It’s pretty wild how much the space industry is changing, right? Companies are trying to get stuff into orbit faster and cheaper than ever before. One company, Apex Satellites, seems to be really shaking things up. They’re doing things differently when it comes to building satellites, and it looks like it’s paying off. They’ve got this idea of making satellite parts like you’d buy a regular computer, which is a big shift from the old way of doing things.

Key Takeaways

- Apex Satellites is the only company making ‘off-the-shelf’ satellite parts, which is a totally new approach.

- They’ve set records for how fast they can build and launch these satellites.

- Apex is building a huge factory, making them the biggest satellite producer in the business.

- They’ve raised a lot of money, showing investors believe in their mass-production idea for space.

- Their strategy gives them a strong advantage because they’re the only one doing it this way.

Apex Satellites: Revolutionizing Spacecraft Manufacturing

It feels like just yesterday the space industry was all about custom-built rockets and satellites, taking ages and costing a fortune. But Apex is changing all that. They’re the only company making satellite buses that you can just order off the shelf. Think of it like buying a computer instead of building one from scratch. This approach lets customers spend less time and money worrying about the nuts and bolts of spacecraft construction and more time actually doing cool stuff in space, like Earth observation or communication.

The Dawn of Off-the-Shelf Satellite Buses

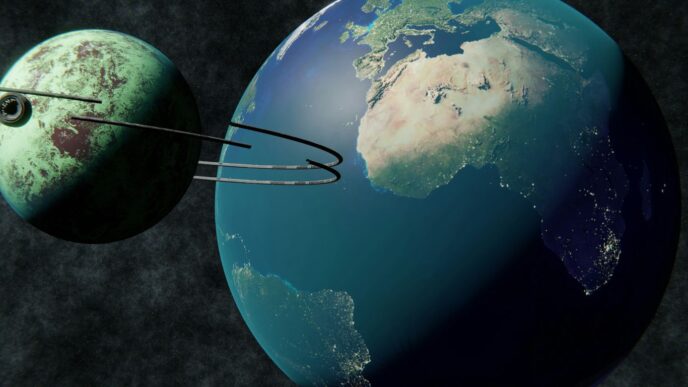

Before Apex, getting a satellite ready for launch was a huge undertaking. Companies had to design and build everything from the ground up for each specific mission. This meant long waits, high costs, and a lot of risk. Apex saw this problem and decided to create standardized satellite platforms, called buses. These buses have all the essential components – power, propulsion, communication – ready to go. Customers can then add their specific payload, the part that actually does the mission’s job. This shift to a productized model is a big deal, making space more accessible.

Setting New Records in Production Speed

Apex isn’t just talking about speed; they’re proving it. Their Aries SN1 satellite bus, launched in March 2024, was built faster than any other production small satellite bus in history. We’re talking about setting new industry records for how quickly these things can be manufactured and how reliable they are. This rapid production capability is a game-changer, especially with the growing demand for satellites.

A New Era of Space Manufacturing

What Apex is doing marks a significant shift in how we think about making things for space. It’s moving from a craft-based industry to a manufacturing-based one. They’ve built a massive facility, aiming for over 100,000 square feet of production space. This kind of scale is unheard of in the commercial space sector and positions them to meet the huge demand for standardized spacecraft. It’s like opening a factory that can churn out reliable satellites, making space missions more predictable and affordable for everyone.

Strategic Market Positioning and Product Diversification

Apex isn’t just building satellites; they’re strategically positioning themselves to own a huge chunk of the market. They figured out early on that the space industry was spending way too much time and money building custom satellites for every single mission. It’s like ordering a unique car for every trip you take instead of just grabbing one from a dealership. Apex decided to flip that script.

Aries Platforms for Earth Observation and Communications

The Aries satellite bus is their first big play. Think of it as the reliable sedan of the satellite world. It’s designed for common tasks like looking down at Earth (Earth observation) and relaying signals (communications). This isn’t some pie-in-the-sky concept; they’ve already proven it works. The successful launch of Aries SN1, which happened faster than anyone thought possible, shows that these aren’t just theoretical designs. They’re building them, testing them, and getting them into orbit. This focus on a standardized, mass-producible platform is a big deal, especially with the growing need for large satellite constellations. It means customers can get what they need without the long lead times and massive costs associated with custom builds. This approach is key to capturing a significant share of the commercial space market, and it’s a smart way to start building market share in space.

Introducing the Comet Satellite Bus

But Apex isn’t stopping with just one model. They know that different missions need different tools. That’s why they introduced the Comet satellite bus. This is their bigger, more powerful option. While Aries is like the versatile sedan, Comet is more like the capable SUV or even a light truck. It’s designed to handle more complex missions and larger payloads. This diversification is smart because it allows Apex to go after a wider range of customers. They can now serve not only the commercial sector but also defense applications, which often have more demanding requirements. Having multiple product lines means they aren’t putting all their eggs in one basket. It’s about offering a full spectrum of solutions, from smaller, cost-effective buses to more robust platforms, all built using their streamlined manufacturing process.

Capturing Commercial and Defense Markets

By offering both the Aries and Comet platforms, Apex is setting itself up to win business across the board. They’re not just aiming for the commercial companies launching constellations; they’re also looking at government agencies and defense contractors who need reliable, quickly deployable satellites. This dual-pronged approach is a solid strategy. It diversifies their customer base and revenue streams, making the company more resilient. The ability to produce these standardized buses at scale means they can undercut competitors on price and delivery time, which is a huge advantage. It’s a clear move to become the go-to provider for a wide variety of satellite needs, both in orbit and on the ground.

Facility Expansion and Production Scaling

So, Apex isn’t just talking about making more satellites; they’re actually building the factories to do it. It’s a pretty big deal, honestly. They’ve put a lot of money into expanding their manufacturing space, and it’s not just a little bit of extra room. We’re talking about a massive increase in capacity.

Doubling Manufacturing Capacity

Apex has been busy. They’ve secured funding specifically to ramp up how many satellite bus platforms they can churn out each month. Think about it – instead of building one here and there, they’re setting up for a much faster pace. This means they can actually build satellites before they get an order, which is a game-changer in this industry.

Largest Industrial Capacity in Commercial Space History

This is where things get really interesting. Apex is planning to more than double the size of their California manufacturing facility. The goal is to have over 100,000 square feet of production space. That’s huge. It’s apparently the biggest industrial capacity for making satellite buses that the commercial space world has ever seen. It really shows they’re serious about mass production.

Meeting Exploding Demand for Standardized Spacecraft

Why all this expansion? Well, the demand for satellites, especially for big constellations, is just going through the roof. Companies need lots of them, and they need them fast. By having all this standardized production capacity ready to go, Apex is in a prime spot to supply all those new satellites that are needed for everything from Earth observation to communication networks. It’s all about being ready for what the market is asking for, and right now, it’s asking for a lot of standardized spacecraft.

Apex’s Business Model and Financial Milestones

So, how does Apex actually make money and what’s their financial story? It’s pretty interesting, actually. They’ve really changed the game by focusing on making satellite parts, called satellite buses, in a standardized way, almost like building cars on an assembly line. This is a big deal because, before Apex, companies had to build each satellite from scratch, which is super expensive and takes forever.

Achieving Unicorn Status with Series D Funding

Apex recently hit a major financial milestone, raking in a massive $200 million in their Series D funding round. This big cash injection means they’re now valued at over a billion dollars – yep, they’re officially a "unicorn" company. What’s cool is that this funding came from investors who really get the space business, including some folks who used to work at SpaceX. It shows they have a lot of faith in Apex’s plan to mass-produce satellites.

This money isn’t just for show; it’s going to help Apex build even more satellite parts and expand their factories. They’re basically getting ready for a huge surge in demand for satellites, which seems to be happening all over the place.

The Power of Mass-Produced Satellite Manufacturing

Apex’s whole business model is built around making satellite buses quickly and affordably. Think about it: instead of spending years and millions designing a custom satellite for one specific job, customers can now buy a pre-made bus from Apex and just add their own special equipment, called payloads. This saves everyone a ton of time and money.

Here’s a quick look at how their model works:

- Standardized Platforms: Apex creates a few different types of satellite buses (like the Aries and Comet models) that can be used for many different missions. This means they can build a bunch of them ahead of time.

- Reduced Lead Times: Because they have these buses ready to go, customers can get their satellites built and launched much faster than before.

- Lower Costs: Mass production naturally brings down the cost per unit, making space missions more accessible.

- Focus on Payloads: Customers can spend less time worrying about the basic satellite structure and more time developing the unique technology that goes on board.

This approach is a big reason why they’ve been able to win contracts with the U.S. Space Force and other big players in the defense and commercial sectors.

Revenue Streams in Space Manufacturing

Apex makes money primarily by selling these satellite bus platforms. They have different models designed for various needs:

- Aries Platforms: These are used for Earth observation and communication missions. They’re a solid, reliable choice for many commercial needs.

- Comet Bus: This is their bigger, more powerful option, designed to capture a wider range of market segments, including more demanding defense applications.

- Nova Platform: This newer bus is designed for payloads ranging from 200 to 500 kilograms, showing their continued product development.

Beyond just selling the buses, Apex is also positioned to support large-scale constellation deployments. This means they can secure big, long-term contracts with companies or government agencies that need hundreds or even thousands of satellites. Their ability to produce at scale is what really sets them apart and drives their revenue growth.

Apex’s Competitive Advantages and Market Dominance

So, what makes Apex stand out in the crowded space scene? It really boils down to a few key things that give them a serious edge. First off, they’re the only game in town when it comes to off-the-shelf satellite buses. Think about it – instead of every company building a satellite from scratch, which takes ages and costs a fortune, Apex has these standardized platforms ready to go. This means customers can get their missions up and running way faster and cheaper. It’s like buying a pre-built house versus trying to construct one yourself.

Monopolistic Market Position as the Sole Off-the-Shelf Provider

This whole "off-the-shelf" thing isn’t just a small detail; it’s their main selling point. Apex has basically created a whole new category in the market. They’re not just competing; they’re defining the space for productized satellite platforms. This unique position means they don’t have direct competitors doing exactly what they do. They’re the go-to for anyone who needs a satellite bus quickly and reliably, without the hassle of custom development. This allows them to capture a huge chunk of the market, especially as the demand for satellite constellations keeps growing. It’s a pretty sweet spot to be in, honestly.

Proven Flight Heritage and Reliability

It’s one thing to say you have a great product, but it’s another to show it works. Apex has been racking up some impressive flight history. Their Aries SN1 mission, for example, was the fastest build of a production small satellite bus ever. That’s not just a record; it’s proof that their manufacturing process leads to reliable hardware that can actually perform in space. Having this kind of proven track record builds a lot of trust with customers, especially those in defense and critical communications where failure just isn’t an option. They’ve got the data to back up their claims, which is a big deal in this industry.

Building an Impenetrable Market Moat

When you combine being the only provider of a certain type of product with a solid history of success, you start building what people call a market moat. Apex is doing just that. Their manufacturing scale, the speed at which they can produce satellites, and their established customer base all make it incredibly difficult for anyone else to jump in and compete effectively. They’re not just ahead; they’re building a fortress. This is especially important given the rapid expansion of the space industry and the increasing need for mass-produced spacecraft [8fc7]. It’s clear they’re playing the long game, and their current position makes them a formidable force for years to come.

The Apex Team and Culture of Innovation

So, how does Apex actually pull off making so many satellites so fast? It really comes down to the people. They’ve put together a team that’s a wild mix, and honestly, that seems to be the secret sauce. You’ve got folks who’ve served in the military, fresh grads just starting out, experienced engineers from big old aerospace companies, and even people from totally different industries. It’s like they grabbed a bit of everything, and it just works.

A Blend of Aerospace and Diverse Industry Expertise

What’s cool is that Apex doesn’t just hire rocket scientists. They actively look for people with different backgrounds. Think about it: someone who worked in, say, fast-moving consumer goods might have ideas about production efficiency that a lifelong aerospace engineer wouldn’t even consider. This mix means they’re not just stuck doing things the old way. They’re constantly challenging how things have always been done. It’s this blend that helps them come up with new solutions and build satellites faster than anyone thought possible.

Empowering Team Members for Mission Success

It’s not just about hiring smart people; it’s about letting them do their thing. Apex seems to give its employees the space to bring their ideas to the table. You see it in their Q&A posts – they highlight engineers, recruiters, and operations leads, showing that everyone’s contribution matters. They’re not just cogs in a machine; they’re encouraged to speak up and make a difference. This approach means that when a problem pops up, you’ve got a whole team ready to tackle it with different perspectives.

Fostering Collaboration and Respect

Building something as complex as a satellite, especially at this speed, needs a lot of teamwork. Apex seems to have built a place where people can actually work together. They talk about respect and making sure everyone feels heard. This isn’t just corporate fluff; when you’re trying to break production records, you need everyone pulling in the same direction. It sounds like they’ve figured out how to get a bunch of really smart, driven people to collaborate effectively, which is pretty impressive. It’s this combination of diverse talent and a supportive environment that really drives Apex forward.

The Future of Space Manufacturing is Here

So, what does all this mean? Apex isn’t just building satellites; they’re changing how they’re made. By offering ready-to-go satellite buses, they’re letting companies skip the headache of building their own from scratch. This means faster launches, lower costs, and more focus on what really matters – exploring and using space. With their massive factory expansion and backing from some big names, Apex is clearly setting the pace for what’s next in space. It looks like the days of custom-built satellites taking forever are numbered.

Frequently Asked Questions

What is Apex Satellites?

Apex Satellites is a company that makes satellite parts called ‘buses’. Think of a bus like the body of a car that holds all the important stuff for the satellite to work in space. Apex is special because they make these buses ready-made, like buying a car off the lot instead of building one from scratch. This makes getting satellites into space much faster and cheaper.

Why is Apex’s way of making satellites important?

Before Apex, companies had to spend a lot of time and money designing and building each satellite bus uniquely. Apex’s ‘off-the-shelf’ approach means they can build many buses quickly and at a lower cost. This helps other companies focus on what their satellite will do, like taking pictures of Earth or providing internet, instead of worrying about the basic satellite parts.

What are the Aries and Comet satellite buses?

Aries is one of Apex’s satellite buses, and they built one called Aries SN1 really fast, setting a speed record! It’s good for smaller tasks like Earth observation. Comet is their newer, bigger, and more powerful satellite bus. It can handle more things and helps Apex serve different customers, including those in defense.

How big is Apex’s manufacturing facility?

Apex is building a huge factory space, planning for over 100,000 square feet. This is the biggest space manufacturing facility for satellite buses in the world! Having so much space allows them to make a lot of satellite buses at once to keep up with the growing demand.

Has Apex received a lot of funding?

Yes! Apex has raised a lot of money, reaching over a billion dollars in value, which means they are a ‘unicorn’ company. They recently got $200 million in funding. This shows that investors believe their idea of mass-producing satellite parts is a great way to do business.

What makes Apex different from other satellite companies?

Apex is the only company that makes satellite buses ready to buy. They focus on making many of the same reliable parts quickly and affordably. This unique position, along with their speed and ability to produce on a large scale, makes them a leader in the space industry.