Giants and Innovators: The Biggest Robotics Companies

It feels like every other week there’s a new company popping up with a shiny robot promising to change the world. But when we talk about the real heavy hitters, the ones actually shaping automation on a massive scale right now, a few names consistently come up. These are the companies that have been around, building the backbone of industrial automation, and also those pushing the envelope with groundbreaking new designs.

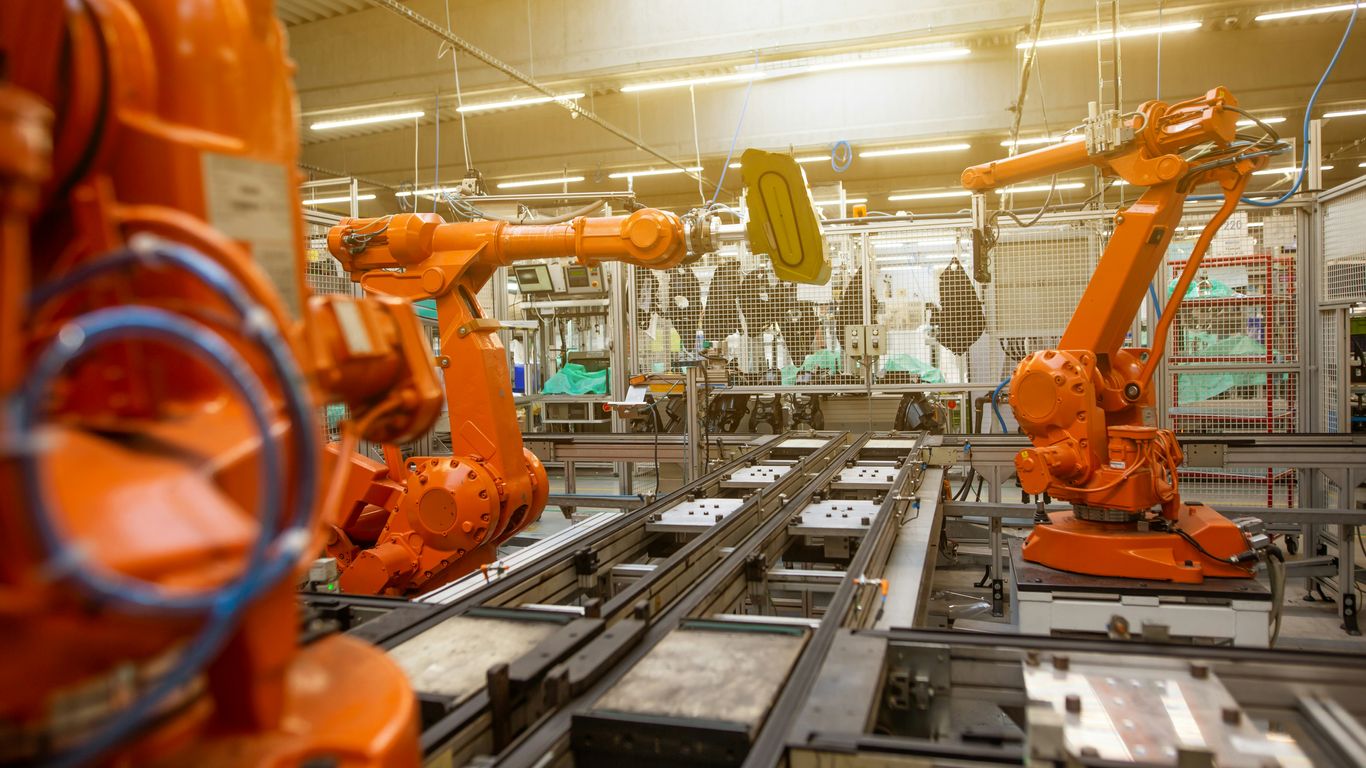

ABB, FANUC, and KUKA: Enduring Industrial Leaders

These three are like the old guard of industrial robotics, and for good reason. They’ve been powering assembly lines for decades, especially in big industries like automotive and electronics. You’ll find their robots doing everything from welding car frames to placing tiny components on circuit boards. They’ve got a huge global presence and a reputation for building machines that just keep running, day in and day out. While they’re known for their massive, high-payload robots, they’re also increasingly integrating AI and smarter features into their systems to keep up with the times.

- ABB: Known for its broad range of robotic solutions, often integrated with digital tech like AI and smart sensors.

- FANUC: A giant in industrial robots and cobots, with massive deployments and a focus on reliability.

- KUKA: Famous for its distinctive orange robots, with a strong foothold in automotive manufacturing.

Boston Dynamics: Pushing the Boundaries of Mobility

When you think of robots that can actually move in complex environments, Boston Dynamics is probably the first name that springs to mind. Their robots, like Spot and Atlas, aren’t typically found on factory floors doing repetitive tasks. Instead, they’re built for navigating rough terrain, inspecting dangerous sites, or serving as platforms for advanced research into mobility and human-like movement. They’re showing us what’s possible when robots can interact with the real, unpredictable world.

Agility Robotics: Pioneering Humanoid Logistics

Agility Robotics is tackling a different kind of challenge: getting humanoid robots to work in places like warehouses. Their ‘Digit’ robot is designed to walk, carry loads, and perform tasks that are difficult for traditional wheeled robots. Think about moving packages around a distribution center or helping with deliveries. They’re focused on practical applications that can help solve labor shortages in logistics and beyond, making warehouses more efficient and adaptable.

Emerging Stars in the Robotics Landscape

While the big names in industrial automation get a lot of attention, there’s a whole other world of robotics companies popping up, shaking things up, and making automation more accessible. These "emerging stars" aren’t just chasing the same old factory floor goals; they’re looking at new ways robots can help out, often with a focus on making things easier and cheaper for businesses that might not have huge budgets.

Standard Bots: Affordable Precision Cobots

Standard Bots is one of those companies that’s really caught my eye. They’re making collaborative robots, or "cobots," that are designed to be more affordable. Their main product, the Core cobot, comes in at a list price of $37,000. That might still sound like a lot, but compared to many other cobots out there, especially those that don’t even list their prices, it’s a pretty significant step towards making precision automation available to smaller manufacturers. It’s got a decent reach and payload, and importantly, it’s built with AI-powered programming help. This means you don’t necessarily need a whole team of robotics experts to get it up and running, which is a huge win for smaller shops.

Doosan Robotics: Expanding Cobot Applications

Doosan Robotics is another player that’s been busy expanding its reach. They offer a pretty wide range of cobots, and they’re finding ways to use them in all sorts of industries, not just the usual suspects like electronics manufacturing. Think about packaging, food service, or even some light assembly tasks. They’re really pushing the idea that cobots can be flexible tools for a lot of different jobs, making them more versatile than people might initially assume. It’s all about finding those specific tasks where a cobot can make a real difference without requiring a massive overhaul of existing processes.

UBTECH Robotics: Humanoids Beyond the Factory Floor

UBTECH Robotics is taking a different path, focusing more on humanoid robots and their use outside of traditional factory settings. While many companies are still figuring out how to make robots walk and carry things reliably in warehouses, UBTECH is looking at applications in education, customer service, and even as companion robots. They’ve got a strong presence in Asia, and their work shows a vision for robots that interact more directly with people in everyday environments, rather than just performing repetitive tasks in isolation. It’s a different kind of automation, one that’s more about interaction and assistance than pure industrial output.

Specialized Robotics for Unique Challenges

Honeybee Robotics: Solutions for Extreme Environments

When you think about robots, you probably picture them on a factory floor or maybe even delivering packages. But what about places where humans just can’t go, or where conditions are seriously harsh? That’s where companies like Honeybee Robotics come in. They’re building robots designed to handle some of the toughest jobs imaginable, from deep space exploration to mining in difficult terrain.

Think about it: sending a robot to Mars means it has to withstand extreme temperatures, radiation, and dust storms. Honeybee Robotics develops the kind of specialized tools and robotic systems that can actually do that. They’ve worked on projects for NASA, creating robotic arms and sample collection systems that can operate reliably millions of miles away. It’s not just about space, though. Their technology can also be applied to challenging industrial settings here on Earth, like underwater exploration or hazardous material handling. Their focus is on creating robust, reliable machines that can perform critical tasks where failure isn’t an option.

Furhat Robotics: Advancing Social and Companion Robots

Moving from extreme environments to human interaction, Furhat Robotics is taking a different path. They’re all about creating robots that can communicate and interact with people in a more natural, social way. Their flagship product, the Furhat robot, is designed to be a versatile platform for developing social robots.

What makes Furhat interesting is its ability to convey emotions and engage in conversations. It’s not just a machine that follows commands; it’s built to be a companion, a teacher, or even a customer service agent. Imagine a robot that can help teach children new languages, provide companionship for the elderly, or guide visitors in a museum. Furhat Robotics is working on making these kinds of interactions possible. They provide a software development kit that allows developers to create custom applications for the robot, focusing on everything from speech recognition and synthesis to facial expressions and gestures. This approach allows for a wide range of uses, pushing the boundaries of what we expect from robots in our daily lives.

The Evolving Role of AI in Robotics

AI-Driven Adaptability in Modern Robots

It’s pretty wild how much artificial intelligence is changing what robots can do these days. Gone are the days of robots just doing one specific, repetitive task. Now, thanks to AI, robots are getting way smarter and more flexible. Think about it: a robot that can actually learn from its surroundings and adjust its actions on the fly? That’s a game-changer.

This means robots aren’t just for super controlled factory lines anymore. They can handle more varied jobs, like picking different kinds of items in a warehouse or even helping out in places that aren’t perfectly set up for them. The ability for robots to adapt means they can be used in a lot more situations, making automation a real possibility for more businesses.

Here’s a look at how AI is making robots more adaptable:

- Object Recognition: Robots can now ‘see’ and identify different objects, even if they look a bit different each time.

- Dynamic Pathfinding: They can figure out the best way to move around obstacles, even if those obstacles weren’t there before.

- Task Learning: Some advanced robots can learn new tasks by watching humans or through trial and error, without needing a programmer to rewrite their code.

Machine Learning for Predictive Automation

Machine learning, a big part of AI, is also making automation smarter by helping us predict what might happen. Instead of just reacting to problems, robots and the systems they’re part of can start to anticipate them.

This is huge for keeping things running smoothly. Imagine a robot arm on an assembly line. Instead of waiting for it to break down, machine learning can analyze its performance data – like vibration patterns or motor temperature – and predict when maintenance will be needed. This way, you can schedule repairs before a costly shutdown occurs.

It’s not just about preventing breakdowns, either. Machine learning can also help optimize processes. For example, in logistics, it can predict the best routes for delivery robots or figure out the most efficient way to sort packages based on real-time demand. This predictive power means businesses can operate more efficiently and save money by avoiding unexpected issues and making smarter decisions.

Accessibility and ROI for Manufacturers

It used to be that only the big players with deep pockets could afford to bring robots into their operations. That’s really changing now, though. We’re seeing a big push to make automation more accessible, especially for smaller businesses that might not have huge budgets. This isn’t just about getting robots; it’s about making sure they actually pay for themselves and help the business grow.

Lowering Entry Costs for Small Businesses

Think about it: a few years ago, setting up a robotic system could cost a fortune. Now, companies are coming out with more affordable options. These aren’t the massive, complex machines of the past. We’re talking about smaller, more user-friendly robots, often called cobots (collaborative robots), that can work alongside people. They’re designed to be easier to set up and program, which cuts down on the initial investment and the need for highly specialized technicians. This means a small workshop or a medium-sized factory can actually start automating tasks without breaking the bank.

Faster Payback Periods with Cobots

One of the biggest questions for any business owner is, "When will I see my money back?" With these newer, more accessible robots, the payback period is getting shorter. Many businesses are finding that cobots can pay for themselves in as little as 12 to 24 months. This is a huge deal. It means the investment isn’t just sitting there; it’s actively contributing to the bottom line by increasing production speed, improving quality, and reducing errors. Plus, some systems are designed to be pretty much plug-and-play, which saves a ton on integration costs and gets the robot working faster.

Addressing Labor Shortages Through Automation

Let’s be honest, finding and keeping good workers can be tough these days. Many manufacturers and logistics companies are struggling to fill open positions, especially for repetitive or physically demanding jobs. This is where robots are stepping in. They can take over those tasks that are hard to staff, keeping production lines moving and supply chains functioning smoothly. By automating these roles, businesses can maintain consistent output and focus their human workforce on more complex, value-added activities. It’s not about replacing people entirely, but about using robots to fill gaps and make the overall operation more resilient.

Regional Strengths in Global Robotics

It’s pretty wild how robotics development isn’t happening in just one place anymore. Different parts of the world are really leaning into specific areas, making them stand out. It’s like each region has its own superpower when it comes to building robots.

North American Robotics Innovation

Over in North America, especially the US, there’s a huge push for funding new robotics companies. Think about companies like Boston Dynamics, pushing the limits with robots that can move in ways we haven’t seen before, or Agility Robotics with their humanoids designed for warehouse work. Then you have Standard Bots, focusing on making these advanced machines more affordable for smaller businesses. It feels like the US is really good at taking big, ambitious ideas and turning them into practical, often mobile, robots. They’re also strong in areas needing specialized tech, like space exploration with companies like Honeybee Robotics.

Asian Dominance in Industrial and Consumer Robotics

Asia, particularly Japan and South Korea, continues to be a powerhouse for industrial robots. Companies like FANUC and Yaskawa have been around for ages, building reliable machines for factories that churn out everything from cars to electronics. It’s not just the big factories, though. You’re seeing a lot of development in consumer robotics and humanoids too, with companies like UBTECH Robotics making waves. They seem to have a knack for mass production and integrating robots into everyday life and large-scale manufacturing.

European Leadership in Research and Social Robotics

Europe, on the other hand, is really shining in research and development, especially when it comes to robots that interact with people. Companies like ABB, with their deep roots in industrial automation, are also pushing into smarter, more connected systems. But it’s also where you find a lot of work on social robots and robots for specific, often challenging, environments. There’s a strong focus on how robots can assist in areas like healthcare or even just provide companionship, with a lot of academic and research backing driving these innovations forward.

The Road Ahead

So, looking at all these companies, it’s pretty clear robotics is really taking off in 2025. We’ve got the big players like ABB and FANUC still doing their thing in factories, but it’s also super interesting to see all the new startups popping up. Companies like Standard Bots are making it easier for smaller businesses to get into automation with more affordable robots, and others are pushing the boundaries with humanoids and AI that can actually learn. It feels like we’re moving past just robots doing repetitive jobs and into a future where they can handle more complex tasks and even work alongside us in new ways. Whether it’s on a factory floor, in a warehouse, or even in our homes, robots are becoming a bigger part of how things get done.