Dealing with the healthcare supply chain can feel like a juggling act, right? Things are always changing, and keeping everything running smoothly is a big job. From making sure medicines stay at the right temperature to figuring out why certain supplies suddenly disappear, it’s a constant puzzle. Plus, with global events and the need for more local production, it’s more complicated than ever. Let’s break down some of the main points about how the healthcare supply chain works and what we can do to make it better.

Key Takeaways

- The healthcare supply chain is vital for patient care, but it faces constant disruptions and shortages.

- Managing temperature-sensitive items and preventing product shortages are major hurdles.

- Building resilience through better communication and cost control is key to a strong supply chain.

- Technology like AI and real-time tracking can significantly improve supply chain operations.

- Collaboration between partners and transparency are essential for optimizing inventory and managing risks.

Understanding the Healthcare Supply Chain Landscape

The healthcare supply chain is pretty complicated, isn’t it? It’s basically the whole system that gets medical stuff, from bandages to complex machines, to the people who need them, like doctors and nurses. When it works right, patients get the care they need, when they need it. But when it doesn’t, well, that’s when things get messy.

The Critical Role of Healthcare Supply Chain Management

Think about it: if a hospital runs out of something as simple as sterile gloves or a specific medication, it can stop procedures cold. That’s why managing this whole process is so important. It’s not just about ordering supplies; it’s about making sure the right things are in the right place at the right time, all while keeping costs in check. Getting this right means better patient care and smoother operations.

Navigating Persistent Disruptions and Shortages

Lately, it feels like there’s always something going wrong. We’ve seen shortages of everything from basic items like saline solutions to more specialized things like contrast dyes used in scans. A lot of this is because so much of what we need is made overseas. When there are problems in other countries, like trade issues or even natural disasters, it hits us right here. Plus, things like inflation and not having enough workers also make it harder to keep shelves stocked. It’s not just a little hiccup anymore; for many supply chain folks, dealing with shortages takes up a huge chunk of their week, sometimes more than 10 hours, and for some, it’s over 80 hours! This means doctors sometimes have to cancel or reschedule appointments, which is just awful for patients.

Impact of Global Dependencies and Geopolitical Tensions

We rely on countries all over the world for different parts and products. For example, a lot of essential gases used in healthcare come from just a few places. If there’s a conflict or political tension in one of those regions, it can cause big problems for us. This global connection means that what happens far away can directly affect whether a hospital has what it needs to treat someone. It’s a constant balancing act, trying to figure out where things come from and what could go wrong.

Addressing Key Challenges in Healthcare Supply Chains

The healthcare supply chain is a complicated beast, and let’s be honest, it’s been through a lot lately. We’ve seen shortages pop up for all sorts of things, from basic gauze to specialized drugs. It feels like every week there’s a new problem to figure out. The unpredictability of these shortages is what really makes managing them a headache. It’s not just about having enough stuff; it’s about having the right stuff, when and where it’s needed, and making sure it’s still good when it gets there.

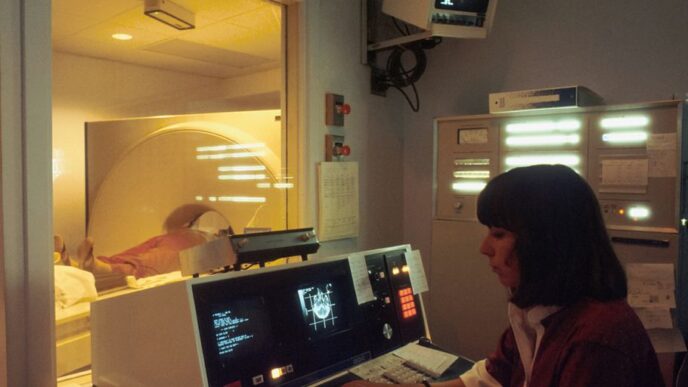

Managing Temperature-Sensitive Products

Some medical products are really picky about their environment. Think vaccines or certain biotech drugs – they need to stay within a specific temperature range from the moment they’re made until they reach the patient. Even a small temperature bump can ruin them, which is a huge waste and, more importantly, can be dangerous. We’re talking about needing special trucks, careful monitoring, and packaging that can keep things cool for ages. It’s a whole separate layer of complexity that adds to the cost and the risk.

Combating Product Shortages and Demand Spikes

This is probably the most talked-about issue. We’ve got shortages happening more often, and they can be pretty random. One month it’s contrast dye, the next it’s a particular antibiotic. These shortages aren’t just inconvenient; they can actually force hospitals to delay or even cancel surgeries and treatments. Trying to guess when demand will suddenly shoot up is tough, and when production gets interrupted somewhere along the line, it creates a ripple effect that hits us hard. Having backup plans and working closely with suppliers are key here, but it’s a constant juggling act. You can find more insights on the topic here.

Ensuring Traceability and Authenticity

Knowing where every single item came from and where it’s going is super important. This helps make sure we’re not accidentally using fake or tampered-with medications or devices. Without clear tracking, it’s hard to be sure everything is legitimate and safe. It also means that if there is a problem, like a recall, we can pinpoint exactly which products are affected and get them out of circulation quickly. This is all about patient safety and keeping things above board with regulations.

Strategies for Enhancing Supply Chain Resilience

It’s tough out there for healthcare supply chains right now. We’ve all seen the news about shortages and delays, and it feels like things are just getting more complicated. But there are ways to build a stronger, more reliable system. It’s not about hoping for the best; it’s about planning for the worst and building in flexibility.

Prioritizing Resilience and Competitive Advantage

Think of supply chain resilience not as an extra cost, but as a way to get ahead. Organizations that really focus on this are the ones that invest in making their whole system digital, and they spend smart on people, operations, and the right technology. It’s about seeing this as a core part of how you compete. Building a supply chain that can handle unexpected bumps means you can keep providing care without interruption, which is a huge advantage. We need to look at making our supply chains more robust, and that means looking at where our products come from and how we get them. Diversifying suppliers and looking at domestic production are big parts of this. You can find more information on how to build a stronger supply chain here.

Developing Proactive Communication Plans

When disruptions happen, and they will, having a plan to talk to everyone involved is key. This means reaching out to your suppliers before there’s a problem, figuring out what you can use if something isn’t available, and setting up ways to plan and work together using data. It also means having a good stock of critical items, like personal protective equipment (PPE). Working closely with the companies you buy from helps you understand what’s going on and manage the impact of any issues. A good communication plan can make a big difference when things get tough.

Controlling Costs and Optimizing Revenue

It’s also about being smart with money. Healthcare systems need to find ways to cut costs where they can, while also making sure the parts of the business that bring in money, like operating rooms and specialty pharmacies, are running as smoothly as possible. This means keeping a close eye on what you’re buying, getting leaders involved, and making sure everyone is accountable. By managing costs and making sure revenue streams are strong, you create a more stable financial picture, which helps support your supply chain efforts.

Leveraging Technology for Supply Chain Improvement

It feels like everywhere you look these days, technology is being talked about as the answer to all our problems, and the healthcare supply chain is no different. We’re seeing a big push to use digital tools to get a clearer picture of what’s happening from start to finish. Think of it like having a live map of all your medical supplies, instead of just getting a report a week later. This kind of visibility helps spot issues early, like a shipment getting delayed or a product running low in a specific hospital. Getting this real-time view is key to making smarter, faster decisions.

Embracing Digitization for Supply Chain Visibility

So, what does this digitization actually look like? It’s about moving away from paper trails and old computer systems to more connected, digital platforms. This means using things like cloud-based software that can track products as they move from the manufacturer all the way to the patient. It helps manage shipping better, keeps an eye on how things are performing, and can even help find ways to save money by making sure every dollar spent is accounted for. It’s about having all the information in one place, so you’re not chasing down details from different departments or suppliers.

Utilizing AI and Predictive Analytics

Beyond just seeing what’s happening now, technology can help us guess what might happen next. Artificial intelligence (AI) and predictive analytics are getting a lot of attention for this. By looking at past data – like how much of a certain medication was used last winter or during flu season – these tools can help predict future needs more accurately. This means hospitals and clinics can order the right amount of supplies, avoiding both shortages and having too much stock sitting around. It’s about being proactive instead of just reacting when a problem pops up. For example, better forecasting can help make sure critical medicines are available when patients need them most.

Implementing Real-Time Tracking and Delivery Verification

Finally, there’s the actual movement of goods. Real-time tracking means knowing exactly where a shipment is at any given moment. This is especially important for things that need to be kept at specific temperatures, like certain vaccines or medications. Delivery verification goes a step further, confirming that the right items arrived at the right place, in the right condition. This helps prevent errors, ensures product integrity, and gives everyone involved peace of mind. It’s about making sure the right product gets to the right patient, safely and on time.

The Power of Collaboration in Healthcare Supply Chains

It’s pretty clear by now that nobody can go it alone in the healthcare supply chain game. The old way of just trying to get the best deal for yourself, no matter what, just doesn’t cut it anymore. We saw that big time during the pandemic – when one part of the chain broke, everything else felt the ripple effect. So, working together isn’t just a nice idea; it’s pretty much a necessity if we want things to run smoothly and keep patients getting what they need.

Breaking Down Silos for Effective Risk Management

Think about it: different departments within a hospital, or even different companies that make medical supplies, often operate in their own little worlds. They might not share information about potential problems, like a supplier having issues or a sudden jump in demand for a certain product. This lack of communication means risks can build up without anyone really noticing until it’s too late. When everyone starts talking and sharing what they know – even the not-so-good stuff – it’s way easier to spot trouble early. This means you can actually do something about it before it becomes a full-blown crisis. It’s like having a bunch of people watching the road instead of just one person. More eyes mean fewer surprises.

Fostering Partnerships for Inventory Optimization

Nobody wants to be stuck with too much of one thing and not enough of another. That’s where partnerships really shine. Instead of each hospital or clinic trying to guess how much of a certain drug or piece of equipment they’ll need, they can team up. Maybe a manufacturer works directly with a hospital system to manage their stock. This way, the manufacturer knows what the hospital needs and can make sure it’s there, and the hospital doesn’t have to tie up a ton of money in inventory that might just sit there. It’s about sharing the load and the risk, and usually, it means less waste and better availability for everyone involved. It’s a win-win, really.

Building Trust and Transparency with Stakeholders

All this collaboration stuff only works if people trust each other and are open about what’s going on. If a supplier is having a problem getting raw materials, they need to be able to tell their customers honestly, instead of just hoping for the best. And customers need to be upfront about their demand. When you build that trust, you can work through problems together. It means being clear about pricing, about delivery times, and about any potential hiccups. This open communication is the glue that holds these partnerships together and makes the whole supply chain stronger. When everyone feels like they’re on the same team, working towards the same goal, it makes a huge difference.

Future Outlook and Innovative Solutions

Looking ahead, the healthcare supply chain is really starting to shift gears. The pandemic showed us just how fragile things can get when we rely too much on one place for our supplies. Now, there’s a big push to bring manufacturing back home and spread out where we get our stuff from. It’s not just about having enough, but about having it reliably, no matter what’s happening in the world. This move towards diversifying sources and strengthening domestic production is key to building a more stable system.

We’re also getting smarter about predicting problems. Tools that use advanced analytics can look at past data and give us a heads-up about potential shortages, sometimes with over 90% accuracy. This means we can get ahead of issues before they even start, which is a huge win for keeping things running smoothly and making sure patients get what they need. It’s all about being proactive instead of just reacting to crises.

Diversifying Sourcing and Strengthening Domestic Production

Predicting Product Shortages with Advanced Analytics

Driving Innovation Through Strategic Technology Adoption

Moving Forward: Building a Stronger Healthcare Supply Chain

So, after looking at all this, it’s pretty clear the healthcare supply chain is a tough nut to crack. We’ve seen how things like global events, unexpected shortages, and even just getting products where they need to go on time can really mess things up. It’s not just about having the right stuff; it’s about making sure it gets there safely and without costing a fortune. But the good news is, people are working on it. By focusing on things like better communication with suppliers, using new technology to keep track of everything, and even looking at where our products come from, we can make things better. It’s a big job, but getting this right means better care for patients, which is what it’s all about.

Frequently Asked Questions

What exactly is the healthcare supply chain and why is it important?

Think of the healthcare supply chain like a giant delivery system for all the things hospitals and doctors need, like medicines, bandages, and special machines. It’s a bit like getting groceries delivered to your house, but way more important because it’s about keeping people healthy. This system has faced a lot of problems lately, like not having enough supplies or things getting delayed, which can make it harder for doctors to treat patients.

What are ‘disruptions’ in the healthcare supply chain?

Imagine you need a special medicine, but it’s suddenly hard to find because the factory that makes it had a problem, or maybe there was a big storm that stopped trucks from delivering it. These kinds of unexpected problems, like shortages or delays, are what we mean by disruptions. They happen a lot in healthcare because so many things need to come from different places all over the world.

Why do problems in other countries affect our medical supplies?

Sometimes, certain medicines or medical tools are made in only a few places far away. If something happens in those places, like a new rule or a natural disaster, it can stop us from getting what we need. This is called being dependent on other countries. It’s like if your favorite toy was only made in one factory, and that factory closed – you wouldn’t be able to get the toy anymore.

What does it mean to manage ‘temperature-sensitive products’?

Some medicines and treatments need to be kept very cold, like ice cream. If they get too warm, they can spoil and won’t work anymore. So, the delivery system has to be extra careful to keep them at the right temperature all the way from where they’re made to the hospital. This is called managing ‘temperature-sensitive products’.

How can we make the healthcare supply chain stronger and more reliable?

This means making sure we have enough of the important medical supplies and medicines, even when unexpected things happen. It’s like having a backup plan. We can do this by finding different places to get our supplies from, working closely with the companies that make them, and using smart technology to predict when we might run out of something.

How does technology help improve the healthcare supply chain?

Using technology helps a lot! We can use computers and apps to see exactly where our supplies are at any moment, like tracking a package online. We can also use smart computer programs that can guess when we might have shortages before they happen. Working together with other companies and sharing information also makes the whole system work better and keeps everyone safer.