Revolutionizing Energy Storage With Advanced Materials

Energy storage is a big deal these days, right? With all the talk about renewable energy and electric cars, we need ways to store that power effectively. Super-capacitors are one of those technologies that have been getting a lot of attention. They can charge up and discharge really fast, and they tend to last a long time, which is pretty neat.

Metal-Organic Framework Supercapacitors: The Future of Energy Storage

So, what makes a good super-capacitor? You need materials that conduct electricity well, have a lot of surface area for storing charge, and are stable when you’re using them. For a while, porous carbons were the go-to. But now, there’s a new player in town: Metal-Organic Frameworks, or MOFs. These are pretty cool because scientists can tweak their structure and chemistry to get just the properties they want. This adaptability makes MOFs really promising for building the next generation of super-capacitors.

Challenges and Opportunities in MOF Supercapacitors

MOFs are definitely exciting, but they aren’t perfect yet. Compared to the carbons we’ve been using, MOFs often have a smaller voltage window, meaning they can’t handle as wide a range of voltages. They can also be a bit slower when it comes to charging and discharging. It’s not all bad news, though. Lots of researchers around the world are working hard to fix these issues. The potential benefits of MOFs are so big that it’s worth the effort.

Here’s a quick look at some of the points:

- Voltage Window: MOFs typically operate between 1 to 1.5 V, while some carbons reach 2.5–2.7 V.

- Kinetics: MOF-based electrodes can be slower than carbon ones.

- Research Focus: Ongoing global efforts aim to improve these limitations.

Enhancing Charge Storage and Electrochemical Stability

MOFs are built from metal ions linked together by organic molecules, forming intricate, porous structures. This design gives them a massive internal surface area, which is exactly what you want for storing electrical charge. Think of it like having way more nooks and crannies to pack things into. The challenge is making sure these structures stay stable when they’re constantly being charged and discharged. Scientists are experimenting with different combinations of metals and organic linkers, as well as ways to process the MOFs, to create materials that not only store a lot of energy but also keep doing it reliably over many cycles.

Advancements in Coatings and Surface Treatments

Protective Solutions for Enhanced Durability

So, you know how things just get worn out, right? Like your favorite mug getting chipped or your car’s paint fading? Well, advanced coatings are like giving materials a superhero suit. They’re designed to really beef up how long things last and how well they hold up against all sorts of rough stuff. We’re talking about protection against rust, scratches, and even the sun’s harsh rays. Think about nanotechnology-infused coatings; these things are pretty amazing at fighting off corrosion and wear. This means less money spent on repairs and replacements down the line.

Functional Benefits Beyond Durability

But it’s not just about making things tougher. These new coatings can do all sorts of cool tricks. Ever wish your windows would just clean themselves? Some coatings can do that, repelling dirt and grime. Others have special properties to stop germs from growing, which is a big deal for things like medical equipment or even kitchen counters. It’s like giving a material a whole new set of skills.

Here’s a quick look at some types:

- Nano-coatings: Great for stopping rust and protecting against UV light. You’ll find these on planes and cars.

- Self-cleaning coatings: These surfaces naturally push away dirt, meaning less scrubbing. Think buildings and electronics.

- Anti-microbial coatings: They actively prevent bacteria from growing, making them useful in hospitals and food places.

- Thermal barrier coatings: These keep heat out or in, used in engines and power plants.

Eco-Friendly Formulations and Multifunctional Traits

What’s also neat is that companies are trying to make these coatings better for the planet. This means using fewer nasty chemicals when they’re made and applied, which is good for the workers and the environment. Plus, some coatings are getting really clever, doing more than one job. Imagine a paint that changes color when it gets too hot, or a fabric coating that’s both waterproof and keeps you cool. It’s all about making materials smarter and more sustainable.

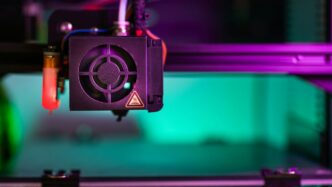

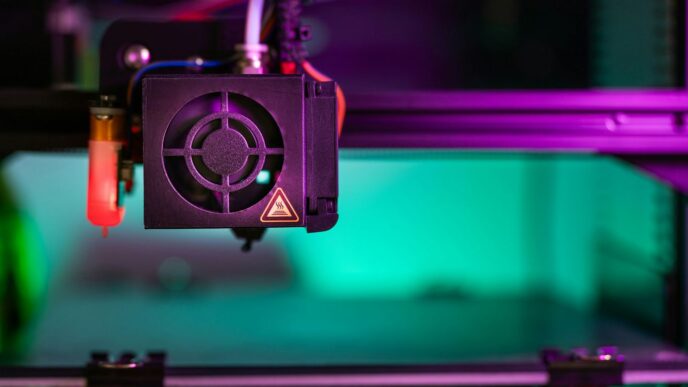

The Impact of 3D Printing on Material Solutions

You know, 3D printing, or additive manufacturing as the fancy folks call it, has really shaken things up. It’s not just about making cool little trinkets anymore. We’re talking about a whole new way to build things, especially when it comes to the materials we use. Traditional manufacturing often means starting with a big block of stuff and carving away what you don’t need. That’s a lot of waste, right? 3D printing flips that. It builds things layer by layer, only using what’s necessary. This means less scrap and a lot more freedom for designers.

Additive Manufacturing for Intricate Geometries

This is where 3D printing really shines. It can create shapes that were just impossible to make before. Think about complex internal structures or very delicate lattices. These aren’t just for looks; they can make parts lighter, stronger, or give them special properties. For example, in aerospace, you can design components with internal cooling channels that follow the exact shape needed, something you couldn’t do with old methods. It’s like giving engineers a whole new toolbox for designing.

Streamlining Efficiency and Reducing Waste

Beyond just the cool shapes, 3D printing is making manufacturing smarter. Because you’re building directly from a digital file, you can make parts on demand. This cuts down on the need for huge inventories and reduces the risk of old stock becoming obsolete. Plus, as mentioned, the ‘add to it’ approach means way less material gets thrown away. It’s a big win for both the bottom line and the planet.

Here’s a quick look at how it helps:

- Less Material Waste: Builds only what’s needed.

- On-Demand Production: Reduces inventory and obsolescence.

- Tooling Elimination: No need for expensive, custom molds for many parts.

- Faster Prototyping: Quickly test and iterate designs.

Customized Fabrics and Unique Applications

And it’s not just metal and plastic. 3D printing is even making its way into textiles. Imagine creating fabrics with specific textures or integrated functionalities, all printed directly. This opens doors for things like custom medical supports that perfectly fit a patient’s body or performance wear designed for very specific athletic needs. The ability to tailor materials and designs down to the smallest detail is what makes 3D printing such a game-changer for so many industries. It’s still evolving, but the potential is pretty massive.

Artificial Intelligence in Advanced Materials Discovery

It’s pretty wild how fast things are changing in the world of materials science, and a big part of that is thanks to artificial intelligence. Think about it: we’re not just mixing stuff together and hoping for the best anymore. AI is starting to really help us figure out what materials will work best for specific jobs, and it’s doing it way faster than we ever could before.

AI-Driven Corrosion-Resistant Alloy Development

One area where AI is making a big splash is in creating alloys that don’t rust or degrade easily. Researchers have been using machine learning to predict how different metal mixes will hold up against corrosion. It’s not just about predicting problems, though; these AI models can actually suggest new combinations of metals that are likely to be more resistant. This is a huge deal for industries where corrosion can cause major failures and costs. For example, one project saw AI improve prediction accuracy by at least 15% compared to older methods. The AI was initially built to tackle pitting corrosion in tough alloys, but it turns out it’s useful for other material properties too.

Bridging Textual and Numerical Data for Holistic Understanding

Here’s where it gets really interesting. A lot of what we know about materials, especially how they behave in certain conditions like corrosion, is written down in text. Think about lab notes, research papers, or even just descriptions of how a material was made or tested. Traditional AI models mostly work with numbers, so they were missing out on all that valuable text information. But now, scientists are combining AI that understands numbers with AI that can read and understand text. This means they can get a much more complete picture of how materials work. It’s like finally being able to read the instructions and see the diagrams at the same time, leading to a better grasp of complex material behaviors.

Accelerating R&D with Data-Driven Approaches

Basically, AI is speeding up the whole process of finding and developing new materials. Instead of long, drawn-out experiments, AI can sift through vast amounts of data, identify patterns, and point researchers in the right direction. This means we can:

- Discover new materials much quicker.

- Improve the materials we already have.

- Test and scale up new materials for real-world use faster.

- Reduce the time and money spent on research and development.

It’s all about using data smartly to make better materials, faster. This approach helps us tackle tough problems that were hard to solve with older methods and can lead to better products and technologies across many industries.

The Rise of Graphene in Modern Industries

Graphene. You’ve probably heard the name, right? It’s this super thin sheet of carbon atoms, just one atom thick, arranged in a honeycomb pattern. Sounds simple, but this stuff is seriously impressive. It’s incredibly strong, conducts electricity like a champ, and is really good at moving heat around. Think of it like a superhero material that’s showing up everywhere.

Graphene’s Remarkable Electrical and Mechanical Properties

So, what makes graphene so special? Well, for starters, it’s ridiculously strong. Stronger than steel, but way lighter. This makes it a dream for engineers looking to build tougher, lighter things. Then there’s its electrical conductivity. It lets electricity flow through it with very little resistance. This is a big deal for electronics. It’s also a great conductor of heat, which is useful for managing temperature in devices.

Here’s a quick look at some of its key properties:

- Tensile Strength: Around 130 GPa (Gigapascals) – that’s a lot!

- Electrical Conductivity: About 10^6 S/cm (Siemens per centimeter) – super high.

- Thermal Conductivity: Around 3000-5000 W/(m·K) (Watts per meter-Kelvin) – excellent heat transfer.

- Density: Approximately 0.77 mg/m² (milligrams per square meter) for a single layer – incredibly light.

Applications in Electronics and Energy Storage

Because of these amazing properties, graphene is popping up in all sorts of places. In electronics, it could lead to faster, more efficient computer chips and flexible screens that you can actually bend. Imagine a phone that folds up or a tablet that rolls like a poster. For energy storage, graphene is a game-changer for batteries and supercapacitors. It can help them charge faster, hold more power, and last longer. This is huge for everything from electric cars to portable gadgets.

Enhancing Composites for Aerospace and Automotive Design

Beyond electronics, graphene is making waves in materials science, especially for composites. By adding even small amounts of graphene to plastics or metals, manufacturers can create materials that are much stronger and more durable. This is a big win for the aerospace and automotive industries. Think about airplanes or cars that are lighter but also safer and more fuel-efficient. It’s like giving traditional materials a serious upgrade. This material is really opening up new possibilities for how we design and build things.

Smart Textiles and Interactive Clothing

It’s pretty wild how clothes are changing, isn’t it? We’re not just talking about new styles anymore. Smart textiles are basically fabrics that have technology woven right into them. Think about your workout gear, but instead of just wicking sweat, it could actually be keeping an eye on your heart rate or how much oxygen is in your blood. This isn’t science fiction; it’s happening now.

Real-Time Health Monitoring Capabilities

So, how does this health tracking work? It’s all about tiny sensors and special threads. These aren’t your grandma’s knitting needles, that’s for sure. They can pick up on subtle changes in your body. Imagine wearing a shirt that tells your doctor if your heart rhythm is off, or a bandage that monitors wound healing by checking temperature and moisture levels. It’s like having a personal health assistant built right into your clothes. This could be a huge deal for people with chronic conditions or even just for athletes wanting to fine-tune their training.

Here’s a quick look at what these fabrics can track:

- Heart rate and rhythm

- Body temperature

- Respiration rate

- Blood oxygen levels

- Muscle activity

Conductive Fibers for Device Charging and Connectivity

Beyond just health stuff, these smart fabrics can also connect you to your devices. They use conductive fibers, which are basically threads that can carry electricity. This means your jacket could potentially charge your phone as you walk around, or your backpack could have built-in speakers. It’s about making our clothing more functional and integrated with the tech we use every day. No more digging for a charger when your battery is low – your clothes might just do the work for you. It also opens up possibilities for interactive clothing, where the fabric itself can light up or change patterns based on what you’re doing or listening to.

Nanoparticle Enhancements for Fabrics

And it gets even more interesting. Scientists are adding nanoparticles to these textiles. These are super, super tiny particles that can give fabrics new abilities. For example, they can make a shirt more breathable, or a jacket completely waterproof without making it stiff. Some nanoparticles can even make fabrics resistant to bacteria and odors, which is pretty handy for activewear or medical uniforms. It’s all about making textiles do more than just cover us; they’re becoming active participants in our lives, improving comfort, hygiene, and performance in ways we’re only just starting to explore.

Phase-Change Materials in Memory Technology

Understanding Atomic-Level Transition Mechanisms

Phase-change materials (PCMs) are pretty neat for computer memory because they can store data by changing their physical state. Think of it like flipping a switch between two different forms – a glassy, disordered state and a more ordered, crystalline state. This change happens when you apply a quick pulse of heat. The cool part is that once it’s in a certain state, it tends to stay that way even when the power is off, which is why it’s called non-volatile memory. This makes it great for things like storing your files or settings.

However, even though we use these materials all the time, scientists are still figuring out exactly what’s going on at the tiniest level when they switch states, especially in that glassy, amorphous form. It’s a bit like knowing a light switch works without knowing all the tiny electrical bits inside.

Device Applications of Phase-Change Memory

PCMs are the heart of phase-change random-access memory (PCRAM). This type of memory is a strong contender for future electronics because it’s fast – we’re talking operations in nanoseconds – and it can be scaled up. The way it works involves using a tiny bit of PCM that can be rapidly heated and cooled. This heating and cooling cycle changes the PCM between its amorphous (high resistance, representing a ‘0’) and crystalline (low resistance, representing a ‘1’) states. This ability to switch between two distinct resistance states is the fundamental principle behind PCRAM data storage.

Researchers have even developed PCMs that use very little power, sometimes a thousand times less than older versions. They do this by creating specific structures, like ‘nano-bridges,’ that help control where the phase change happens. This is important because lower power consumption means devices can last longer on a single charge.

Temperature-Dependent Crystallization Kinetics

The speed at which these materials change from their glassy state to their crystalline state, and how stable they are in each state, is really important. This is known as crystallization kinetics, and it’s heavily influenced by temperature. When you apply a thermal pulse, the atoms in the PCM start to rearrange. The rate of this rearrangement dictates how quickly the memory bit can be written.

Different PCMs have different speeds and temperature requirements for this transition. For example, some materials might crystallize very quickly at a certain temperature, while others might need a slightly higher temperature or more time. Understanding these temperature-dependent behaviors helps engineers design memory devices that are both fast and reliable. It’s a balancing act between getting the data written quickly and making sure it stays put until you need it again.

Wrapping It Up

So, we’ve looked at a bunch of cool new materials and how they’re changing things in different industries. From supercapacitors that could power our gadgets for longer to smart fabrics that do more than just cover us, it’s pretty wild. AI is even helping us find and create these materials faster. It’s clear that these advanced materials aren’t just a passing trend; they’re becoming a big deal for making products better, more efficient, and sometimes, even more sustainable. It’s going to be interesting to see what comes next as companies keep figuring out new ways to use them.