Introduction

In the realm of industrial processes and scientific research, efficient and rapid drying of materials is often of utmost importance. Blast drying ovens are the unsung heroes in this domain, playing a crucial role in expediting the drying process across various industries. In this article, we will explore what blast drying ovens are, how they work, and their applications in today’s fast-paced world.

Unveiling Blast Drying Ovens

What Are Blast Drying Ovens?

Blast drying ovens are specialized drying equipment designed to quickly and uniformly remove moisture from a wide range of materials, from laboratory glassware to industrial components. They achieve this by combining the principles of convection and forced-air circulation.

The Inner Workings

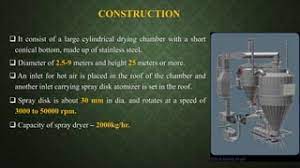

- Convection-Based Heating: Blast drying ovens use electric or gas-powered heating elements to generate heat within the chamber.

- Forced-Air Circulation: Powerful fans circulate the heated air, ensuring uniform heat distribution and faster drying.

- Temperature Control: Precise temperature control is a hallmark of blast drying ovens, allowing users to set and maintain specific drying temperatures.

- Timer Functionality: Timers can be set to control the duration of the drying process, preventing over-drying.

The Significance of Blast Drying Ovens

Rapid Drying

The primary advantage of blast drying ovens is their ability to expedite the drying process significantly. This speed is invaluable in industries where time is of the essence, such as pharmaceuticals and food production.

Preservation of Quality

By drying materials quickly and evenly, blast drying ovens help preserve the quality of products. This is particularly crucial in laboratories and industries where precise outcomes are essential.

Applications Across Industries

Pharmaceutical Industry

- Drug Formulation: Blast drying ovens aid in the rapid drying of pharmaceutical formulations, ensuring the timely production of medications.

- Quality Control: They play a role in quality control processes by quickly assessing the moisture content of drug samples.

Food Industry

- Food Preservation: Blast drying ovens help extend the shelf life of food products by reducing moisture content.

- Snack Production: In snack manufacturing, these ovens are used to dry various snack items before packaging.

Research and Laboratories

- Sample Preparation: In research settings, blast drying ovens are crucial for preparing samples for analysis by removing moisture.

- Glassware Drying: They efficiently dry laboratory glassware, preventing contamination in experiments.

Advantages of Blast Drying Ovens

Energy Efficiency

Blast drying ovens are energy-efficient, as they reduce drying time, leading to lower energy consumption.

Precision and Control

Precise temperature and timer settings provide users with a high level of control over the drying process.

Conclusion

In a world where efficiency and precision are paramount, blast drying ovens serve as indispensable tools in various industries and research settings. Their ability to rapidly and uniformly dry materials not only saves time but also upholds product quality and consistency.