Aerospacelab’s Rapid Ascent in Satellite Manufacturing

It’s pretty wild how fast Aerospacelab has grown since they started back in 2018. They’ve really made a name for themselves in building satellites, and it’s not just luck. A big part of their success comes from doing almost everything themselves, from the initial design all the way to getting the satellites working in space. This approach, called vertical integration, means they have a lot more control over quality and how quickly they can get things done.

Founding and Early Successes

When Aerospacelab first got going, they focused on proving they could actually build and launch satellites that worked. They managed to get their first satellites into orbit through SpaceX’s rideshare missions, which is a pretty cost-effective way to get up there. Since then, they’ve had a string of successful launches, putting several satellites into orbit that are all doing their jobs. This consistent flight heritage is a huge deal in the satellite world, showing customers they can rely on Aerospacelab to deliver working hardware.

Vertical Integration as a Core Strategy

What really sets Aerospacelab apart is their commitment to vertical integration. They design and build most of their satellite parts in-house. This means they’re not waiting on other companies for critical components, which speeds things up and helps keep costs down. They’ve even said this approach can cut their satellite manufacturing costs by a lot. Plus, when you control so much of the process, you can keep a closer eye on quality and make sure everything is ready when it needs to be.

Flight Heritage and On-Orbit Performance

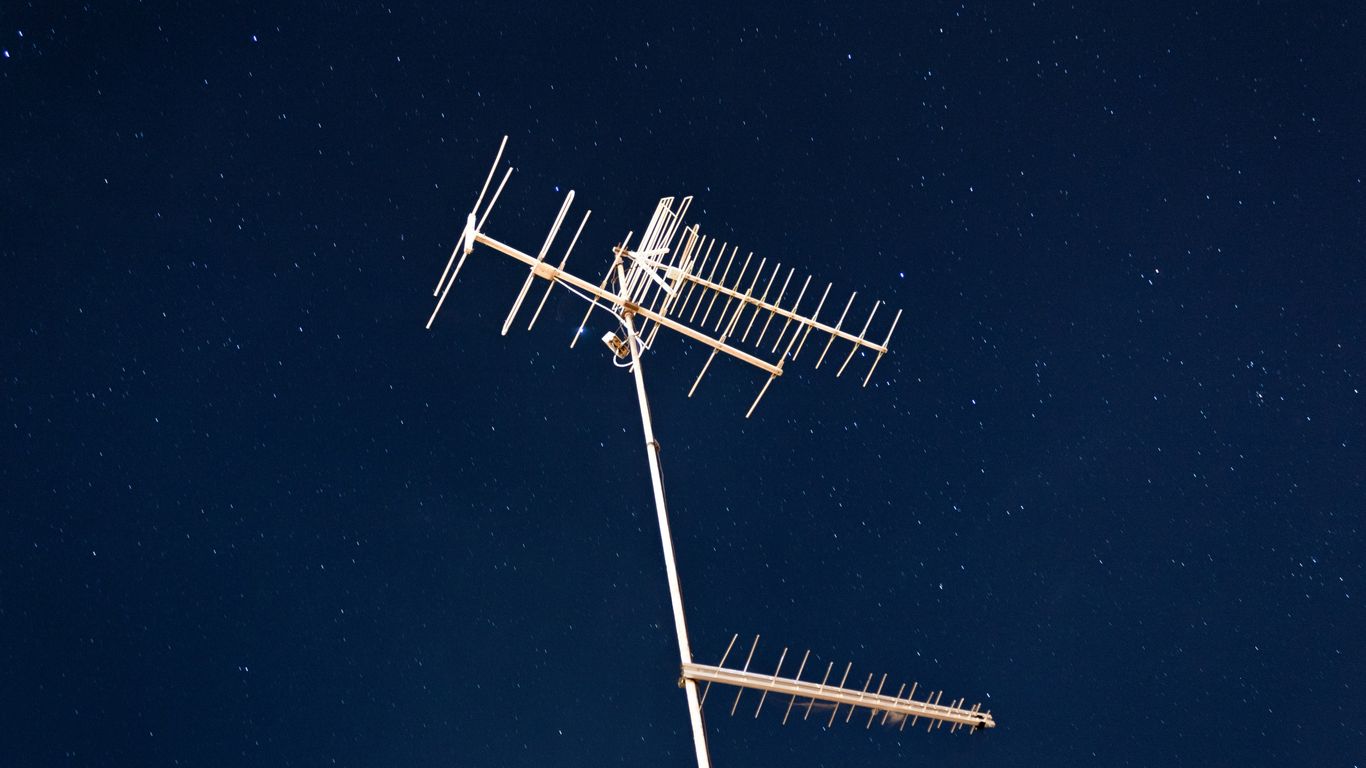

Having satellites actually working in space is the ultimate proof of a manufacturer’s capability. Aerospacelab has achieved this with multiple successful missions. They’ve launched satellites carrying different kinds of sensors, like those for radio frequency detection and high-resolution imaging. The fact that they’ve had several satellites commissioned and working in record time after launch is pretty impressive. It shows their systems are not only built well but also integrate smoothly with launch vehicles and ground systems, which is exactly what you want when you’re building constellations.

Expanding Global Footprint and Production Capacity

Aerospacelab isn’t just building satellites; they’re building the factories to build lots of satellites, and they’re doing it in key places. It’s a big move, showing they’re serious about meeting the growing need for space tech.

US Expansion and Market Reach

Things really kicked off in the US with a new factory in Torrance, California. This place is pretty modern, with 35,000 square feet of space that includes high-bay areas and cleanrooms. They’ve got the latest gear and are trying to be eco-friendly too. Right now, they can build about two satellites a week, even with just one shift running. They’re already working on satellite systems for Xona Space Systems there. This US presence is all about tapping into the demand from American customers, especially government and military contracts. It’s a smart move to be closer to these big clients.

The Charleroi Megafactory

But the real showstopper is the planned megafactory in Charleroi, Belgium. This place is going to be huge, designed to churn out up to 500 satellites a year. Think of it as a dedicated satellite production line. It’s set to open in 2026 and will have a massive 7,000 square meters of production space, plus another 4,000 square meters of cleanroom. This facility is poised to be one of the largest satellite manufacturing sites globally. It’s a big bet on the future, aiming to handle the massive orders expected for large constellations.

European Manufacturing Prowess

Beyond the megafactory, Aerospacelab is solidifying its European roots. They’ve got a facility in Monnet, which has been running since mid-2022. It can currently produce about 25 satellites annually, but they can push it to 40 if needed. Having these European bases is important, not just for serving local customers but also for cost efficiency. Plus, with significant contracts from the European Space Agency (ESA) for technology demonstrations, having strong manufacturing capabilities in Europe puts them in a good spot to win more business, especially for big projects like the IRIS² constellation.

Here’s a quick look at their production plans:

- Monnet Center Factory: Operational, capacity of 25-40 satellites/year.

- US Factory (Torrance, CA): Opening soon, capacity of 75-100 satellites/year.

- Charleroi Megafactory: Planned for 2026, capacity of up to 500 satellites/year.

Pioneering Constellation Technology

Aerospacelab isn’t just building individual satellites; they’re really focused on putting together entire constellations, which are basically groups of satellites working together. It’s a big step up from just launching one or two. They’ve got this thing called the Versatile Satellite Platform, or VSP for short. Think of it as a standard base model for their satellites that can be quickly changed up for different jobs. This means they can swap out different sensors or equipment depending on what a customer needs, whether it’s for taking pictures of Earth or something else.

Versatile Satellite Platform (VSP)

The VSP is pretty neat because it’s designed to be adaptable. It’s got a modular core, which is like a building block system. This makes it faster and cheaper to get a satellite ready for a specific mission. They can fit all sorts of things onto it, like cameras for high-resolution images or equipment to detect radio signals. This flexibility is key to their strategy of mass-producing satellites that can still be customized.

Supporting Key Constellations

Aerospacelab is already involved in some pretty big projects. They’re working on the Telesat Lightspeed constellation, which is a major undertaking. They also have a shot at building the IRIS² constellation, a big European project for secure satellite communications. This involves a lot of satellites, and Aerospacelab’s ability to build them quickly and in large numbers is what makes them a strong contender. They’ve had a few successful launches recently, putting their satellites into orbit without any major hiccups, which is always a good sign.

Future Constellation Development

Looking ahead, Aerospacelab is planning to build its own constellation. This will be a network of satellites equipped with different types of sensors, like optical and radio frequency ones. Having their own constellation gives them a chance to test out new technologies and also provides a recurring source of business. They’re also keeping an eye on opportunities for direct-to-device communication satellites, which could be a big market in the coming years. It seems like they’re trying to cover a lot of bases in the satellite world.

Aerospacelab’s Commitment to Innovation and Quality

In-House Design and Manufacturing

Aerospacelab really focuses on doing a lot of the work themselves. They design and build about 90% of their satellite parts right there in their own facilities. They’re even aiming to get that number up to 99% by 2026. This approach means they have a lot more control over how things are made, which helps keep quality high and makes sure they can stick to their schedules. It’s like making your own pizza from scratch versus ordering one – you know exactly what goes into it.

TRL-9 Implementation

When Aerospacelab talks about TRL-9, they mean they’re using technology that’s already proven and ready to go. Think of it like using a well-tested engine for a new car model instead of trying out a brand-new, unproven design. This focus on readiness means their satellites are more reliable from the get-go. They’ve had a string of successful launches, with satellites performing as expected right after they get into orbit. It’s a big deal for customers who need their missions to work without a lot of fuss.

Acquisition of AMOS for Optical Expertise

To really beef up their capabilities, Aerospacelab picked up a company called AMOS. This Belgian business is really good with optics, which is super important for satellites that take pictures or gather other visual data. By bringing AMOS into the fold, Aerospacelab gets that specialized knowledge in-house. It helps them build better cameras and sensors for their satellites, making them more versatile for different kinds of Earth observation missions. It’s a smart move to get more specialized skills without having to build them from the ground up.

Strategic Partnerships and Commercial Growth

Collaborations with SpaceX Rideshare

Getting satellites into space used to be a really big deal, often meaning you had to book a whole rocket. But things are changing, and Aerospacelab has been right there, making the most of new opportunities. They’ve been busy sending their satellites up on SpaceX’s Rideshare missions, like Transporter 8, 9, and 10. This approach is a game-changer because it makes launching satellites much more affordable and accessible.

Think of it like sharing a bus instead of renting a whole limo. Aerospacelab has successfully launched eight satellites this way, and they’re all doing their jobs up there. This isn’t just about getting satellites into orbit; it’s about proving they can do it reliably and efficiently, which is exactly what customers want to see. It really helps keep build and payroll costs under control.

Securing Commercial and Government Contracts

Aerospacelab isn’t just talking about the future; they’re building it, and they’re getting paid to do it. They’ve landed some pretty significant deals lately. For instance, they’re working with MDA Space on the AURORA constellation, providing 200 battery charge regulators. This is a big step because it means they’re not just building satellites, but also key components for mass production.

On the government side, they’re expanding their U.S. presence, partly to work with institutions like the Space Development Agency (SDA). The SDA is all about having lots of different options and not relying on just one company for critical parts. Aerospacelab’s track record and their position as a major European satellite maker fit right into this plan. They’ve also got commercial customers like Xona and Vyoma, showing they can serve a variety of needs.

The IRIS² Constellation Opportunity

There’s a big European project called IRIS² that aims to create a secure communication constellation. Aerospacelab is in the running for a piece of this action, and it’s a pretty massive opportunity. Being a finalist means they’ve already shown they have the capabilities to handle such a large-scale project.

What’s interesting is how Aerospacelab sees this. While a contract like IRIS² would be huge, the CEO, Benoît Deper, has mentioned that moving too fast with massive government projects can sometimes cause problems, referencing past projects that ran late. He believes Aerospacelab’s ability to be flexible and adapt quickly, thanks to their vertical integration and smaller size compared to giants like Airbus, gives them an edge.

- Speed and Adaptability: Aerospacelab can adjust designs and manufacturing processes faster than larger, more established companies.

- Vertical Integration: Having control over many parts of the manufacturing process reduces reliance on outside suppliers and potential delays.

- Cost Efficiency: Deper suggests that moving quickly can ultimately be cheaper, avoiding the cost overruns that often plague large, slow-moving projects.

It’s a balancing act, really. Landing a contract like IRIS² would be a massive boost, but the company is also focused on maintaining its agile culture as it grows.

Addressing Industry Challenges and Future Outlook

Scaling from Startup to Maturity

Moving from a nimble startup to a company that can churn out hundreds of satellites a year is a big jump. Aerospacelab is right in the middle of this transition. They’ve got big plans, like their "megafactory" in Charleroi, Belgium, which is set to be one of the biggest satellite production sites globally. This factory alone is designed to crank out 500 satellites annually by 2027. The trick here is managing costs as they ramp up production. Building in Europe, with its potentially lower labor costs and government backing, could be a smart move to keep things affordable. Plus, they’ve secured funding that seems to line up with their growth targets and what the market needs.

Meeting Demand for Mass Production

So, you build a massive factory, but then you need customers to fill it, right? Aerospacelab is focusing on big projects, like telecom constellations and government-backed projects, such as the IRIS² initiative in Europe. These kinds of large-scale projects are exactly what their new facilities are built for. They’re also looking at other big telecom constellations for things like broadband and direct-to-device communication, which could bring in steady business. It’s all about making sure their production capacity matches the actual demand.

Competitive Landscape and Aerospacelab’s Edge

The satellite manufacturing world is getting crowded. Companies like Terran Orbital, Apex, and York are also making waves, especially in the US. But Aerospacelab has a few things going for it. Their commitment to vertical integration means they handle a lot of the manufacturing in-house, from design to testing. This approach helps them control timelines and costs, and it reduces risks for their customers. They’ve already shown they can deploy satellites quickly, with three successful launches and quick commissioning times. This speed is a big deal, especially when you’re competing for large contracts like IRIS², where being fast can make a huge difference. While bigger companies might have more resources, Aerospacelab’s agility and lack of internal bureaucracy could be their secret weapon.

Looking Ahead

Aerospacelab has really made a name for itself in the space world. They’ve managed to get a bunch of satellites into orbit successfully, which is no small feat. Plus, they’re building out a huge factory and expanding into the US, showing they’re serious about growth. It seems like they’re focused on making space tech more accessible and are working with some big names, like MDA Space for the Telesat Lightspeed project. With their own factory coming online and a growing list of customers, Aerospacelab is definitely a company to watch as they continue to shape how we build and use satellites.