So, you know, the world of making computer chips is pretty big and always changing. It’s not just about the chips themselves, but also all the special machines that make them. These machines are super important for everything from your phone to big data centers. We’re going to look at how these companies that make the equipment are doing, what new stuff is coming out, and some of the tricky parts of doing business globally. It’s all about understanding the folks who make the tools for the tech we use every day, the semiconductor equipment suppliers.

Key Takeaways

- The semiconductor world has different parts, from designing chips to making them. Each part needs special tools.

- Some big companies make the equipment for semiconductors, but smaller, newer companies are also showing up with cool ideas.

- New ways of making chips, like better lithography and advanced packaging, are making the equipment market grow.

- Where these companies do business matters a lot, especially with things like trade issues between the U.S. and China.

- Making semiconductor equipment costs a lot of money, and there are risks with supply chains, but there are also chances for new business.

Understanding the Semiconductor Ecosystem

Breaking Down the Semiconductor Value Chain

The semiconductor industry is complex, with many steps from design to finished product. It’s helpful to think of it as a chain, where each link is vital. This chain includes everything from research and development to manufacturing, testing, and packaging. Each stage requires different skills, equipment, and investments. Understanding this chain is key to understanding the whole industry. It’s not just about making chips; it’s about the entire process that makes it possible. For example, you can think of it like this:

- Design: Creating the blueprint for the chip.

- Manufacturing: Actually building the chip in a fab.

- Packaging: Protecting the chip and connecting it to other components.

Upstream: Chip Design and R&D

This is where the magic starts. Upstream involves the companies that design the chips and conduct the research and development. These companies don’t actually make the chips themselves. Instead, they create the designs that are then sent to manufacturers. This part of the industry is all about innovation and pushing the boundaries of what’s possible. It requires a lot of brainpower and investment in new technologies. The eye technology market is a good example of an industry that relies heavily on upstream innovation. It’s a high-risk, high-reward area, but it’s essential for the entire semiconductor ecosystem.

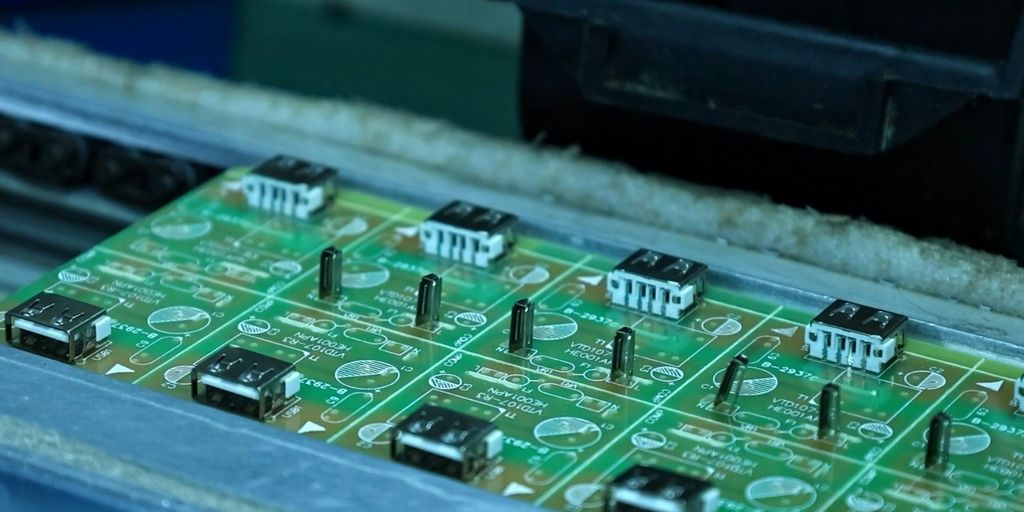

Midstream: The Billion-Dollar War for Chip Manufacturing

Midstream is where the chips are actually made. This is a capital-intensive business, requiring huge factories (fabs) and advanced equipment. Only a few companies in the world can compete at this level. The cost of building and equipping a fab can easily run into the billions of dollars. It’s a constant race to develop smaller, faster, and more efficient chips. This part of the industry is also heavily influenced by geopolitical factors, as countries compete to secure their access to chip manufacturing capabilities. It’s a tough business, but it’s at the heart of the semiconductor industry. The equipment used in this stage is very specialized, and the companies that make this equipment are key players in the overall ecosystem.

Key Players in Semiconductor Equipment Suppliers

Leading Semiconductor Equipment Manufacturers

When you think about who makes the machines that make the chips, a few names always come up. These companies are the giants, the ones with the biggest market share and the most influence. ASML is a big name because of their lithography systems, which are super important for making advanced chips. Then you have Lam Research and Tokyo Electron, both making a range of equipment used in different parts of the chip-making process. KLA is another key player, specializing in inspection and metrology equipment, which makes sure the chips are being made correctly. These companies aren’t just selling equipment; they’re shaping the future of the whole industry.

Emerging Innovators in Equipment Technology

It’s not just the big guys that matter. There are also smaller, more specialized companies that are coming up with new ideas and technologies. These innovators might focus on a specific area, like advanced packaging or new materials. They often work closely with chip manufacturers to test out their new equipment and processes. Keeping an eye on these emerging companies is important because they could be the ones that come up with the next big breakthrough.

Here are some areas where these innovators are making waves:

- Advanced packaging equipment

- Equipment for new materials

- AI-powered equipment optimization

Strategic Partnerships and Collaborations

No one can do it all alone in the semiconductor world. That’s why you see a lot of partnerships and collaborations between equipment manufacturers, chip makers, and research institutions. These partnerships let companies share knowledge, resources, and risks. For example, an equipment maker might work with a chip manufacturer to develop a new process, or a research lab might partner with a company to commercialize a new technology. These collaborations are key to driving innovation and keeping the industry moving forward. It’s a complex web of relationships, but it’s what makes the semiconductor industry so dynamic.

Technological Advancements Driving Growth

Lithography Advancements and Their Impact

Lithography is still super important. The push for smaller, more powerful chips means lithography tech needs to keep getting better. We’re talking about things like EUV (extreme ultraviolet) lithography, which lets companies make chips with smaller features. This isn’t just about shrinking stuff down; it’s about making chips that are faster and use less power. The progress is slowing down a bit as we hit some physical limits, but new methods are still being developed.

The Rise of Advanced Packaging Technologies

It’s not just about what’s on the chip, but how you put it all together. Advanced packaging is becoming a big deal. Instead of just laying chips side-by-side, companies are stacking them on top of each other. This makes things more compact and improves performance. Think of it like building up instead of out. This is especially important for things like AI and high-performance computing, where you need a lot of power in a small space. The demand for high transistor-density devices is surging, driven by AI applications.

AI and Machine Learning in Equipment Optimization

AI isn’t just in the chips; it’s helping make them. Companies are using AI and machine learning to optimize the equipment used to manufacture semiconductors. This means things like predicting when equipment needs maintenance, adjusting settings to improve yield, and even designing new processes. It’s all about making the manufacturing process more efficient and less wasteful. This helps with equipment optimization and keeps costs down, which is always a good thing.

Navigating Global Market Dynamics

Regional Dynamics and Investment Strategies

Okay, so the semiconductor game isn’t played the same everywhere. You’ve got the Western regions, like the US and Europe, with their own strengths and weaknesses. Then you have Asia, which is a HUGE player, especially with manufacturing. Understanding these regional dynamics is key. It’s not just about where chips are made, but also where the money is flowing. Who’s investing where, and why? These investment strategies are shaping the future of chip production.

The Impact of U.S.-China Trade Tensions

Let’s be real, the U.S.-China thing is a big deal. It’s like this constant tug-of-war that affects everyone. Trade restrictions and tariffs can seriously mess with the supply chain, making it harder (and more expensive) to get stuff where it needs to go. Plus, it pushes companies to rethink where they’re doing business. Are they too reliant on one country? Should they move some operations elsewhere? It’s a headache, but companies have to deal with it.

Diversifying Supply Chains for Resilience

Speaking of headaches, relying on just one or two suppliers is a recipe for disaster. If something goes wrong – a natural disaster, a political issue, whatever – you’re screwed. That’s why diversifying supply chains is so important. It’s about spreading the risk around. Find new suppliers, build relationships in different countries, and don’t put all your eggs in one basket. It might cost a bit more upfront, but it’s worth it for the peace of mind. China’s OSAT expansion is something to keep an eye on, as well as U.S. export restrictions on chip equipment.

Challenges and Opportunities for Semiconductor Equipment Suppliers

Biggest Challenges in Semiconductor Manufacturing

Okay, so, making semiconductors isn’t a walk in the park. One of the biggest headaches is just how complex the whole process is getting. We’re talking about needing super precise equipment, and keeping up with the demand for smaller devices that do more is a constant race. Plus, there’s the ever-present pressure to cut costs while still pushing the limits of what’s possible. It’s a tough balancing act. Here’s a quick rundown of some key challenges:

- Maintaining Moore’s Law is getting harder and more expensive.

- The need for extreme precision in manufacturing processes.

- Keeping up with the demand for increasingly complex chip designs.

Capital Investment and Fab Construction Costs

Building a new fab? Get ready to open your wallet wide. These things cost billions, and the price tag just keeps going up. It’s not just the construction itself; it’s the advanced equipment, the specialized workforce, and the ongoing maintenance. Securing funding for these projects is a major hurdle, and it means companies need to be really smart about their investment strategies. It’s a high-stakes game, and only those with deep pockets (or really convincing business plans) can play. The cost of semiconductor capital equipment is a barrier to entry for smaller players.

Supply Chain Risks and Geopolitical Tensions

The world of semiconductors is global, which means it’s also vulnerable. Geopolitical tensions, like the U.S.-China trade tensions, can throw a wrench into the whole system. We’ve seen how easily supply chains can be disrupted, whether it’s due to trade wars, natural disasters, or even just plain old logistical snags. Companies are now scrambling to diversify their supply chains and bring manufacturing closer to home, but that’s easier said than done. It’s all about securing semiconductor supply chains in an uncertain world. The industry is implementing export controls, reshoring initiatives, and strategic alliances to mitigate these risks.

Future Outlook for Semiconductor Equipment Suppliers

Predictive Insights for Industry Roadmaps

Okay, so what’s next for the semiconductor equipment world? Honestly, trying to predict the future is always a bit of a gamble, but we can look at current trends and make some educated guesses. One thing is for sure: the demand for more advanced chips isn’t going away anytime soon. That means equipment suppliers need to be ready to support the development of even smaller, faster, and more efficient semiconductors. We’re talking about things like:

- Investing in new materials research.

- Improving equipment precision and reliability.

- Working closely with chip manufacturers to anticipate their needs.

Anticipating Next-Generation Semiconductor Products

Think about where technology is headed. Self-driving cars, AI, the metaverse – all of these things need serious computing power. And that computing power comes from semiconductors. So, equipment suppliers need to be thinking about what kinds of chips these applications will require. Will it be more specialized chips? Will there be a shift towards new architectures? These are the questions that will shape the future of the industry. The Underground Mining Equipment Market is also seeing similar advancements, requiring robust and efficient technologies.

Sustaining Innovation in a Dynamic Market

This industry moves fast. What’s cutting-edge today is old news tomorrow. To stay ahead, semiconductor equipment suppliers need to be constantly innovating. That means investing in R&D, fostering a culture of creativity, and being willing to take risks. It also means keeping a close eye on what’s happening in other parts of the world. The semiconductor landscape trends and investments are constantly evolving, and companies need to be agile enough to adapt. Here’s a quick look at some key areas for sustained innovation:

- Advanced Lithography: Pushing the boundaries of what’s possible with EUV and beyond.

- Advanced Packaging: Developing new ways to connect chips and improve performance.

- Materials Science: Exploring new materials that can enable smaller, faster, and more efficient transistors.

Conclusion

So, that’s a quick look at the companies that make the stuff for semiconductors. It’s a pretty important area, especially with how much we use electronics these days. These companies are always working on new things, trying to make chips better and faster. It’s a tough business, with lots of changes happening all the time. But, they keep pushing forward, and that’s what helps all our gadgets work. It’ll be interesting to see what they come up with next.

Frequently Asked Questions

What exactly do semiconductor equipment suppliers do?

Semiconductor equipment suppliers make the special machines and tools needed to create computer chips. Think of them as the companies that build the factories and all the gear inside those factories that turn raw materials into the tiny brains of our electronics.

Why are these suppliers so important?

These companies are super important because without their fancy machines, we couldn’t make the chips that power our phones, computers, cars, and everything else. They’re like the unsung heroes behind all our modern tech.

Who are the main players in this industry?

Some of the big names you might hear are ASML, Applied Materials, Lam Research, and KLA. They’re the giants in this field, but there are also many smaller, clever companies coming up with new ideas.

What new technologies are changing this industry?

They’re always working on making machines that can print smaller lines on chips (this is called lithography), pack more chip parts into tiny spaces, and use smart computer programs like AI to make everything work better and faster.

What are the biggest challenges these companies face?

Things like trade disagreements between countries, especially the US and China, can make it tricky. Also, building a chip factory costs a huge amount of money, and making sure all the parts get to the right place on time can be a big headache.

What does the future hold for semiconductor equipment suppliers?

The future looks bright but busy! We’ll see more advanced chips, more factories being built in different parts of the world, and a constant push for new inventions to keep up with our growing need for faster and smarter electronics.