Foundations of Nano Materials Science: From Synthesis to Properties

Getting started in nano materials science can feel a bit like learning a new language, but it’s really about understanding how we make tiny things and what makes them tick. It all begins with how we create these materials at the nanoscale. Think of it as building with LEGOs, but the bricks are atoms and molecules.

Physical Synthesis of Nanoparticles, Clusters, and Quantum Dots

This is where we get hands-on with making nanoparticles, those tiny clusters of atoms, and quantum dots, which are super small semiconductor particles. There are a few main ways to do this. One common method is the "bottom-up" approach, where we start with individual atoms or molecules and build them up. This can involve chemical reactions in solution or gas-phase processes. Another way is "top-down," where we take a larger piece of material and break it down into smaller pieces. Think of milling or grinding, but on a much, much smaller scale.

- Gas-phase synthesis: This often involves vaporizing a material and then letting it cool and condense into nanoparticles. Methods like inert gas condensation are used here.

- Liquid-phase synthesis: This is very common and includes techniques like chemical reduction of metal salts, sol-gel processes, and microemulsion methods. It’s often easier to control size and shape this way.

- Solid-state synthesis: While less common for direct nanoparticle formation, it can be used to create precursors or for high-temperature reactions.

The size and shape of these nanostructures are super important because they directly affect their properties. For example, quantum dots change color depending on their size, which is pretty neat.

Atomic Layer Deposition and Etching Techniques

When we need really precise control over thin films, we turn to Atomic Layer Deposition (ALD) and Atomic Layer Etching (ALE). ALD is like painting a surface, one atomic layer at a time. It’s a self-limiting process, meaning each step deposits a fixed amount of material, leading to incredibly uniform and conformal coatings, even on complex shapes. This is a big deal for making things like advanced computer chips.

ALE works in a similar layer-by-layer fashion but removes material. It’s the opposite of deposition, allowing for very fine control over feature sizes and profiles. This is crucial for miniaturization in electronics.

Here’s a quick look at how ALD works:

- Precursor A pulse: A gas containing one reactant is introduced into the chamber.

- Purge: Excess precursor A and byproducts are removed.

- Precursor B pulse: A gas containing a second reactant is introduced.

- Purge: Excess precursor B and byproducts are removed.

This cycle repeats until the desired film thickness is achieved. The precision is amazing.

Emerging Horizons in Nanoscience and Nanotechnology

So, what’s next? Well, the field is always moving. We’re seeing new ways to make materials with unique structures, like 2D materials (think graphene, but there are many others) that are just one or a few atoms thick. These have wild electrical and mechanical properties. We’re also looking at "designer" materials, where we can tailor properties by precisely controlling composition and structure at the atomic level. The goal is to create materials that can do specific jobs, whether it’s better energy storage, faster computing, or even new medical treatments. It’s a really exciting time to be working in this area.

Exploring Advanced Materials and Their Applications

Nanostructured Materials: Synthesis, Properties, and Applications

We’re seeing some really interesting work happening with nanostructured materials. These are materials where we’ve deliberately shaped them at the nanoscale, often down to just a few atoms across. This control over structure at such a tiny level can lead to some pretty unique properties that you just don’t get with bulk materials.

Think about it: changing the size and shape of particles can alter how they interact with light, how strong they are, or even their electrical behavior. For instance, quantum dots, which are tiny semiconductor particles, have colors that change depending on their size. This is because their electronic properties are quantized, meaning they can only exist at specific energy levels, and these levels are dictated by the dot’s dimensions.

Organic and Hybrid Organic-Inorganic Materials for Optoelectronics

When we talk about optoelectronics – that’s devices that interact with light and electricity, like LEDs and solar cells – organic and hybrid materials are really shaking things up. Traditional silicon is great, but it’s rigid and can be expensive to process. Organic materials, on the other hand, can be flexible, lightweight, and sometimes even printed using techniques similar to how we print newspapers.

We’re looking at things like organic light-emitting diodes (OLEDs) that are already in our phones and TVs, offering vibrant colors and deep blacks. Then there are the hybrid materials, which mix organic components with inorganic ones, like metal oxides or nanoparticles. This combination can give us the best of both worlds: the processability of organics with the stability and performance of inorganics. This synergy is key to developing next-generation displays and energy harvesting devices.

Advances in Perovskite Materials and Optoelectronics

Perovskites have become a huge topic in materials science lately, especially for optoelectronics. These are a class of materials with a specific crystal structure, and they’ve shown incredible promise for solar cells. They can convert sunlight into electricity with efficiencies that are rapidly catching up to, and sometimes even surpassing, silicon.

What’s really exciting is how easy they are to make. You can often process them from solutions, meaning you could potentially ‘print’ solar cells onto flexible surfaces. However, there are still challenges, like making them stable enough to last for decades in real-world conditions and ensuring they don’t contain lead, which is common in high-performing perovskites today. Research is ongoing to find lead-free alternatives and better encapsulation methods to protect them from moisture and heat.

Innovations in Functional and Structural Materials

Advanced Functional Materials for a Sustainable Environment

We’re seeing some really interesting work happening with materials designed to help us live more sustainably. Think about materials that can capture carbon dioxide directly from the air, or catalysts that make industrial processes way more efficient, using less energy and producing fewer byproducts. It’s not just about making things cleaner, but also about creating materials that last longer and can be recycled more easily. For instance, new types of cements are being developed that require less energy to produce and have a smaller carbon footprint compared to traditional Portland cement.

Here’s a quick look at some areas:

- CO2 Capture: Materials like Metal-Organic Frameworks (MOFs) and certain porous polymers are showing promise in selectively absorbing CO2.

- Efficient Catalysis: Developing new catalysts for chemical reactions that speed things up without needing high temperatures or pressures.

- Durable Construction: Innovations in concrete and other building materials to extend their lifespan and reduce the need for frequent repairs or replacements.

Advanced Structural Materials: Synthesis, Properties, and Applications

When we talk about structural materials, we’re usually thinking about things that need to be strong and reliable, like in buildings, vehicles, or aircraft. The focus here is on creating materials that offer better performance, whether that means being lighter, tougher, or more resistant to wear and tear. This often involves new ways of putting materials together at a small scale to get big improvements in their overall strength and durability.

For example, composite materials, which combine different types of materials like polymers with fibers, are getting a lot of attention. They can be tailored to have specific properties that a single material just can’t match.

Some key aspects include:

- Lightweighting: Developing materials that are strong but weigh less, which is a big deal for transportation to save fuel.

- High-Performance Composites: Combining materials like carbon fiber or glass fiber with resins to create strong, stiff, and lightweight components.

- Wear Resistance: Creating surfaces and bulk materials that can withstand friction and abrasion for longer periods, reducing maintenance needs.

Metal-Organic Frameworks and Related Porous Materials

This is a pretty cool area where scientists are building materials with incredibly tiny, well-defined pores. Think of them like molecular sponges. Metal-Organic Frameworks (MOFs) are a big part of this, but there are others too, like Covalent Organic Frameworks (COFs) and zeolites. The way these are put together allows for a lot of control over the size and shape of the pores. This precise control makes them useful for a wide range of applications, from storing gases to filtering liquids.

Their applications are pretty diverse:

- Gas Storage: Storing gases like hydrogen or methane safely and efficiently.

- Separations: Filtering specific molecules out of gas or liquid mixtures, which is useful in chemical industries.

- Catalysis: Acting as supports for catalysts, increasing their effectiveness.

Here’s a simplified look at some common types:

| Material Type | Key Feature | Example Application |

|---|---|---|

| MOFs | Metal nodes and organic linkers | Gas storage, catalysis |

| COFs | Covalently bonded organic units | Gas separation, sensing |

| Zeolites | Crystalline aluminosilicates | Catalysis, water purification |

| Mesoporous Silica | Large, uniform pores | Drug delivery, chromatography |

Cutting-Edge Applications in Electronics and Energy

This section looks at how we’re using new materials in electronics and energy. It’s a pretty exciting area because these materials can do things we only dreamed of a few years ago. We’re talking about making devices that are more efficient, last longer, and can work in places we never thought possible.

Next-Generation Optoelectronics for Unconventional Environments

Optoelectronics, which deals with light and electronics, is getting a major boost from nanomaterials. Think about solar cells that can be printed on flexible surfaces or windows that generate power. These aren’t just for sunny days; we’re developing materials that can capture light even in low-light conditions or convert heat into electricity. This opens doors for powering devices in remote locations or integrating energy generation into everyday objects.

Some key areas include:

- Flexible and Wearable Electronics: Using nanomaterials to create bendable displays, sensors, and power sources that can be worn or integrated into clothing.

- Low-Light Energy Harvesting: Developing materials that are highly efficient at converting ambient light, even indoors or on cloudy days, into usable electricity.

- Thermoelectric Devices: Materials that can convert waste heat directly into electricity, which is great for capturing energy from engines or industrial processes.

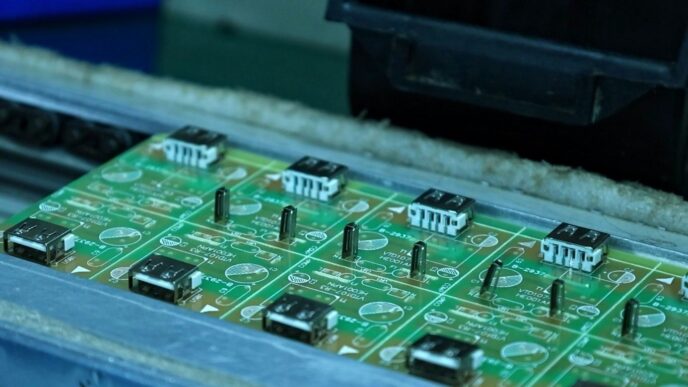

Semiconductor Materials: Synthesis, Characterization, and Applications

Semiconductors are the backbone of modern electronics, and nanomaterials are changing the game. By controlling the size and structure of semiconductor materials down to the nanoscale, we can fine-tune their electrical and optical properties. This leads to faster transistors, more efficient LEDs, and advanced sensors.

Here’s a quick look at what’s happening:

- Quantum Dots: These tiny semiconductor crystals have unique light-emitting properties that are useful for displays and lighting. Their color can be precisely controlled by their size.

- Nanowires and 2D Materials: Materials like graphene and silicon nanowires offer new pathways for creating smaller, faster, and more energy-efficient electronic components.

- Advanced Sensors: Nanostructured semiconductors are being used to create highly sensitive sensors for detecting gases, chemicals, and biological markers.

Novel Multiferroic, Metamaterials, and Thermoelectric Devices

This is where things get really interesting. We’re exploring materials that combine multiple properties, like magnetism and electricity (multiferroics), or materials engineered to interact with electromagnetic waves in unusual ways (metamaterials). Thermoelectric devices, as mentioned before, are also a big focus for energy harvesting.

Consider these examples:

- Multiferroic Materials: These could lead to new types of memory devices and sensors that are more energy-efficient and faster.

- Metamaterials: These engineered materials can manipulate light and radio waves in ways not possible with natural materials, leading to applications in advanced antennas, cloaking devices, and super-lenses.

- Thermoelectric Generators: Improving the efficiency of converting heat into electricity is key for waste heat recovery in everything from cars to data centers. Nanostructuring is a major strategy for boosting the performance of these devices.

These advancements are not just theoretical; they are paving the way for a future with more capable, efficient, and sustainable electronic and energy systems.

The Intersection of Nanotechnology and Biology

Biomaterials: Surface Modifications and Biological Performance

It’s pretty wild how tiny materials are changing medicine, right? We’re talking about biomaterials, which are basically materials designed to interact with biological systems. The real magic happens when we tweak their surfaces. Think of it like giving a material a special coating or texture so it plays nicely with our bodies. This can mean making implants that don’t get rejected or creating scaffolds that help tissues grow back better.

Surface modifications can do a lot:

- Improve biocompatibility: Making sure the material doesn’t cause a bad reaction.

- Promote cell adhesion and growth: Encouraging our own cells to attach and multiply.

- Add antimicrobial properties: Stopping nasty bugs from setting up shop.

- Control drug release: Making sure medications get where they need to go, when they need to get there.

The goal is to make these materials work with the body, not against it. It’s a delicate balance, and scientists are constantly finding new ways to fine-tune these interactions for better health outcomes.

Nanotoxicology and Nanomedicine: Biosafety and Health Effects

Okay, so we’ve got all these amazing nano-tools for medicine, but we also have to be super careful. That’s where nanotoxicology comes in. It’s all about understanding how these tiny particles might affect our health and the environment over time. It’s not just about whether they’re safe right away, but what happens after prolonged exposure.

Researchers are looking into:

- How nanoparticles move through the body.

- What happens when they accumulate in organs.

- Potential long-term health risks, like inflammation or even cancer.

This research is super important for making sure that the nanomedicines we develop are actually safe for people to use. It’s a bit like testing a new drug – you wouldn’t give it to someone without knowing all the side effects, right? Nanotoxicology is that crucial safety check for the nano-world.

Nanomaterials for Drug Delivery, Imaging, and Immunoengineering

This is where things get really exciting. Nanomaterials are like tiny delivery trucks and super-powered microscopes for medicine. For drug delivery, imagine nanoparticles carrying medicine directly to a tumor, leaving healthy cells alone. This means less side effects and more effective treatment.

Then there’s imaging. Nanoparticles can be designed to light up specific cells or tissues, making it easier for doctors to see what’s going on inside the body. This helps in diagnosing diseases earlier and more accurately.

And immunoengineering? That’s about using nanomaterials to help our immune system fight diseases, like cancer. They can be used to train immune cells or deliver vaccines more effectively. It’s a whole new way of thinking about how we can use our own body’s defenses, boosted by nanotechnology.

Functional Materials for Bioelectric Modulation and Sensing

Our bodies run on electricity, from our brains sending signals to our hearts beating. Nanomaterials are starting to play a role in understanding and even influencing these bioelectric signals. Think about sensors that can detect tiny electrical changes in nerve cells or materials that can help repair damaged nerves by guiding electrical impulses.

These materials can be used to:

- Monitor: Detect subtle electrical activity in the body for diagnostic purposes.

- Stimulate: Gently encourage nerve regeneration or muscle function.

- Interface: Create better connections between electronic devices and biological tissues.

It’s a bit like building tiny electronic bridges and sensors within the body. This area holds a lot of promise for treating neurological disorders, improving prosthetics, and developing new ways to understand how our bodies work at the most basic electrical level.

Advanced Characterization and Manufacturing Techniques

So, you’ve got these amazing new nanomaterials, right? That’s awesome. But how do you actually know what you’ve made and if it’s any good? That’s where the "Advanced Characterization and Manufacturing Techniques" section comes in. It’s all about the tools and methods we use to see these tiny things and then build with them.

Electron Microscopy and Spectroscopy of Nanomaterials

This is like having super-powered glasses for the nanoscale. Electron microscopes, like TEM (Transmission Electron Microscopy) and SEM (Scanning Electron Microscopy), let us see individual atoms and the shapes of nanoparticles. They work by shooting electrons at a sample instead of light. Spectroscopy adds another layer, telling us about the chemical makeup and electronic structure of these materials. It’s pretty wild to get that level of detail.

Structural and Chemical Characterization of Metals and Alloys

When we’re dealing with metals and their alloys at the nanoscale, we need specific ways to check them out. Techniques like X-ray diffraction (XRD) tell us about the crystal structure, which is super important for how a material behaves. We also use things like energy-dispersive X-ray spectroscopy (EDS) to figure out the elemental composition. Knowing the exact mix and how the atoms are arranged is key to making strong, reliable metal nanomaterials.

XPS and Synchrotron Techniques for Advanced Materials

Surface science is a big deal in nanomaterials. X-ray Photoelectron Spectroscopy (XPS) is fantastic for analyzing the very top layers of a material. It tells us what elements are there and in what chemical states. Synchrotron radiation, on the other hand, is like a super-charged X-ray source. It allows for really high-resolution imaging and analysis, often used for complex structures or when you need to study materials under specific conditions, like high temperatures or pressures.

Science and Technology of Welding, Joining, and Additive Manufacturing

Okay, so we’ve characterized our nanomaterials. Now, how do we actually build things with them? This section looks at the latest in manufacturing. Additive manufacturing, or 3D printing, is a huge area, especially for creating complex shapes with nanomaterials. Welding and joining techniques are also being adapted for these advanced materials, which can be tricky because their properties are so different from bulk materials. The goal is to create precise, strong, and functional structures from the ground up.

Emerging Trends in Nano Materials Science

So, what’s next in the world of tiny materials? It feels like we’re always on the cusp of something new, and that’s definitely true for nano materials science.

Smart Composite Materials and Their Applications

Think about materials that can change their properties on command. That’s the idea behind smart composites. They’re not just strong; they can react to their surroundings. For example, some can change shape when heated or cooled, or even repair themselves if they get a small crack. This is huge for things like aerospace, where a self-healing wing could prevent a minor issue from becoming a major problem. We’re also seeing them used in adaptive structures that can adjust to different loads or environmental conditions. It’s like giving materials a brain, allowing them to sense and respond.

Powder Metallurgy Advances: Materials, Processes, and Applications

Powder metallurgy is getting a serious upgrade with nanotechnology. Instead of just pressing and sintering metal powders, we’re now using nano-sized powders to create materials with properties we couldn’t achieve before. This means stronger, lighter, and more durable parts. Imagine engine components that can withstand higher temperatures or medical implants that are more compatible with the human body. The precision you can get with these advanced processes is pretty remarkable. It’s opening doors for manufacturing complex shapes that were previously impossible or too expensive to make.

Machine Learning for Materials Science: From Methods to Applications

This is where things get really interesting. We’re starting to use artificial intelligence, specifically machine learning, to speed up the discovery and design of new nano materials. Instead of trial and error in the lab, which can take years, algorithms can analyze vast amounts of data to predict which combinations of elements or structures will have the desired properties. This computational approach is dramatically shortening the time it takes to bring new materials from concept to reality. It’s helping researchers find materials for everything from better batteries to more efficient solar cells much faster than ever before. It’s like having a super-smart assistant that can sift through millions of possibilities in minutes.

Looking Ahead

So, we’ve covered a lot of ground, from tiny nanoparticles to complex 2D materials and even how we’re using computers to figure out new stuff. It’s pretty wild how much is happening in materials science right now. We’re seeing new ways to make things and new applications popping up everywhere, from medicine to electronics and even for a greener planet. It feels like we’re just scratching the surface, and there are definitely challenges ahead, like making sure these materials are safe and figuring out how to produce them on a bigger scale. But honestly, the progress is exciting, and it’s going to be interesting to see what comes next.