General

What is Surface Mount Technology?

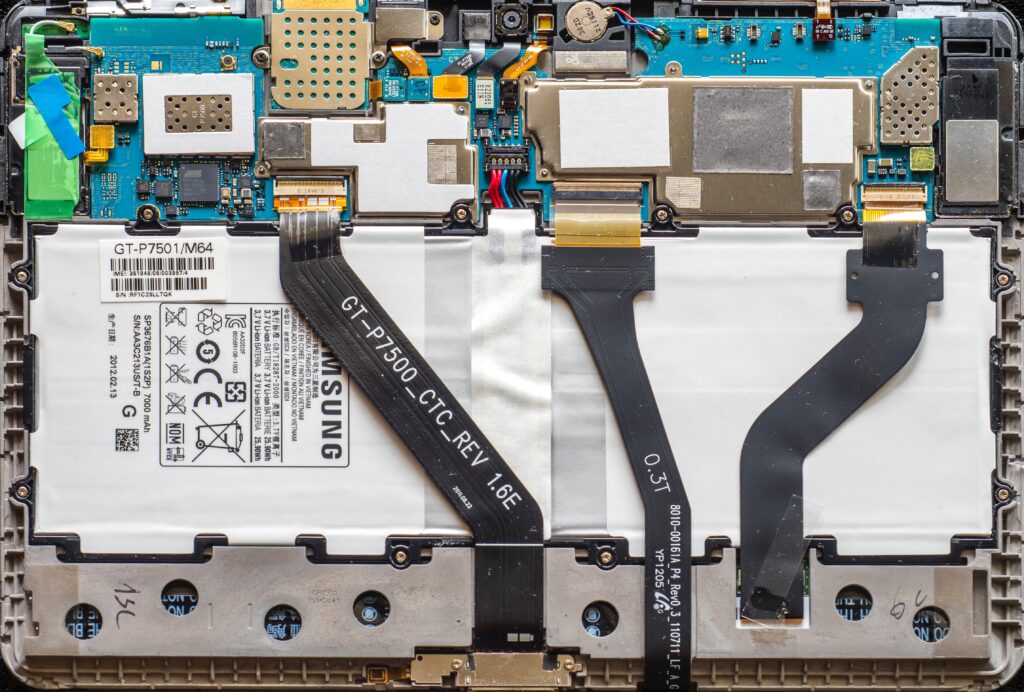

Surface Mount Technology is a method by which the electronic components are safely mounted directly to the face of an individually printed circuit board, without coming into contact with any external elements. An electronic component placed in this way is called a surface-mounted device. The benefit of using this technology is that components do not need to be placed into an inactive state; they are always active. This type of mounting method provides an inexpensive method of mounting electronic components and also has various advantages over component placements such as desktop and other micro Circuit Boards.

There are many advantages to surface mount technology for electronics, such as flexibility and reliability. The less-than-ideal placement of electronic components can lead to failure or premature death of the device, or even both. Components are less likely to be knocked off a circuit board and more likely to come in contact with a grounded surface, which can reduce the risk of shorting or shorts in the long run. This type of mounting allows for the placement of most electronic components right out of the way, while still providing a safe way to place wires and other components.

Another advantage to using surface mount technology for electronics is that it is easy to replace damaged or broken components. Since the circuits are always fully functioning, there is no need to spend time, money, or space on repairs or replacing components that break. There is also the ability to replace damaged Smds quickly and easily because Smd components can be easily replaced.

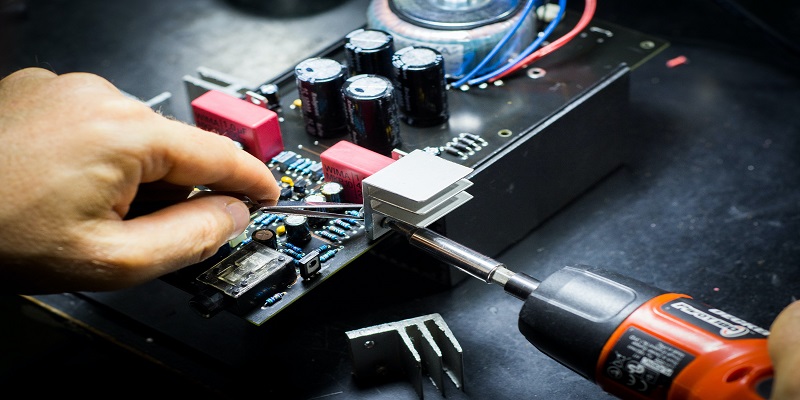

There are a variety of different ways to use surface mount technology for electronics. One of the most common methods of mounting electronic components, and probably the easiest to learn and use, is through the use of printed circuit boards (PCBs). These are soldered directly onto a surface and can then be easily removed and placed elsewhere if the need arises. To remove a PCB, all one needs to do is remove the backing that holds it in place. Some people prefer to use different mounting methods for different applications, but most agree that PCBs are the easiest and most cost-effective option.

With surface mounting becoming such a popular choice for electronics manufacturing, the need for companies to purchase their own printed circuit boards was reduced. It was discovered that buying a cheap circuit board and then mounting it yourself provided the same results as professionally manufactured ones at a fraction of the cost. As electronic assembly technology became more advanced, printed circuit boards quickly replaced surface-mounted ones as the preferred method of electronics assembly.

The popularity of surface mounting continued to grow as companies found it easier and cheaper to replace PCBs than to purchase them each time they were damaged. With increased production, chipmakers found that they could assemble many more chips on a single PC board than they could previously. This led to a need for chipmakers to find new ways to save money on components. Surface Mount Technology became an easy solution to this problem. Virtually every major chip manufacturer has a surface-mounted PCB available for use.