Understanding The Core Of Robotics

So, what exactly makes a robot a robot? At its heart, robotics is about building machines that can do things for us. Think of it as giving a machine a set of instructions and the ability to carry them out, often in places or for tasks that are tricky for people.

What Is Robotics Automation?

Robotics automation is basically using these machines, robots, to handle jobs. These jobs might be super repetitive, like putting the same screw into a thousand widgets, or maybe they’re just too dangerous for a person, like working with really hot metal. The main idea is to get things done more efficiently, with fewer mistakes, and sometimes, just to keep people out of harm’s way. It’s about making work easier and safer by letting machines take over certain tasks.

Key Components Of Robotic Systems

Robots aren’t just random parts thrown together; they have specific bits that make them work. You can break them down into a few main categories:

- Sensors: These are like the robot’s eyes and ears. They help the robot understand what’s going on around it. This could be anything from detecting light and temperature to seeing objects or measuring distance. Without sensors, a robot would be bumping into things constantly.

- Actuators: These are the parts that make the robot move. Think of them as the robot’s muscles. They take electrical signals and turn them into physical motion, whether it’s moving an arm, a wheel, or a gripper.

- Control System: This is the robot’s brain. It’s the computer and software that process information from the sensors and tell the actuators what to do. It’s where the programming lives, dictating the robot’s actions and decisions.

These three parts work together. Sensors gather info, the control system figures out what to do with that info, and actuators carry out the action. It’s a pretty neat loop when it all works right.

Exploring Different Types Of Robots

Robots aren’t just one-size-fits-all. They come in various shapes and sizes, each designed for specific jobs. Think of them like specialized tools in a giant toolbox.

Industrial Robots In Manufacturing

These are probably the robots you picture first. They’re the heavy lifters and precision workers on assembly lines. You’ll find them welding car parts, painting car bodies, or precisely placing components on circuit boards. They’re built for speed, strength, and doing the same task over and over without getting tired or making mistakes. Their main job is to crank out products efficiently and consistently.

- Welding: Spot welding, arc welding, and more.

- Painting: Applying coatings evenly.

- Assembly: Picking and placing parts.

- Material Handling: Moving items around the factory floor.

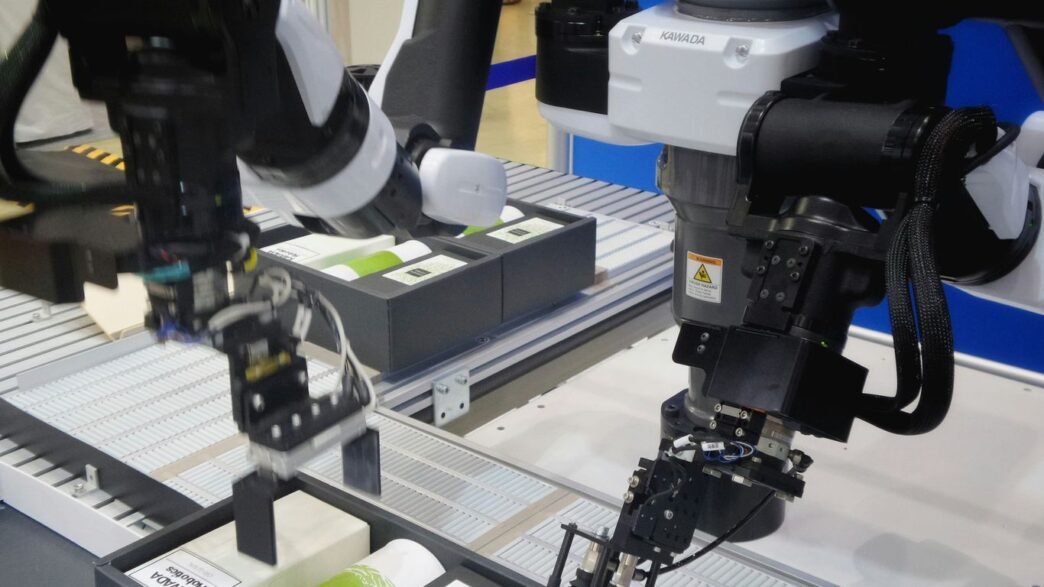

Collaborative Robots Working With Humans

These are the friendlier robots, often called ‘cobots’. Unlike their industrial cousins who usually work in cages, cobots are designed to work right alongside people. They’re built with safety features to prevent injuries, like sensors that stop them if they bump into something. Cobots are great for tasks that need a human touch but could use a bit of robotic help, like assisting with intricate assembly or quality checks. They’re not as fast or strong as industrial robots, but they’re much more flexible.

Autonomous Mobile Robots Navigating Environments

These robots are the explorers. Instead of being fixed in one spot, they move around. Think of them as self-driving forklifts or delivery carts in warehouses and factories. They use sensors and software to map out their surroundings and figure out the best way to get from point A to point B without bumping into anything or anyone. They’re super useful for moving materials around large facilities, taking inventory, or even cleaning floors.

How Robots Perform Their Tasks

So, how exactly do these machines go from being inert metal and plastic to doing actual work? It’s a combination of sensing the world around them, moving in specific ways, and following instructions. Think of it like a person – you see something, you decide what to do about it, and then you move to do it.

Sensors And Perception

Robots need to "see" or "feel" their environment to know what’s going on. This is where sensors come in. They’re like the robot’s eyes and ears. There are all sorts of sensors:

- Vision sensors (cameras): These help robots identify objects, read barcodes, or check for defects. It’s how they know if a part is in the right place.

- Proximity sensors: These detect if something is close by, like a person walking near a robot arm, so the robot can stop or slow down.

- Tactile sensors: These are like a robot’s sense of touch, letting it feel pressure or grip an object without crushing it.

- Lidar and Radar: Used often in mobile robots, these help map out surroundings and avoid obstacles.

The data from these sensors is what allows a robot to understand its immediate surroundings. It’s the first step in making any decision.

Actuators And Movement

Once a robot knows what’s happening, it needs to act. That’s where actuators come in. They are the parts that create movement. Think of them as the robot’s muscles.

- Electric Motors: These are super common and can be used for rotating joints or moving linear components.

- Hydraulic Actuators: These use pressurized fluid and are great for heavy lifting or when a lot of force is needed.

- Pneumatic Actuators: These use compressed air, often for simpler, faster movements like gripping or pushing.

These actuators work together, controlled by the robot’s brain, to make the robot’s arms move, its wheels turn, or its grippers grab things. It’s all about translating commands into physical motion.

Control Systems And Programming

This is the "brain" part. The control system is the computer that takes all the information from the sensors and figures out what the actuators should do. It’s all based on the programming, or the instructions, given to the robot.

- Programming Languages: Robots are programmed using specific languages, often similar to computer programming, but tailored for robot control. This tells the robot the sequence of actions to perform.

- Algorithms: These are sets of rules or calculations that help the robot make decisions. For example, an algorithm might tell the robot how to pick up an object of varying size or how to plot the shortest path to a destination.

- Feedback Loops: The control system constantly checks if the robot is doing what it’s supposed to. If a sensor says the arm isn’t quite in the right spot, the control system will adjust the actuators to correct it. This continuous checking and adjusting is key to accuracy.

Benefits Of Implementing Robotics

So, why are so many companies jumping on the robotics bandwagon? It really comes down to a few big wins that can make a real difference to the bottom line and how work gets done.

Boosting Efficiency and Productivity

This is probably the most obvious one. Robots don’t need breaks, they don’t get tired, and they can perform tasks much faster than a person. Think about an assembly line; a robot can put together the same part thousands of times a day without slowing down. This consistent speed means more products get made in less time. It’s like having a super-powered employee who’s always on task.

Enhancing Precision and Quality

Humans are great, but we all make mistakes, especially when doing the same thing over and over. Robots, on the other hand, are built for precision. They can perform tasks with a level of accuracy that’s hard for people to match, especially with tiny components or complex movements. This means fewer defects, less wasted material, and a more reliable final product. For industries where even small errors matter, like making electronics or medical devices, this is a huge deal.

Reducing Labor Costs and Risks

Let’s be honest, labor is a big expense for most businesses. Robots can take over repetitive or physically demanding jobs, which can lower overall labor costs. But it’s not just about saving money. Some jobs are just plain dangerous for people – think working with hazardous chemicals, heavy lifting, or in extreme temperatures. Robots can handle these tasks, keeping human workers out of harm’s way and reducing workplace injuries. It’s a win-win for both the company and its employees.

Challenges In Robotics Implementation

Bringing robots into a workplace isn’t always as simple as just plugging them in and watching them go. There are definitely some bumps in the road that companies run into.

Initial Investment Costs

Let’s be real, robots cost money. A lot of money, sometimes. The price tag for the actual robot is just the start. You also have to think about the specialized software, the installation, and any modifications needed for your factory floor or workspace. It’s a big upfront commitment, and not every business can just drop that kind of cash without a second thought. It’s like buying a fancy new car – the sticker price is one thing, but then you’ve got insurance, gas, and maintenance to consider.

Integration With Existing Workflows

This is a big one. You’ve got your current way of doing things, your established processes, and then you introduce a robot. Getting the robot to play nice with everything else can be a real headache. Sometimes, you need custom programming to make it talk to your existing machines or software. Other times, it means rethinking how your human workers do their jobs so they can work alongside the new robotic team members. It’s not always a smooth transition, and it can take a lot of planning and tweaking.

Need For Skilled Personnel

Robots aren’t magic. Someone needs to know how to set them up correctly, keep them running, and fix them when they inevitably break down. This means you either need to train your current staff to handle these new responsibilities, or you have to go out and hire people who already have these specific skills. Finding folks with the right technical know-how for robotics can be tough, and it adds another layer of complexity and cost to the whole operation.

The Evolving Landscape Of Robotics

Advancements In Artificial Intelligence

Robots aren’t just doing the same old thing anymore. A big reason for this is artificial intelligence, or AI. Think of AI as the brain that lets robots learn and figure things out on their own. Instead of needing a human to program every single move, AI allows robots to adapt to new situations. They can get better at tasks over time, almost like practicing. This means robots can handle more complex jobs that used to require human judgment. We’re seeing robots that can recognize objects, understand spoken commands, and even make decisions based on what they ‘see’ and ‘hear’. This learning ability is changing what robots are capable of.

Future Applications Across Industries

Because of these AI improvements, robots are popping up in more places than ever. It’s not just factories anymore. We’re looking at robots in warehouses sorting packages, helping out in hospitals with simple tasks, and even exploring places too dangerous for people, like deep underwater or outer space. Imagine robots assisting elderly people at home or helping farmers monitor crops. The list keeps growing. It’s pretty wild to think about how many different jobs robots might do in the next decade.

Ethical Considerations For Responsible Use

All this new robot power brings up some important questions, though. As robots get smarter and take on more tasks, people worry about jobs. What happens to the workers whose jobs can now be done by a robot? There are also concerns about privacy, especially with robots that have cameras and sensors in our homes or workplaces. And who is responsible if a robot makes a mistake? We need to figure out rules and guidelines to make sure robots are used in ways that are fair and safe for everyone. It’s a balancing act between using cool new technology and making sure it helps society, not hurts it.

Wrapping It Up

So, we’ve taken a look at how robots do their thing. It’s not magic, just a mix of sensors, brains, and moving parts working together. From the factory floor to helping out in hospitals, robots are becoming a bigger part of our world. Sure, there are things to figure out, like how they fit into jobs and making sure they’re safe. But as the tech gets better, we’ll likely see them doing even more cool stuff. It’s a field that’s always changing, and it’s pretty interesting to see where it all goes next.