Infineon is really making waves in the semiconductor world, and it’s not hard to see why. They’re working on some pretty advanced stuff that’s going to power a lot of the tech we use, and will use, in the future. Think faster computers, greener energy, and even robots that can do more. It seems like Infineon is focused on making things more efficient and powerful, which is a big deal for a lot of industries right now.

Key Takeaways

- Infineon is a leader in semiconductor materials like silicon, SiC, and GaN, using an integrated manufacturing approach to speed up innovation.

- Their new wafer technologies, like ultra-thin silicon and 300-mm GaN, are designed to make AI data centers and power systems more efficient.

- Infineon is building the world’s largest SiC fab in Malaysia and innovating with 300-mm GaN wafers to increase production capacity.

- The company’s semiconductors are enabling advancements in emerging tech, including humanoid robots and quantum computing, while also addressing cybersecurity risks.

- Infineon plays a significant role in driving decarbonization and digitalization through solutions for renewable energy, electric vehicles, and energy-efficient industrial applications.

Infineon’s Leadership in Semiconductor Materials

Infineon is really making waves in the semiconductor world, and a big part of that is how they’re handling different materials. It’s not just about one thing anymore; they’re mastering silicon (Si), silicon carbide (SiC), and gallium nitride (GaN). This approach, which they call Integrated Device Manufacturing (IDM), lets them build better power electronics for all sorts of new tech. Think about powering up AI data centers or even those futuristic humanoid robots – Infineon’s materials are key.

Mastering Silicon, SiC, and GaN Technologies

It’s pretty impressive how Infineon has gotten so good with these three main semiconductor materials. They’ve put a lot of work into research and development, understanding what makes each one special. This has led to some cool innovations, like making the world’s thinnest silicon power wafer, just 20 micrometers thick, on a 300-millimeter base. They also have a huge range of silicon power products, like their CoolMOS™ technology, which offers a great balance of price and performance. This deep knowledge across different materials is what sets them apart.

The Advantages of Wide-Bandgap Semiconductors

When we talk about SiC and GaN, we’re talking about wide-bandgap semiconductors. These materials can handle higher voltages and temperatures than traditional silicon, and they switch on and off much faster. This means devices can be smaller, more efficient, and generate less heat. For applications like electric vehicles or high-power charging systems, this is a game-changer. It allows for more power in a smaller package, which is exactly what we need for many modern technologies. You can see some of the benefits of these materials on Infineon’s technology page.

Infineon’s Integrated Device Manufacturing Strategy

Infineon’s IDM strategy is pretty smart. Instead of just designing chips, they also manufacture them. This gives them a lot of control over the whole process, from the raw materials to the final product. It means they can really push the boundaries of what’s possible with materials like SiC and GaN. They’re even working on making GaN chips on 300-millimeter wafers, which will allow for much higher production volumes. This integrated approach helps them bring new technologies to market faster and ensures they can meet the growing demand for high-performance semiconductors. It’s a big reason why they’re seen as a leader in the industry, with a strong leadership team guiding the way.

Powering the AI Revolution with Infineon

The world’s appetite for artificial intelligence is growing like crazy, and that means data centers are working overtime. We’re talking about a massive increase in electricity use, with some estimates saying AI could gobble up a significant chunk of global power by 2030. Training just one AI model can use as much energy as hundreds of homes do in a year! This surge is driven by powerful processors like GPUs and TPUs, which need a lot of juice – sometimes up to 2,000 watts each. It’s clear that how we manage power for these systems needs a serious upgrade.

Ultra-Thin Wafer Technology for AI Data Centers

Infineon is tackling this power challenge head-on with some really smart tech, especially their ultra-thin wafer technology. Think about it: getting power from the grid down to the tiny voltages needed by AI chips is tricky. Infineon’s approach, using a vertical power delivery design with their special MOSFET technology, helps cut down on wasted energy and makes the whole system more reliable. This is a big deal for AI companies looking to grow without burning through tons of electricity. They’re also making waves with their mastery of silicon, silicon carbide (SiC), and gallium nitride (GaN) materials, all processed on these super-thin wafers. This lets them create next-gen power conversion solutions that are key for everything from renewable energy to electric cars and industrial gear.

Revolutionizing Power Delivery for AI Applications

Beyond just the chips themselves, Infineon is working with big players like Nvidia to rethink how AI data centers get their power. They’re looking at 800-volt direct current (VDC) architectures that could let server racks handle massive power levels, like 1 megawatt and beyond. This means more computing power for less energy, which is a win-win for data center operators and the environment. It’s all about making power conversion super efficient, from the moment it comes from the grid all the way to the core processors. This focus on energy efficiency isn’t just for data centers; it’s also driving demand in consumer electronics and industrial systems.

Infineon’s Role in Physical AI Systems

Infineon’s influence extends beyond just the digital brain of AI. They’re also a major player in bringing

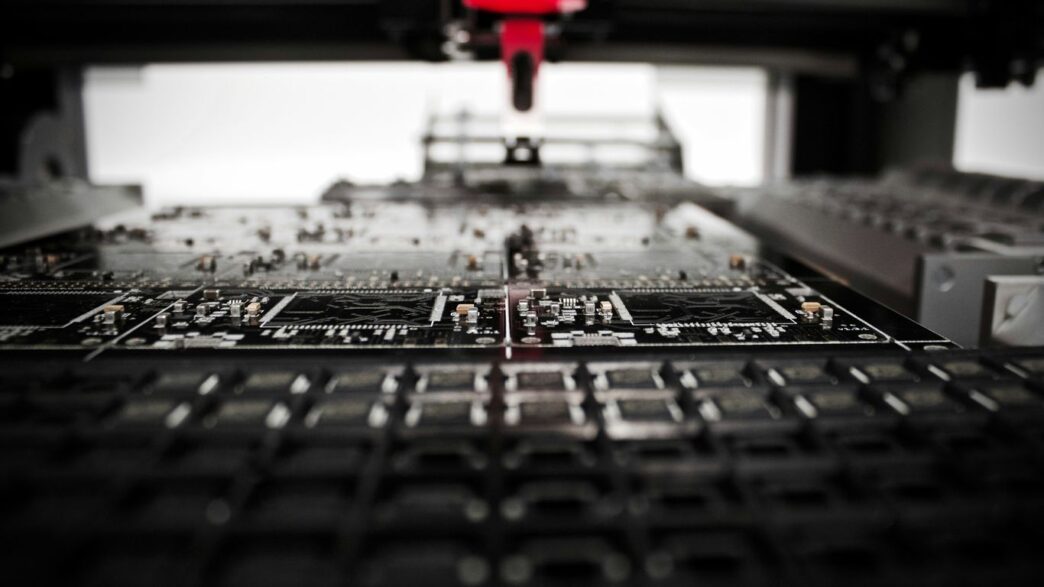

Advancements in Power Semiconductor Manufacturing

Infineon isn’t just keeping up with the semiconductor world; they’re actively shaping it. Their manufacturing innovations are pretty impressive, especially when you look at how they’re handling different materials and wafer sizes. It’s not just about making chips; it’s about making them better, more efficient, and ready for whatever comes next.

World’s Largest SiC Fab in Malaysia

Infineon recently opened what’s being called the world’s largest factory for silicon carbide (SiC) power chips in Malaysia. This is a big deal because SiC is a material that’s really good for handling high power and high temperatures, making it perfect for things like electric cars and renewable energy systems. Having the biggest factory means they can make a lot more of these important chips, which helps meet the growing demand. It’s all about scaling up production to support the shift towards greener technologies.

300-mm GaN Power Wafer Innovation

Gallium Nitride (GaN) is another hot material in power semiconductors, and Infineon is pushing the envelope here too. They’re working on making GaN power wafers that are 300 millimeters in size. Why does that matter? Well, bigger wafers mean you can fit more chips on each one, which usually leads to lower costs and higher production volumes. This is key for making GaN technology more accessible for a wider range of applications, from consumer electronics to industrial gear.

Scalable GaN Manufacturing on 300-Millimeter Wafers

Building on the 300-mm GaN wafer development, Infineon is focused on making this manufacturing process scalable. This means they’re not just making a few advanced wafers; they’re figuring out how to produce them consistently and in large quantities. The goal is to deliver high-quality GaN products faster and more reliably. This scalability is what will really drive the adoption of GaN, allowing for smaller, more powerful, and more efficient electronic devices. Think about it: more power in a smaller package, and at a better price point. That’s the kind of progress that makes a difference.

Infineon’s Impact on Emerging Technologies

Infineon is really making waves in some pretty wild, futuristic tech. It’s not just about making chips anymore; it’s about enabling entirely new possibilities. Think about humanoid robots or the mind-bending world of quantum computing – Infineon’s semiconductor know-how is a big part of making that happen.

Enabling Humanoid Robots with Advanced Semiconductors

Building robots that can actually interact with the world like we do is a huge challenge. Infineon is stepping up to the plate here. They’ve got a solid mix of silicon (Si), silicon carbide (SiC), and gallium nitride (GaN) based solutions. This means they can provide the brains and the brawn for these advanced machines. We’re talking sensors, connectivity, and safety features all rolled into one. It’s pretty cool to think that the chips powering these robots are coming from a company that’s been around for a while, but is now pushing into such new territory. They’re aiming to be the go-to semiconductor partner for robotics, and honestly, it seems like they’re on the right track. The market for these robots is predicted to be massive, and Infineon wants a big piece of that pie.

The Future of Quantum Computing

Quantum computing sounds like science fiction, but it’s becoming a reality, and Infineon is involved. While they aren’t building the quantum computers themselves, their advanced semiconductors are key to improving their performance. This is a complex area, and it requires specialized components that can handle the unique demands of quantum systems. Infineon’s work in this space is about pushing the boundaries of what’s possible with these next-generation machines. It’s a long game, for sure, but their innovation is a key differentiator in this competitive market.

Securing Quantum Computing with Post-Quantum Cryptography

Now, here’s where things get really interesting. Quantum computers, while amazing, also pose a big threat to our current digital security. They could potentially break the encryption we rely on today. That’s where post-quantum cryptography comes in, and Infineon is right in the middle of it. They’re a major player in security controllers, and they’re working on making sure that even when quantum computers arrive, our data stays safe. They’ve even got the first common criteria certification on a security controller for this purpose. It’s a dual role: helping quantum computing advance while simultaneously building the defenses against its potential risks. This kind of forward-thinking is what sets them apart.

Driving Decarbonization and Digitalization

Infineon isn’t just making chips; they’re building the foundation for a greener, more connected world. Think about it: every step towards reducing our carbon footprint and making our systems smarter relies on advanced power semiconductors. It’s a big job, and Infineon is right in the thick of it.

Infineon’s Role in Renewable Energy Solutions

Renewable energy sources like wind and solar are fantastic, but they need reliable ways to manage power. That’s where Infineon’s silicon carbide (SiC) technology comes in. Their CoolSiC™ products are built tough, handling high voltages (from 400V up to 3.3kV) and working well even in tough environments. This means more stable power from solar panels and wind turbines, getting clean energy to us more reliably. They’re even making their 200mm SiC wafers in Malaysia, aiming to be the most cost-effective producer out there. This focus on efficiency helps make renewable energy more practical and affordable.

Powering Electric Vehicles with Advanced Semiconductors

Electric vehicles (EVs) are a huge part of decarbonization, and they’re basically computers on wheels that need a lot of power management. Infineon’s chips are key here. They help convert the battery’s power efficiently to drive the motor and manage all the other electrical systems. Their work with SiC and Gallium Nitride (GaN) allows for smaller, lighter, and more efficient power components. This translates to EVs that can go further on a single charge and charge faster. It’s not just about the car itself, either; it’s about the charging infrastructure too, which also needs robust power electronics.

Energy-Efficient Technologies for Industrial Applications

Beyond renewables and EVs, industries are also looking to cut down on energy use. Infineon’s power semiconductors are used in everything from factory automation to motor control systems. By making these systems more efficient, they reduce wasted energy. Their ultra-thin wafer technology, for example, can cut power loss by over 15%. This might not sound like much in a single device, but when you multiply it across thousands of machines in a factory or millions of devices worldwide, the energy savings add up significantly. It’s about making digital systems work smarter and use less power, which is a win-win for businesses and the planet.

Strategic Partnerships and Market Opportunities

Infineon isn’t just building amazing chips in isolation; they’re actively teaming up with other big players to make sure their tech gets where it needs to go. It’s like they know that to really power the future, especially with AI, you need to work together.

Collaboration with Nvidia for AI Data Centers

Think about AI data centers. They gobble up a ton of power, right? Infineon is working with Nvidia on this really cool 800 Volt direct current (VDC) architecture. The goal is to let server racks handle massive amounts of power, like 1 Megawatt or even more. This isn’t just about more power; it’s about doing it more efficiently. This kind of partnership is key to making AI more sustainable and scalable. By getting the power right from the grid all the way to the core processors, they’re aiming for data centers that can compute more while using less energy. It’s a smart move that positions Infineon right at the heart of the AI revolution.

Building a Partner Ecosystem for Innovation

Beyond just one big partnership, Infineon is focused on building a whole network of collaborators. They understand that creating the next generation of power solutions requires input from many different areas. This ecosystem approach helps them stay on top of what’s needed for things like:

- Powering AI data centers efficiently.

- Bringing advanced robotics to life with smart semiconductors.

- Developing the complex systems needed for quantum computing.

They’re not just selling components; they’re helping to build the whole system by working with others. This includes providing a wide range of chips – silicon, SiC, and GaN – along with sensors and security features, which is pretty much everything needed for cutting-edge tech like humanoid robots.

Market Implications of Infineon’s Breakthroughs

So, what does all this mean for the market? Well, Infineon’s focus on things like ultra-thin wafers and advanced materials like SiC and GaN is opening up some serious business opportunities. They’re predicting their AI-related business could hit over a billion euros in the next couple of years. That’s a big deal. Plus, their work on energy efficiency isn’t just good for AI; it’s also a big win for electric vehicles, renewable energy, and industrial applications. Basically, as the world pushes for more digital solutions and less carbon emissions, Infineon’s technology is becoming more and more important. Their recent moves, like opening that huge SiC factory in Malaysia and pushing forward with 300-mm GaN wafers, show they’re serious about meeting this growing demand and staying ahead of the game.

Infineon: Leading the Charge in Semiconductor Innovation

So, what’s the big picture here? Infineon isn’t just making chips; they’re really shaping how we use power in everything from AI servers to robots. Their work with different materials like silicon, SiC, and GaN, plus their super-thin wafer tech, means more efficient gadgets and less wasted energy. It’s pretty clear they’re aiming to stay ahead of the game, especially with big trends like going green and making everything digital. They’re definitely a company to watch as technology keeps moving forward.

Frequently Asked Questions

What makes Infineon a leader in computer chips?

Infineon is a top company in making computer chips because they are really good at using different materials like silicon, silicon carbide, and gallium nitride. They make their own chips from start to finish, which helps them create special solutions for things like electric cars and super-fast computers.

How is Infineon helping with Artificial Intelligence (AI)?

Infineon is making special, super-thin computer chips that help AI computers use less energy. They are also creating chips that allow AI systems to power things like robots, making them smarter and more efficient.

What is special about Infineon’s new factories?

Infineon has built the biggest factory in the world for silicon carbide chips in Malaysia. They are also making new, larger gallium nitride chips on 300-millimeter wafers, which means they can make more chips faster and better.

How does Infineon help with green energy and electric cars?

Infineon’s chips are important for making renewable energy sources like solar and wind power work better. They also make the advanced chips needed for electric vehicles to go further and charge faster, helping to reduce pollution.

What is ‘wide-bandgap’ technology?

Wide-bandgap materials, like silicon carbide and gallium nitride, are special types of materials used in chips. They allow chips to handle more power and work much faster and more efficiently than regular silicon chips, especially in tough conditions.

What is Infineon doing for future technologies like quantum computing?

Infineon is working on making quantum computers a reality by providing key parts and technology. They are also developing ways to keep information safe from quantum computers using special security chips, which is called post-quantum cryptography.