Microelectronics keep getting smaller, faster, and more important in our lives. With all this change, companies like GlobalFoundries are stepping up with new MEMS (Micro-Electro-Mechanical Systems) technology. In 2025, global foundries mems is changing how devices are made and used. From cars to smart gadgets, these tiny systems are everywhere, and GlobalFoundries is working to make them even better for the future.

Key Takeaways

- GlobalFoundries MEMS is helping to shrink devices and make them more energy efficient.

- Their technology is being used in cars, factories, and everyday electronics.

- Strategic partnerships are speeding up new ideas and products.

- The company is focusing on meeting worldwide demand, especially in North America, Asia, and Europe.

- MEMS from GlobalFoundries are playing a big role in AI, 5G, and smart connected devices.

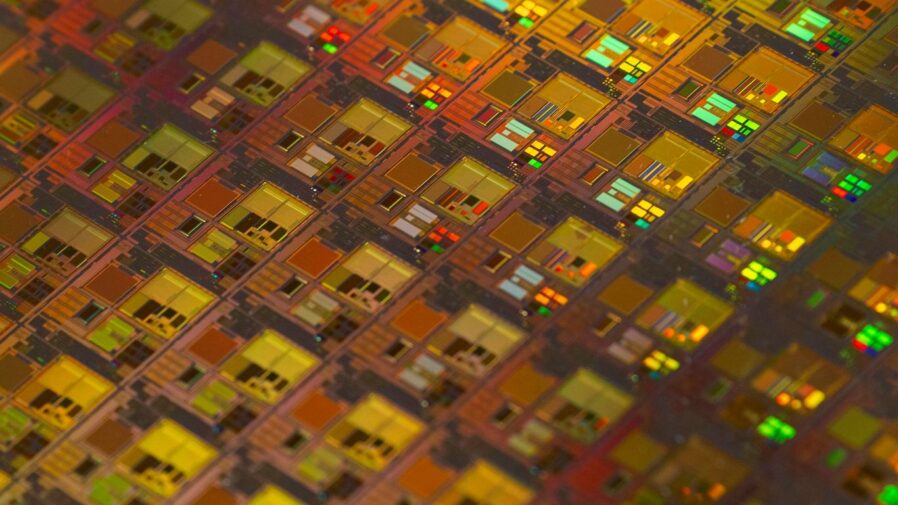

GlobalFoundries MEMS Technology: Pioneering Next-Generation Devices

Micro-Electro-Mechanical Systems (MEMS) are changing the way electronics are made and work. GlobalFoundries is playing a big role in this shift, thanks to its focus on advanced MEMS fabrication and bringing new ideas to the table. Their MEMS solutions are helping push forward the boundaries for smaller, smarter, and more energy-saving devices. Let’s look at what sets their MEMS work apart.

Advantages of MEMS in Microelectronics

MEMS tech, especially as used by GlobalFoundries, brings some real-world benefits:

- Smaller size: Chips and sensors take up less space, so devices can be tinier while doing more.

- Low power use: Many MEMS components use tiny amounts of energy, which is huge for anything battery-powered.

- Versatility: MEMS can combine mechanical and electrical parts right on the same chip, letting them handle things like motion, sound, and environmental sensing with less fuss.

- Cost efficiency: When mass-produced, MEMS can be much cheaper compared to traditional alternatives.

Key Breakthroughs in MEMS Fabrication Processes

Over the past year, GlobalFoundries has made some big improvements in how they make MEMS, helping them get better results and lower costs. Here are a few breakthroughs:

- Wafer-level packaging, allowing MEMS to be sealed and tested directly during manufacturing, cutting waste.

- Monolithic integration, which means MEMS and regular chips (CMOS) are made together, reducing assembly headaches.

- Improved process control, with cleaner production, tighter quality checks, and better yields—especially important as device sizes shrink.

| Process Step | GF MEMS Technique | Result |

|---|---|---|

| Wafer Bonding | Advanced low-temp bonding | Fewer defects, faster steps |

| Dry Etching for Structures | Precise deep silicon etches | Smoother, more complex MEMS |

| In-line Measurement | AI-powered inspection | Better consistency |

Strategic Partnerships Accelerating Innovation

GlobalFoundries doesn’t work alone. Its work with others in the MEMS world speeds up progress. Some ways these partnerships help include:

- Joint R&D with sensor designers and equipment makers makes sure new MEMS ideas can be built at scale.

- Shared knowledge means faster problem-solving, especially for packaging or integrating MEMS with new chip technologies.

- Early work with clients in cars, phones, and industrial devices brings new use cases and keeps the company a step ahead.

In summary, GlobalFoundries has made big moves with MEMS tech, with smarter processes, winning partnerships, and a focus on the real needs of the next wave of electronics. The future looks promising for this approach as devices keep shrinking and demanding more from less.

Industry Applications Fueled by GlobalFoundries MEMS Innovations

When you look around at today’s tech, it’s wild how many places you find MEMS (Micro-Electro-Mechanical Systems) chips doing the heavy lifting. Now, GlobalFoundries has really made a name for itself lately, pushing MEMS into new spots that used to be out of reach. Let’s break down some of the biggest changes happening because of their work.

Enhancing Performance in Automotive Electronics

Cars aren’t just about engines anymore. These days, MEMS sensors made by companies like GlobalFoundries are vital for stuff like parking sensors, automated emergency braking, and keeping your SUV from rolling when you’re on a sharp curve. The accuracy and ruggedness that MEMS bring have helped drive adoption in electric vehicles and the latest driver-assist features.

Here’s where MEMS makes a difference in cars:

- Real-time crash detection and airbag deployment

- Well-tuned positioning for autonomous driving

- Sensors that withstand huge swings in temperature and vibration

| MEMS Automotive Application | Benefit |

|---|---|

| Accelerometer (Crash) | Instant airbag deployment |

| Gyroscope (Stability) | Advanced driver assist |

| Pressure sensor (Tire) | Improved fuel efficiency |

Revolutionizing Industrial Automation and IoT

The industrial world is getting much smarter, and most of it is thanks to sensors that tell machines exactly what’s happening around them. MEMS can measure tilt, pressure, sound, and more, allowing factories to automate stuff that used to require a person watching over it. That’s changing how plants run their lines and how supply chains stay on track.

Here’s what’s clear about GlobalFoundries MEMS in industry:

- Enable predictive maintenance (machines can warn you before breaking down)

- Track products through harsh environments

- Link massive networks of small IoT sensors for real-time data

With better data coming in, manufacturers cut costs and spot issues a whole lot faster.

Empowering Consumer Electronics with Miniaturization

Consumer gadgets just keep shrinking, but somehow, manufacturers keep stuffing in more sensors and features. The MEMS work GlobalFoundries is doing helps fit barometers, microphones, and motion trackers into smaller housings—so your phone, earbuds, or smart watch can still do everything you want them to, without getting bulkier.

MEMS tech in home and personal devices:

- Motion detection for fitness tracking

- Tiny microphones for noise canceling

- Pressure sensors for smarter screens and controls

One key reason GlobalFoundries stands out is the speed at which they’re bringing improved MEMS products to the market, supporting device makers aiming for slimmer, more power-efficient gadgets. This kind of innovation was recently mentioned in a high-level overview of growth initiatives at Deutsche Bank’s 2025 Technology Conference, highlighting just how central these developments are to industry goals.

MEMS in microelectronics is helping a lot of industries get quicker, smarter, and more reliable. Everywhere from your dashboard to your desk lamp, GlobalFoundries is setting a new pace.

Addressing Market Demands with Energy-Efficient GlobalFoundries MEMS Solutions

Meeting the world’s ever-growing appetite for microelectronics requires not just more innovation, but smarter, greener solutions. GlobalFoundries is tackling this challenge with energy-efficient MEMS (Micro-Electro-Mechanical Systems) carefully engineered for today’s toughest market needs. These solutions play a critical role in shrinking carbon footprints and supporting the move toward sustainable electronics worldwide. With more devices connected and on-the-go than ever, energy efficiency isn’t just a nice-to-have—it’s a business imperative.

Power Optimization for Portable Devices

Portable devices are everywhere, and battery life is always a complaint. GlobalFoundries’ MEMS are designed with minimum power drain, which is crucial for wearables, IoT tags, and all-day gadgets. Here’s what sets their solutions apart:

- Ultra-low power operation means less charging and happier users.

- Smart sleep modes built into MEMS can dynamically reduce consumption.

- MEMS switches often replace bulkier relays, cutting both energy use and size.

A quick comparison of conventional vs. GlobalFoundries MEMS:

| Feature | Conventional MEMS | GlobalFoundries MEMS |

|---|---|---|

| Avg. Power Draw (µW) | 8 | 2 |

| Sleep Mode Support | Limited | Advanced |

| Package Size (mm²) | 2.5 | 1.2 |

MEMS Contribution to Sustainable Manufacturing

Sustainability starts with smarter factories. GlobalFoundries is pushing greener manufacturing with its MEMS production. Some steps they take:

- Recycle and treat process water within their fabs.

- Use energy from renewable sources wherever possible.

- Design MEMS that reduce the need for extra materials, meaning less waste.

- Opt for eco-friendly chemicals throughout the process.

These moves don’t just protect the environment—they help reduce costs and improve yields for customers.

Meeting Environmental Standards in Semiconductor Production

World governments set tight rules on emissions, waste, and electrical usage, so staying in line is a must. GlobalFoundries’ focus on energy-saving MEMS is helping them meet—and sometimes beat—these standards. Take a look at how they match up:

- EU’s RoHS: All MEMS packages are compliant, minimizing hazardous metals.

- Greenhouse Gas Goals: Achieving lower emissions by designing energy-friendly fabs.

- Minimizing electronic waste with longer-lasting MEMS tech.

The result? As the global semiconductor foundry market keeps expanding (projected industry expansion), GlobalFoundries stays ahead by matching innovation with responsibility.

Shaping the Competitive Landscape through Specialized MEMS Offerings

GlobalFoundries competes with top industry names like TSMC, Samsung, and UMC, all driving hard in the semiconductor race. What sets GlobalFoundries apart is their focus on unique MEMS processes that others haven’t fully explored yet. Rather than just chasing small node sizes, they’ve built a reputation for:

- Custom MEMS designs for niche markets

- Flexible manufacturing to handle both low and high-volume runs

- Working closely with end-users to tweak products to their exact needs

According to recent market data, the foundry sector itself is poised for significant growth, making these specialized solutions more important as competition stiffens.

| Company | Market Focus | Strengths |

|---|---|---|

| TSMC | Advanced nodes | Scale, R&D |

| Samsung | Memory, logic | Technology, breadth |

| GlobalFoundries | MEMS, RF, specialty | Flexibility, specialized MEMS |

| UMC | Mid-range nodes | Collaboration, customer service |

Collaborative Ecosystems and Customer-Centric Approaches

Teaming up with fabless companies and smaller tech developers keeps GlobalFoundries’ MEMS work fresh and responsive. They invest time into

- Joint development projects with chip designers

- Regular feedback loops with end-users

- Fast adaptation to changing product specs

Collaborative relationships have let GlobalFoundries update fabrication processes without long downtimes, giving them an edge over less agile foundries. Customer input doesn’t just inform improvement; it defines what gets produced.

Expanding the Reach in Niche Markets

MEMS isn’t just about size — it’s about matching technology to actual use-cases that mainstream electronics might miss. Here’s where GlobalFoundries leans in:

- Biomedical sensors

- RF components for IoT devices

- Precision automotive electronics

By zeroing in on these less crowded sectors, GlobalFoundries gets away from "me-too" products and avoids direct fights over commodity chips. Their customized approach sways customers that value tailored technology rather than sheer volume or scale.

In summary, while the market’s giants pursue broader, high-capacity trends, GlobalFoundries grabs market share by focusing its MEMS technology on specific needs and tight customer feedback — an approach that’s shaping the modern competitive landscape.

Regional Impact: Expanding GlobalFoundries MEMS Operations Worldwide

GlobalFoundries is not just a local player—it’s a company with a worldwide footprint in MEMS manufacturing and innovation. As the market for MEMS keeps growing and evolving, GlobalFoundries’ regional strategies matter more than ever. Their push into different global markets helps them reach new customers and stay resilient even as market demand shifts. Let’s break it down by region.

Growth in the North American Semiconductor Market

North America has seen a boost in local semiconductor manufacturing thanks to new policies and investments. MEMS manufacturing here benefits from:

- Collaboration with high-tech companies in Silicon Valley and other hubs.

- Incentives from federal and state governments for domestic production.

- A focus on R&D that helps speed up MEMS process upgrades.

Here’s a rough breakdown of where the biggest investments are landing in the US and Canada:

| Area | Key Focus | Notable Impact |

|---|---|---|

| US Southwest | New fab construction | Job creation, new tech |

| New York | Research partnerships | University collaborations |

| Canada | Proximity to auto sector | Growth in sensors, MEMS |

Strengthening Presence in Asia Pacific Regions

Asia Pacific remains ground zero for electronics manufacturing. GlobalFoundries’ expansion in this region hinges on:

- Setting up fabs close to major electronics makers in Taiwan and China.

- Adapting to fast-moving consumer tech cycles.

- Tapping into local engineering talent for advanced MEMS designs.

Some unique characteristics of this region include high-volume output and quick turnaround for new MEMS applications, especially for phones, wearables, and industrial systems.

Supporting European Automotive and Industrial Sectors

The auto and industry space in Europe is tight-knit and demands a lot from MEMS suppliers. GlobalFoundries works here by:

- Building MEMS fab capacity near German and French automotive centers.

- Working with EU research groups focused on green tech and energy efficiency.

- Customizing MEMS solutions to meet strict European standards.

Europe also values sustainability, so energy-efficient MEMS solutions are a big draw. Here are some current focus areas in the region:

- Automotive safety sensors and smart control units.

- Industrial automation components that need high reliability.

- MEMS used for monitoring and efficiency in renewable energy systems.

In summary, GlobalFoundries strengthens its place as a leader by tuning its approach to the unique demands of each region. Their global presence lets them ride out market shifts and stay connected to the tech trends shaping MEMS worldwide.

Driving the Evolution of Technology Nodes with MEMS Integration

As the limits of chip technology are pushed further each year, GlobalFoundries is finding clever ways to bring MEMS (Micro-Electro-Mechanical Systems) onto the same platforms as cutting-edge semiconductor technology nodes. This isn’t just about making things smaller. Integrating MEMS with technology nodes like 10nm, 7nm, 5nm, and even going toward 3nm is changing the rules for what tiny chips can do in real life.

Leveraging Advanced 10nm to 3nm Nodes for MEMS

The step from 10nm down to 3nm nodes puts GlobalFoundries and its clients in a spot to create denser and faster chips, but also more capable MEMS sensors and actuators. Here’s why that matters:

- MEMS devices fabricated on these advanced nodes are tinier and run cooler than ever before.

- They process data at higher speeds, opening new possibilities for sensors that react in real time to their environment.

- Precision is better; moving to smaller nodes means tight manufacturing tolerances, the kind needed for sensitive sensors and actuators.

Let’s look at how MEMS integration stacks up across nodes:

| Technology Node | Typical MEMS Benefit | Key Applications |

|---|---|---|

| 10nm | Power efficiency, moderate cost | Smartphones, wearables |

| 7nm | Higher density, improved sensitivity | Automotive, IoT devices |

| 5nm | Faster response, lower heat | Edge AI, industrial data |

| 3nm | Peak performance, ultra-compact size | Healthcare, mobile AI |

MEMS Role in High-Performance, Compact Chips

Getting MEMS onto the latest chips creates products that are faster, smaller, and smarter. A few real-world impacts show up:

- MEMS filters and switches make wireless chips smaller and better at grabbing weak signals in noisy places.

- On-chip MEMS timing devices give more reliable clocks to computers and smartphones, meaning less drift and better sync for our gadgets.

- MEMS microphones are built right into powerful SoCs, making voice recognition smarter without adding bulk.

For engineers, this is a game changer because it creates space for new features without bumping up power costs or the size of the product.

Impact of Technology Node Miniaturization on MEMS Applications

Shrinking node sizes isn’t just one of those industry buzzwords. It means real improvements for consumers and manufacturers alike:

- Product battery life goes up, since smaller nodes cut energy use.

- MEMS sensors work better and in more places—think health monitors or smartwatches that need to be both tough and tiny.

- New classes of gadgets become possible. Chips with embedded MEMS on advanced nodes let companies invent products we haven’t seen yet.

For GlobalFoundries, this race to ever-smaller nodes combined with MEMS know-how is bringing out chips that, not long ago, belonged in science fiction.

Enabling the Future: GlobalFoundries MEMS in AI and Smart Connectivity

Supporting Artificial Intelligence Hardware Platforms

GlobalFoundries is pushing MEMS (Micro-Electro-Mechanical Systems) technology to new heights, especially for AI hardware. MEMS sensors and actuators help AI chips collect and process real-world data faster and with less energy.

Here’s how GlobalFoundries’ MEMS is making an impact:

- Integrating diverse MEMS sensors directly onto AI chips to improve data collection.

- Reducing lag in AI-driven applications by using on-chip MEMS filters and oscillators.

- Lowering the overall energy needs for machine learning tasks by blending analog and digital MEMS components.

In a fast-moving field like AI, the foundry’s readiness to provide specialized chips is a big deal. As highlighted by their CTO, even legacy tech and specialty processes like power GaN or MRAM still have an important role in practical innovation.

MEMS for Seamless 5G and IoT Communications

The spread of 5G and billions of IoT devices means reliable, miniaturized, and efficient MEMS are more vital than ever. GlobalFoundries’ efforts here are shaping how devices connect, share data, and function across multiple networks.

- MEMS switches reduce network latency in 5G modems and base stations.

- RF MEMS filters cut out noise, delivering clearer signals on crowded bands.

- MEMS timing solutions provide accurate clocking for synchronized communication.

A simple breakdown of where MEMS helps most:

| Application Area | MEMS Role | Benefit |

|---|---|---|

| 5G Base stations | RF Filters | Cleaner, reliable signal |

| IoT sensors | Mini MEMS sensors | Small, low-power nodes |

| Wearables | MEMS Oscillators | Stable, precise timing |

By focusing on these technologies, GlobalFoundries is meeting both carrier and consumer needs in a rapidly expanding IoT universe.

Enhancing Security and Data Reliability Through MEMS

Security and data integrity can’t be ignored—especially for AI and connected devices that process sensitive data or run critical systems. MEMS technology brings a layer of hardware-based security that complements existing software solutions. Some direct outcomes include:

- Hardware random number generators using MEMS for secure encryption keys.

- Tamper-detection systems built with MEMS micro-switches to detect physical breaches.

- MEMS-based environmental sensors for real-time threat detection (like temperature or vibration anomalies).

These features add a layer of trust, reliability, and peace of mind for manufacturers and end users. As industries rethink how hardware and software interact, companies like GlobalFoundries are making their mark by shaping what’s essential in connected tech.

Wrapping Up: GlobalFoundries and the Road Ahead

Looking at where things are headed, it’s clear that GlobalFoundries is playing a big part in how microelectronics will look in 2025 and beyond. Their focus on MEMS and other specialized chip technologies is helping all sorts of industries, from cars to smart gadgets, keep up with what people want. The foundry market is growing fast, and companies like GF are making sure that new ideas actually make it into real products. With more devices needing to be smaller, faster, and use less power, the work GlobalFoundries is doing matters more than ever. As the world keeps moving toward smarter tech, it’s going to be interesting to see how GF and its partners keep pushing the limits of what’s possible in microelectronics.

Frequently Asked Questions

What are MEMS and why are they important in microelectronics?

MEMS stands for Micro-Electro-Mechanical Systems. These are tiny devices, often smaller than a grain of sand, that combine electrical and mechanical parts. They help make electronic gadgets smaller, faster, and more energy-efficient, which is important for things like smartphones, cars, and smart home devices.

How is GlobalFoundries making MEMS better for the future?

GlobalFoundries is working on new ways to make MEMS devices even smaller and more powerful. They use advanced tools and work with other tech companies to create MEMS that use less energy and fit into more types of electronics.

Where are GlobalFoundries MEMS used the most?

GlobalFoundries MEMS are found in many places, like cars, factories, and everyday gadgets. In cars, they help with safety and control systems. In factories, they make machines smarter and more connected. In consumer electronics, they help make devices lighter and more portable.

How do MEMS from GlobalFoundries help save energy?

MEMS made by GlobalFoundries are designed to use less power. This means that devices like smartphones and wearables can last longer on a single charge. It also helps factories and other industries use less electricity, which is better for the environment.

How does GlobalFoundries compete with bigger companies like TSMC and Samsung?

GlobalFoundries focuses on special types of chips and MEMS that meet the needs of certain industries, like cars and industrial machines. They also work closely with their customers to make sure they get exactly what they need, which helps them stand out from bigger competitors.

Is GlobalFoundries expanding its MEMS business around the world?

Yes, GlobalFoundries is growing its MEMS operations in places like North America, Asia, and Europe. They are building new factories and working with local companies to support industries like automotive, industrial automation, and consumer electronics in different regions.