So, additive manufacturing, you know, the whole 3D printing thing, but for serious stuff like planes? It’s really changing the game in the aerospace world. Instead of old-school methods, we’re talking about building parts layer by layer, which means we can make them lighter, stronger, and way more complicated than before. This article is going to look at how laser additive manufacturing is making a big difference in aerospace applications, from making new parts to fixing old ones, and what challenges come with it.

Key Takeaways

- Laser additive manufacturing lets us create lighter aircraft parts and design them with better aerodynamics.

- This technology speeds up how fast we can make prototypes and get parts into production.

- We can now combine multiple parts into a single piece, which makes things stronger and simpler.

- Different laser processes like powder bed fusion and directed energy deposition are used for various aerospace needs.

- Making sure these parts meet strict aerospace standards and certifications is a major focus.

Revolutionizing Aerospace Components Through Laser Additive Manufacturing

Laser additive manufacturing, often called 3D printing for metals, is really shaking things up in the aerospace world. It’s not just about making cool shapes anymore; it’s about fundamentally changing how we design and build aircraft parts. Think about it: instead of starting with a big block of metal and cutting away what you don’t need, you’re building parts up, layer by tiny layer, directly from a digital design. This approach opens up a whole new level of design freedom.

Enabling Lightweight Structures and Enhanced Aerodynamics

One of the biggest wins here is weight reduction. Aircraft need to be as light as possible to save fuel, and laser additive manufacturing is a big help. We can create intricate internal structures, like lattices or hollow sections, that are impossible with traditional methods. These designs reduce material use without sacrificing strength. For example, a titanium bracket that used to weigh 10 kilograms might now come in at just 5 kilograms using this technology. This isn’t just about saving weight; it also allows for more complex external shapes that can improve airflow, leading to better aerodynamic performance. Imagine wings or fuselage sections with smoother, more optimized contours that reduce drag.

Accelerating Prototyping and Production Cycles

Remember the old days of waiting months for a new part prototype? Laser additive manufacturing cuts that down dramatically. You can go from a digital file to a physical part in days, sometimes even hours. This speed allows engineers to test more designs, iterate faster, and get products to market much quicker. It also means we can produce smaller batches of parts more economically. For specialized or low-volume aircraft, this is a game-changer. It also means we can make replacement parts on demand, right where they’re needed, cutting down on inventory and shipping times. The U.S. Navy, for instance, is looking at reducing part acquisition times from months down to just a few weeks.

Integrating Multiple Components into Single Parts

Another huge advantage is the ability to combine multiple parts into a single, monolithic component. Traditionally, a complex assembly might involve dozens of individual pieces that need to be manufactured separately and then bolted, welded, or fastened together. Each connection point is a potential failure point and adds weight. With laser additive manufacturing, we can design and print these complex assemblies as one piece. This reduces assembly time, eliminates weak points from joints, and often results in a lighter, stronger final product. It simplifies the supply chain and manufacturing process considerably.

Key Laser Additive Manufacturing Processes for Aerospace

When we talk about making airplane parts with lasers, it’s not just one single method. There are a few main ways this technology works, and each has its own strengths for different kinds of components.

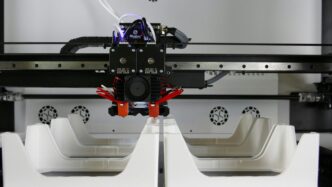

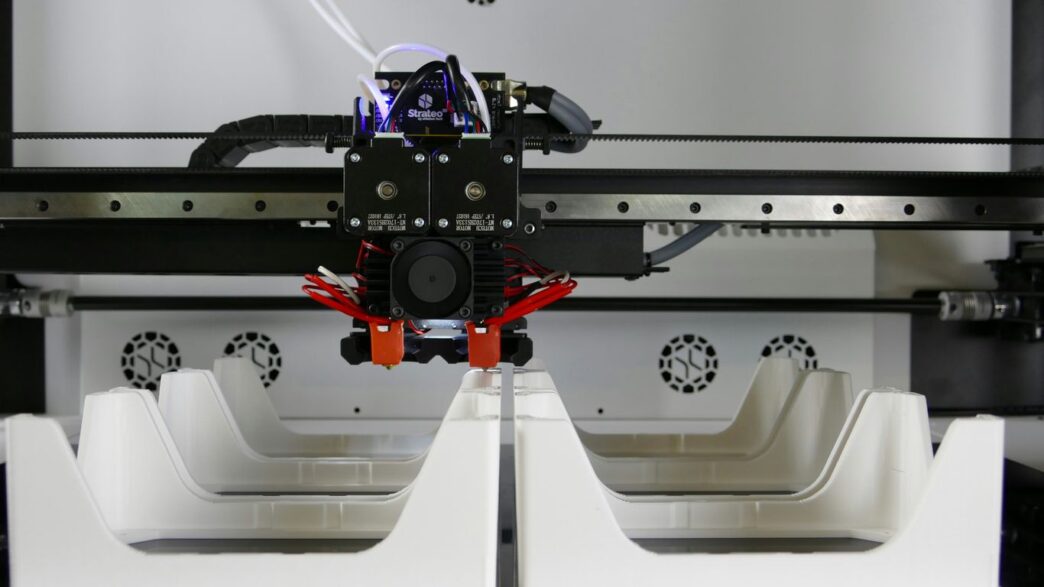

Powder Bed Fusion Techniques

This is probably the most common approach you’ll hear about. Think of it like building a part from a bed of fine powder, layer by tiny layer. A laser comes in and selectively melts or sinters (heats just enough to fuse without fully melting) the powder particles together, following a digital design. Once a layer is done, a new thin layer of powder is spread over the top, and the laser goes again. It’s pretty neat because it can create really intricate shapes that would be impossible with traditional methods.

- Selective Laser Melting (SLM) / Direct Metal Laser Sintering (DMLS): These are very similar. SLM fully melts the metal powder, while DMLS sinters it. Both use a laser to fuse metal powders like titanium, aluminum, or high-strength steel. They’re great for complex, dense parts where you need good material properties.

- Electron Beam Melting (EBM): Similar to SLM/DMLS but uses an electron beam instead of a laser. It often works in a vacuum and can be faster for certain materials, though it might not achieve the same level of surface finish as laser-based methods.

Directed Energy Deposition Methods

Instead of a bed of powder, these methods essentially spray powder or wire into the path of a focused laser or electron beam. The material melts as it hits the build surface or the existing part, fusing in place. This is often used for repairing parts or adding features to existing components, and it can build larger parts more quickly than powder bed methods.

- Laser Engineered Net Shaping (LENS): This is a prime example. It uses a laser to melt metal powder that’s fed through a nozzle, building up a part directly. It’s good for creating solid, dense parts and can even be used to repair high-value components.

- Wire Arc Additive Manufacturing (WAAM): While not strictly laser-based, it’s a related directed energy process that uses an electric arc to melt wire feedstock. It’s known for its speed and ability to produce very large structures.

Laser Consolidation for Net-Shape Parts

This technique is a bit more specialized. It involves using a laser to fuse a layer of powder or a pre-placed material to create a solid part, often with minimal post-processing. The goal here is to get the part very close to its final shape right off the machine, reducing the need for extensive machining afterward. This is particularly attractive for aerospace because it cuts down on waste and manufacturing time. It’s like getting a near-perfect shape straight out of the printer, which saves a lot of effort down the line.

Material Innovations in Laser Additive Manufacturing for Aerospace

When we talk about making airplane parts with lasers, the materials are a huge deal. It’s not just about having a cool 3D printer; it’s about what you’re printing with. The aerospace industry needs materials that can handle extreme temperatures, high stress, and still be as light as possible. That’s where the innovation is really happening.

Advanced Metal Alloys for High-Performance Applications

We’re seeing a lot of work with superalloys, like those nickel-based ones used in jet engines. These materials can take a beating from heat and pressure. Titanium alloys are also big because they’re strong but light. Think about it, every pound saved on an aircraft means better fuel efficiency. Companies are also looking at materials like Invar, which doesn’t expand or contract much with temperature changes, that’s pretty handy for certain parts. Even exotic stuff like tantalum is being explored for its unique properties.

- Nickel-based superalloys: Great for hot sections of engines.

- Titanium alloys: Offer a good strength-to-weight ratio.

- Invar alloys: Useful for parts needing dimensional stability.

- Tantalum: Explored for specialized, high-demand applications.

Development of Hybrid and Multi-Material Structures

Why stick to just one material when you can combine the best of several? Laser additive manufacturing is starting to let us build parts that aren’t just one solid block of metal. We can create structures where one area might be super strong, and another might be designed for heat resistance, all in the same part. This is a game-changer for designing components that do multiple jobs. Imagine a bracket that’s strong where it needs to be, but has a built-in vibration dampening section made from a different material. It’s complex, but the potential is massive.

Microstructural Characteristics and Mechanical Properties

This is where things get a bit technical, but it’s super important. How the metal solidifies during the laser printing process creates a specific internal structure, called the microstructure. This structure directly affects how strong the part is, how it bends, and how it holds up over time. For example, the speed of the laser and the amount of power used can change the size and shape of the metal grains. Getting this right is key to making sure the printed parts perform as well as, or even better than, traditionally made ones. Controlling these microstructural details is how we ensure the final part meets all the tough requirements of aerospace.

| Material Type | Key Properties | Common Applications in Aerospace AM | Challenges |

|---|---|---|---|

| Nickel Superalloys | High temperature strength, creep resistance | Turbine blades, combustion chambers, exhaust components | Porosity, residual stresses, achieving desired grain structure |

| Titanium Alloys | High strength-to-weight, corrosion resistance | Airframes, structural components, landing gear parts | Oxidation, powder handling, achieving full density |

| Aluminum Alloys | Lightweight, good thermal conductivity | Brackets, housings, complex internal structures | Lower melting point, potential for cracking, limited high-temp performance |

| Stainless Steels | Corrosion resistance, good mechanical properties | Fasteners, brackets, ducting | Density, potential for warping, achieving fine surface finish |

Transformative Applications in Aerospace

Laser additive manufacturing, or 3D printing with lasers, is really changing the game for aircraft and spacecraft. It’s not just for making little plastic models anymore; we’re talking about actual flight-critical parts. This technology lets us create complex shapes that were just impossible with older methods, leading to lighter, stronger, and more efficient components.

Engine Components and Structural Parts

Think about jet engines. They’re incredibly complex machines with parts that have to withstand insane temperatures and pressures. Laser additive manufacturing is perfect for making things like turbine blades, combustion chambers, and fuel nozzles. Because we can build these parts layer by layer, we can design them with internal cooling channels or intricate geometries that improve performance and fuel efficiency. This ability to create optimized, integrated designs is a major reason why laser AM is becoming so popular for engine parts. For example, a single complex bracket that used to be made from several pieces welded together can now be printed as one solid part, reducing weight and potential failure points.

On-Demand Manufacturing and Replacement Parts

One of the coolest things about this tech is its potential for "on-demand" manufacturing. Instead of keeping huge warehouses full of spare parts that might never get used, airlines and manufacturers can print a replacement part when and where it’s needed. This is especially useful for older aircraft where original tooling might be long gone, or for parts needed in remote locations. It cuts down on inventory costs and reduces downtime. Imagine a scenario where a specific, hard-to-find component fails on a plane mid-route; with the right digital design and a laser additive manufacturing system nearby, a replacement could be produced in a matter of hours, not weeks or months.

Tooling and Fixture Fabrication

It’s not just about the final flight parts, either. Laser additive manufacturing is also a big help in making the tools and fixtures needed to build and assemble aircraft. We can quickly print custom jigs, molds, and assembly aids that are perfectly shaped for a specific task. This speeds up the manufacturing process and improves accuracy. For instance, a complex assembly fixture that might take months to machine traditionally can be designed and printed in days, allowing production lines to adapt more quickly to new designs or modifications.

Navigating the Challenges of Aerospace Applications

While laser additive manufacturing (LAM) opens up a world of possibilities for aerospace, it’s not all smooth sailing. Getting these advanced parts from the printer into a flying aircraft involves some serious hurdles. We’re talking about making sure every single part is exactly right, every single time. It’s a big deal when lives are on the line, so the industry has to be super careful.

Ensuring Material Consistency and Quality Control

One of the biggest headaches is making sure the materials used behave predictably. With LAM, you’re building parts layer by layer, and tiny variations in the powder, the laser’s power, or even the room temperature can change how the final piece turns out. We need to know that a part made today will have the same strength and durability as one made next month. This means keeping a close eye on everything that goes into the process.

- Powder Quality: The metal powder used has to be just right – consistent particle size and composition are key.

- Process Monitoring: Keeping track of things like laser power, scan speed, and layer thickness during the build is vital.

- Post-Build Testing: Rigorous testing of finished parts is non-negotiable to confirm they meet all the required mechanical properties.

Developing Robust Inspection and Qualification Protocols

Once a part is made, how do you really know it’s good? Traditional manufacturing has well-established ways to check things, but LAM is newer. We’re still figuring out the best ways to inspect these complex, often internal, structures. Think about it: how do you check for tiny flaws deep inside a part without damaging it? Developing these inspection methods and then getting them approved by aviation authorities is a long road.

Meeting Stringent Certification Requirements

This is where everything comes together. Aviation is one of the most regulated industries out there, and for good reason. Any new technology, especially one like LAM that changes how parts are made, needs to go through a tough certification process. This involves proving that the parts are not only safe but also reliable over the long haul. The Federal Aviation Administration (FAA) and other global bodies have specific guidelines, and meeting them requires extensive data, testing, and documentation that demonstrates the LAM process and its outputs are as dependable as, if not more so than, traditional methods. It’s a complex dance of engineering, testing, and paperwork, but it’s what keeps us all safe in the skies.

The Future Landscape of Laser Additive Manufacturing in Aviation

So, where’s all this laser additive manufacturing (LAM) stuff headed in aviation? It’s pretty exciting, honestly. We’re not just talking about making slightly better parts; we’re looking at a whole new way of building planes and spacecraft. Think faster, cheaper, and way more adaptable. The integration of LAM with Industry 4.0 principles is set to redefine aerospace manufacturing.

Advancements in Process Efficiency and Cost Reduction

Right now, a big hurdle is making LAM faster and less expensive. Companies are pouring resources into developing new laser systems and optimizing existing ones. We’re seeing faster print speeds and better material utilization, which directly cuts down on costs. It’s not just about the machines, though. Software is getting smarter too, helping to predict and prevent issues before they happen, saving time and materials. Imagine a future where a complex engine part can be printed in hours, not days, and at a fraction of the current cost. That’s the goal.

Integration with Industry 4.0 Principles

This is where things get really interesting. LAM fits perfectly into the whole Industry 4.0 idea – smart factories, connected systems, and data-driven decisions. We’re talking about using AI and machine learning to monitor the printing process in real-time, making adjustments on the fly to guarantee quality. This means:

- Real-time quality control: Sensors and AI can detect defects as they form, stopping the print or correcting the issue immediately.

- Predictive maintenance: Machines can tell us when they need servicing before they break down, avoiding costly downtime.

- Digital twins: Creating virtual replicas of parts and processes allows for extensive testing and optimization without using physical materials.

- Supply chain integration: LAM can be linked directly to design and inventory systems, allowing for truly on-demand production.

Emerging Opportunities and Research Frontiers

The research community is buzzing with new ideas. We’re seeing work on:

- New material development: Beyond just metals, researchers are exploring ceramics and composites for even lighter and stronger components.

- Multi-material printing: The ability to print with multiple materials in a single part opens up possibilities for integrated functionalities, like embedding sensors or conductive pathways directly into structures.

- Larger build volumes: As machines get bigger, we’ll be able to print entire aircraft sections, not just small components.

- Advanced post-processing: Developing faster and more automated ways to finish printed parts will be key to widespread adoption.

It’s a dynamic field, and the pace of innovation is only picking up. What seems like science fiction today could be standard practice in aviation within the next decade.

Wrapping It Up

So, we’ve talked a lot about how laser additive manufacturing is shaking things up in the aerospace world. It’s not just about making parts faster, though that’s a big deal. It’s about making them lighter, stronger, and sometimes in ways we couldn’t even imagine before. While there are still some hurdles to jump, like getting everything certified and making sure the quality is always top-notch, the direction is clear. This technology is here to stay and will keep pushing what’s possible for planes and spacecraft. It’s pretty exciting to think about what the next few years will bring as more companies get on board with this advanced way of building things.