Pioneering Space Exploration Milestones

Boeing has been a big player in space stuff for a really long time, pretty much since the US really started getting serious about it back in the late 1950s. They were involved in a bunch of early programs that helped us learn how to get into space and explore.

Early Contributions to US Space Programs

Think about the big names: Mercury, Gemini, Apollo. Boeing was right there, designing, building, and even operating the hardware for these missions. It wasn’t just about building rockets; it was about creating the systems that kept astronauts alive and allowed them to do their jobs. They also worked on Skylab and the Space Shuttle, showing they could handle both human spaceflight and more complex robotic missions.

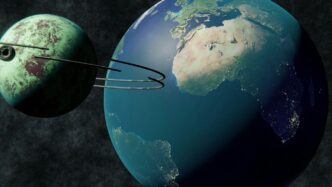

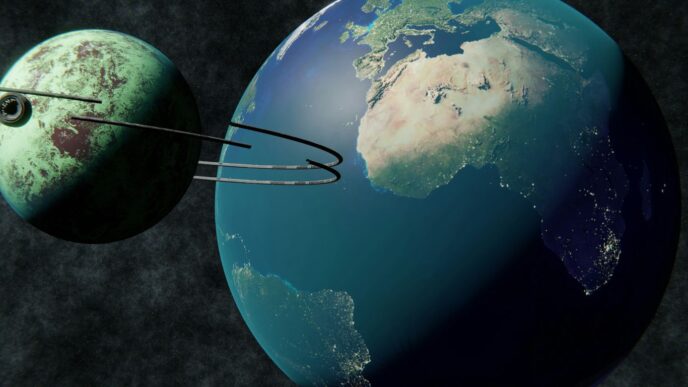

Orbiter 1: First US Lunar Orbiter

One of their early standout achievements was Orbiter 1. This was the first US spacecraft to successfully orbit the Moon, back in 1966. It sounds simple now, but getting something to orbit another celestial body was a massive deal back then. It paved the way for all the lunar missions that followed, giving us our first close-up looks at the Moon’s surface from orbit.

Supporting Human and Robotic Missions

Beyond just getting things into space, Boeing has been key in keeping the International Space Station (ISS) running. They still work with NASA and other countries to make sure the ISS is a top-notch place for science. This means supporting everything from the hardware that keeps the station together to the systems that help astronauts live and work there. It’s a continuous effort to make sure these complex missions can keep going and achieve their scientific goals.

Advancements in Satellite Technology

Innovations in Satellite Structures

When we talk about satellites, it’s not just about what they do, but also how they’re built. Boeing has been busy figuring out ways to make satellite structures tougher and lighter. Think about it, sending anything into space costs a fortune, so every pound saved really adds up. They’ve looked at different materials and designs to make sure these spacecraft can handle the rough ride of launch and the harsh conditions of space, all while being as efficient as possible. It’s a constant balancing act between strength and weight.

Additive Manufacturing for Lighter Satellites

This is where things get really interesting. Additive manufacturing, or 3D printing as most people know it, is changing the game for satellite parts. Instead of making parts the old way, by cutting them out of a bigger block of material (which wastes a lot), 3D printing builds them up layer by layer. This means they can create complex shapes that are super strong but use way less material. This approach allows for designs that were previously impossible, leading to significant weight reductions in satellite components. Imagine printing a bracket that’s perfectly shaped for its job, with internal structures that provide strength without adding bulk. It’s a big deal for making satellites more affordable and capable.

Enhancing Satellite Communication Systems

Satellites are basically communication hubs in the sky, right? Boeing has been working on making these communication links better. This involves everything from improving the antennas to developing smarter ways to manage the data flow. They’re looking at ways to make signals more secure and reliable, so information gets where it needs to go without getting lost or messed with. This is super important for everything from military operations to global internet access. They’re also exploring new ways to connect different types of satellites and ground systems, making the whole network work more smoothly.

Driving Innovation Through Research and Development

Boeing doesn’t just build planes and satellites; they’re constantly tinkering, dreaming up what’s next. It’s a big part of how they stay ahead. Think of it like this: you can’t just keep making the same old thing and expect to be the best, right? That’s where their research and development (R&D) teams come in. They’re the ones looking at new materials, figuring out smarter ways to build things, and generally pushing the boundaries of what’s possible in aerospace and defense. It’s a massive undertaking, with billions poured into R&D every year. This commitment to looking forward is what keeps Boeing at the forefront of the industry.

Boeing Research and Technology’s Role

At the heart of all this innovation is Boeing Research and Technology (BR&T). This isn’t just a side project; it’s a major engine for the whole company. BR&T tackles research that can benefit pretty much every part of Boeing, from the smallest satellite component to the biggest commercial jet. They’re the ones exploring far-out ideas that might not pay off for years, but could be game-changers down the line. It’s about anticipating what the company will need in the future, even if that future is still a ways off. They also work on making existing technologies better, finding new uses for things we already have.

Investing in Future Technologies

Keeping up with the latest tech is expensive, no doubt about it. Boeing tries to make this more manageable by teaming up with other companies and researchers. It’s a bit like sharing the cost of a really big project. They’ll co-invest in research, and then everyone involved gets to share the results. This way, nobody has to carry the whole burden alone. It’s a smart way to tackle big problems and explore new frontiers without breaking the bank. They’ve been looking into things like additive manufacturing, or 3D printing, for decades, even before it became a common buzzword. That kind of long-term vision is key.

Intellectual Property Protection Strategies

When you’re inventing new things, you want to make sure nobody else just takes your ideas. That’s where intellectual property (IP) protection comes in. Boeing has to be really careful about this. One big challenge is keeping their data safe from cyber threats – their operations are pretty connected, so protecting that information is a constant battle. Plus, the market is changing fast. There are more companies making similar products now than ever before. Boeing invests a ton in R&D to stay competitive, so they need to make sure their investments are protected and that others aren’t just copying their hard work. They have programs to recognize employees who come up with new inventions, which helps encourage that innovative spirit.

The Future of Aerospace and Defense

Looking ahead, Boeing is really focused on what’s next for flying and defense. It’s not just about building planes and satellites anymore; it’s about making them smarter, greener, and more capable. The company is putting a lot of energy into areas that will shape how we travel and how our nations stay secure for decades to come.

Sustainable Aviation Initiatives

Making flying better for the planet is a big deal. Boeing is working on ways to cut down on emissions and make planes more fuel-efficient. They’re looking at new designs and materials that can make a real difference. Think about planes that use less fuel or even new types of power sources down the line. It’s a complex puzzle, but they’re tackling it head-on.

- Developing advanced aerodynamic designs.

- Researching sustainable aviation fuels (SAFs).

- Exploring new propulsion systems.

Autonomous Systems and Future Mobility

Self-flying planes and drones are no longer just science fiction. Boeing is investing heavily in autonomous technology. This isn’t just for military applications; it’s also about making air travel safer and more accessible. Imagine air taxis or delivery drones operating smoothly and safely in our skies. The goal is to integrate these new systems responsibly, building public trust along the way.

Digital Transformation in Manufacturing

Behind the scenes, Boeing is also changing how it builds things. They’re bringing more digital tools and automation into their factories. This means using data to make better decisions, working with robots to help with tasks, and generally making the whole production process more efficient and precise. It’s all about building better products, faster and with higher quality, by using smart technology.

Global Collaboration and Talent

It’s pretty clear that nobody builds a rocket or a fancy new airplane all by themselves. Boeing knows this, and they’ve been working hard to connect with smart people and organizations all over the planet. It’s not just about getting things done; it’s about bringing different ideas to the table.

International Engineering and Technology Centers

Boeing has set up shop in various countries, not just to have a presence, but to tap into local talent and expertise. Think of it like having specialized workshops in different cities, each good at something unique. These centers help them understand different markets and get fresh perspectives on engineering challenges. It’s a way to spread the work out and also learn from how others approach problems. They’ve got folks in places like Europe and Asia working on everything from software to advanced materials. It’s a big network, and it seems to be working.

Attracting and Developing Global Talent

Finding good people is tough, no matter where you are. Boeing is really trying to bring in the best and brightest from everywhere. They’re not just looking for experienced engineers; they’re also bringing in recent grads and people with all sorts of backgrounds. It’s about building a team that reflects the world we live in. They offer training and chances to work on cool projects, hoping that keeps people around and helps them grow. The idea is that a diverse team brings more creative solutions to the table. They seem to be investing in programs to help their employees learn new skills, especially in areas like digital tech and sustainable practices.

Partnerships for Technological Advancement

Working with universities and other companies is a big part of Boeing’s strategy. They can’t possibly invent everything themselves, and honestly, why would they try? By teaming up, they can share the costs of research and development, which is super expensive. They partner with academic institutions and even smaller tech firms to get access to new ideas and technologies. It’s a give-and-take situation. For example, they might work with a university on a specific material science problem or collaborate with another company on a new communication system. This open approach helps them stay on the cutting edge without breaking the bank.

Looking Ahead

So, what’s next for Boeing Satellite Systems? It’s clear they aren’t slowing down. From their early days helping us reach the moon to today’s work on smarter factories and sustainable flight, they’ve consistently pushed the boundaries. With billions invested in research and development, and a focus on new tech like 3D printing and automation, Boeing is setting itself up for the future. They’re not just building planes and satellites; they’re building the next chapter of how we connect, travel, and explore space. It’s going to be interesting to see what they come up with next.