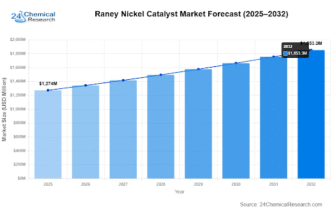

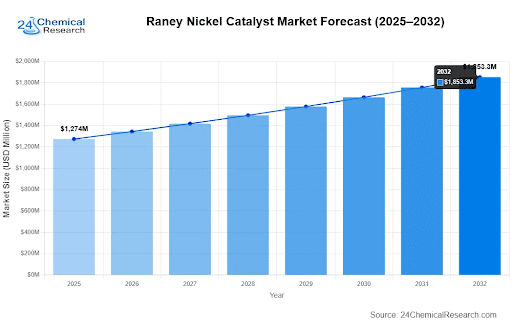

Global Raney Nickel Catalyst Market continues to expand steadily, with its valuation reaching USD 1.274 billion in 2024. According to the latest industry analysis, the market is projected to grow at a CAGR of 5.5%, reaching approximately USD 1.753 billion by 2030. This growth is primarily driven by increasing applications in hydrogenation processes across pharmaceuticals, petrochemicals, and food processing industries, where the demand for efficient and selective catalytic systems remains high.

Raney nickel catalysts serve as indispensable components in organic synthesis, particularly for hydrogenation and desulfurization reactions. Their unique porous structure and high surface area make them preferred choices for industries transitioning toward more sustainable chemical processes. As regulatory bodies emphasize green chemistry principles, manufacturers are increasingly innovating to enhance catalyst lifetime and recyclability.

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/198452/raney-nickel-catalyst-market-2023-2032-2023-2032-948

Recent Developments & Innovations

-

Polymer-Supported Raney Nickel Boosts Clean Chemistry

Researchers at SINOPEC have pioneered polymer-supported Raney nickel catalysts using materials like polyamide. These composite catalysts enable 100% conversion and virtually eliminate unwanted byproducts in hydrogenation reactions achieving unmatched selectivity. The result: cleaner processes and simpler separation.

-

Ag–Raney Nickel Hybrid Excels in Water-Based Reduction

An innovative hybrid catalyst fuses silver nanoparticles onto Raney nickel. It has been shown to efficiently reduce aromatic nitro compounds including nitrofurazone in aqueous solutions under mild, ambient conditions. It’s easily recoverable and retains over 95% of its activity even after six uses.

-

Vital in Biomass Conversion

Raney nickel is emerging as a prominent catalyst in the field of biomass upgrading. Due to its high activity and robust performance, it is increasingly used to convert raw biomass and derived compounds into platform chemicals, advancing sustainable chemical sourcing.

Market Overview & Regional Analysis

Europe currently leads the global Raney nickel catalyst market, accounting for approximately 38% of total consumption, due to its advanced pharmaceutical and specialty chemical industries. Stringent environmental regulations in the region further drive innovation in catalytic processes. North America follows closely, with its robust petrochemical sector contributing significantly to demand.

The Asia-Pacific region demonstrates the fastest growth potential, with China and India emerging as production hubs. While these countries benefit from cost advantages in manufacturing, they face challenges in meeting the purity standards required by multinational corporations. Meanwhile, the Middle East’s expanding petrochemical sector presents new opportunities, though adoption rates remain moderated by the preference for alternative catalysts in crude oil refining.

Key Market Drivers and Opportunities

Three major factors propel the Raney nickel catalyst market forward: (1) expanding pharmaceutical API production requiring selective hydrogenation, (2) growing demand for biofuel processing catalysts, and (3) increasing investments in sustainable chemical manufacturing. The pharmaceutical sector accounts for 42% of overall demand, followed by petrochemical applications at 35% and food processing at 18%.

Emerging opportunities lie in the development of modified Raney nickel formulations for chiral hydrogenations and the integration of these catalysts in continuous flow systems. The push toward bio-based chemical production also opens new application avenues, particularly in converting plant-derived feedstocks. Equipment manufacturers and catalyst suppliers are collaborating closely to develop application-specific solutions that improve process economics.

Challenges & Restraints

The market faces several headwinds, including nickel price volatility (with prices fluctuating 15-20% annually), tightening environmental regulations on metal leaching, and competition from homogeneous catalysts. Recycling challenges persist, as spent Raney nickel catalysts require specialized handling due to their pyrophoric nature. Trade barriers in key markets like India, which imposes import duties on catalysts, further complicate the supply chain landscape.

Smaller producers struggle with quality consistency, while end-users increasingly demand catalysts with precisely controlled particle size distribution and aluminum content. The development of nickel-free alternatives for sensitive applications also threatens traditional Raney nickel market share in pharmaceutical intermediates.

Type

- Powder Form

- Extrudate Form

- Others

Application

- Hydrogenation Reactions

- Dehydrogenation Reactions

- Desulfurization Processes

- Other Chemical Syntheses

Key Players

- BASF SE

- Evonik Industries

- Johnson Matthey

- W.R. Grace & Co.

- Haldor Topsoe

- Clariant AG

- Axens S.A.

- JGC C&C

- Alfa Aesar

- Süd-Chemie India

Report Scope

This comprehensive analysis covers the global Raney Nickel Catalyst Market from 2024 through 2030, providing detailed insights into:

- Market size estimations and growth forecasts across key regions

- In-depth segmentation by product form and application sectors

- Value chain analysis from raw materials to end-use industries

The report includes detailed profiles of 25+ major manufacturers, examining:

- Production capacities and expansion plans

- Product specifications and technology portfolios

- Recent merger & acquisition activities

- Competitive positioning strategies

Our research methodology combines:

- Primary interviews with C-level executives from leading catalyst producers

- Analysis of trade data and customs records

- Plant capacity utilization rate tracking

- Patent analysis and R&D expenditure trends

About 24chemicalresearch

Founded in 2015, 24chemicalresearch has rapidly established itself as a leader in chemical market intelligence, serving clients including over 30 Fortune 500 companies. We provide data-driven insights through rigorous research methodologies, addressing key industry factors such as government policy, emerging technologies, and competitive landscapes.

- Plant-level capacity tracking

- Real-time price monitoring

- Techno-economic feasibility studies

With a dedicated team of researchers possessing over a decade of experience, we focus on delivering actionable, timely, and high-quality reports to help clients achieve their strategic goals. Our mission is to be the most trusted resource for market insights in the chemical and materials industries.

International: +1(332) 2424 294 | Asia: +91 9169162030

Website: https://www.24chemicalresearch.com/

Follow us on LinkedIn: https://www.linkedin.com/company/24chemicalresearch