Advancements in 3D Animation and Visualization

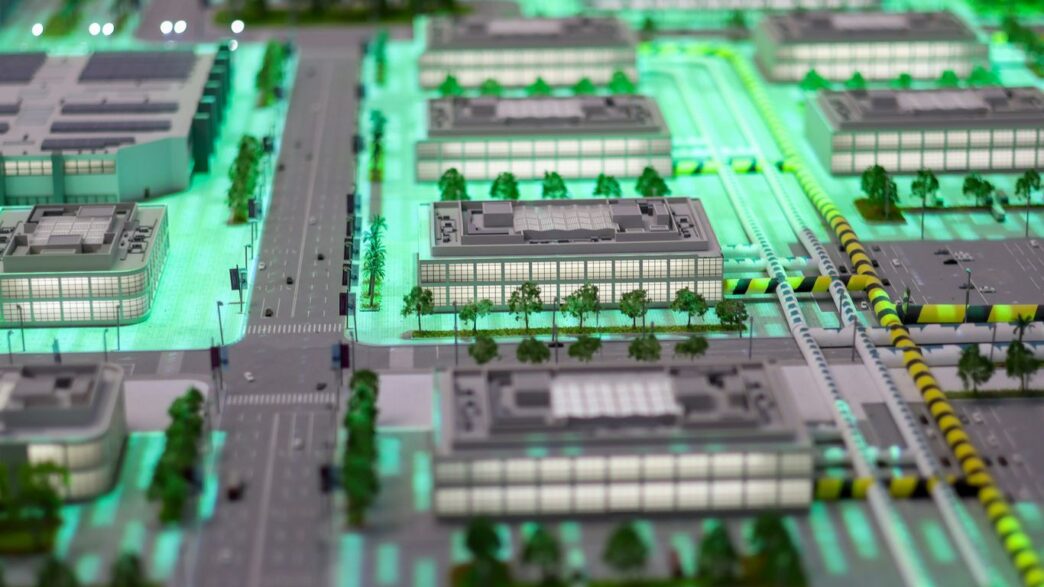

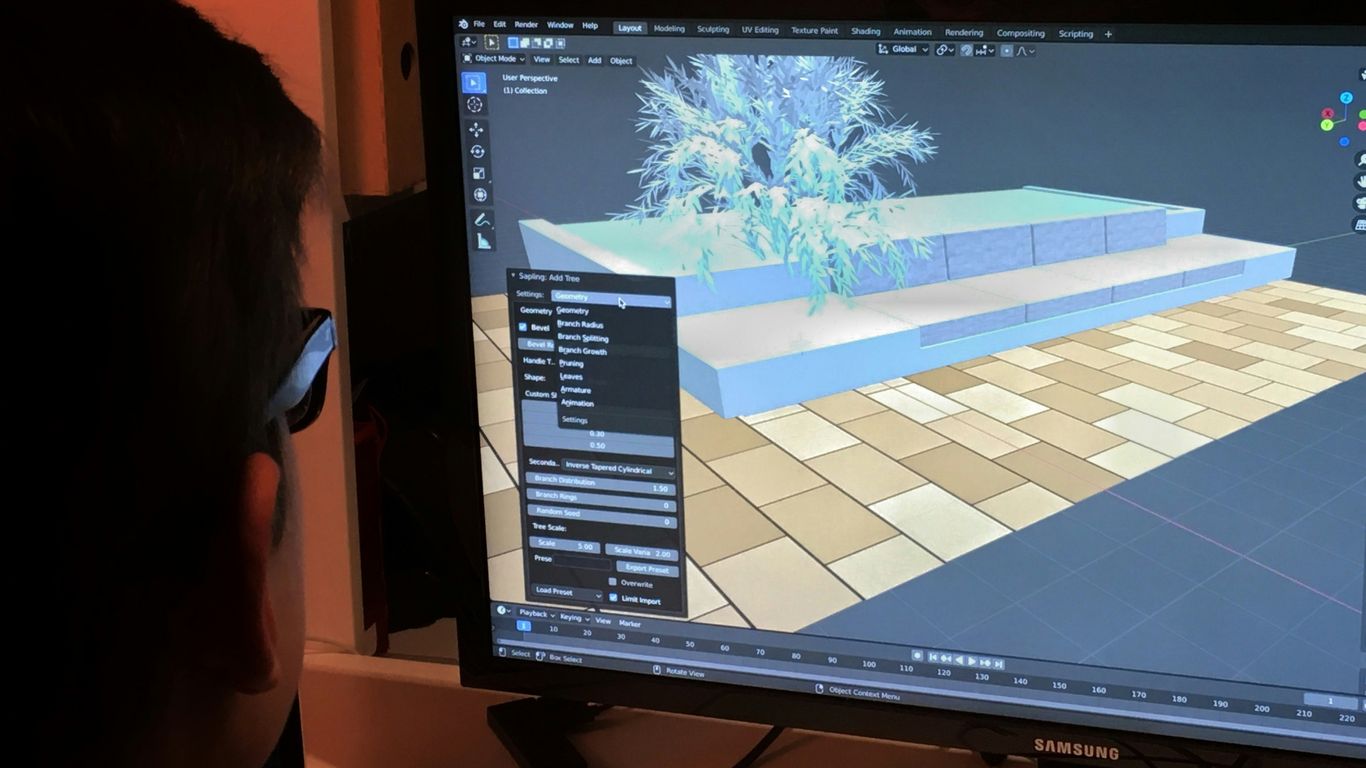

Enhanced Graphical Realism with NVIDIA Omniverse Integration

It’s getting harder to tell the difference between a simulation and reality these days, and that’s a good thing. Tools like NVIDIA Omniverse are really changing the game for simulation software. Think about it: instead of just looking at lines and numbers, you can now see your simulated world with incredible detail. This means when you’re looking at a factory floor layout or a city traffic model, it looks and feels much more real. This boost in visual detail helps everyone involved, from engineers to managers, get a better handle on what the simulation is showing them. It’s not just about pretty pictures, though; it makes complex systems easier to understand at a glance.

Immersive Experiences Through Virtual Reality

Beyond just looking good on a screen, simulations are becoming experiences you can step into. Virtual Reality (VR) is making this possible. Imagine putting on a VR headset and actually walking around your simulated building design or seeing how a new logistics process plays out from a first-person view. This isn’t just for fun; it helps teams spot problems or opportunities they might miss on a flat screen. It’s a powerful way to collaborate too. Multiple people can be in the same virtual space, looking at the same model, and discussing it as if they were really there. This makes decision-making much more intuitive and effective.

Driving Innovation with Visual Clarity

Ultimately, all these improvements in 3D animation and VR come down to making things clearer. When a simulation looks more like the real world, and you can interact with it in more natural ways, it sparks new ideas. It helps us:

- Spot potential issues before they become real problems.

- Communicate complex ideas more easily to people who aren’t simulation experts.

- Test out more ‘what-if’ scenarios because it’s faster and more engaging to set them up and review the results.

This focus on visual clarity is pushing simulation technology forward, making it a more accessible and powerful tool for solving tough problems across many different fields.

The Rise of AI-Powered Simulation Modeling

Artificial intelligence isn’t just a buzzword anymore; it’s actively changing how we build and use simulation models. In 2025, AI is moving from a nice-to-have to a must-have for anyone serious about simulation.

AI as a Data Analyst Co-Pilot

Think of AI tools like advanced assistants. They can sift through mountains of simulation output, summarize key findings, and even let you ask questions about the results in plain language. This means you spend less time digging through spreadsheets and more time understanding what the simulation is telling you. It’s like having a super-smart analyst working alongside you 24/7.

Embedding Machine Learning for Risk-Free Testing

We’re seeing more and more machine learning models being built directly into simulations. This is a game-changer for testing AI-driven solutions. You can try out new algorithms in a completely safe, simulated environment. See how they perform under different scenarios without any real-world consequences. This also helps simulation modelers get better, data-driven inputs, making their models more accurate.

Reinforcement Learning for Policy Optimization

Another exciting area is reinforcement learning (RL). By connecting simulation models to RL libraries, we can train agents to make decisions. These agents learn by trial and error within the simulation, figuring out the best strategies over time. This is incredibly useful for fine-tuning operational policies before they’re put into practice in the real world. It’s a way to test and refine complex decision-making processes without the usual risks.

Cloud-Based Solutions Revolutionizing Collaboration

It’s getting easier and easier to work together on simulation projects, thanks to cloud solutions. Think about it: no more wrestling with software updates or worrying if everyone has the latest version. The cloud is really changing the game for how teams connect and build models.

AnyLogic Cloud for Seamless Model Execution

Running complex simulations used to tie you down to a specific machine. Now, with AnyLogic Cloud, you can just fire up your models from pretty much anywhere. It handles the heavy lifting, so you’re not limited by your own computer’s power. Plus, multiple people can access and run experiments, which is a big deal for team projects. It’s like having a super-powered simulation lab available on demand.

Web-Based Model Building and Editing

This is where things get really interesting. The upcoming AnyLogic 9 is taking cloud collaboration to the next level. You won’t just run models in the cloud; you’ll actually build and edit them right there in your web browser. Imagine your whole team working on the same model at the same time, seeing each other’s changes as they happen. It cuts down on confusion and speeds up the whole development process. No more emailing files back and forth or wondering who has the most current version.

Accessing Latest Tools Without Desktop Updates

One of the biggest headaches with software is keeping it updated. With cloud-based tools, that hassle disappears. You’ll always be working with the newest features and improvements automatically. This means you can focus on your simulation work instead of managing software installations and updates. It’s a much smoother way to keep your simulation capabilities current and ready for whatever challenges come your way.

Next-Generation Digital Twins with Real-Time Data

Digital twins are getting a serious upgrade, moving beyond static representations to become dynamic, living models. The big story here is how they’re now hooked up to real-world data, making them way more useful. Think of it like this: your digital twin isn’t just a blueprint anymore; it’s a live mirror of what’s actually happening.

MQTT as a Standard for IoT Communication

So, how are these twins staying so connected? A lot of it comes down to a communication method called MQTT. It’s a lightweight way for devices, especially those in the Internet of Things (IoT) world, to send messages back and forth. It’s pretty efficient, which is key when you’re dealing with lots of data coming in constantly from sensors and machines. It’s becoming the go-to for getting simulation models and physical assets talking.

Enabling Live Updates from Sensors and Systems

Because of protocols like MQTT, simulation models can now get live updates. This means if a machine’s temperature spikes in the real world, the digital twin can show that change almost instantly. This isn’t just for manufacturing, either. It applies to supply chains, smart cities, and pretty much any system where real-time information matters. It allows for much more accurate monitoring and quicker responses to issues.

Bridging the Gap Between Digital and Physical Worlds

The real magic happens when the digital and physical worlds start to feel like one. With real-time data flowing in, digital twins can do more than just show you what’s happening; they can help you predict what might happen. This connection allows for better decision-making, proactive maintenance, and a deeper understanding of how systems perform under actual conditions. It’s a big step towards making simulations truly reflect reality.

Multimethod Simulation for Complex Challenges

Integrating System Dynamics, Discrete-Event, and Agent-Based Modeling

Sometimes, trying to model a really complicated situation with just one tool just doesn’t cut it. That’s where multimethod simulation comes in. It’s like having a toolbox with different kinds of wrenches, screwdrivers, and hammers – you pick the right one for each part of the job. In 2025, we’re seeing more and more people combine different simulation approaches, like system dynamics for big-picture trends, discrete-event for step-by-step processes, and agent-based for individual behaviors. This blend lets us get a much clearer picture of how complex systems actually work. It’s about using the strengths of each method to overcome the weaknesses of using just one.

Flexibility for Diverse Business Problems

Think about a supply chain. You’ve got the overall flow of goods (system dynamics), the individual trucks and warehouses (discrete-event), and the decisions made by each person or company involved (agent-based). Trying to model all of that with just one method would mean making a lot of simplifications that might not be accurate. Multimethod modeling allows us to build models that are closer to reality because we can represent these different layers of complexity together. This flexibility means we can tackle a wider range of problems, from healthcare patient flow to city traffic management, without having to force the problem into a single modeling style.

The Unique Advantage of Supporting All Three Main Paradigms

What’s really neat is that some software now supports all three main simulation paradigms – system dynamics, discrete-event, and agent-based – all within the same model. This means you’re not limited. You can start with a high-level view and then zoom in on specific parts with different modeling techniques. It’s a big deal because it means:

- No more forcing problems: You can model things the way they are, not the way you’d have to simplify them for a single method.

- Better accuracy: By combining methods, models can capture more nuances and interactions, leading to more reliable insights.

- Wider application: This approach opens the door to solving problems that were previously too difficult or too abstract to model effectively with older, single-method tools.

It’s a powerful way to get a more complete and truthful understanding of intricate systems.

Embracing Digital Transformation for Competitive Edge

So, what does all this tech talk really mean for businesses trying to stay ahead? It boils down to making smart moves with the tools available today. Companies that jump on these digital changes are simply more productive and can handle bumps in the road better than those who wait around. It’s not just about having the latest gadgets; it’s about using them to work smarter and build better.

Leveraging AI and Real-Time Data

Think of AI as your super-smart assistant for crunching numbers and spotting patterns you might miss. It helps make sense of all the data coming in from sensors and systems, giving you a clearer picture of what’s happening right now. This isn’t science fiction anymore; it’s about using AI to predict problems before they happen and make quick, informed decisions. For example, using AI to analyze project data can help teams figure out the environmental impact of their choices early on, leading to more sustainable buildings and products.

The Importance of Cloud Collaboration

Remember the days of emailing huge files back and forth and everyone working on slightly different versions? Yeah, me neither. Cloud solutions change all that. They let teams work together on models and projects from anywhere, at any time. This means less confusion, faster feedback, and everyone being on the same page. Plus, you get access to the newest software updates automatically, so you’re always working with the best tools without a hassle.

Staying Ahead with Cutting-Edge Simulation Technologies

It’s a bit like keeping your tools sharp. The simulation technologies we’re seeing now, like advanced digital twins and multimethod modeling, are game-changers. They let you test out complex scenarios without real-world risks. You can try different approaches, see what works best, and fine-tune your plans before you even break ground or start manufacturing. This kind of foresight saves time, cuts down on waste, and ultimately gives you a serious advantage over the competition.

Wrapping It Up

So, looking back at Building Simulation 2025, it’s clear things are moving fast. We’re seeing more realistic visuals, AI getting smarter and actually helping out, and the cloud making everything more accessible. Digital twins are getting a serious upgrade too, with real-time data making them way more useful. It feels like simulation is becoming less of a niche tool and more of a go-to for making big decisions across different industries. It’s exciting to see how these changes will help people build better, smarter, and maybe even more sustainable things in the future. Definitely something to keep an eye on.