally, other factors must be taken into account when deciding to buy a 3D printer for your company. Considerations could include expected payback period; whether upgrades will be possible over time; and whether all-in-one solutions provide enough capacity.

3D printers can be used with various materials, from plastics to advanced metals. For instance, GE Aviation’s LEAP engine features 3D-printed cobalt-chrome fuel nozzles that weigh 25% less and five times stronger than their traditional manufactured counterparts – however their strength ultimately depends on both material type and its infill density.

Speed

3D printing may take several hours or even days, depending on the size and material chosen for your object. A faster printer can produce objects faster, while choosing cheaper or weaker materials will shorten printing times further.

3D Printing (also referred to as additive manufacturing) is an innovative process which uses computer-aided design software to produce three-dimensional items through layering methods, creating three-dimensional objects through an additive process. 3D printing can use various raw materials including plastics, composites and bio-materials with finished products ranging in size, rigidity and color.

At the start of any printing process, digital models of an object must be created using CAD software and divided into two-dimensional slices for translation into printer instructions.

FFF (fused filament fabrication) and SLA (stereolithography) are among the most widely-used 3D printing technologies. SLA employs laser technology to precisely print with resin, producing parts with uniform mechanical properties in all directions – an approach which makes possible complex engineering parts and consumer goods.

Materials

3D printing processes use powders, plastics, and resins – some even work with metal – to form parts for use in 3D printers. The strength of printed products depends on factors including material choice, design considerations, post-processing steps taken post-printing.

Stronger 3D print materials include acrylonitrile butadiene styrene (ABS), which is known for its strength and safety, polycarbonate which approximates steel in strength yet still remains flexible, transparent, or nitinol which is commonly used as medical implants and can bend to extreme degrees without breaking.

Most printers utilise one of three technologies – Fused Deposition Modeling (FDM), Stereolithography – Laser Beam Curing (SLA), or Direct Metal Laser Sintering (DMLS). Each process involves heating filament or powder through a nozzle before depositing layer upon layer on an build platform to form the finished part. Some models may also utilize UV light as part of the consolidation process.

Customization

3D printing provides manufacturers with an efficient alternative to traditional manufacturing technologies that involve multiple steps; it enables them to digitalize manual processes and automate production, saving both time and money by cutting labor costs and eliminating waste.

3D printers provide businesses with an innovative tool for producing products tailored to meet customers’ specific needs, making them particularly beneficial in industries that must match products to specific anatomy such as hearing aids or orthodontic aligners; such as hearing aids or orthodontic aligners requiring personalized devices for maximum performance.

With 3D printing’s growing popularity, more individuals are taking an interest and purchasing it for home use. 3D printing offers an easier way to produce items without large investments in machinery; manufacturing risks can also be reduced by eliminating errors while producing parts on demand as needed; this helps minimize inventory and minimize financial costs associated with storage excess products.

Sustainability

Companies using 3D printing can produce items as needed, thereby cutting material waste, energy consumption and emissions. Furthermore, recycled plastics used during the printing process help minimize landfill waste; further cutting carbon emissions by eliminating carbon-intensive supply chains between manufacturing facilities.

3D printers create parts by melting, fusing or sintering small amounts of material at a time – so only a fraction of an original solid block is consumed compared with subtractive manufacturing processes such as machining which involve taking away large chunks from it.

Preparing the model for printing begins with computer-aided design (CAD) software that generates precise drawings and technical illustrations that act as blueprints for 3D printers to follow. 3D printers offer several advantages over traditional tools and equipment; local production reduces shipping, inventory and holding costs significantly, as does their use as part of local infrastructure development programs such as Arup’s ecological village project which featured an impressive 12 meter-high 3D printer that could produce most elements using locally available and natural materials.