Thinking about getting something 3D printed in Edmonton? It’s not as complicated as it sounds, even if you’re not a tech whiz. Whether you need a quick prototype for a new gadget or a batch of parts for a bigger project, local 3D printing services can really help out. They’ve got the machines and the know-how to turn your digital designs into real objects, often faster than you might expect. Let’s break down what you can find when looking for 3d printing services edmonton.

Key Takeaways

- Edmonton offers a range of 3D printing services, from making early prototypes to handling larger production runs.

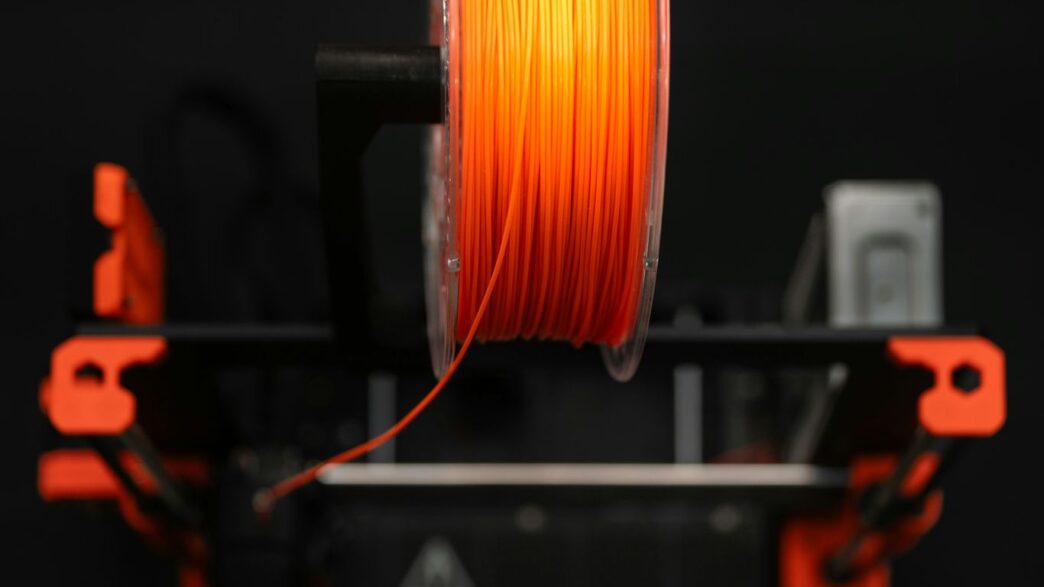

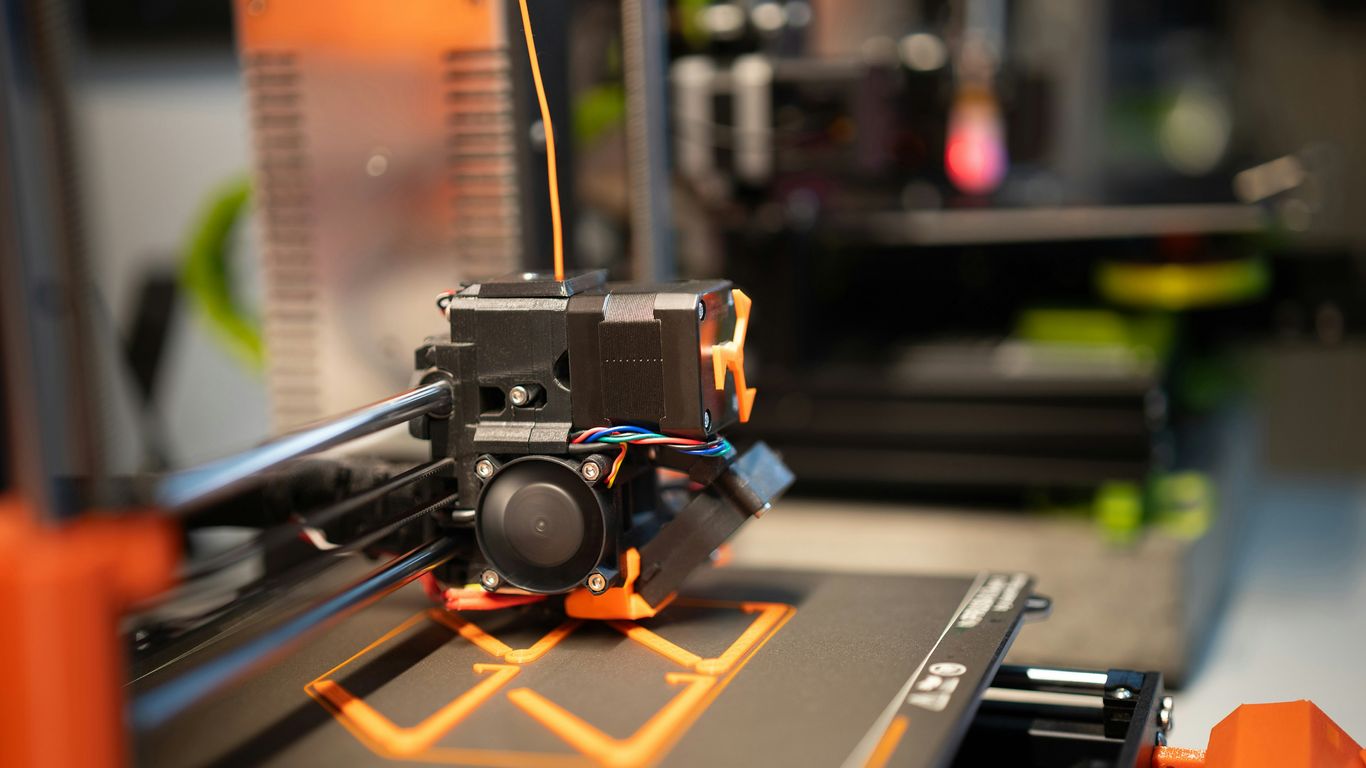

- Various printing technologies like SLS, SLA, DMLS, and FDM are available, each suited for different needs.

- A wide selection of materials, including plastics, resins, and metals, can be used depending on the project’s requirements.

- Local 3D printing helps speed up product development and can make supply chains more reliable.

- Services often include design help, quality checks, and quick delivery, serving industries from oil and gas to medical.

Edmonton’s Premier 3D Printing Services

When you’re looking to get parts made in Edmonton, there are some really solid local options for 3D printing. It’s not just about making cool trinkets anymore; this technology is seriously changing how businesses operate, from coming up with new ideas to actually making things in larger amounts. Edmonton’s 3D printing scene is growing fast, offering everything from quick prototypes to parts ready for the factory floor.

High-Quality Custom 3D Printing

Getting exactly what you need is key, right? Local Edmonton services focus on making custom 3D prints that fit your project perfectly. Whether it’s a one-off prototype for a new gadget or a specific component for industrial use, they can handle it. They use advanced printers and good materials to make sure the final part is just right. It’s all about precision and making sure you get a reliable product every time. They can even help with the design if you’re not quite sure how to get your idea into a printable file. This means you can get your custom parts made without a lot of hassle.

Advanced Prototyping Solutions

For anyone developing a new product, speed is everything. 3D printing is a game-changer for prototyping. Instead of waiting weeks for traditional manufacturing, you can get a physical model of your design in days, sometimes even hours. This lets you test it, see what works, and what doesn’t, and make changes quickly. This rapid iteration process is super important for getting a product right before you invest a lot in mass production. It helps avoid costly mistakes down the line.

Local Expertise and Support

One of the best things about using local 3D printing services in Edmonton is the personal touch. You’re not just sending a file off into the void. You can talk to people who know the technology, understand the materials, and can give you advice tailored to your specific needs. They can help you pick the best printing method and material for your project, which can save you time and money. Plus, having a local partner means faster communication and quicker turnaround times, which is a big plus when you’re on a tight schedule.

Diverse 3D Printing Technologies Available

When you’re looking to get something 3D printed in Edmonton, you’ll find a bunch of different ways to do it. Each method has its own strengths, kind of like how different tools are better for different jobs. It’s not just about picking one; it’s about picking the right one for what you need.

Selective Laser Sintering (SLS)

SLS is a pretty powerful process for making parts that are both tough and accurate. It’s great for making prototypes that actually work and even for parts you’ll use in the long run. Instead of melting plastic filament like some other methods, SLS uses a laser to fuse together fine plastic powders, layer by layer. Think of it like drawing with a laser on a bed of powder. This makes it a fast way to get functional parts made from materials like Nylon 12. It’s becoming a go-to for more serious industrial uses.

Stereolithography (SLA) and FDM

Stereolithography, or SLA, is known for its really smooth surfaces and fine details. It uses a UV laser to cure liquid resin, layer by layer. This makes it a top choice if you need a visual prototype that looks good or if you need parts with very precise dimensions. On the other hand, Fused Deposition Modeling (FDM) is probably the most common type you’ll hear about. It works by extruding melted plastic filament through a nozzle, building up the part layer by layer. FDM is super versatile and can handle a wide range of projects, from simple models to more complex functional parts, often at a lower cost.

Direct Metal Laser Sintering (DMLS)

For projects that need the strength and properties of metal, Direct Metal Laser Sintering (DMLS) is the way to go. This process uses a high-powered laser to melt and fuse fine metal powders together, creating solid metal parts directly from your digital design. It’s ideal for creating complex metal components that would be difficult or impossible to make with traditional manufacturing methods. Think aerospace parts, intricate medical implants, or high-performance automotive components.

Multi Jet Fusion (MJF) and PolyJet

HP’s Multi Jet Fusion (MJF) is another advanced technology that’s really good for producing strong, functional parts quickly. It uses a fusing agent and heat to fuse nylon powders, resulting in parts with consistent mechanical properties. MJF is often a solid alternative to injection molding for smaller production runs. PolyJet, on the other hand, is like an inkjet printer for 3D printing. It jets tiny droplets of photopolymer onto a build platform and cures them with UV light. This allows for incredibly fine details and the ability to print with multiple materials and colors in a single part, making it perfect for realistic prototypes and complex assemblies.

Extensive Material Selection for Every Project

Choosing the right material is a big deal when you’re 3D printing. It’s not just about what looks good; it’s about how the part will perform. Here in Edmonton, we’ve got a pretty wide range of options to fit just about any need, from quick prototypes to parts that need to hold up in tough conditions.

High-Performance Polymers and Plastics

We work with a lot of different plastics. For things that need to be strong and maybe a bit flexible, we have materials like Nylon 12 (PA12), which is great for functional parts and can even be dyed for a better look. If you need something tougher, there’s Polycarbonate (PC), known for its impact resistance and heat tolerance. And for everyday prototyping, standard PLA is always a solid, cost-effective choice. It’s easy to print and gives you a good feel for the design.

Engineering Resins and Metals

Beyond basic plastics, we get into more specialized stuff. Engineering resins can mimic properties like ABS or even offer higher temperature resistance, making them suitable for more demanding applications. For metal parts, we can work with materials like aluminum, stainless steel, and titanium. These are usually processed using technologies like DMLS, and they’re perfect for parts that need the strength and durability of metal but can be made with the design freedom of 3D printing. Think aerospace components or intricate tooling.

Flexible and Durable Material Options

Sometimes, you need a part that can bend or absorb shock. We have flexible materials, often based on TPU, that are good for seals, gaskets, or parts that need to withstand repeated flexing. On the other end, for parts that need to resist wear and tear over time, we have durable options that can handle abrasion and stress. The key is matching the material’s properties to the part’s intended use.

Here’s a quick look at some common materials and their uses:

| Material Type | Common Examples | Key Properties | Typical Applications |

|---|---|---|---|

| Standard Plastics | PLA, ABS | Easy to print, good for visual prototypes | Concept models, basic functional parts |

| Engineering Plastics | Nylon 12 (PA12), PC | Strength, durability, heat resistance | Jigs, fixtures, end-use parts, automotive components |

| Flexible Materials | TPU | Elasticity, impact absorption | Seals, grips, vibration dampeners |

| Resins | Standard, Tough, High Temp | Detail, smooth finish, specific mechanical traits | Detailed prototypes, medical models, tooling |

| Metals | Aluminum, Stainless Steel | High strength, thermal conductivity, durability | Aerospace parts, custom tooling, complex machinery |

Streamlining Production with 3D Printing

Moving from a single prototype to a full production run can feel like a big leap, but 3D printing makes it way simpler. It’s not just for making one-off models anymore; it’s a real manufacturing tool. This technology lets you get your product to market faster and more efficiently.

Rapid Prototyping for Faster Iteration

When you’re developing a new product, you need to test things out, right? 3D printing lets you create prototypes quickly. You can print a part, see how it fits or works, make changes to the design, and print it again. This cycle can happen in days, not weeks or months. It means you can try out different ideas and fix problems early on, saving a lot of time and money down the road. We’ve seen companies go from a rough idea to a tested design in just a few weeks thanks to this speed.

Low-Volume Production Capabilities

Sometimes, you don’t need thousands of parts. Maybe you need a hundred for a special project, or fifty for a limited release. Traditional manufacturing methods can be really expensive for small batches because of the setup costs. 3D printing, however, is perfect for this. You can print exactly the number of parts you need without huge upfront investment. This makes it a great option for custom products or niche markets. It’s a flexible way to produce items when the demand isn’t massive.

Supply Chain Resilience and Local Manufacturing

Relying on overseas suppliers can be risky. Shipping delays, quality control issues, and communication problems can all slow you down. Having 3D printing services right here in Edmonton means you can get parts made locally. This shortens lead times significantly and gives you more control over your production. It also helps build a more robust supply chain, reducing dependence on distant factories. Supporting local manufacturing means faster access to parts and a more reliable way to get your products made. You can even get an instant 3D printing quote online by uploading your files, making the process straightforward.

Partnering for Your Manufacturing Needs

Design and Consultation Services

Sometimes you’ve got a great idea, but getting it from a sketch to a printable file can be a hurdle. That’s where we come in. Think of us as your design buddies. We can help you refine your concepts, make sure they’re actually printable, and even suggest material choices that fit your project’s needs. We’ll look at your CAD files, give you feedback on how to make them stronger or lighter, and generally help you get to a point where you’re ready to print. It’s all about making sure your project starts off on the right foot. We can also help you figure out the best way to design for specific 3D printing technologies, which can save you a lot of headaches down the line.

Quality Control and Assurance

We know that when you need parts, you need them to work. That’s why quality is a big deal for us. We have a few ways we check things to make sure you’re getting what you expect.

- Dimensional Checks: We use precise tools to measure your parts and compare them against your design files. This way, we can catch any size discrepancies.

- Visual Inspections: We look over each part for any surface flaws, like rough spots or unwanted textures.

- Material Verification: We keep track of the materials used, so you know exactly what you’re getting.

For larger orders, we can even do more detailed inspections, like First Article Inspections (FAI), to give you extra peace of mind before we ramp up production.

Fast Turnaround and Delivery

Time is money, right? We get that. When you need a prototype yesterday, waiting weeks just won’t cut it. Our setup is designed to move quickly. We have systems in place to get your quote back fast, start printing soon after you approve, and get the finished parts to you without unnecessary delays. We work with reliable shipping partners to make sure your order arrives safely and on schedule, whether it’s across town or across the country. We aim to keep you informed every step of the way, so you know when to expect your parts.

Industries Benefiting from 3D Printing in Edmonton

Edmonton’s industrial landscape is really starting to see the benefits of 3D printing, and it’s not just for making little trinkets. This technology is actually changing how big industries operate right here in the city.

Petrochemical and Agricultural Sectors

For the petrochemical industry, think about needing custom parts for processing equipment or components that can handle harsh chemicals. Instead of waiting weeks or months for a specialized piece from overseas, local 3D printing services can produce these on-demand. This means less downtime for refineries and chemical plants. Similarly, in agriculture, custom parts for machinery or specialized tools can be printed quickly, helping farmers and agricultural tech companies keep things running smoothly. It’s all about getting the right part, fast, without the usual supply chain headaches. This local manufacturing capability is a big deal for keeping operations efficient.

Automotive and Aerospace Applications

While Edmonton might not be a primary hub for car or plane manufacturing, there are still significant applications. Think about creating complex, lightweight components for specialized vehicles or custom tooling for maintenance operations. The ability to rapidly prototype and produce end-use parts with advanced materials means that companies involved in these sectors can innovate faster. For instance, custom jigs and fixtures for assembly lines can be printed in a fraction of the time and cost compared to traditional methods. This agility is key for staying competitive.

Medical Devices and Consumer Products

This is another area where 3D printing is making a real impact. For medical devices, it means custom implants, surgical guides, and anatomical models can be produced with incredible precision. This level of customization can lead to better patient outcomes. On the consumer product side, it allows for rapid iteration of designs. If you’re developing a new gadget or a piece of sporting equipment, you can go from concept to a physical prototype in days, not weeks. This speeds up the whole product development cycle significantly, letting businesses test and refine their ideas much more effectively. It’s a game-changer for bringing new products to market quickly and efficiently, supporting the growing innovation scene in Edmonton.

Wrapping It Up

So, there you have it. Edmonton’s got some serious options when it comes to getting things 3D printed. Whether you’re just starting out with a rough idea for a prototype or you’re ready to scale up for full production, there are local businesses ready to help. They’ve got the tech, the materials, and the know-how to turn your digital designs into real-world objects. It’s pretty cool how this technology is making manufacturing more accessible and faster right here in our city. Don’t let your ideas just sit on a computer screen – get them printed!