Tech News

Instructions for picking the best laser etcher machine

Picking the best laser engraver machine can be a staggering task with many decisions open watching out. Whether you’re a subject matter expert, a business person, or part of a substantial collecting action, picking the right laser shaper is fundamental for achieving definite and valuable results. The following are a few vital elements to consider while pursuing your choice.

Reason and Application: Characterising the reason and planned utilization of the engraver cutter laser is fundamental before jumping into the specialized details. Is it true or not that you want to involve it in specialist projects, prototyping, signage, or modern assembling? Various applications might require explicit highlights and capacities.

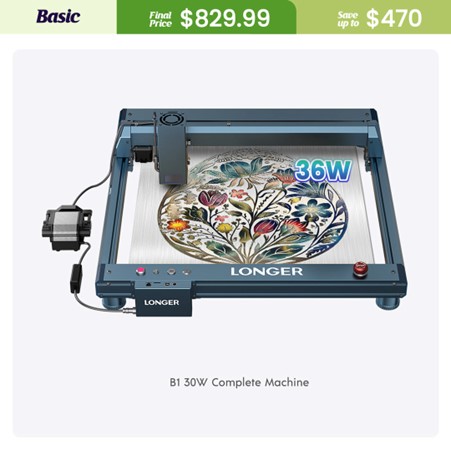

Laser Power and Type: Laser cutters accompany shifting power levels, ordinarily estimated in watts. Higher-wattage lasers can cut through thicker materials and work at speedier velocities. Consider the materials you’ll be working with and pick a machine with satisfactory power for your necessities. Besides, there are different kinds of lasers, each with advantages and cutoff points. Go for lasers that are flexible and reasonable for cutting a large number of materials.

Cutting Region and Bed Size: The cutting region or bed size decides the most extreme elements of the material you can work with. Pick a machine with a bed size that obliges the size of the materials you’ll regularly utilize. Remember that more significant cutting regions might require more space in your studio or office.

Accuracy and Exactness: The accuracy of a laser shaper is essential, particularly for complex plans and delicate subtleties. Search for engraving machines with high-goal optics and exact movement control frameworks. Furthermore, features like self-adjustment and cameras should be considered for precise material arrangement and enlistment.

Speed and Throughput: The cutting pace of the laser cutter influences efficiency and productivity. Quicker machines can do additional tasks significantly quicker, making them ideal for high-volume creation conditions. Notwithstanding, it’s fundamental to offset speed with accuracy and quality, as rapid cutting speed might think twice about eventual outcomes.

Programming and Similarity: The product that controls the laser shaper assumes a massive part in its ease of use and usefulness. Pick a machine that is viable with industry-standard plan programming. Moreover, think about the UI and convenience, particularly if you’re a fledgling or want to have various administrators.

Upkeep and Backing: Like some other pieces of gear, the best engraving machine requires regular support to guarantee ideal execution and life span. Think about the openness of essential parts for upkeep and the accessibility of extra parts. Besides, pick a respectable maker or provider offering magnificent client service and guaranteeing inclusion.

Financial Plan and Cost of Possession: While it’s enticing to decide on the most component-rich laser shaper accessible, taking into account your financial plan and the all-out cost of ownership is fundamental. Figure the underlying price tag and progressing expenses, such as consumables, upkeep, and energy utilisation. Assess the profit from speculation in light of your expected use and business objectives.

Well-being Elements: Laser cutters can present dangers because of their powerful laser radiates. Search for machines with security highlights, such as interlock frameworks, emergency stop fastens, and encased workspaces to safeguard administrators from expected risks. Also, it guarantees consistency with important well-being principles and guidelines.

Surveys and Suggestions: Lastly, an intensive examination should be conducted by understanding audits, looking for proposals from industry peers, and talking with educated specialists. Genuine encounters and bits of knowledge can give significant direction in picking the best engraving machine for your particular requirements.

Choosing the best laser cutter machine includes cautious thought of different variables. By thoroughly assessing these elements and focusing on your prerequisites, you can select an educated choice that augments efficiency, effectiveness, and quality in your laser-cutting activities.