Innovations in High-Performance Materials

It feels like every day there’s some new material promising to do things we only dreamed of a few years ago. When engineers need materials that can handle serious stress, extreme temperatures, or corrosive environments, they’re turning to some pretty amazing stuff. Think about what it takes to send rockets into space or build machinery that runs non-stop – these applications demand materials that just don’t quit. Chemical engineers have been busy tweaking the building blocks of matter to create plastics, ceramics, and metals that are tougher, lighter, and more resilient than ever before. Many of these advanced materials actually got their start in the space program, but now they’re showing up everywhere, from your car to your medical implants.

Advanced Plastics for Demanding Environments

Forget the flimsy plastic you might be thinking of. We’re talking about high-performance plastics that can stand up to conditions that would melt or break down regular materials. These plastics are strong, surprisingly light, and can handle temperatures well over 160°C. Plus, they resist chemicals and don’t warp easily. The cool part is they’re still pretty easy to work with, meaning engineers can mold them into complex shapes and even give them different colors or make them clear. This makes them a great replacement for older, heavier materials in tough spots.

- Exceptional strength-to-weight ratio

- Resistance to high temperatures and harsh chemicals

- Good dimensional stability

- Ease of processing and molding

High-Strength Ceramics in Extreme Conditions

Ceramics aren’t just for coffee mugs anymore. High-performance ceramics are now essential in industrial settings where things get really hot, wear down quickly, or involve a lot of friction. You’ll find them in pump parts, cutting tools, bearings, and even engine components. These advanced ceramics are much stronger and less likely to chip or crack than traditional ones. Some can even be made at lower temperatures, which saves money. They’re perfect for situations where durability is absolutely key.

| Application Area | Ceramic Component Examples |

|---|---|

| Industrial Equipment | Pump parts, extrusion dies, bearings, seals |

| High-Temperature Use | Filters, membranes, furnace linings |

| Automotive & Aerospace | Engine parts, thermal barriers, sensors |

| Cutting & Wear | Cutting tools, wear-resistant coatings |

Lightweight Metal Alloys for Aerospace

When every ounce counts, especially in aircraft and spacecraft, lightweight metal alloys are a lifesaver. Alloys based on aluminum, magnesium, and titanium are being developed to offer incredible structural strength without the heavy weight. This not only makes vehicles more fuel-efficient but also allows for greater payloads. Beyond aerospace, these advanced metals are also finding their way into things like prosthetic limbs and artificial joints, where a combination of strength, lightness, and biocompatibility is needed. Even certain types of stainless steel are engineered for extreme corrosion resistance in tough industrial environments.

The Rise of Nanomaterials in Engineering

You know, it’s pretty wild how small things can make such a huge difference. We’re talking about materials so tiny you can’t even see them without a super powerful microscope – we’re in the nanometer range here, which is like a billionth of a meter. It turns out, when you shrink materials down to this size, they start acting differently, often way better than their bigger counterparts. This shift is opening up all sorts of new possibilities in engineering.

Nanotechnology for Enhanced Material Properties

So, what’s the big deal with these tiny particles? Well, a lot, actually. When you get down to the nanoscale, materials can show off some pretty neat tricks. Think about it:

- Tougher stuff: They can become much harder and resist scratches better. Imagine tools that don’t dull as easily or coatings that stay pristine.

- Stronger and more flexible: Some materials get a boost in how much tension they can handle without breaking, while also becoming more bendy. This is great for things that need to be both robust and adaptable.

- Better chemical resistance: They can stand up to harsh chemicals without degrading, which is a lifesaver for equipment used in tough industrial settings.

- Different melting points and magnetic behavior: Their physical characteristics can change in predictable ways, allowing engineers to fine-tune materials for specific jobs.

- Improved surface interactions: This can make powders easier to mix into liquids, which is handy for making paints, inks, or even certain food products.

Chemical engineers are really the ones figuring out how to make these materials and then how to actually use them on a large scale. It’s not just about making them; it’s about building the systems to produce them reliably for everyday products.

Applications of Nanoscale Particles

These tiny wonders aren’t just theoretical. They’re already showing up in places you might not expect:

- Sunscreens and Cosmetics: Nanoparticles are used to make sunscreens more effective and less visible on the skin. They can also improve the look and feel of makeup.

- Sensors: Super sensitive sensors that can detect diseases, check food quality, or monitor environmental hazards are being developed using nanomaterials. They’re so small they can even explore inside a single cell.

- Medicine: Tiny particles are being designed to deliver drugs directly to cancer cells, potentially leading to earlier diagnosis and better treatment. It’s a whole new way to think about medicine.

Nanofiber Technology Across Disciplines

Beyond just particles, we’ve also got nanofibers. These are like super-thin threads, also measured in nanometers. They’re a big part of nanotechnology and are popping up everywhere:

- Biomedical: Think about artificial tissues or better ways to deliver medicine within the body.

- Electronics: Nanofibers can be used to create more efficient and smaller electronic components.

- Composites: They can be woven into other materials to make them stronger and lighter, which is a big deal for everything from cars to airplanes.

Researchers are looking into all sorts of nanofibers, like ones that can interact with living cells or conduct electricity. It’s a rapidly growing field, and it feels like we’re just scratching the surface of what’s possible.

Advanced Materials for Structural Monitoring and Control

Keeping an eye on how structures are doing and making sure they’re safe is a big deal, especially for things like bridges, buildings, and even machinery that get used a lot. We need to know if they’re holding up okay over time. This is where structural monitoring and control come into play, and they’re getting a serious upgrade thanks to new materials.

Smart Materials for Structural Health Monitoring

Think of materials that can actually tell you when something’s wrong. That’s the idea behind smart materials. They can sense changes in their environment or within the structure itself, like stress, strain, or even tiny cracks forming.

Here are some ways these materials are used:

- Fiber Optics: Tiny optical fibers embedded in concrete or composites can detect changes in light signals caused by deformation or damage. It’s like giving the structure eyes.

- Piezoelectric Sensors: These materials generate an electrical charge when squeezed or stressed. By measuring this charge, engineers can figure out how much force the structure is under or if it’s been impacted.

- Shape Memory Alloys (SMAs): These metals can remember their original shape. If a structure is deformed, SMAs can be triggered (often by heat) to return to their original form, helping to fix minor damage or at least indicating that damage has occurred.

These smart materials are changing how we assess the health of structures, moving from periodic checks to continuous, real-time feedback.

Techniques for Analyzing Operational Performance

Once you’ve got data from your smart materials, you need ways to make sense of it. This involves looking at both static (unchanging) and dynamic (changing) characteristics of a structure.

Some common analysis methods include:

- Vibration Analysis: By studying how a structure vibrates, engineers can detect changes that might indicate damage or weakening. Think of it like tapping a glass to hear if it’s cracked.

- Strain Gauging: Attaching sensors that measure how much a material stretches or compresses under load gives direct insight into stress levels.

- Acoustic Emission Monitoring: This technique listens for the tiny sounds (like clicks or pops) that materials make when they are being damaged. It can pinpoint the exact location of damage initiation.

Control Systems Enhancing Structural Safety

Monitoring is great, but sometimes you need to actively do something to keep a structure safe. That’s where structural control systems come in. These systems can help reduce the impact of things like earthquakes or strong winds.

There are a few main types:

- Passive Control: These systems, like tuned mass dampers (heavy weights that move to counteract vibrations), don’t need external power and just react to the structure’s movement.

- Active Control: These systems use sensors and actuators (like motors or hydraulic systems) to apply forces that actively oppose unwanted motion. They require power and a control system.

- Semi-Active Control: A middle ground, these systems can adjust their properties (like damping) in real-time based on sensor input but don’t generate their own forces.

By combining advanced materials for monitoring with smart control systems, engineers are building safer, more resilient structures for the future.

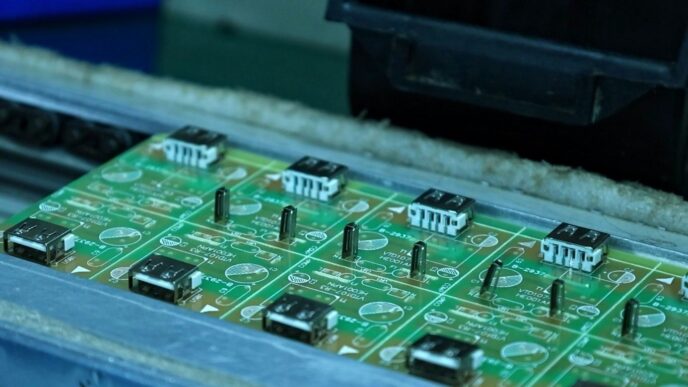

Additive Manufacturing and Novel Structures

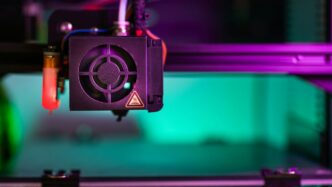

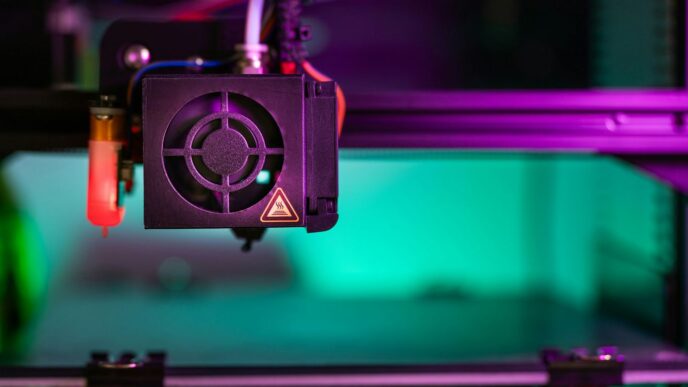

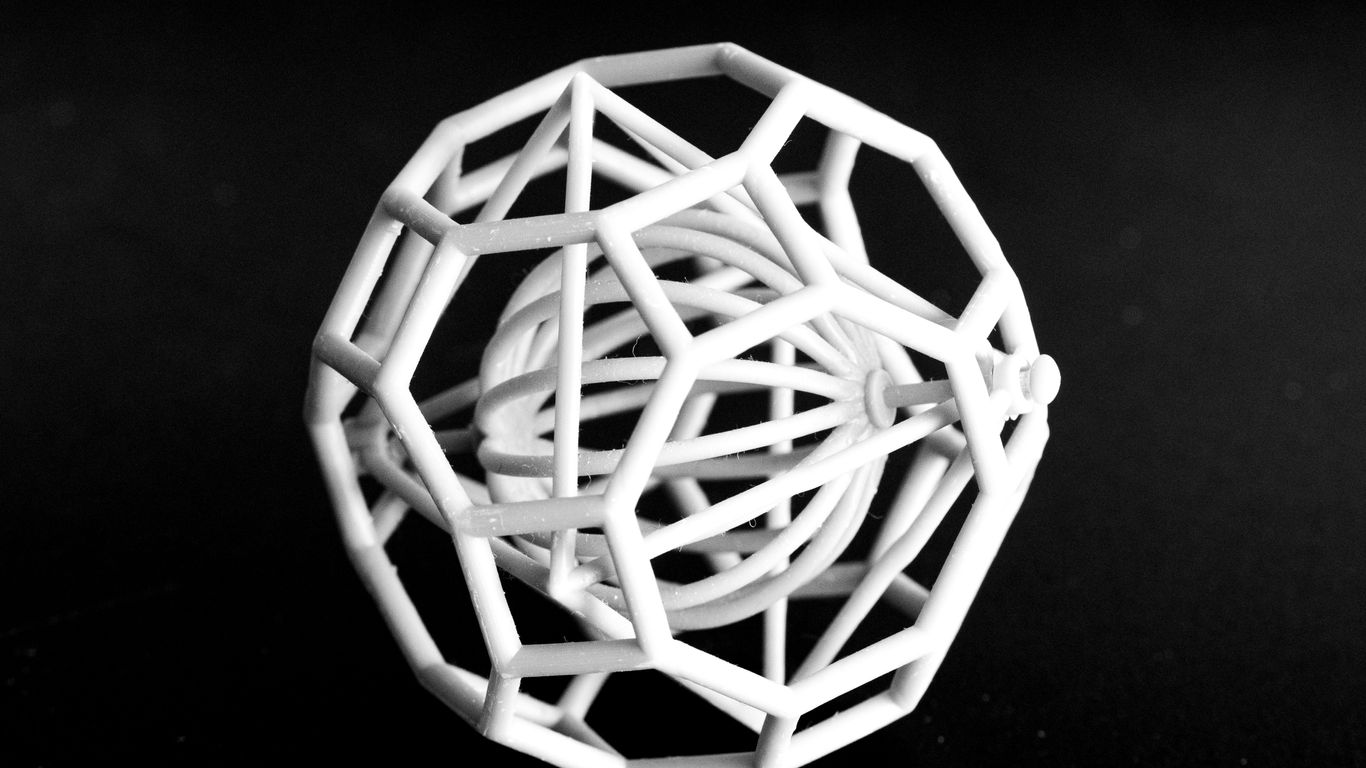

Additive manufacturing, often called 3D printing, is really changing how we make things. Instead of carving away material or using molds, it builds objects layer by layer from a digital design. This bottom-up approach means we can create incredibly complex shapes that were just not possible before. Think intricate internal channels or organic forms. It’s a big deal for making custom parts quickly, especially for prototypes or one-off items.

3D Printing for Customized Designs

This is where additive manufacturing really shines. Need a part that fits a very specific space or has unique performance requirements? 3D printing makes it feasible. It’s not just about making things look cool; it’s about making them work better. For example, in medicine, custom implants or prosthetics can be printed to perfectly match a patient’s anatomy. In aerospace, components can be optimized for weight and strength in ways that traditional manufacturing can’t match. The ability to iterate designs rapidly and produce them on demand is a game-changer for innovation.

Building Complex Structures Layer by Layer

The process itself is pretty neat. You start with a digital 3D model, and then the printer deposits material, layer by tiny layer, fusing them together. This can be done with plastics, metals, ceramics, and even composites. Because it builds up, you can create internal voids, lattice structures, or interlocking parts that would be impossible to assemble otherwise. This opens up possibilities for lighter, stronger, and more functional designs across many fields.

Here’s a look at some common additive manufacturing processes:

- Fused Deposition Modeling (FDM): Melts and extrudes thermoplastic filament layer by layer.

- Stereolithography (SLA): Uses a UV laser to cure liquid photopolymer resin.

- Selective Laser Sintering (SLS): Uses a laser to fuse powdered material together.

- Material Jetting: Deposits droplets of build material that are then cured.

Materials Selection for Additive Processes

Choosing the right material is key, and it depends heavily on the printing technology and the intended application. You’ve got everything from standard ABS plastics for prototyping to high-performance polymers like PEEK for demanding environments. Metal powders, such as titanium alloys and stainless steels, are used for strong, durable parts. Ceramics are also being printed for high-temperature applications. The material properties need to be compatible with the printing process, meaning they need to flow, fuse, or cure correctly at the required temperatures and pressures. It’s a whole new ballgame compared to traditional manufacturing where material properties are often more forgiving.

Composite Materials with Superior Attributes

When we talk about materials that really push the boundaries in engineering, composites are definitely a big deal. Think of them as a team effort, where different materials are combined to create something way better than any single ingredient could be on its own. This isn’t just about mixing stuff together; it’s a smart way to get specific, top-notch properties that you just can’t find elsewhere.

Metal Matrix Composites for Strength and Conductivity

These guys are pretty interesting. We’re talking about taking a metal, like aluminum or magnesium, and mixing in other things – often ceramic particles or fibers. The goal? To get the best of both worlds. You get the toughness and electrical smarts of the metal, but with added muscle from the reinforcements. This makes them great for situations where you need things to be strong but also conduct electricity or heat well, like in some electronics or automotive parts. It’s like giving a strong metal a super-powered upgrade.

Producing Advanced Composite Materials

Making these advanced composites isn’t exactly like baking a cake. It involves some pretty precise steps to make sure everything bonds correctly and you get the properties you’re aiming for. Here’s a general idea of how it often goes:

- Material Selection: Picking the right base material (the matrix) and the reinforcing bits (fibers, particles) is the first big step. This depends entirely on what you want the final composite to do.

- Mixing and Forming: This is where the magic happens. Depending on the type of composite, you might melt the matrix and stir in the reinforcements, or use special processes to layer fibers and then bind them.

- Curing or Solidification: Once mixed and shaped, the material needs to set. This could involve cooling a molten metal, heating a polymer, or using pressure to make sure everything sticks together tightly.

- Finishing: Sometimes, there are extra steps like machining or surface treatments to get the composite ready for its final job.

Nanocomposites for Specialized Applications

Now, let’s talk about going really, really small. Nanocomposites take the idea of combining materials and shrink it down to the nanoscale. We’re talking about adding tiny particles, even just a few nanometers across, into a base material. This tiny scale makes a huge difference. These nanocomposites can show off some pretty wild improvements in things like strength, resistance to wear, and even how they react chemically. They’re showing up in everything from tougher coatings to more sensitive sensors, proving that sometimes, the smallest additions make the biggest impact.

Wrapping It Up

So, we’ve looked at some pretty wild stuff happening in engineering materials and structures. From tiny nanomaterials that do big jobs to new ways of building things layer by layer with 3D printing, it’s clear things are moving fast. These advancements aren’t just for show; they’re helping us build stronger, safer, and more efficient things, whether it’s for space or just down the road. It’s a complex field, for sure, but the progress being made is really something. It makes you wonder what the next big thing will be.