Ever wonder what goes into making the tech we use every day? Like, who actually makes the chips for Apple products? It’s a pretty complex process, way more involved than you might think. This whole world of semiconductors has a lot of moving parts, from the initial idea all the way to the tiny chip inside your phone. We’re going to break down how it all works, focusing on the big players and how Apple gets its hands on those essential components. It’s a story of global connections, big money, and some serious tech know-how.

Key Takeaways

- Apple mostly gets its chips from TSMC, a company in Taiwan. TSMC is really good at making advanced chips, which Apple needs for its devices.

- Apple designs its own chips but doesn’t make them. This is called the ‘fabless’ model. It lets Apple focus on design while letting other companies handle the expensive manufacturing part.

- Intel, a big chip company from the U.S., is trying to catch up in chip making. They’re building new factories and services to make chips for other companies, hoping to bring more chip production back to the U.S.

- The chip industry is very global, with lots of production happening in places like Taiwan. This can cause problems, especially with world events, so companies are trying to spread out their manufacturing to different countries.

- Making chips isn’t just about building them. After they’re made, chips go through lots of testing and packaging to make sure they work right before they end up in your electronics.

Understanding the Semiconductor Supply Chain

Let’s talk about how chips are made and get to your phone or computer. It’s not as simple as one company doing everything. It’s a whole chain of events, with different companies specializing in different parts. It’s like a global puzzle, and if one piece is missing, everything gets held up. The semiconductor supply chain is highly complex, but this complexity demands proactive measures rather than inaction.

From Design to Device: The Journey of a Chip

Think of it like this: first, someone designs the chip. Companies like ARM or NVIDIA are big in design. They create the blueprints. Then, those blueprints go to a manufacturer, who actually builds the chip. After that, the chips get tested and packaged up. Finally, they’re shipped off to companies like Apple, who put them in your iPhone. It’s a long trip!

- Design: Creating the chip blueprint.

- Manufacturing: Building the chip from the design.

- Testing: Making sure the chip works right.

Key Stages of Semiconductor Production

There are several key steps in making semiconductors. It starts with raw materials like silicon. Then comes the design phase, followed by fabrication (making the actual chip). After that, there’s testing and packaging. And finally, distribution. Each stage is super important, and delays in any one area can cause problems down the line. The fabrication stage is often the most complex and expensive.

- Raw Materials: Getting the base materials.

- Fabrication: Turning materials into chips.

- Testing & Packaging: Ensuring quality and preparing for use.

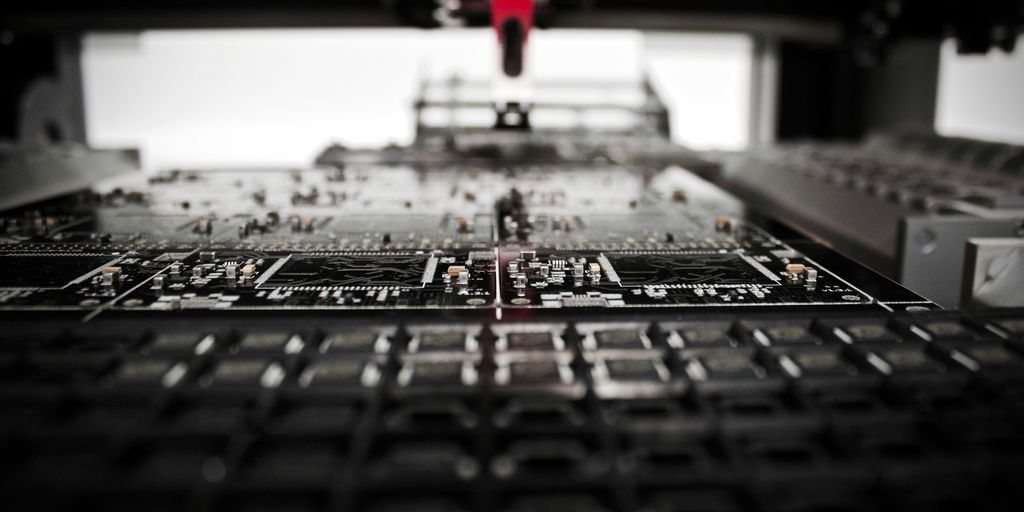

The Role of Foundries in Chip Manufacturing

Foundries are the factories that actually make the chips. They take the designs from companies like Apple and turn them into real, working chips. TSMC and Samsung are two of the biggest foundries in the world. They have huge, expensive factories and are experts in manufacturing. Without foundries, companies like Apple couldn’t make their chips. These foundries are essential for chip manufacturing.

| Foundry | Specialization |

|---|---|

| TSMC | Advanced Process Nodes |

| Samsung | Memory Chips, Mobile Processors |

| GlobalFoundries | Specialized Solutions |

Who Makes Chips for Apple: The Dominance of TSMC

TSMC’s Unmatched Power in Advanced Nodes

TSMC really is the king when it comes to making advanced chips. They make over 60% of the world’s semiconductors and basically have a monopoly on the really advanced stuff – we’re talking 3nm, 5nm, and 7nm chips. Big names like Apple, NVIDIA, AMD, and Qualcomm? They all depend on TSMC. It’s kind of wild to think about how much power one company has in this space. TSMC’s success didn’t happen overnight. When the company started, its tech was a couple of generations behind Intel’s. But, they had great yields, which showed they had a solid engineering base. TSMC plans to invest a lot in the U.S., which is a big deal for the industry.

Apple’s Reliance on TSMC for Cutting-Edge Chips

Apple and TSMC are basically best friends in the chip world. Apple relies on TSMC to make the brains of their iPhones, iPads, and Macs. It’s a big deal because Apple always wants the newest, fastest chips, and TSMC is one of the few companies that can deliver. Back in 2016, TSMC was already mass-producing 10nm chips for Apple, grabbing most of the iPhone orders. Samsung had some issues with their chips overheating, which helped TSMC really take over Apple’s business. This close relationship is a big reason why Apple can keep pushing the limits of what their devices can do.

Why Apple Chose TSMC Over Intel

So, why didn’t Apple go with Intel? Well, Intel struggled with its 10nm process for a while. In 2011, Intel tried to get Apple’s chip business, but TSMC was already in talks with Apple. Tim Cook wasn’t impressed with Intel’s foundry abilities. He basically told Morris Chang, the founder of TSMC, not to worry because Intel wasn’t good at making chips for others. Apple realized that TSMC offered better quality, cost, and reliability for making iPhone chips. It wasn’t that TSMC stole Intel’s business; Intel just didn’t keep up with the future of chip manufacturing. Even now, Intel still depends on TSMC to get its products out faster. In the AI world, they need TSMC more than ever.

The Fabless Model: Apple’s Strategic Approach

Designing In-House, Manufacturing Externally

Apple operates under what’s called a "fabless" model. This means they design their own chips – the brains of their iPhones, iPads, and Macs – but they don’t actually manufacture them. Instead, they outsource the manufacturing to specialized companies. This allows Apple to focus on what they do best: innovation and design. It’s like designing a dream house but hiring a construction company to build it. This approach lets Apple pour resources into creating cutting-edge chip architectures without the huge capital investment needed for building and maintaining fabrication plants (fabs).

Benefits of the Fabless Semiconductor Model

There are several reasons why Apple chooses this fabless route:

- Focus on Core Competencies: Apple can channel its energy and resources into chip design and software integration, which are key differentiators for their products. They don’t have to worry about the complexities of running a fab, like yield rates and equipment maintenance.

- Access to Cutting-Edge Manufacturing: By partnering with leading foundries, Apple gains access to the most advanced manufacturing processes available. This ensures that their chips are built using the latest technology, giving them a performance edge. For example, Android and iOS have different hardware requirements, and this model allows Apple to optimize for their specific needs.

- Cost Efficiency: Building and operating a state-of-the-art fabrication plant is incredibly expensive. Outsourcing manufacturing allows Apple to avoid these massive capital expenditures and instead pay for production capacity as needed.

- Flexibility and Scalability: The fabless model gives Apple the flexibility to adjust production volumes based on demand. They can easily scale up or down their orders with their manufacturing partners without being constrained by their own fab capacity.

Key Partners in Apple’s Chip Production

While Apple designs its chips, they rely on a network of partners to bring those designs to life. The most important partner is undoubtedly TSMC (Taiwan Semiconductor Manufacturing Company). TSMC is the world’s largest dedicated independent semiconductor foundry, and they’ve been instrumental in manufacturing Apple’s A-series and M-series chips. Other key players are involved in testing and packaging, global semiconductor equipment, ensuring the chips are functional and ready for use in Apple products. Apple’s reliance on TSMC is so great that Tim Cook wasn’t impressed with Intel’s foundry capabilities. This strategic partnership is a cornerstone of Apple’s success in the chip world.

Intel’s Comeback and Foundry Ambitions

Intel’s Struggle in Advanced Process Nodes

For a while there, it felt like Intel was always playing catch-up. They used to be the undisputed kings of chip manufacturing, but then companies like TSMC and Samsung started pulling ahead. It wasn’t just about speed; it was about efficiency and power consumption too. Intel had some missteps, and it cost them. They were slow to adopt new technologies, and that let the competition gain a real advantage. This lag impacted their ability to produce cutting-edge chips, especially for mobile devices and other power-sensitive applications.

Intel Foundry Services: A New Chapter

But Intel isn’t just sitting around. They’re making a big push to get back in the game with Intel Foundry Services IFS. The idea is to not only make their own chips but also to manufacture chips for other companies, like TSMC does. It’s a huge investment, and it’s a complete shift in strategy for them. They’re building new factories, developing new manufacturing processes, and trying to convince companies that they can be a reliable partner. It’s a tough road ahead, but they’re serious about becoming a major player in the foundry business again. It’s a long-term play, and it’s going to take time to see if it pays off. Intel even got their first outsourcing contract from Andy Grove, for the production of microprocessors with the 1.5-um process.

Securing U.S. Chip Independence

There’s a lot of talk about bringing chip manufacturing back to the U.S., and Intel is right in the middle of it. The government is offering incentives to companies that build factories here, and Intel is taking advantage of that. The goal is to reduce reliance on overseas manufacturers, especially in Taiwan, given the geopolitical tensions. It’s about national security and making sure the U.S. has a reliable supply of chips for everything from military equipment to smartphones. Intel’s foundry ambitions are tied to this push for U.S. chip independence, and they’re hoping to play a key role in making it happen. It’s a big challenge, but it’s also a huge opportunity for them. The true competition is TSMC’s innovative rise.

Here are some key aspects of Intel’s strategy:

- Massive investments in new fabs (fabrication plants) in the US and Europe.

- Focus on advanced process technologies to compete with TSMC and Samsung.

- Aggressive pursuit of government subsidies and partnerships.

Geopolitical Landscape of Chip Manufacturing

The China-Taiwan Semiconductor Dilemma

The concentration of semiconductor manufacturing in East Asia, particularly with TSMC and Samsung leading the way, presents some interesting challenges. Rising tensions between China and Taiwan are causing companies to rethink their supply chains. Everyone’s looking at building new fabs in the U.S., Japan, and even Europe to spread the risk around. It’s not just about where the chips are made, but also about who controls the tech and the potential impact of any conflict. Taiwan’s central role is a double-edged sword – amazing tech, but also a big geopolitical target.

Diversifying Supply Chains for Resilience

Diversification is the name of the game right now. Companies are trying to move away from relying too much on one region. This means investing in new manufacturing plants in different countries and looking for alternative suppliers. It’s a costly process, but the idea is to make the semiconductor supply chain more resilient to disruptions, whether they’re caused by political issues, natural disasters, or even just plain old trade wars. It’s like not putting all your eggs in one basket, but with really expensive, high-tech eggs.

Government Regulations and Trade Wars

Government regulations and trade wars are playing a huge role in shaping the chip industry. For example, the U.S. government has put restrictions on advanced semiconductor manufacturing equipment going to China, which makes it harder for companies like SMIC to compete. These kinds of policies can have a big impact on where chips are made and who has access to the latest technology. Plus, tariffs and trade agreements can change the cost of moving chips around the world, further complicating the supply chain. It’s a complex web of rules and regulations that everyone in the industry has to navigate.

Beyond Fabrication: Testing and Packaging

Ensuring Chip Functionality and Reliability

So, the chips are made, right? Not so fast! They aren’t ready to go into your iPhone just yet. Testing and packaging are super important steps that make sure the chips actually work and keep working. Think of it like baking cookies – you wouldn’t just throw them in a box straight from the oven, would you? You’d let them cool and maybe add some frosting to make them look and taste better. It’s the same idea with chips. They need to be checked for any defects and then protected so they can handle all the bumps and bruises of being inside a device.

The Importance of Back-End Processes

This part of the process is often called "back-end," and it’s a bigger deal than many people realize. It’s not just about slapping a chip into a package. It involves a bunch of complex steps:

- Assembly: Putting the chip together with other components.

- Packaging: Encasing the chip in a protective material.

- Testing: Running the chip through a series of tests to make sure it meets performance standards. OSAT services are crucial here.

These steps are becoming even more important as chips get smaller and more powerful. Advanced packaging techniques are needed to handle the heat and complexity of modern chips. It’s a whole field of its own, with companies constantly innovating to find better ways to protect and connect these tiny powerhouses.

Global Distribution of Finished Semiconductors

Once the chips are tested and packaged, they’re ready to be shipped off to device manufacturers all over the world. This is where logistics come into play. Getting these chips from the chip manufacturing plants to the factories where iPhones and other devices are assembled is a massive undertaking. It involves:

- Coordinating shipments across different countries.

- Dealing with customs regulations.

- Ensuring the chips arrive on time and in perfect condition.

It’s a complex web of transportation and logistics that keeps the global electronics industry humming. And if there are any disruptions along the way, like a port closure or a trade war, it can have a ripple effect on the entire supply chain.

The Future of Apple’s Chip Supply

Innovations in Semiconductor Technology

The semiconductor world is always changing, and that means Apple’s chip supply will have to change too. We’re seeing new materials being explored, like graphene and carbon nanotubes, which could lead to faster and more efficient chips. Chiplet designs are also gaining traction, allowing for more modular and customizable processors. This could let Apple mix and match different chip components to create highly specialized chips for their devices. Plus, advancements in areas like 3D stacking promise to pack even more transistors into a smaller space. It’s a wild time for chip tech!

Potential Shifts in Manufacturing Partnerships

Right now, TSMC’s dominance is pretty clear, especially when it comes to the most advanced chips. But things could shift. Intel is making a big push to get back into the foundry game with its Intel Foundry Services (IFS). If Intel can actually deliver on its promises, Apple might consider diversifying its manufacturing partners to reduce its reliance on TSMC. Samsung is also still in the mix, though they’ve had some struggles keeping up with TSMC’s pace. It’s all about who can offer the best combination of performance, cost, and reliability. Here’s a quick look at potential foundry players:

- TSMC: The current leader, known for its advanced process nodes.

- Intel: Trying to make a comeback with significant investments.

- Samsung: Still a contender, but needs to improve its technology.

Impact of Global Events on Chip Availability

We’ve all seen how global events can mess with the chip supply. Trade tensions, natural disasters, and even pandemics can cause major disruptions. That’s why Apple is probably looking at ways to make its supply chain more resilient. This could mean diversifying manufacturing locations, stockpiling key components, or even investing in its own chip manufacturing capabilities down the road. The name of the game is to avoid being caught off guard by unexpected events. The economic and geopolitical implications are huge, and Apple knows it.

Wrapping Things Up

So, we’ve taken a good look at how Apple gets its chips. It’s not just one company doing everything, right? There’s a whole bunch of players involved, from the folks who design the chips to the big factories that actually make them. Companies like TSMC and Samsung are super important here, making those tiny, powerful brains for our iPhones and other gadgets. It’s a complicated setup, with different steps happening all over the world. This whole system shows just how connected the tech world is, and how many different companies have to work together to get those devices into our hands. It’s pretty wild when you think about it.

Frequently Asked Questions

Who actually makes the chips inside Apple’s products?

Apple designs its own chips, like the A-series for iPhones and M-series for Macs. But they don’t actually make them. Instead, they hire special factories called ‘foundries’ to do the manufacturing. The main company that makes Apple’s most important chips is TSMC, which stands for Taiwan Semiconductor Manufacturing Company.

Why is TSMC so important to Apple’s chip production?

TSMC is super important to Apple because they are the best at making the smallest and most powerful chips. These tiny chips are what make iPhones and Macs so fast and energy-efficient. Apple needs these cutting-edge chips to make their products stand out, and TSMC is the only one who can consistently deliver them at the quality and scale Apple needs.

Why did Apple choose TSMC over Intel for making its chips?

Apple decided to work with TSMC instead of Intel for a few big reasons. First, Intel struggled for a while to make chips as small and good as TSMC’s. Second, TSMC focuses only on making chips for other companies, so they became really good at it and were a reliable partner. Intel, on the other hand, mostly made chips for its own products, and Apple felt TSMC was a better fit for their needs.

What does ‘fabless’ mean in the world of chipmaking, and how does Apple use it?

The ‘fabless’ model means a company designs its chips but doesn’t own the factories (fabs) to make them. They send their designs to foundries like TSMC. This lets Apple focus on designing amazing chips without having to spend billions on building and running chip factories, which is a very expensive and difficult business.

What is Intel doing to get back into the chip manufacturing game?

Intel is trying hard to catch up in chip manufacturing. They’ve started a new part of their company called Intel Foundry Services (IFS) to make chips for other companies, just like TSMC does. Their goal is to become a major player again and help the U.S. make more of its own chips, so we don’t rely so much on factories in other countries.

How do global politics and geography affect where chips are made?

The chip industry is very concentrated in places like Taiwan and South Korea. This can be risky because if there are problems in those areas, it could affect the world’s chip supply. Companies and governments are now trying to build more chip factories in other countries, like the U.S. and Europe, to spread out the risk and make sure there are always enough chips available.