Materials Science 2020: A Transformative Year

Wow, 2020. It feels like ages ago, doesn’t it? But looking back, it was a seriously big year for materials science. Things were really starting to shift, moving away from the old ways of doing things. It wasn’t just about one or two big breakthroughs, but more about a fundamental change in how scientists even approach finding new materials.

The Evolving Landscape of Materials Discovery

For a long time, finding new materials felt a bit like being a lone artisan. You’d spend ages tinkering, trying things out based on experience and maybe a bit of luck. It was slow, and honestly, pretty expensive. But in 2020, we saw a real push to change that. The idea was to move from that ‘craft’ approach to something more like an assembly line – a way to make way more discoveries, way faster. This shift was all about getting more ‘shots on goal,’ so to speak. The more experiments you can run, the better your chances of stumbling upon something amazing.

From Artisanal Craft to Industrial Scale

Think about it: the old way was like a blacksmith forging a single sword. The new way is more like a factory producing thousands. This transition is huge. It means rethinking everything from the lab equipment we use to how we share information. We’re talking about moving from individual labs doing their own thing to a more coordinated, large-scale effort. It’s a big change, and it’s not something that happens overnight. It requires new ways of thinking and new tools.

The Promise of Artificial Intelligence in Materials Science

And then there’s AI. In 2020, AI wasn’t just a buzzword anymore; it was starting to show real potential in materials science. It wasn’t quite the magic wand some people imagined, but it was becoming a powerful tool. AI could help scientists sift through the mind-boggling number of possibilities out there, pointing them in the right direction. It’s like having a super-smart assistant that can analyze data and suggest promising avenues for research, saving tons of time and effort. This was a big step towards making materials discovery more systematic and less reliant on pure chance.

AI’s Growing Role in Materials Science 2020

It feels like everywhere you look these days, AI is being talked about, and materials science is no exception. For a long time, finding new materials felt a bit like searching for a needle in a haystack. There are just so many possibilities out there, more than we can even imagine. In 2020, AI started to look less like a futuristic dream and more like a practical tool for scientists.

Beyond the Hype: AI as a Foundation

Sure, some people talk about AI like it’s a magic wand that can instantly solve problems. You see headlines about AI discovering millions of new materials, and it sounds amazing. But the reality is a bit more down-to-earth. AI in 2020 was really about building a better foundation for how scientists work. Think of it like laying the groundwork for a house; it’s not the house itself, but you can’t build anything without it. This means changing how we approach research, what we assume, and what we aim for. It’s not just about the AI models themselves, but about how we use them and what we build on top of that initial groundwork.

Leveraging Large Language Models for Discovery

Large language models (LLMs), like the ones people were starting to get familiar with, began showing promise in materials science too. These models can process and understand vast amounts of text and data. Imagine feeding an LLM all the published research papers on a specific type of material. It could potentially spot connections or suggest new avenues of research that a human might miss.

- Identifying patterns in existing research.

- Suggesting new combinations of elements or structures.

- Helping to summarize complex scientific literature.

The Need for Experimental Validation

Even with all the computational power AI brings, it’s not a replacement for real-world testing. AI can suggest promising materials, but scientists still need to make them in the lab and test their properties. The world is just too complicated to perfectly simulate. So, while AI can speed up the initial search and generate ideas, experiments remain the ultimate test. This means we need to get better and faster at doing those experiments, scaling up from what felt like artisanal craft to something more like an industrial process.

Accelerating Innovation Through Data and Infrastructure

It feels like we’re at a bit of a crossroads in materials science. For a long time, progress felt steady, but lately, it’s like the easy discoveries are all gone. We need new ways to find the next big thing, and that’s where data and how we handle it come in. Think of it like trying to build something complex without a good blueprint or all the right tools – it’s just going to take forever and probably won’t turn out great.

Building Cross-Departmental Datasets

One of the biggest hurdles we’ve seen is how scattered all our information is. Different labs, different projects, even different government agencies often keep their data in their own little silos. This means people might be doing the same work without even knowing it, or they can’t easily combine information to get a bigger picture. It’s like having a bunch of puzzle pieces but no way to put them together. We really need to get better at sharing and organizing this data so everyone can benefit.

- Standardize data formats: Make sure everyone is collecting and storing data in a way that’s easy for others to understand and use.

- Create central repositories: Think of a big, shared library where all this materials data can live, making it findable and accessible.

- Incentivize data sharing: Right now, scientists are mostly rewarded for publishing papers. We need to find ways to recognize and reward the sharing of good datasets too.

Maximizing Utility of Public Data

There’s a ton of data out there already, especially from government-funded research. The problem is, it’s often hard to find, difficult to use, or not in a format that’s helpful for modern analysis, especially with AI. We’ve got to make this public data more accessible and useful. Imagine if all the raw ingredients for a fantastic meal were available, but they were all in different, unlabeled jars scattered across a huge warehouse – you’d need a lot of effort just to find and prepare them. Making this data work for us could save a lot of time and money, preventing duplicated efforts and speeding up new discoveries.

Developing Materials Science Foundation Models

This is where things get really interesting, especially with AI. Just like how large language models can understand and generate text by learning from massive amounts of written information, we’re starting to see the potential for ‘foundation models’ in materials science. These models would learn from vast datasets of material properties, structures, and experimental results. The goal is to create models that can predict new material behaviors or even suggest entirely new materials with desired properties. However, these models are only as good as the data they’re trained on. If the data is messy, incomplete, or biased, the model’s predictions will be too. So, cleaning up and expanding our datasets is absolutely key to making these powerful AI tools actually work for us in discovering the materials of the future.

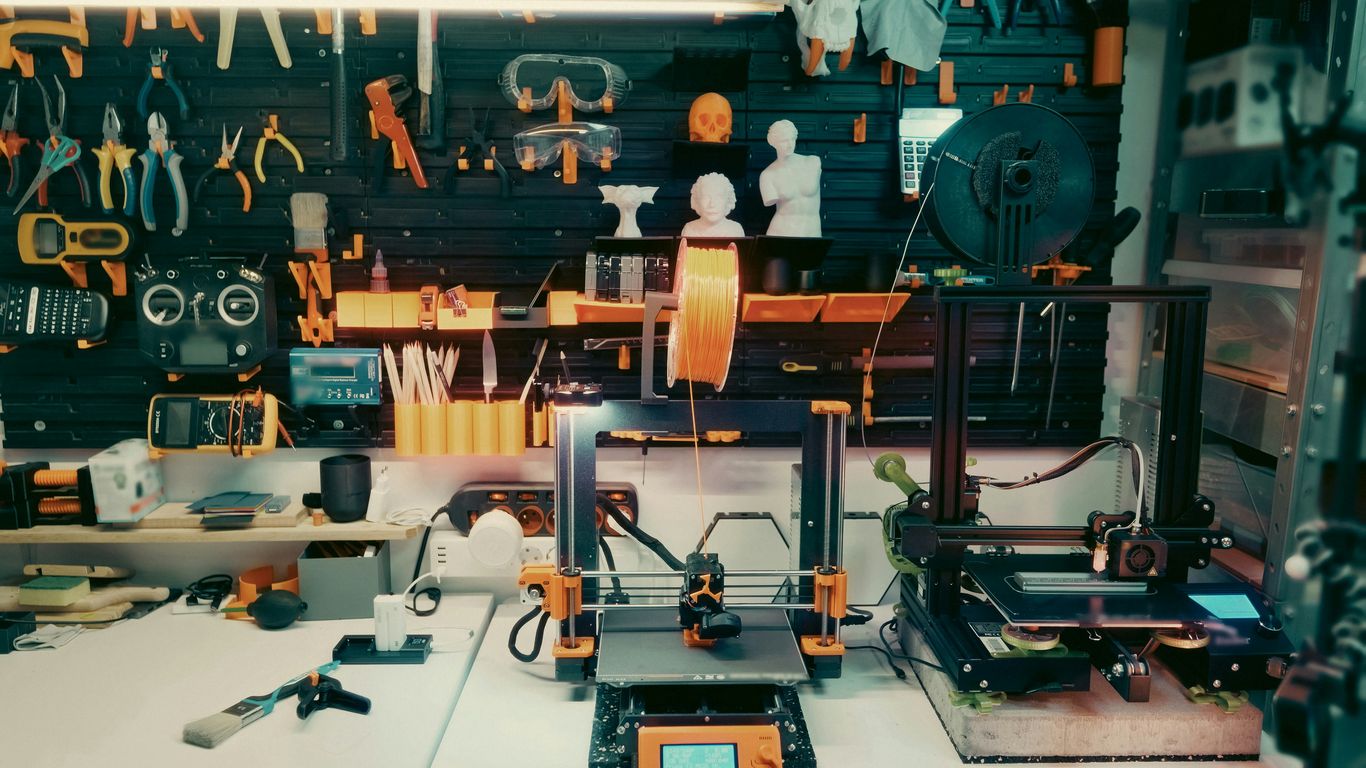

Robotic Laboratories and Experimental Throughput

Remember when science felt like it was done by lone geniuses in dusty labs? Well, things are changing, and fast. In 2020, we saw a big push towards making labs run themselves, at least partly. Think of it as giving science a serious upgrade in speed and efficiency.

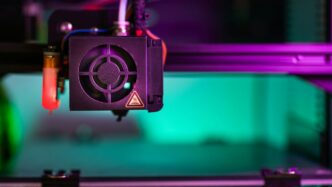

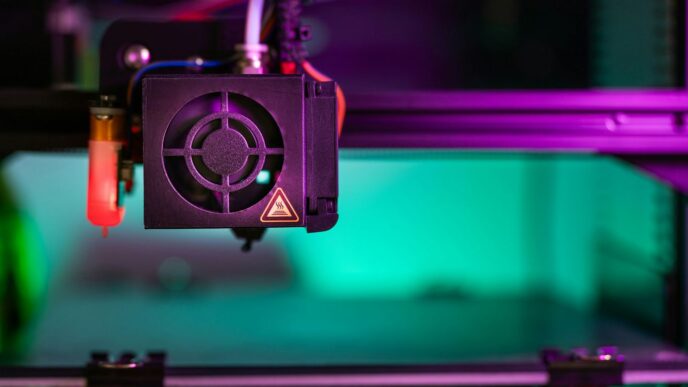

The Vision for Robotic Cloud Laboratories

This is where the idea of "self-driving labs" really started to take hold. Instead of scientists manually mixing chemicals or running tests one by one, robots are stepping in. The goal is to have these automated systems, often controlled remotely, handle the repetitive and time-consuming parts of experiments. This allows human researchers to focus on the bigger picture, like designing new experiments or figuring out what the results actually mean. It’s like having a tireless assistant who never complains about late nights or tedious tasks. These aren’t just theoretical ideas anymore; small-scale versions are already proving their worth, churning out new materials that might have taken years to discover otherwise.

Scaling Experimental Capabilities

One of the biggest hurdles in materials science has always been the sheer time it takes to make and test new compounds. Traditional methods are often slow and can only handle a few samples at a time. Robotic labs change that. They can run many experiments in parallel, dramatically increasing the number of materials that can be synthesized and characterized. Imagine a system that can test hundreds of variations of a material overnight. This leap in throughput is what’s needed to keep up with the pace of AI-driven predictions. Without faster ways to test these predictions, AI’s potential remains limited.

Enhancing Research Efficiency

So, how does this all work in practice? It’s a combination of smart robotics, AI, and a lot of data. Here’s a simplified look at the process:

- Automated Synthesis: Robots precisely measure and mix chemicals to create new materials based on AI-generated recipes.

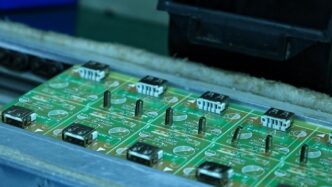

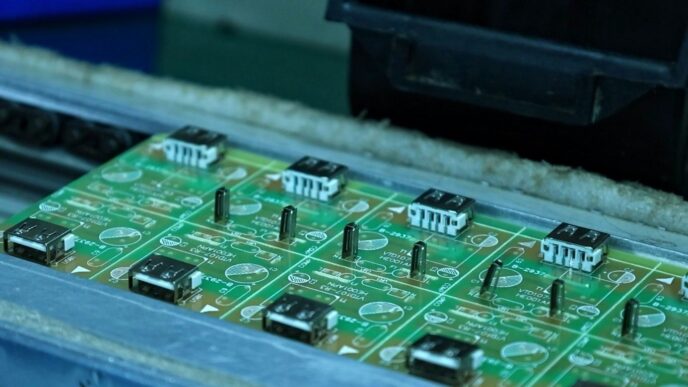

- High-Throughput Characterization: Automated tools quickly analyze the properties of the newly made materials, like their structure or how they conduct electricity.

- Data Feedback Loop: The results from characterization are fed back into AI models, which then refine their predictions and suggest the next set of experiments.

This closed loop, where machines perform experiments and AI learns from the outcomes, is what makes these labs so powerful. It’s a cycle of discovery that can run continuously, accelerating the pace of innovation in ways we’re only just beginning to understand.

Economic Impact and Future Potential

The Long Road from Lab to Market

It’s easy to get excited about new materials, but let’s be real, getting them from a lab bench to something you can actually buy takes ages. Think about plastics – the first ones showed up way back in the 1860s, but they didn’t really become a big deal for consumers until the 1920s. That’s a long time! It’s a similar story for things like Velcro, which took decades to go from a neat idea to something everyone used. Even the batteries in our phones, the lithium-ion kind, were first made in the 1950s but only became common much, much later. This long timeline is a big reason why private companies sometimes shy away from funding early-stage materials research. They need to see a quicker path to making money.

Government Investment in Basic Research

Because private companies can be hesitant, government funding plays a huge role. Historically, research that the government backed, especially the non-military kind, has paid off big time. Studies show returns of 150% to 300% on investments made after World War II. This kind of research might not have an immediate product, but it lays the groundwork for future industries. Without this foundational support, many game-changing materials might never get off the ground. It’s like planting seeds for a forest that will only be enjoyed by future generations.

Anticipating Future Breakthroughs

So, what’s next? We’re seeing a push towards materials that can help with big challenges, like climate change. Imagine machines that pull carbon dioxide right out of the air, or new ways to store energy that are way better than what we have now. There’s also a growing interest in finding materials from less common places, like the deep sea or even space, though we need to be super careful about the environmental impact. The real economic value often comes not just from the material itself, but from the entirely new industries and technologies it makes possible. The semiconductor industry, worth hundreds of billions, is a prime example of how materials science breakthroughs can reshape the global economy.

Key Discoveries and Applications in Materials Science 2020

2020 was a pretty interesting year for materials science, even with everything else going on. We saw some really neat stuff happening, especially in areas that directly impact our daily lives and future technologies. It wasn’t just about inventing entirely new substances out of the blue; a lot of progress came from tweaking and improving what we already had.

Advancements in Battery Technology

Batteries are everywhere, right? From our phones to our cars, and especially for storing energy from renewable sources. In 2020, researchers kept pushing the envelope. They were looking at new ways to make battery anodes and cathodes work better. The goal was simple: longer life, faster charging, and making them safer. Think about electric vehicles needing to go further on a single charge or grid-scale storage that can handle solar and wind power fluctuations. These improvements, even if they seem small on paper, add up to a big difference in how we use and store energy. It’s like getting a little more juice out of every charge, which is a win for everyone.

Innovations in Semiconductor Materials

Semiconductors are the brains behind all our electronics. In 2020, the focus was on developing materials that could handle more power and operate more efficiently. This means faster computers, more capable smartphones, and even advancements in things like 5G technology. The push was towards materials that could manage heat better and allow for smaller, more powerful chips. It’s a constant race to pack more performance into smaller spaces, and 2020 saw some solid steps forward in the materials that make this possible.

The Role of Materials in Energy Storage

Beyond just batteries for devices, 2020 also highlighted materials crucial for larger-scale energy storage. This is super important for making renewable energy sources like solar and wind more reliable. When the sun isn’t shining or the wind isn’t blowing, we need ways to store that energy. Materials science plays a big part here, looking at everything from advanced battery chemistries to new types of capacitors and even exploring materials for hydrogen storage. The ability to store energy efficiently and affordably is key to a cleaner energy future, and 2020 brought us closer to that reality.

Looking Ahead

So, 2020 was a pretty interesting year for materials science, even with everything else going on. We saw how new materials can really change things, from the gadgets we use every day to bigger stuff like energy and even space travel. It’s clear that just tweaking old ideas isn’t always enough anymore. We need new ways to find and test materials, and that’s where things like AI are starting to show some real promise. But it’s not magic; it’s about building better tools and processes. The big takeaway is that we need to do more, try more things, and work together to really speed up discoveries. The future of technology depends on it, and it looks like we’re just getting started.