The Kodiak Self-Driving Truck: A New Era in Logistics

Revolutionizing Freight with AI-Powered Autonomy

It feels like just yesterday we were talking about self-driving cars, and now, here we are, seeing big rigs with no one behind the wheel. Kodiak is really pushing this forward. They’ve built a system, called the Kodiak Driver, that uses artificial intelligence to handle the heavy lifting – literally. This isn’t just about making trucks drive themselves; it’s about fundamentally changing how goods get from point A to point B. Think about it: fewer delays, more consistent delivery times, and a way to deal with the ongoing shortage of truck drivers. Kodiak’s approach is all about making freight movement smarter and more dependable. They’ve already moved a lot of freight, over 4,500 loads by the end of 2023, which shows they’re not just experimenting. They’re operating.

Expanding Operational Design Domain Beyond Highways

For a long time, self-driving trucks were mostly seen on highways. That made sense, right? Highways are pretty predictable. But Kodiak is taking things further. They’ve started driving their trucks on regular roads, the kind with stop signs, tricky intersections, and tight turns. This is a big deal because it means their system can handle more complex routes, not just the open road. They’ve also taken their technology off paved surfaces entirely, working with the U.S. Army on dirt and gravel paths. This shows how adaptable the Kodiak Driver is. It’s not just for long-haul trucking anymore; it can handle different kinds of jobs in various places.

Ensuring Safety and Reliability in Diverse Environments

When you’re talking about trucks that drive themselves, safety is the number one thing on everyone’s mind. Kodiak seems to get that. They’ve put their system through a lot, including bad weather like rainstorms and tricky situations like construction zones. Their technology has proven it can handle these challenges. Plus, by expanding where their trucks can drive, they’re showing that the system is reliable in more than just ideal conditions. They’ve even developed special versions, like the Kodiak DefensePods, for military use, which need to work in tough spots like dust, mud, and water. This broad testing and adaptation points to a system built for real-world unpredictability.

Kodiak Driver: Versatile Technology for Any Mission

Revolutionizing Freight with AI-Powered Autonomy

The Kodiak Driver isn’t just for the highway anymore. We’ve taken this technology and made it work in all sorts of places. Think about it: our system runs the same smart software that’s been driving long-haul trucks across the country, but we’ve also adapted it for tougher jobs. We call these special versions ‘DefensePods,’ which are basically our swappable sensor units, but built for more rugged use. This adaptability means the Kodiak Driver can handle pretty much any mission you throw at it.

Expanding Operational Design Domain Beyond Highways

We’ve really pushed the limits with where the Kodiak Driver can go. It’s already proven itself on over 18,000 miles of busy freight routes, handling everything from construction zones to tricky merges and bad weather. But we didn’t stop there. In 2023, we started driving on local roads, dealing with stop signs, busy intersections, and tight turns. That was a big step. Then, we took it even further, working with the U.S. Army to drive on dirt and gravel roads. Not many other self-driving companies can say they’ve expanded their operating area so quickly. We’re the only ones who can handle both regular road trucking and complex military situations, even when GPS is spotty or the terrain is rough.

Ensuring Safety and Reliability in Diverse Environments

Our technology is built to be tough and dependable, no matter the situation. We’ve put it through its paces in all sorts of conditions, from busy highways to unpaved military training grounds. This flexibility comes from a few key design choices:

- Platform-Agnostic Design: The Kodiak Driver isn’t tied to just one type of truck. We’ve shown this by integrating it into three different vehicle types. This means it can be fitted onto a wide range of trucks, making it easy to adopt.

- Modular SensorPods: We moved all the important sensors into these special pods. This makes them easy to swap out if something goes wrong, which means less downtime for the truck. It also means we don’t need bulky sensors sticking out of the roof, making the whole system cleaner and easier to maintain.

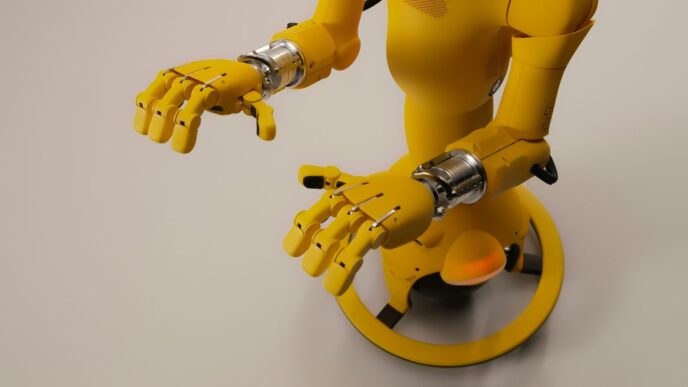

- Adapting for Defense and Off-Road Applications: For military needs, we created specific versions of our technology. For example, we took an F-150 and outfitted it with the Kodiak Driver in under six months. It was built to handle dust, mud, rocks, and water, showing how adaptable our system is for defense work and other challenging environments.

Advancements in Kodiak’s Autonomous Platform

Kodiak’s technology isn’t just standing still; it’s constantly getting better. They’ve been busy making their system smarter, faster, and more adaptable. It’s pretty wild how much has changed even in the last year or so.

Introducing the Gen5 Platform: More Power, New Capabilities

Think of the Gen5 platform as the latest upgrade for Kodiak’s brains. It’s got more processing power, which means it can handle more complex situations on the road. Plus, they’ve redesigned the hardware to be more modular. This is a big deal because it makes repairs and upgrades way easier. All the important sensors are now tucked away in these things called SensorPods, which used to be on the roof. This not only makes the system more robust but also cuts down on downtime when something needs fixing.

Pioneering Autonomous Electric Class 8 Trucks

This is a pretty significant step. Kodiak rolled out what they’re calling the first-ever autonomous electric Class 8 truck. They’ve taken their self-driving tech and put it onto an electric Peterbilt. It’s a combination that really points to the future of trucking – zero emissions and no human driver needed. It’s not just about the electric part, though. The autonomous system itself helps make these trucks more efficient.

Reducing Fuel Consumption and Emissions with Autonomy

Even on their regular diesel trucks, the autonomous tech makes a difference. By driving more smoothly and efficiently, these trucks can use about 10% less fuel. That’s not just good for the bottom line; it’s also better for the environment. When you combine that fuel saving with electric trucks, you get a really powerful way to cut down on pollution from the freight industry. It’s a win-win, really.

Strategic Partnerships for Scaled Deployment

Making self-driving trucks a reality isn’t just about building the tech; it’s about making sure that tech can be built, installed, and maintained at a large scale. Kodiak knows this, and they’ve been busy teaming up with some big names to get there.

Collaboration with Bosch for Production-Grade Hardware

One of the most significant moves Kodiak has made is their partnership with Bosch. This collaboration is all about getting the hardware needed for their autonomous system ready for mass production. Think of it like this: you can build a great prototype in your garage, but to sell millions of cars, you need a factory and reliable parts. Bosch is a giant in automotive manufacturing, so working with them means Kodiak can get specialized, dependable hardware that’s built to last and can be integrated right onto the truck assembly line or by upfitters. This isn’t just about making a few trucks; it’s about making thousands, and Bosch has the experience to help make that happen.

Scaling Manufacturing for Commercial Success

Getting the technology right is one thing, but scaling up manufacturing is a whole different ballgame. Kodiak’s goal is to see their trucks on the road, hauling freight every day. To do that, they need a solid supply chain and manufacturing process. Partnering with companies like Bosch helps them achieve this by providing:

- Reliable Components: Access to high-quality, tested parts that meet automotive standards.

- Manufacturing Expertise: Leveraging Bosch’s deep knowledge in producing complex systems at volume.

- Integration Support: Ensuring the autonomous hardware works perfectly with the rest of the truck.

This focus on manufacturing is what separates a cool tech demo from a real business that can serve the logistics industry.

Integrating Autonomous Systems on Factory Lines

Kodiak isn’t just thinking about retrofitting existing trucks. They’re working towards integrating their autonomous driving system, the Kodiak Driver, directly into the truck manufacturing process. This means that when a new truck rolls off the assembly line, it can already be equipped with the necessary hardware and software for autonomous operation. This approach simplifies installation, improves reliability, and makes it easier to deploy fleets of self-driving trucks. It’s a more efficient way to build the future of trucking, making sure the technology is part of the vehicle from the very beginning.

Operational Excellence and Command Center Capabilities

Expanding Truckport Network for 24/7 Service

Kodiak’s approach to autonomous trucking isn’t just about the trucks themselves; it’s about building a whole ecosystem to support them. A big part of that is the Truckport network. Think of these as specialized hubs where the self-driving trucks can stop, get serviced, refuel or recharge, and swap out trailers. By growing this network, Kodiak can keep its trucks running around the clock, making sure freight keeps moving without long downtimes. This means more consistent deliveries and better use of the autonomous fleet.

Real-Time Monitoring and Support for Autonomous Missions

Even though the trucks drive themselves, there’s still a human element involved. Kodiak operates a command center where teams keep an eye on all the trucks out on the road. They use advanced software to monitor everything from the truck’s location and performance to its sensor data. If anything unexpected pops up, like a tricky road condition or a system alert, the command center team can step in. They can provide remote assistance, reroute the truck, or even guide it to a safe stop. This constant oversight is key to making sure the autonomous missions are safe and efficient.

Ensuring Safe and Timely Freight Deliveries

Putting it all together, the Truckport network and the command center work hand-in-hand to make sure freight gets where it needs to go, on time and without issues. The network keeps the trucks moving, and the command center provides the backup and oversight needed for those times when the unexpected happens. This combination helps build confidence in the technology and shows how autonomous trucks can fit into the existing logistics picture. It’s about making sure the whole system is reliable, from the moment a truck leaves its hub to the moment it completes its delivery.

The Future of Trucking with Kodiak AI

Preparing for Commercial Driverless Deployment

So, what’s next for Kodiak? They’re really gearing up for a future where trucks drive themselves, no human needed. It’s not just about getting the tech right, but also about building the infrastructure to support it. They’ve been busy expanding their network of "truckports" – basically, places where these autonomous trucks can stop, get serviced, and switch loads. Think of it like pit stops for self-driving big rigs. They recently opened a new one in Georgia, working with Pilot, and have another at a Ryder facility in Houston. This expansion is key to making sure these trucks can operate around the clock, 24/7.

Innovations Driving the Autonomous Future

Kodiak isn’t just sticking to highways anymore. They’ve shown their system can handle local roads, dealing with stop signs, tricky intersections, and tight turns. And get this, they’ve even taken their tech off-road, working with the U.S. Army on dirt and gravel. That’s a pretty big leap from just cruising down the interstate. They’ve also introduced their Gen5 platform, which is basically a more powerful, sleeker version of their autonomous system. A big change is moving all the important sensors into "SensorPods." This makes them easier to swap out and fix, meaning less downtime for the trucks. Plus, they’ve rolled out what they say is the first autonomous electric Class 8 truck. Combining electric power with self-driving tech is a big deal for reducing emissions and making trucking cleaner.

Leading the Charge in National Security and Technology

It’s not just about moving goods from point A to point B. Kodiak’s technology is also being adapted for defense applications. They’ve put their system into an F-150 designed to handle tough conditions like dust, mud, and water. This shows how flexible their "Kodiak Driver" system is – it can be put on different types of vehicles for different jobs. They’re also working with big names like Bosch to make sure the hardware they use is top-notch and can be produced at a large scale. This partnership is important for getting these trucks out there commercially. It’s all about making sure the technology is reliable and can be manufactured efficiently. They even have a Command Center that keeps an eye on all their trucks, day and night, making sure everything runs smoothly and deliveries happen on time. It’s a whole system designed for the future of moving stuff.

The Road Ahead

So, what does all this mean for the future of getting stuff from point A to point B? Kodiak’s work shows that self-driving trucks aren’t just a sci-fi dream anymore. They’ve proven their tech works on highways, in tricky city streets, and even off-road for military needs. By teaming up with companies like Bosch for hardware and expanding their operations, they’re getting ready for the real world. This isn’t just about making trucks drive themselves; it’s about making shipping faster, more reliable, and maybe even a bit greener, especially when you think about combining this with electric power. It’s a big step, and it looks like Kodiak is right there, helping to steer the whole industry forward.