Big rockets are cool, no doubt about it. They light up the sky and make you feel small. But there’s a whole other world happening with smaller launch vehicles, the ones built for tiny satellites. These little guys, often called small launchers, are popping up everywhere. They’re trying to find their place in a space that’s getting crowded fast. Will they make it, or will the big players push them out? Let’s take a look at the leo aerospace scene and see what’s going on.

Key Takeaways

- The leo aerospace market is seeing a lot of new companies, partly because it’s cheaper and easier to get started compared to building big rockets.

- Some regions, like Europe, have a gap in their launch capabilities, and these smaller companies are stepping in to fill it.

- Companies like Rocket Lab and Galactic Energy are leading the way, but even they are starting to look at building bigger rockets.

- The biggest challenge for leo aerospace startups is the competition. There are many companies trying to do the same thing, and bigger rockets are getting cheaper, making it tough to compete.

- New ways of building rockets, like 3D printing, and ideas like reusing rocket parts or launching from the sea, are helping leo aerospace companies try to stand out.

The Evolving Landscape Of Leo Aerospace

It feels like just yesterday that getting anything into space was a monumental, incredibly expensive task, usually reserved for governments and a few very big companies. But things have really shifted, haven’t they? The whole scene around launching small things into orbit, what we call Low Earth Orbit or LEO, has exploded. It’s like a whole new neighborhood popped up in space, and a lot of new players are moving in.

The Rise Of Small Launchers

Think about it: for a long time, if you wanted to send a satellite up, you were basically buying a ticket on a giant rocket, whether you needed all that space or not. This meant smaller projects, like those for scientific research or even just testing new tech, were either way too expensive or just not feasible. That’s where the small launchers come in. These companies are building rockets that are specifically designed to carry smaller payloads, making space access much more affordable and flexible. It’s democratizing space, plain and simple.

Drivers Of Industry Change

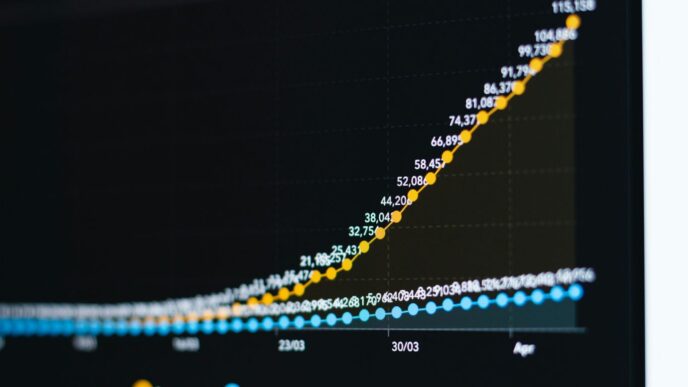

So, what’s behind this big change? A few things, really. For starters, there’s been a huge increase in demand for satellites. We’re talking about constellations for global internet, better Earth observation for tracking climate change, and all sorts of new communication services. Plus, governments are pushing for more space activity, like NASA’s Artemis program aiming for the Moon, which creates opportunities for smaller companies to contribute. The money flowing into space startups has also been pretty wild; in 2021 alone, venture capital poured over $15 billion into these companies. It’s a mix of new needs and new money making things happen.

The Impact Of Miniaturization

Another big piece of the puzzle is how small everything is getting. Satellites themselves are shrinking, becoming more capable, and costing less to build. This miniaturization means you don’t need a massive rocket to put them into orbit. You can now launch a whole bunch of these smaller, cheaper satellites together on a dedicated small rocket, or even piggyback them onto larger ones. This trend is changing how we think about space missions, allowing for more specialized and responsive capabilities that just weren’t possible before.

Early Achievements In Leo Aerospace

It’s pretty wild to think about how quickly the small launch sector has grown. Just a few years ago, the idea of companies building rockets specifically for small satellites seemed like a niche dream. But now? It’s a whole thing. One of the biggest early wins for these startups was simply proving that the market was there and hungry for their services. Hundreds of companies popped up, all looking to grab a piece of the pie. This wasn’t just about ambition; it was about recognizing a gap. Building and operating smaller rockets requires less cash and fewer massive facilities compared to the giants of the industry, making it easier for new players to jump in. This lower barrier to entry meant that places previously on the sidelines of space access, like Europe, started seeing their own domestic rocket companies emerge.

Speaking of Europe, this is where we saw a really clear early achievement. The continent was facing a bit of a launch problem. With some of their bigger rockets out of commission, their options for getting payloads into orbit became really limited, mostly down to just one small launcher. This created a "launch vacuum," and it was a big deal. It’s similar to how the US eventually solved its own launch needs with a wave of commercial companies. Having these European small launchers means the continent can handle its own space needs without being dependent on just one or two providers. Plus, it’s a great way to attract business and help countries like the UK reach their goals of becoming major small satellite launch hubs.

Here’s a quick look at what that means:

- Market Niche Attracts Startups: The reduced cost and complexity of small launchers drew in a huge number of new companies.

- Addressing European Launch Gaps: Small rockets provided a much-needed alternative for European countries needing independent access to space.

- Responsive Space Missions: These smaller rockets are perfect for quick launches, letting companies test satellites fast or allowing governments to get assets into orbit on short notice.

This whole situation really highlights how these smaller companies, even with their initial hurdles, were able to carve out a space for themselves and start solving real problems. It’s a testament to their innovation and the growing demand for flexible launch options. It reminds me a bit of how SpaceX started with the Falcon 1, aiming to make space more accessible, and look at them now.

Key Players In The Leo Aerospace Sector

Rocket Lab’s Electron

Rocket Lab has really made a name for itself in the small launch game. Their Electron rocket is pretty much the workhorse for getting small satellites into orbit. It’s designed to be reliable and frequent, which is exactly what a lot of companies need when they’ve got a satellite ready to go. They’ve managed to launch dozens of missions, sending up all sorts of payloads for governments and private businesses. Their success shows that there’s a real market for dedicated small launch services. They’re also working on making Electron reusable, which could bring costs down even further.

Galactic Energy’s Ceres-1

Galactic Energy is another company that’s been making waves, especially out of China. Their Ceres-1 rocket is also built for the small satellite market. It’s a solid-fuel rocket, which generally means it’s quicker to get ready for launch compared to liquid-fuel rockets. They’ve had a good run of successful launches, proving their capability. It’s interesting to see how different companies approach the same problem, and Galactic Energy’s focus on solid fuel for their small launcher is a distinct strategy.

Emerging Chinese Competitors

Beyond Galactic Energy, China has a whole bunch of companies popping up in the small launch sector. It feels like every few months, there’s a new name or a new rocket design being announced. These companies are often backed by significant investment and government support, which helps them move pretty fast. They’re not just building rockets; they’re also looking at building out space infrastructure and services. It’s a competitive landscape, and it’s going to be fascinating to watch how these players develop and if they can compete on a global scale. Some of the names you might hear more about include companies like i-Space and LandSpace, though the field is quite dynamic.

Strategic Development For Leo Aerospace Companies

Building Expertise With Small Rockets

Starting small is often the smartest way to go in the rocket business. Many companies that aim for the stars begin by focusing on smaller launch vehicles. This approach lets them build up their technical know-how, test their systems, and get a feel for the market without the massive investment needed for huge rockets. It’s like learning to ride a bike before trying to race a motorcycle. You get to understand the mechanics, the balance, and how to handle unexpected bumps along the way. This hands-on experience is invaluable.

Think about it: developing a small rocket means fewer parts, less complex engineering, and a quicker path to flight. This allows for faster iteration and learning from failures, which, let’s be honest, happen a lot in this industry. Companies can refine their manufacturing processes, their software, and their operational procedures on a smaller scale. This builds a solid foundation for whatever comes next. It’s about proving you can get to orbit reliably before you try to haul bigger payloads.

Transitioning To Larger Vehicles

Once a company has a handle on small launchers, the next logical step is often to scale up. This isn’t just about making a bigger rocket; it involves rethinking many aspects of the design and production. You have to consider new materials, more powerful engines, and more sophisticated guidance systems. It’s a whole new ballgame, really. The challenges multiply, but so does the potential reward. Bigger rockets mean bigger contracts and the ability to serve a wider range of customers.

This transition requires significant investment and a clear strategy. Companies need to secure funding, expand their manufacturing capabilities, and hire more specialized talent. They might also need to develop new ground support equipment and launch infrastructure. It’s a complex process that demands careful planning and execution. Some companies might aim for a direct jump to medium-lift, while others might take a more gradual approach, developing intermediate-sized vehicles first. The goal is to move up the value chain and compete for more lucrative missions.

The Falcon 1 To Falcon 9 Precedent

We’ve seen this play out before, most famously with SpaceX. Their journey started with the Falcon 1, a relatively small rocket designed to prove their capabilities. It had its share of early struggles, including a few launch failures. But they learned from each attempt, iterating on the design and improving their processes. This persistence eventually paid off, paving the way for the development of the much larger and highly successful Falcon 9. This transition from a small, experimental vehicle to a workhorse of the launch industry is a powerful example for other startups. It shows that a strategic, step-by-step approach, coupled with resilience, can lead to remarkable achievements in the competitive world of spaceflight. It highlights how early successes, even on a smaller scale, can build the confidence and the financial backing needed for more ambitious projects, like those involving advanced propulsion systems for satellites OhmSpace.

Here’s a look at how some companies might approach this scaling:

- Phase 1: Small Launch Vehicle Development: Focus on reliability and cost-effectiveness for small payloads.

- Phase 2: Technology Maturation: Refine manufacturing, testing, and launch operations based on early flight data.

- Phase 3: Medium-Lift Development: Design and build a larger rocket capable of carrying more significant payloads.

- Phase 4: Reusability Integration: Incorporate reusable technologies to further reduce launch costs.

- Phase 5: Heavy-Lift or Specialized Missions: Target the most demanding launch requirements or niche markets.

Challenges And Future Outlook For Leo Aerospace

Intense Market Competition

The small launch market is getting pretty crowded, and honestly, it feels like everyone and their dog wants a piece of the pie. We’ve seen a ton of startups pop up, all promising to get your tiny satellites into orbit faster and cheaper. But here’s the thing: not all of them are going to make it. It’s a tough business, and only the companies with solid tech, smart business plans, and maybe a bit of luck are going to stick around. Think about it, you’ve got established players and then all these new kids on the block. It’s a real dogfight out there.

The Threat Of Larger Launchers

While the focus has been on small launchers for small satellites, there’s always the looming presence of bigger rockets. These giants can carry more payload, and sometimes, they can even offer competitive pricing for certain types of missions. It means that the small launch companies can’t just rest on their laurels. They need to keep innovating and finding ways to be indispensable, even when a bigger rocket could technically do the job. It’s like a small shop trying to compete with a big box store – you’ve got to offer something special.

High Failure Rate For Startups

Let’s be real, space startups have a notoriously high failure rate. Building rockets is incredibly complex and expensive. One bad launch, one technical glitch, and poof, all that hard work and investor money can go up in smoke. It’s not just about having a cool idea; it’s about flawless execution, rigorous testing, and a whole lot of resilience. Many companies that aim for the stars often find themselves grounded by the harsh realities of engineering and finance. The path forward for Leo Aerospace companies is paved with both incredible potential and significant risk.

Innovation Within Leo Aerospace

Leo Aerospace companies aren’t just building rockets; they’re rethinking how we get to space and what we do when we get there. It’s a wild time, with new ideas popping up all over the place.

Additive Manufacturing In Rocketry

Think of 3D printing, but for rockets. That’s additive manufacturing. Instead of traditional methods that involve lots of separate parts and complex assembly, companies are printing entire rocket engines or components. This can seriously cut down on production time and cost. Plus, it allows for really intricate designs that were impossible before, potentially making engines more efficient. It’s not just about making things faster; it’s about making them better and cheaper.

Developing Reusable Boosters

This is a big one. For a long time, rockets were basically one-and-done. You launched them, and they either burned up on re-entry or landed in the ocean. Now, companies are working hard to make the first stage of the rocket reusable. The idea is that after the booster separates from the main rocket, it can fly itself back to Earth and land safely, ready to be used again. This is a game-changer for launch costs. If you can reuse the most expensive part of the rocket, you can launch a lot more often for a lot less money. It’s like reusing the engine of a car instead of buying a new one every time you need to drive somewhere.

Exploring Sea Launch Capabilities

Launching from land is pretty standard, but what about launching from the ocean? Some companies are looking at using ships or offshore platforms as launch sites. This offers a few advantages. For starters, it can provide more flexibility in choosing launch trajectories, especially for polar orbits. It also means you don’t need to build expensive launch pads on land, and you can move the launch site around to avoid populated areas. It’s a bit more complicated logistically, sure, but it opens up new possibilities for getting payloads into orbit.

The Long Road Ahead for Small Launchers

So, what’s the takeaway from Leo Aerospace’s journey and the broader small launch market? It’s clear that while the dream of making space more accessible with smaller rockets is a powerful one, the reality is tough. We’ve seen how many companies are trying to break into this field, but the competition is fierce, and the big players, like SpaceX, are hard to beat on price. It’s a bit like trying to sell a niche product when a giant retailer offers something similar for way less. Many of these startups, Leo Aerospace included, faced huge hurdles. Whether they can keep pushing forward, find their unique spot, and actually make a profit is still very much up in the air. It’s a challenging business, for sure, and only time will tell which of these ambitious ventures will truly make it.

Frequently Asked Questions

What are small launch companies?

Small launch companies are businesses that build and fly rockets designed to carry smaller satellites into space. Think of them as the delivery trucks for tiny, high-tech packages going to orbit, rather than the giant cargo ships.

Why are there so many small rocket startups?

The idea of sending small satellites is becoming really popular, and it’s cheaper and easier to start a company that builds small rockets compared to huge ones. This means more people and regions can try to get into the space business.

Are small rockets good for quick missions?

Yes! Small rockets are often faster to get ready for launch. This is great for situations where you need to send a satellite up quickly, like for testing new technology or responding to urgent needs.

Who are some big names in small rockets?

Companies like Rocket Lab from the US and Galactic Energy from China are leading the pack. They’ve managed to launch rockets successfully and are becoming well-known in the space industry.

Are small rockets facing competition?

Definitely. Even though there are many small rocket companies, bigger rockets like those from SpaceX can sometimes offer cheaper rides for small satellites. Plus, the small rocket market is getting crowded, making it tough for some companies to survive.

What’s new in small rocket technology?

Companies are using cool new methods like 3D printing to build rockets faster and cheaper. Some are also looking into making their rockets reusable, meaning they can be used more than once, which saves money and resources.