The Kodiak Self-Driving Truck: Addressing Industry Challenges

The trucking industry is a massive part of how things get done in this country, moving tons of freight and making a lot of money. But there’s a big problem: not enough drivers. This shortage is a real headache, slowing things down and making shipping more expensive. It feels like we’ve been talking about this for years, and it’s only getting tougher. That’s where companies like Kodiak Robotics come in, looking to autonomous trucks as a way to help fix this mess.

Pioneering Autonomy in Heavy-Duty Transportation

Kodiak is really focused on making self-driving technology work for big trucks. They’re not just dabbling; they’re building a whole system from the ground up. Think of it like this: they’re taking a regular truck and adding a whole new brain and set of senses. This isn’t just about slapping some sensors on and hoping for the best. It’s about creating a reliable way for these massive vehicles to handle themselves on long journeys.

Bridging the Driver Shortage Gap

This is a huge one. With fewer people wanting to drive trucks long-haul, businesses are struggling to get their goods where they need to go. Autonomous trucks could be a game-changer here. By taking over some of the driving duties, especially on those long, monotonous highway stretches, self-driving trucks can help keep freight moving even when there aren’t enough human drivers available. It’s not about replacing drivers entirely, at least not yet, but about filling a critical need and making the whole system work better.

Enhancing Efficiency in Freight Transportation

Beyond just having enough drivers, autonomous trucks promise to make things run smoother and faster. These trucks can potentially drive for longer periods without needing breaks, operate at optimal speeds to save fuel, and follow precise routes. This all adds up to getting goods delivered more predictably and, hopefully, at a lower cost. It’s about making the entire process of moving freight more streamlined and less prone to delays caused by human factors.

Technological Innovations Driving the Kodiak Self-Driving Truck

Kodiak isn’t just slapping some sensors on a truck and calling it a day. They’ve put a lot of thought into how to make this whole autonomous thing work reliably, especially for those long, tough hauls. It’s all about building a system that can handle pretty much anything the road throws at it.

Sensor Fusion for Robust Navigation

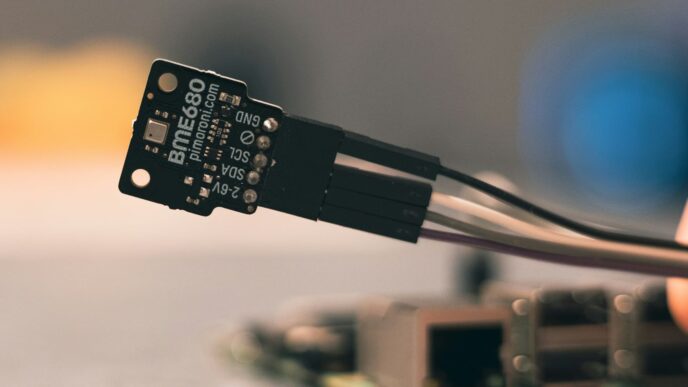

Think of sensor fusion like having multiple eyes and ears, each with different strengths. Kodiak uses a mix of LiDAR, radar, cameras, and sonar. LiDAR is great for precise distance measurement, radar cuts through bad weather, cameras see colors and details, and sonar helps with close-up stuff. By combining the information from all these sensors, the truck gets a much clearer, more complete picture of its surroundings than any single sensor could provide. This layered approach is key to making sure the truck knows exactly where it is and what’s around it, even when conditions aren’t perfect. It helps avoid blind spots and provides backup information if one sensor isn’t working perfectly.

Custom Hardware and Software Integration

Instead of just buying off-the-shelf parts and hoping they work together, Kodiak develops a lot of its own technology. They build custom hardware and software specifically for their trucks. This means they can fine-tune everything to work perfectly with each other. They’re not trying to be experts in making sensors, but they are experts in making those sensors work together in a self-driving system. This custom integration allows them to optimize performance and reliability in ways that using generic parts might not.

Advanced Redundant Systems for Safety

Safety is obviously a huge deal when you’re talking about trucks this big. Kodiak builds in backup systems for all the critical functions. This means if the primary steering system has an issue, there’s a secondary system ready to take over. The same goes for braking and power. They also replaced traditional mirrors with cameras and sensors that give a full 360-degree view. This redundancy is like having a safety net, making the system much more dependable and reducing the risk of a single point of failure causing a problem.

Kodiak Robotics: Vision and Funding for Autonomous Freight

The ‘Killer App’ for Self-Driving Technology

So, why trucking? The folks at Kodiak Robotics saw something pretty big here. They figured that long-haul trucking isn’t just a use for self-driving tech, it’s practically the main reason for it. Think about it: the same long, predictable highway stretches that are a grind for human drivers are actually a sweet spot for autonomous systems. It’s a massive industry, moving tons of goods every day, and it’s facing a real driver shortage. Kodiak’s founders, with their backgrounds at places like Google’s self-driving project, zeroed in on this, believing that focusing all their energy on trucking could actually solve some major problems. It’s a bold idea, but one that makes a lot of sense when you look at the numbers.

Significant Series A Financing

This vision got some serious backing. Kodiak pulled in a hefty $40 million in their Series A funding round. We’re talking about money from some pretty big names in the investment world, like Battery Ventures and Lightspeed Venture Partners. This isn’t just pocket change; it’s fuel for growth. The plan is to use this cash to really beef up their engineering team and push forward with developing their product. They started with a small, focused group, but this funding means they can bring in more experienced folks who know how to get self-driving tech out onto the roads.

Expanding the Engineering Team and Product Development

With all that new funding, the next big step is clear: hiring more smart people and building out the actual technology. Kodiak isn’t trying to reinvent the wheel when it comes to basic sensors like cameras or radar. Instead, they’re focusing on what they call "sensor fusion" – taking data from various sources and combining it to create a super reliable picture of what’s going on around the truck. They’re building custom hardware and software to make sure all these pieces work together perfectly. This means more engineers working on the complex algorithms, the safety systems, and making sure the whole truck operates smoothly and safely, mile after mile.

Real-World Deployments of the Kodiak Self-Driving Truck

Transforming Logistics with Strategic Partnerships

Kodiak’s technology isn’t just theoretical; it’s out there, actually moving freight. One big example is their work with Bridgestone and J.B. Hunt. They’re hauling Bridgestone tires from South Carolina all the way to Dallas. This route is about 900 miles, a trip that usually takes a lot of driver hours or multiple days. With Kodiak’s autonomous trucks, the process gets a lot smoother and, they say, safer too.

Here’s a quick look at how that tire transport works:

- Initial Haul: J.B. Hunt trucks pick up the tires in South Carolina and bring them to a Kodiak facility near Atlanta.

- Autonomous Leg: A Kodiak self-driving truck takes over from there, driving autonomously to Dallas.

- Final Delivery: Once in Dallas, a J.B. Hunt driver handles the final delivery to the customer.

This whole operation is watched over 24/7 by Kodiak’s operations center. It’s kind of like a modern dispatch, making sure everything runs right and keeping track of the trucks and their loads.

Streamlining Tire Transportation Routes

That Bridgestone partnership is a prime example of how autonomous trucks can make specific routes much more efficient. Instead of needing multiple drivers to cover the long distance and comply with driving hour regulations, one autonomous truck can handle the bulk of the journey. This means less downtime and potentially faster delivery times. It’s a practical application that shows the real benefits of this technology in a demanding industry. They’ve already logged millions of miles in commercial autonomous trucking, constantly gathering data to make the system even better.

The Role of the 24/7 Operations Center

Running these autonomous trucks isn’t just about the vehicle itself. Kodiak has set up a central operations center that keeps an eye on everything, all day and all night. This center is key for managing the fleet, monitoring truck performance, and responding to any issues that might pop up. They’ve expanded their operations, with facilities in places like Georgia and Texas, all connected through this command center. It’s this constant oversight that helps make sure the freight gets where it needs to go, safely and on schedule, even when no one is physically in the driver’s seat for most of the trip.

Kodiak’s Growing Expertise and Future Outlook

Millions of Miles Logged in Commercial Autonomous Trucking

Kodiak has been busy, really busy. In 2023 alone, they delivered over 4,500 loads, showing that their autonomous trucks aren’t just prototypes anymore. They’re out there, doing the actual work, 24/7. This isn’t just a few test runs; we’re talking about real commercial operations. Logging millions of miles means they’ve ironed out a lot of kinks that you only find when you’re out on the road day in and day out. It’s this kind of practical experience that builds true confidence in the technology.

Vision for Factory-Integrated Autonomous Systems

Looking ahead, Kodiak isn’t just thinking about adding their tech to existing trucks. Their vision includes working with manufacturers to build autonomous systems right into the trucks from the factory floor. Imagine trucks rolling off the assembly line already equipped with the Kodiak Driver. This approach could make things much simpler and more efficient down the line, cutting down on installation time and making maintenance easier. It’s about making autonomy a standard feature, not an add-on.

Navigating Regulatory Hurdles for Driverless Operation

Of course, getting trucks to drive themselves completely, without a safety driver, involves a lot of paperwork and approvals. Kodiak is actively working through the complex web of federal and state rules. This is a big deal because how these regulations shake out will really shape how quickly and where these driverless trucks can operate. It’s a slow process, but getting it right is key to widespread adoption. They’ve shown their tech works on major freight routes, and the next step is proving it can handle all sorts of conditions safely enough for regulators to give the green light for fully driverless trips.

The Kodiak Driver: Versatility Across Diverse Environments

The Kodiak Driver isn’t just built for the open highway; it’s designed to handle a whole lot more. We’ve put a lot of work into making sure this system can adapt to different situations, which is pretty important for a truck that needs to get goods from point A to point B, no matter what.

Proven Performance on National Freight Lanes

We’ve logged millions of miles on the road, and that’s not just a number. Our trucks have been running on major freight routes all across the country. Think about navigating busy highways, dealing with construction zones that pop up out of nowhere, or merging into traffic that’s moving at full speed. The Kodiak Driver has handled all of that. It’s proven itself to be reliable and efficient on these long hauls, which is the bread and butter of the trucking industry right now.

Expanding Capabilities to Local Roads and Off-Road Terrains

But we didn’t stop there. A big step for us was taking the Kodiak Driver off the highway and onto regular streets. This means dealing with things like stop signs, traffic lights, complex intersections, and tight turns you find in cities and towns. It’s a whole different ballgame compared to highway driving. And then, we took it even further. Working with the U.S. Army, we’ve tested the Kodiak Driver on unpaved surfaces – think gravel and dirt roads. This shows how flexible our system is, going from highways to rougher, less predictable ground.

Adapting for Military Ground Vehicle Applications

This off-road capability is a big deal, especially for military applications. We’ve adapted the Kodiak Driver for use with military ground vehicles. This involves using special hardware, like our DefensePods, which are basically modular sensor packages that can be swapped out. The system is built to work even when GPS signals aren’t great or when the terrain is really challenging. It’s about making sure the technology can perform in tough, unpredictable environments, which is exactly what you need for defense operations. This adaptability means the same core technology can be used for commercial freight and for specialized military needs.

Kodiak’s Commitment to Sustainability and Innovation

It’s pretty clear that Kodiak isn’t just focused on making trucks drive themselves. They’re also thinking about the bigger picture, like how this technology can help the environment and how they can keep making their systems better. They’re looking at combining their self-driving tech with electric trucks, which sounds like a win-win for cleaner air and more efficient shipping.

Integrating Autonomous Systems with Electric Powertrains

Kodiak has already shown they can put their self-driving system, the Kodiak Driver, onto an electric truck. They did this with a Peterbilt Model 579EV. This is a big deal because it means they’re not just thinking about the future of trucking, but a future that’s also greener. Combining zero-emission vehicles with autonomous driving is a smart move for reducing the overall impact of freight transport.

Reducing Fuel Consumption Through Autonomy

Even with their current diesel trucks, the autonomous technology itself helps save fuel. Reports suggest that using their system can cut down fuel use by about 10%. That’s not just good for the planet; it also means trucks can go further on a single tank, which is especially helpful for electric vehicles where range is always a big consideration. It’s all about making things more efficient, which usually leads to less waste.

Introducing the Gen5 Platform for Enhanced Performance

Kodiak keeps updating its technology. They came out with their Gen5 platform, which is supposed to be more powerful and have new features. A neat trick they did was move all the important sensors into these "SensorPods." This gets rid of the need for sensors on the roof, making the trucks easier to fix and keeping them running more often. It’s these kinds of practical improvements that really show they’re serious about making this technology work in the real world, day in and day out.

The Road Ahead

So, what does all this mean for the future of getting stuff from point A to point B? Basically, Kodiak’s self-driving trucks are looking like a really solid bet for making long trips smoother and maybe even cheaper. They’ve put in the work, logged a ton of miles, and seem to have a good handle on the tech. While we’re not quite at a point where you’ll see zero human drivers on every highway tomorrow, Kodiak is definitely paving the way. It’s exciting to think about how this could change things, from how quickly goods get to us to how the trucking industry itself operates. Keep an eye on this space, because the future of freight is rolling in, and it’s driving itself.