Advancements in Applied Materials Semiconductor Manufacturing Equipment

The world of making computer chips is always changing, and Applied Materials is right there at the front, coming up with new ways to make things better. They’re not just building machines; they’re figuring out how to make the whole process smarter, faster, and more efficient. It’s pretty wild how much goes into making these tiny components that power everything from our phones to big data centers.

Leveraging Artificial Intelligence for Enhanced Production

Artificial Intelligence, or AI, is a big deal in chip making now. It’s not just about the chips themselves being used in AI stuff; it’s about using AI to actually make the chips. Think of it like having a super-smart assistant watching over the whole factory floor. AI can spot tiny problems before they become big issues, helping to keep production running smoothly. This means fewer wasted materials and a more consistent product. It’s all about making the complex process of chip fabrication more predictable and reliable.

Internet of Things for Real-Time Process Monitoring

Then there’s the Internet of Things, or IoT. You know, those connected devices? Well, they’re showing up in chip factories too. Sensors are placed all over the equipment and production lines. These sensors collect data constantly – like temperature, pressure, and how fast things are moving. This information is sent out in real-time, so engineers can see exactly what’s happening at any moment. It’s like having a live dashboard for the entire factory. This constant stream of data helps in making quick adjustments and finding ways to improve things step-by-step.

Here’s a look at what IoT helps monitor:

- Equipment Health: Keeping an eye on machine performance to predict when maintenance might be needed.

- Process Parameters: Tracking things like temperature and gas flow to make sure they stay within the right limits.

- Environmental Conditions: Monitoring the cleanroom atmosphere, which is super important for chip quality.

Simulated Fabrication for Accelerated Development

Creating new ways to make chips, or ‘recipes’ as they call them, can take a really long time and cost a lot of money. You have to actually make wafers, test them, and then try again. It’s a slow process. Applied Materials is using simulation, which is basically creating a virtual version of the factory. They can test out new ideas and processes in this digital world without using any real materials or interrupting actual production. This lets them generate a ton of data very quickly, which helps them understand how things will work and find potential problems much faster than before. It’s a way to speed up innovation without the usual delays and costs.

Innovative Materials and Technologies in Semiconductor Fabrication

Exploring Gallium Nitride and Silicon Carbide

Making smaller and faster chips isn’t just about shrinking existing designs. Sometimes, you need entirely new building blocks. That’s where materials like Gallium Nitride (GaN) and Silicon Carbide (SiC) come into play. These aren’t your everyday silicon; they bring some pretty impressive qualities to the table. Think higher operating temperatures, better resistance to high voltages, and the ability to switch signals much faster. This opens doors for chips that can handle more power in a smaller package, which is a big deal for everything from electric vehicles to advanced power electronics. It’s like upgrading from a basic toolkit to a professional set – you can do so much more.

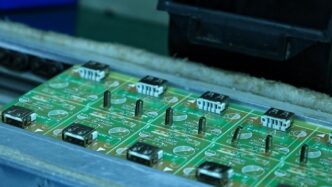

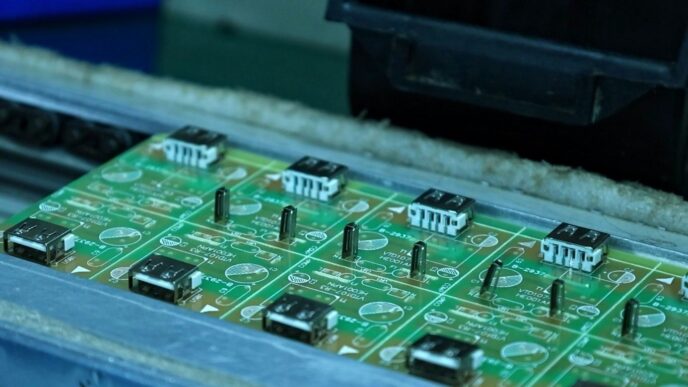

Robotic Wafer Handling and Precision Placement

As chips get smaller, the tiny details matter more. Placing patterns and wiring needs to be incredibly accurate. This is where robots have become super important. We’re talking about machines that can pick up and move wafers with amazing precision. They don’t get tired, they don’t have shaky hands, and they can repeat the same exact movement thousands of times. This level of control is what allows manufacturers to create those incredibly dense and complex circuits we rely on today. It’s a bit like a surgeon performing a delicate operation, but on a microscopic scale.

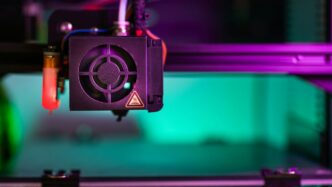

Additive Manufacturing Techniques

Additive manufacturing, often called 3D printing, is also finding its way into chip making. Instead of carving away material, you’re building it up layer by layer. This approach can be really useful for creating complex structures or specialized components that would be difficult or impossible to make with traditional methods. It offers a new way to design and build parts of the semiconductor manufacturing process, potentially leading to more efficient designs and faster production cycles for certain applications. It’s a bit like building with LEGOs instead of sculpting from a block of clay.

Applied Materials’ Commitment to Research and Development

Applied Materials has been around for a while, almost 60 years, and they’ve really been shaping how we make computer chips. The stuff they engineer ends up in everything from your phone to electric cars. They’ve got a ton of patents, over 22,000, and even one of their old chip-making machines is in a museum. But it’s not just about the past; they’re really pushing forward.

Collaborations with Academic Institutions

One big way they’re doing this is by working with universities. They’ve put a lot of effort into initiatives with the Ira A. Fulton Schools of Engineering at Arizona State University (ASU). This partnership is all about speeding up new discoveries and helping researchers tackle real-world problems. They’ve given grants to ASU professors for projects that mix Applied Materials’ tech with new research ideas. Think about Professor Seth Ariel Tongay looking into super-thin 2D materials that could make chips faster and use less power, or Assistant Professor Houqiang Fu studying gallium nitride, which is great for things like electric car chargers because it handles heat and voltage better than regular silicon. They’re also building a big shared facility at ASU Research Park, costing $270 million, where students and researchers can get hands-on experience.

Investing in Future Workforce Development

It’s not just about the research itself; Applied Materials is also focused on the people who will do this work in the future. They’ve started an endowed scholarship that supports six engineering students every year. They even held an event called Applied Materials Innovation Day where students could hear directly from company researchers and leaders. It’s a chance for students to learn about what the company is working on and what they look for in new hires. They want students who are curious and ask good questions. It sounds like a pretty smart way to get talented people interested in the semiconductor field, which they see as a key part of future economies.

Driving Long-Term Industry Innovations

Applied Materials isn’t just looking for the next quick win. They’re aiming for those big, game-changing ideas that might be five or ten years down the road. They call it looking for the "moonshot." By partnering with universities, they’re tapping into a wider pool of bright minds and fresh perspectives. This kind of forward-thinking approach is what keeps the whole semiconductor industry moving forward, creating the technology that impacts our lives every day.

The Role of Simulation in Modern Semiconductor Manufacturing

Generating Synthetic Data for AI Training

Think about trying to teach a computer to do something really complex, like spotting tiny flaws on a silicon wafer. You need tons of examples, right? But getting that much real-world data from a factory floor can take ages and cost a fortune. That’s where simulation comes in. Instead of waiting weeks or months to collect enough actual data, we can use simulation to create "synthetic" data. It’s like having a virtual factory that can churn out as many examples as we need, in just a few days. This means we can train AI models much faster and more thoroughly, without messing with actual production.

Accelerating Project Timelines and Reducing Costs

Building new manufacturing processes or tweaking existing ones is usually a slow and expensive dance. You have to physically make changes, run tests, and analyze results. Simulation lets us skip a lot of that. We can model the entire process flow virtually. This allows us to quickly see where the bottlenecks are, how long things will take, and what the output might look like. We can even predict potential problems before they happen. This virtual testing ground helps us speed up development and avoid costly mistakes that would happen if we tried everything on the real factory floor. It’s a way to get answers and make improvements without the real-world price tag or production downtime.

Evaluating Changes in Simulated Environments

So, you’ve got a new idea for improving your factory’s scheduling or maybe a new way to handle the wafers. Before you roll it out to the whole operation, wouldn’t it be smart to see how it plays out? Simulation gives us that chance. We can set up a virtual version of the factory and test out these changes. This is super helpful for things like Reinforcement Learning, where an AI agent learns by trying things out. In a simulation, the agent can learn in a safe, virtual space. We can also use it to compare different AI models or scheduling rules against each other. It lets us see the differences in key performance indicators and figure out what works best, all without risking actual production.

Addressing Data Challenges with Advanced Solutions

Look, getting enough good data for AI in chip making is a real headache. It takes a ton of time and money, and sometimes, especially for smaller companies, it’s just not possible. Even if you have the cash, the data you have might be old news because the whole manufacturing setup is always changing. Think about it: new tools get added, processes get tweaked, and supply chains shift. These constant changes mean there’s barely enough time for a solid, diverse history of data to build up for training AI models. This is where simulation steps in as a game-changer.

Overcoming Resource Limitations for AI Deployment

Instead of waiting months to collect enough real-world data, simulation lets us create synthetic data. We can model different scenarios and generate vast amounts of information quickly. This means we can train AI models much faster and without the huge cost of cleaning up messy, real-world datasets. It’s like having a virtual test lab where you can experiment endlessly without impacting actual production.

Adapting to Evolving Manufacturing Environments

Semiconductor manufacturing is a moving target. New materials, like Gallium Nitride (GaN) and Silicon Carbide (SiC), are being introduced, and processes are constantly refined to meet demands for smaller, faster chips. Simulation allows us to model these changes, like adding new process steps or dealing with supply chain hiccups, and see how they affect production. We can test out new ideas and predict potential problems before they ever happen on the factory floor.

Building Robust Models with Diverse Datasets

Training AI on just historical data can lead to models that don’t perform well when something unexpected happens. Simulation lets us create edge cases and rare scenarios that might not show up in real data. By training models on these diverse situations, we make them more resilient and accurate. It’s about preparing the AI for anything, not just the usual.

Here’s a quick look at how simulation helps:

- Data Generation: Create large volumes of synthetic data quickly.

- Scenario Testing: Model and evaluate new processes or equipment changes virtually.

- Risk Reduction: Identify potential issues before implementing changes in production.

- Model Improvement: Train AI on a wider range of conditions for better performance.

Wrapping It Up

So, what does all this mean for the future of making chips? Basically, companies that jump on these new ideas – like using AI to make things run smoother, or trying out new materials that can handle more heat and power – are the ones that will do well. It’s not just about making chips smaller anymore; it’s about making them smarter, faster, and more efficient. Applied Materials and others are really pushing the envelope here, and it’s going to be interesting to see how these advancements shape the tech we use every single day. It’s a fast-moving field, and staying ahead means constantly adapting and trying new things.