Intelligent Automation and Enhanced Capabilities

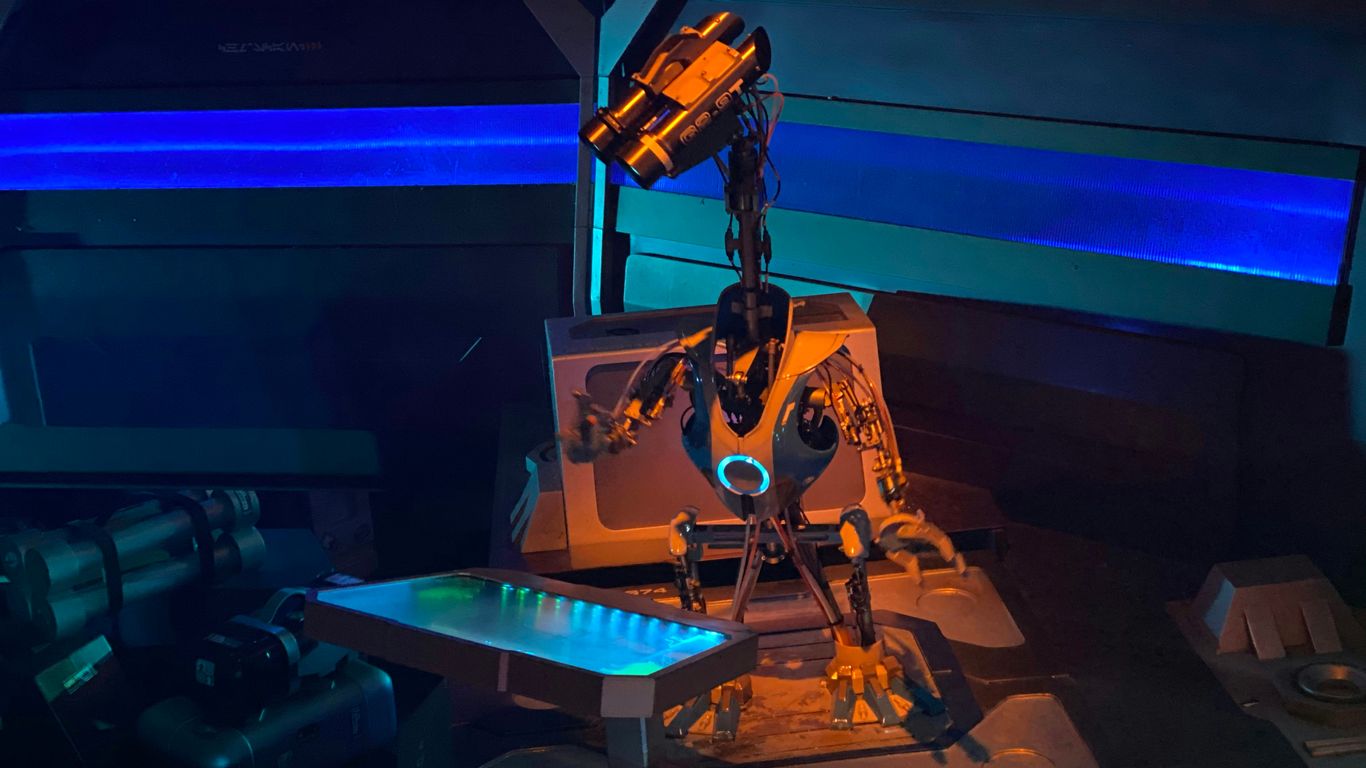

Robots are getting seriously smart, and it’s not just about doing the same old tasks faster. We’re seeing machines that can actually figure things out on their own. Think of it like this: instead of just following a script, these robots can look at a situation, process a bunch of information, and then decide the best way to get something done. This shift from programmed actions to genuine problem-solving is a huge deal.

Hyper-Intelligent Robots and Creative Problem-Solving

Forget robots that just repeat motions. The new wave is all about robots that can tackle unexpected issues. They’re using advanced AI, especially things like machine learning, to learn from their environment and past experiences. This means they can adapt when things don’t go as planned. For example, a robot on an assembly line might encounter a slightly misshapen part. Instead of stopping the whole line, a hyper-intelligent robot could adjust its grip or even figure out a new way to handle the part based on its learned data. It’s like giving them a bit of common sense, which is pretty wild when you think about it.

Autonomous Mobility in Complex Environments

Getting robots to move around on their own is one thing, but getting them to do it in places that are messy, unpredictable, or just plain difficult is another. We’re talking about robots that can drive themselves through a busy warehouse, navigate uneven terrain in a disaster zone, or even explore the ocean floor. They use a combination of sensors – like cameras, lidar, and radar – along with sophisticated mapping and pathfinding software. This allows them to build a picture of their surroundings in real-time and plot a safe course, avoiding obstacles and making smart decisions about where to go next. It’s a big step up from just following a pre-set track.

AI-Driven Machine Learning and Adaptive Behavior

This is really the engine behind a lot of these new capabilities. Machine learning lets robots learn without being explicitly programmed for every single scenario. They can be fed tons of data, and the AI figures out patterns and makes predictions. This leads to adaptive behavior, meaning the robot can change how it acts based on new information.

Here’s a simplified look at how it works:

- Data Input: The robot gathers information from its sensors (sight, touch, sound, etc.).

- Learning & Analysis: AI algorithms process this data, comparing it to what it already knows and identifying new patterns or anomalies.

- Action & Feedback: Based on the analysis, the robot performs an action. It then receives feedback on the outcome of that action, which it uses to refine its future behavior.

- Adaptation: Over time, this continuous loop allows the robot to become more efficient and effective, even in situations it hasn’t encountered before.

Revolutionizing Healthcare Through Robotics

Robots are really starting to make a big splash in hospitals and clinics, and it’s not just science fiction anymore. We’re seeing some pretty cool stuff that’s changing how doctors work and how patients get care. These machines are helping with everything from super delicate surgeries to just making daily life a bit easier for people who need a hand.

Precision Surgical Robotics Advancements

When it comes to surgery, tiny movements matter. Robotic systems are letting surgeons perform operations with a level of accuracy that’s hard for a human hand to match, especially in tight spots. Think minimally invasive procedures – smaller cuts, less pain, and quicker healing times for patients. These robots aren’t replacing surgeons, of course, but they’re giving them better tools to do their jobs.

Here’s a quick look at what these surgical robots can do:

- Enhanced Dexterity: Robotic arms can move in ways human wrists can’t, allowing for more complex maneuvers.

- Improved Visualization: Surgeons often get a magnified, 3D view of the surgical site, making it easier to see what they’re doing.

- Reduced Tremor: Robots can filter out natural hand tremors, leading to steadier instrument control.

- Remote Capabilities: In some cases, surgeons can operate on patients from a distance, which could be a game-changer for remote areas.

Robotic Exoskeletons for Enhanced Mobility

For people who have trouble moving around, whether due to injury, illness, or age, robotic exoskeletons are becoming a real hope. These wearable devices are like powered suits that can help people walk again, lift heavier things, or just move with more ease. It’s pretty amazing to see someone regain some of their independence thanks to this tech. They’re being used in physical therapy to help patients rebuild strength and in daily life to assist with mobility.

Assistive Robots in Patient Care

Beyond the operating room, robots are also showing up to help with everyday patient care. These aren’t necessarily the high-tech surgical kind, but more like helpers. They can assist nurses with tasks like delivering medications or supplies, freeing up human staff to spend more time directly with patients. Some robots are even being developed to provide companionship or help with basic monitoring, which could be a big help in eldercare facilities or for people recovering at home.

Emerging Trends in Robotics 2024

Robotics isn’t just about industrial arms anymore. The field is really branching out, and some of the most interesting stuff is happening in areas that feel a bit more experimental right now. These are the trends that might not be in every factory just yet, but they’re definitely shaping what robots will be able to do in the near future.

Soft and Bio-Inspired Robotics Innovations

Think about how a squid moves or how a gecko climbs. That’s the kind of inspiration driving soft robotics. Instead of rigid metal and plastic, these robots use flexible materials, like silicones and gels. This makes them much safer to work around people and allows them to do delicate tasks, like picking up a ripe tomato without bruising it or gently assisting a patient. The big goal here is to make robots that can interact with the world in a more natural, less forceful way. They can squeeze through tight spaces or conform to irregular shapes, which opens up possibilities in areas like medical devices and even wearable tech.

Micro and Nanorobotics for Specialized Applications

We’re talking about robots so small you can barely see them, sometimes even at the cellular level. These tiny machines are still mostly in the research phase, but the potential is huge. Imagine microscopic robots that can deliver drugs directly to a tumor inside the body, or tiny tools that can repair damaged tissues from the inside out. It’s like having a miniature surgical team working at a scale we’ve never been able to access before. The challenges are immense, of course, like powering them and controlling them precisely, but the payoff could be revolutionary for medicine and materials science.

Swarm Robotics for Coordinated Tasks

Instead of one big, complex robot, swarm robotics uses many smaller, simpler robots that work together. It’s kind of like how ants or bees operate. By coordinating their actions, a swarm can achieve tasks that would be impossible for a single robot, or even a much larger one. Think about mapping out a disaster zone quickly, or collectively building a structure. Each robot might not be super smart on its own, but together, they can solve complex problems through cooperation. This approach is also great for redundancy; if one robot fails, the others can often pick up the slack.

Human-Robot Collaboration and Interaction

It’s pretty wild how robots are moving beyond just doing repetitive tasks in factories. Now, they’re actually starting to work with us, side-by-side. This whole area of human-robot collaboration is really taking off, and it’s changing how we think about teamwork.

Cobots in Shared Workspaces

These aren’t your old-school industrial robots. Cobots, or collaborative robots, are built with safety and ease of use in mind. They have sensors that can detect humans, stopping or slowing down if someone gets too close. This means they can help out on assembly lines, in warehouses, or even in labs without needing to be caged off. The goal is to have robots and people doing what they do best, together. Think of a cobot handling the heavy lifting or the repetitive screwing, while a human worker focuses on quality control or more complex assembly steps. It’s about making jobs safer and more efficient.

Intuitive Interfaces and Natural Language Processing

Talking to a robot used to mean learning a whole new language of commands. Not anymore. Thanks to advances in Natural Language Processing (NLP), robots can now understand what we say in plain English. This makes them way easier to work with. You can just tell a robot what you need, and it can figure out how to do it. This is a big deal for things like:

- Giving instructions for a specific task.

- Asking for status updates on a project.

- Getting feedback on its work.

It’s like having a really helpful, albeit sometimes literal, assistant who can process your requests without needing a complicated setup.

Social Intelligence in Robotic Companions

This is where things get really interesting, and maybe a little sci-fi. We’re starting to see robots designed not just for tasks, but for interaction. These aren’t just about doing chores; they’re being developed to understand social cues, express basic emotions (through lights or sounds, mostly), and generally be more pleasant to be around. This could mean robots that help out in elder care facilities, providing companionship and reminders, or even robots in educational settings that can adapt their teaching style based on a student’s engagement. It’s a complex area, and there are still lots of questions about how well robots can truly understand and respond to human emotions, but the progress is definitely noticeable.

Robotics in Challenging Environments

When we think about robots, we often picture them on factory floors or maybe helping out in a hospital. But some of the most exciting work is happening where humans really can’t or shouldn’t go. These are the places that are too dangerous, too remote, or just too tough for us to handle ourselves. Think about disaster zones, the bottom of the ocean, or even outer space. Robots are stepping up to do the jobs that are just too risky for people.

Disaster Response and Search and Rescue Systems

After a major earthquake or a building collapse, time is super important for finding survivors. Sending in human rescue teams can be slow and dangerous because of unstable structures and potential hazards. That’s where robots come in. Small, tough robots, sometimes equipped with cameras and sensors, can be sent into rubble to look for signs of life. They can get into tight spots that people can’t reach and send back information about what’s going on. Some systems even use multiple robots working together, like a team, to cover more ground faster. These machines are literally saving lives by going where we can’t.

Here’s a look at what these systems can do:

- Reconnaissance: Quickly assess damage and identify safe entry points.

- Locating Survivors: Detect heat signatures, sounds, or even movement.

- Delivering Supplies: Drop small packages like water or medicine to trapped individuals.

- Mapping: Create 3D maps of collapsed areas to help guide human rescuers.

Exploration Robots for Space and Deep Sea

Space and the deep ocean are two of the most extreme places we know of. We can’t just send people down there for extended periods without massive, expensive support. So, we send robots. Think of the Mars rovers, trundling across the red planet, taking pictures and analyzing rocks. Or the remotely operated vehicles (ROVs) that explore miles below the ocean’s surface, discovering new species and mapping the seafloor. These robots are our eyes and ears in places we can only dream of visiting ourselves. They gather data that helps us understand our universe and our own planet better.

Key features of these exploration bots include:

- Extreme Durability: Built to withstand immense pressure, radiation, and temperature swings.

- Advanced Sensors: Equipped with cameras, sonar, spectrometers, and other tools for data collection.

- Autonomy: Capable of making some decisions on their own when communication with Earth is delayed or impossible.

- Mobility: Designed to traverse difficult terrain, whether it’s rocky Martian landscapes or the uneven ocean floor.

Hazardous Material Handling Robots

Dealing with dangerous chemicals, radioactive waste, or other toxic substances is a job nobody wants. It’s incredibly risky for human health. Robots are perfect for these tasks. They can be built to handle materials without getting contaminated or suffering damage. In nuclear power plants, for example, robots are used for inspection and cleanup in areas where radiation levels are too high for people. They can perform repetitive or precise tasks with hazardous materials, reducing the risk of accidents and protecting workers from long-term health problems. It’s all about keeping people safe by letting machines do the dirty, dangerous work.

University-Led Robotics Innovations

Universities are really pushing the boundaries in robotics, often working on projects that are a few steps ahead of what we see in everyday industry. It’s where a lot of the foundational research happens, and some pretty cool stuff is coming out of labs right now.

Human-Robot Collaboration in Search and Rescue

Think about disaster zones. Getting people in there safely is tough, and robots can help. Researchers are developing systems where robots and humans can work together more effectively during rescue missions. The idea is that robots can go into dangerous spots first, scout around, and relay information back to human teams. This way, rescuers can plan their next moves better and stay safer.

- Robots scout hazardous areas. They can use sensors to detect things like unstable structures or gas leaks.

- Humans direct the robots. Operators can guide the robots remotely, making decisions based on the robot’s feedback.

- Information sharing is key. Real-time data from the robots helps human teams make informed choices.

AI-Powered Wearable Robotics

This is a big one, especially for helping people. Universities are creating wearable robots, like exoskeletons, that are powered by AI. These aren’t just clunky suits; they’re designed to be smart. They can learn how a person moves and then assist them. For example, someone with a mobility issue might wear one of these to help them walk or lift things. The AI helps the robot adapt to the user’s specific needs, making it feel more natural and less like a machine is controlling them.

The goal is to make these devices feel like a natural extension of the user’s own body.

Autonomous Systems Development

Beyond just robots that move, universities are focused on creating truly autonomous systems. This means robots that can figure things out on their own, make decisions, and complete tasks without constant human input. Think about robots that can manage a warehouse, explore unknown territories, or even help with complex scientific experiments. They’re working on the algorithms and sensors that allow these systems to perceive their surroundings, plan actions, and adapt to unexpected situations. It’s all about making robots more capable and independent.

Wrapping Up: What’s Next for Robotics?

So, we’ve seen a lot of cool stuff happening in robotics this year. From robots getting smarter with AI to new kinds of flexible robots and even tiny ones that can go places we can’t, it’s pretty wild. These machines are showing up everywhere, helping out in hospitals, factories, and even out in space. It feels like we’re just getting started, and the way robots and people will work together is going to keep changing. It’s going to be interesting to see what happens next as these technologies keep getting better and showing up in more parts of our lives.