The world of semiconductors is moving fast. It feels like every day there’s a new challenge or a big change happening. Whether it’s making sure we have enough chips or figuring out how to make them in a way that’s better for the planet, it’s a lot to keep up with. That’s where semiconductor consultants come in. These folks know the ins and outs of the industry and can help businesses figure out the best way forward, especially when things get complicated.

Key Takeaways

- Working with semiconductor consultants can help businesses get a better handle on their supply chains. They can help find new suppliers and use digital tools to see where everything is, making things more stable.

- These consultants can guide companies in using new tech like AI and digital twins for designing and making chips, which helps with innovation and staying ahead.

- Finding and keeping good workers is a big problem. Semiconductor consultants can help set up training programs and connect schools with companies to get more skilled people into the field.

- Making chips in a way that’s good for the environment is becoming more important. Consultants can advise on using clean energy and developing products that are more sustainable.

- When the market is always changing, semiconductor consultants offer expert advice. They help businesses plan for the future, build factories smarter, and work with others to get an edge.

Navigating Supply Chain Resilience with Semiconductor Consultants

The semiconductor world is pretty wild right now, and keeping your supply chain steady feels like trying to balance a stack of microchips on a windy day. Geopolitical stuff, not enough factory space, and leaning too hard on just a few suppliers – these are the big headaches everyone’s dealing with. It’s no wonder so many companies aren’t super confident about their supply lines. But that’s where consultants come in. They help you see the whole picture and figure out how to make things more stable.

Mitigating Geopolitical Risks Through Strategic Sourcing

Things happening in different countries can really mess with getting the parts you need. Think trade wars, export rules, or just general tension. Consultants can help you figure out where the risks are and how to work around them. They help you find ways to get your materials and chips from places that are less likely to be affected by these global headaches. This might mean looking at suppliers closer to home or finding partners in regions that are more politically stable. It’s all about not putting all your eggs in one basket, especially when that basket is in a shaky spot.

Diversifying the Supplier Base for Enhanced Stability

Relying on just one or two suppliers is a risky game. If they have a problem, you have a problem. Consultants can help you map out your current suppliers and identify opportunities to bring in new ones. This doesn’t just mean finding more companies; it means building a network. They can help you look at domestic options, which are becoming more popular, or explore nearshoring to cut down on long shipping routes. The goal is to spread out your risk so that a hiccup in one place doesn’t stop everything.

Here are some ways consultants help diversify:

- Supplier Mapping: Identifying current dependencies and potential new partners.

- Risk Assessment: Evaluating the stability and reliability of different supplier regions.

- Partnership Development: Facilitating connections with new, reliable sources.

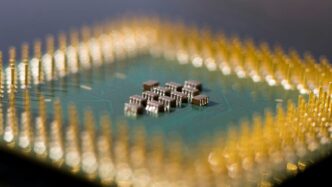

Leveraging Digital Tools for Supply Chain Visibility

It’s tough to manage what you can’t see. Consultants can introduce you to digital tools that give you a real-time look at your entire supply chain. Think of it like having a dashboard for everything, from raw materials to finished products. These tools can help you spot potential problems before they become big issues. For example, using digital twins allows for simulations that can highlight weak spots in your chain. This kind of visibility means you can react faster and keep things moving smoothly, even when unexpected things happen.

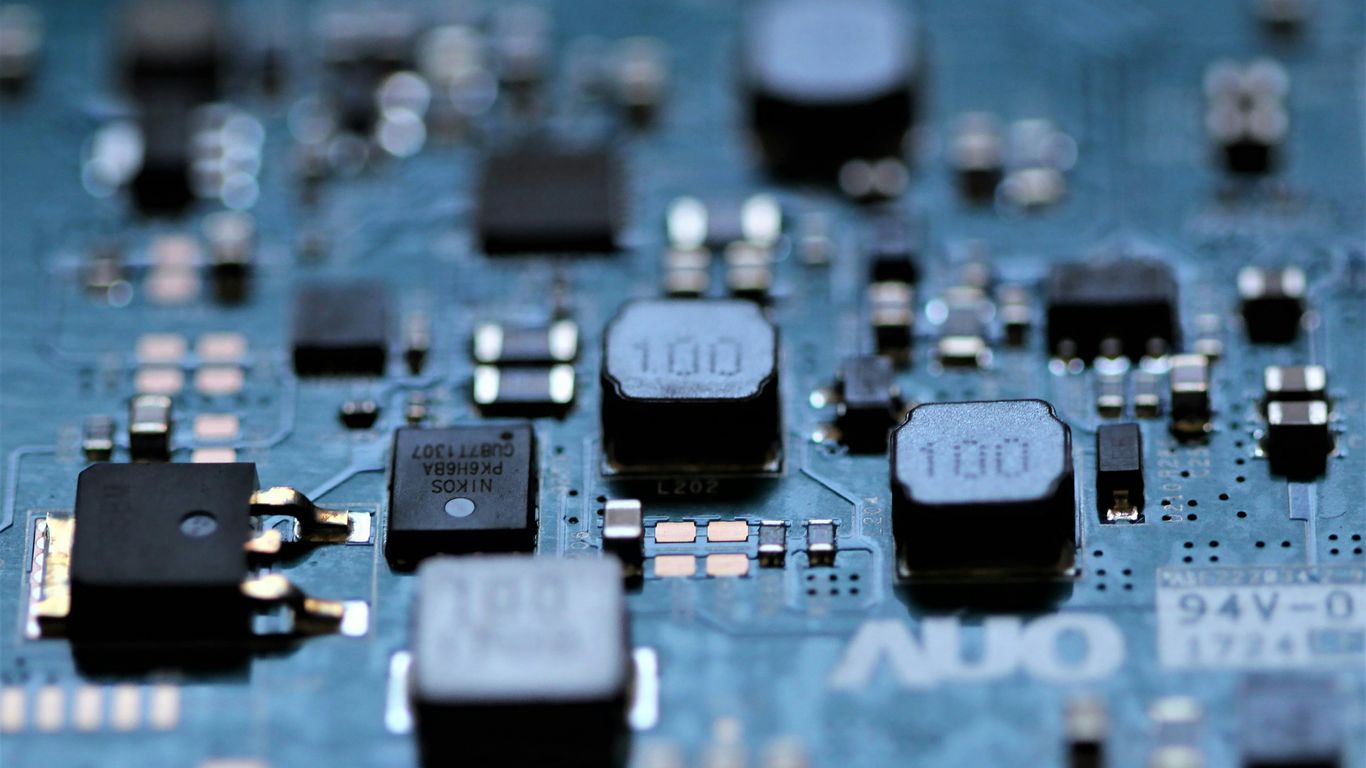

Embracing Innovation with Expert Semiconductor Consultants

The semiconductor world is moving fast, and staying ahead means really leaning into new ideas. It’s not just about making chips anymore; it’s about making them smarter, faster, and more efficient. This is where bringing in some outside help can make a big difference. Consultants can guide you through the latest tech, helping you figure out what’s worth investing in and how to actually make it work for your business.

Integrating Generative AI into Semiconductor Processes

Generative AI is a hot topic, and for good reason. It’s not just for creating art or writing text; it’s starting to show up in how we design and even manufacture semiconductors. Think about using AI to help design new chip layouts or to find problems in existing ones before they become big issues. It can speed up the design cycle significantly. We’re seeing AI used to optimize manufacturing processes too, making things run smoother and reducing waste. This technology has the potential to cut down design time by as much as 30%. Consultants can help you figure out the best AI tools for your specific needs and how to integrate them without disrupting your current operations.

The Role of Digital Twins in Advanced Chip Design

Digital twins are like a virtual copy of a physical thing, and in chip design, they’re becoming super important. Imagine having a perfect digital model of your chip that you can test and tweak endlessly without actually building anything. This lets engineers try out different ideas, simulate how the chip will perform under various conditions, and catch potential flaws early on. This ‘shift-left’ approach, where you identify problems earlier in the process, saves a ton of time and money. Consultants can help you set up and use these digital twins effectively, whether it’s for a single device, a manufacturing process, or even the equipment used in production.

Developing Software-Defined Semiconductors

We’re moving towards a future where chips are more flexible and can be updated through software, much like your smartphone. These software-defined semiconductors (SDSs) allow for greater adaptability and can be tailored for specific tasks without needing a complete hardware redesign. This means products can evolve over time, and companies can respond more quickly to market changes. Developing SDSs requires a different way of thinking about design and manufacturing, often involving closer collaboration between hardware and software teams. Consultants can help you understand the implications of SDSs for your product roadmap and guide you in building the necessary design and production environments to make them a reality.

Addressing the Talent Crisis with Semiconductor Consultants

It’s no secret that the semiconductor industry is facing a serious shortage of skilled workers. We’re talking about a gap that’s projected to need over a million new people globally by 2030. This isn’t just about having enough hands; it’s about having the right skills. Think about it – the tech we rely on for everything from AI to our phones needs incredibly specialized minds to design and build. And with so many experienced folks nearing retirement, we risk losing a ton of know-how. Plus, let’s be honest, the industry sometimes struggles to grab the attention of bright young minds compared to, say, social media companies. Consultants can really help businesses get a handle on this.

Building Robust Workforce Development Programs

Companies can’t just wait for talent to show up. They need to actively build programs that train people up. This means looking beyond the usual recruitment channels. Consultants can help design programs that:

- Identify future skill needs: What will engineers and technicians need to know in five or ten years? It’s not just about current chip tech, but also about AI, automation, and new materials.

- Create hands-on training: Many universities don’t have the fancy equipment needed for real-world chip making. Consultants can help set up partnerships for apprenticeships or even in-house training facilities that mimic actual cleanroom environments.

- Develop reskilling initiatives: For existing employees, consultants can map out paths to learn new skills, keeping the company’s knowledge base strong and adaptable.

Bridging the Gap Between Academia and Industry Needs

There’s often a disconnect between what’s taught in schools and what companies actually need. University programs might be a bit too theoretical, while the industry demands practical, specialized knowledge. Consultants can act as the bridge here. They can work with educational institutions to:

- Update curricula: Suggest specific courses or modules that align with current industry demands, like advanced packaging or verification techniques.

- Facilitate internships and co-op programs: Make it easier for students to get real-world experience in semiconductor labs and manufacturing sites.

- Advise on equipment and facility investments: Help universities acquire the right tools and set up labs that give students practical exposure to industry-standard processes.

Attracting and Retaining Top Semiconductor Talent

Getting good people in the door is one thing, but keeping them is another. The competition for talent is fierce, not just within the semiconductor world but from other tech sectors too. Consultants can help companies stand out by:

- Improving employer branding: Helping companies tell their story better, highlighting the exciting work and the impact semiconductors have on the world. It’s about making the industry seem as cool as it is.

- Designing competitive compensation and benefits: Looking at salary structures, bonuses, and perks to make sure they’re attractive in today’s market.

- Creating clear career paths: Showing employees how they can grow within the company, offering opportunities for advancement and continuous learning. A clear path for growth is often more appealing than just a higher starting salary.

Driving Sustainability Initiatives with Semiconductor Consultants

The semiconductor industry is facing a growing call to operate more responsibly. It’s not just about making the next big chip anymore; it’s about how we make it and what impact it has. Consultants can really help businesses figure out how to do this better.

Utilizing Renewable Energy Sources for Manufacturing

Running a chip factory takes a ton of power. Relying on traditional energy sources means dealing with price swings and a bigger carbon footprint. Consultants can help companies explore and implement ways to use renewable energy, like solar or wind. This not only helps the planet but can also lead to more predictable energy costs over time. Switching to cleaner energy can make operations more stable and reliable. It’s a smart move for both the environment and the bottom line.

Implementing Sustainable Product Development Strategies

It’s not just about the factory; it’s about the chips themselves. Consultants can guide companies in designing chips that use less power when they’re in use. This is becoming super important as more and more devices get connected and need to be energy efficient. They can also look at the materials used in chip production and packaging, finding greener alternatives that reduce waste and pollution. Think about it: chips that perform well but sip power are a win-win.

Ensuring Environmental Efficiency in Chip Production

This is where the nitty-gritty details come in. Consultants can help analyze the entire manufacturing process to find ways to cut down on waste, water usage, and harmful chemicals. This might involve adopting new manufacturing techniques or improving existing ones. They can also help set up systems to track environmental performance, so companies know where they stand and where they need to improve. It’s about making the whole process cleaner and more efficient, step by step.

Strategic Planning with Semiconductor Consultants for Growth

Thinking about the future of your business in the semiconductor world can feel like trying to see through a fog. It’s a fast-moving industry, and knowing where to put your energy and money is key. That’s where semiconductor consultants really come in handy. They help you figure out what’s coming next so you can get ahead of the curve.

Forecasting Future Demand and Market Trends

It’s not just about guessing what people will want. Consultants look at a lot of data – things like how many new gadgets are coming out, what new technologies are being developed, and even what governments are saying about trade. They can help you see if demand for certain types of chips is likely to go up or down. For example, with more smart devices and AI everywhere, the need for specialized chips is only going to grow. Understanding these shifts early means you can adjust your production and development plans before anyone else.

Here’s a quick look at some expected growth areas:

- Consumer Electronics: More connected devices in homes and personal use.

- Automotive: Cars are becoming more like computers on wheels.

- Data Centers: The backbone of cloud computing and AI needs serious processing power.

- Industrial Automation: Factories are getting smarter and more automated.

Optimizing Fab Construction and Operation Strategies

Building a new chip factory, or ‘fab’, is a massive undertaking, costing billions. It’s not just about the initial build; running it efficiently day-to-day is just as important. Consultants can help you make smart choices here. They look at things like:

- Location: Where is the best place to build, considering resources, workforce, and government support?

- Technology: What equipment should you buy to be efficient now and in the future?

- Process Flow: How can you arrange everything to make chips as quickly and with as little waste as possible?

- Energy Use: How can you power the fab reliably and affordably, maybe even using greener sources?

They can also help you plan for the long haul, making sure your fab can keep up with new chip designs and changing market needs without costing a fortune to update.

Securing Competitive Advantage Through Collaboration

No company operates in a vacuum. In the semiconductor industry, working with others is often the best way to get ahead. Consultants can help you find the right partners. This could mean:

- Joint Ventures: Teaming up with another company to share the costs and risks of a big project, like building a new fab.

- Supplier Partnerships: Building stronger relationships with your material and equipment suppliers so you have a more reliable supply chain.

- Research Collaborations: Working with universities or other companies to develop new technologies that you couldn’t create alone.

By working together, companies can share knowledge, reduce costs, and speed up the development of new products. This kind of teamwork is becoming more and more important in a market that’s always changing.

The Value of Semiconductor Consultants in a Dynamic Market

The semiconductor world is always changing, and it feels like it’s moving faster than ever. Think about it: more and more of our lives are tied to electronics, and that means the demand for chips just keeps going up. Some reports even say the whole industry could hit a trillion dollars by 2030. That’s a lot of chips! But getting there isn’t simple. Building new factories, called fabs, costs billions, and designing a single chip can cost a billion too. Plus, things like AI are pushing what we can do with electronics, and we need to figure out how to make these advanced chips without breaking the bank or harming the planet.

Expert Guidance Through Industry Flux

It’s tough to keep up with all the shifts. Geopolitical issues can mess with supply chains, new technologies like generative AI pop up constantly, and everyone’s talking about making things more sustainable. Trying to manage all this on your own can feel like trying to steer a ship through a storm. That’s where consultants come in. They’ve seen these kinds of changes before and know how to help businesses adjust. They can help you figure out where the risks are and how to get around them.

Accelerating Business Growth with Specialized Knowledge

Consultants bring a specific kind of know-how that’s hard to build up internally, especially when you’re busy just trying to keep production going. They can look at your business with fresh eyes and spot opportunities you might have missed. For example, they can help you:

- Figure out which new markets are likely to grow the fastest.

- Find better ways to work with other companies to get things done.

- Plan out how to build and run your factories more efficiently.

Having someone who understands the ins and outs of the semiconductor business can make a big difference in how quickly your company grows.

Ensuring Continuous Operation and Innovation

In this fast-paced industry, staying still means falling behind. Consultants can help you stay on track with what’s next. They can advise on how to bring in new technologies, like using digital twins to design chips better, or how to develop software-defined semiconductors that are more flexible. They also help with the big picture stuff, like making sure you have the right people working for you and that your manufacturing processes are as green as possible. It’s all about keeping things running smoothly today while also getting ready for whatever tomorrow brings.

Wrapping Up: What’s Next for Your Business?

So, the chip world is changing fast. We’ve talked about how important it is to have the right people, especially with AI booming and everyone wanting more tech. It’s not just about finding folks, though; it’s about making sure they have the skills needed for today and tomorrow. Plus, keeping your supply lines strong and thinking about the planet are big deals now too. Bringing in outside help, like consultants who really know this stuff, can make a huge difference. They can help you figure out the best way forward, whether that’s getting new tech, training your team, or just making your operations smoother. Don’t get left behind – getting smart advice now could be the key to growing your business in this exciting, but tricky, industry.

Frequently Asked Questions

Why are semiconductor consultants important for businesses?

Think of semiconductor consultants like expert guides for a tricky journey. The chip world changes super fast, with new tech popping up all the time and global events affecting how chips are made and sold. These consultants know all the ins and outs. They help businesses understand these changes, make smart choices about where to get their chips, and figure out how to use the latest technology to get ahead. They’re basically there to help your business grow and avoid problems in this complex industry.

How can consultants help with supply chain problems?

Imagine trying to get all the pieces for a big Lego set, but some pieces are hard to find or come from far away. That’s like a supply chain for chips. Consultants help businesses find more places to get their chips from, so if one place has a problem, they have others. They also use cool digital tools to see exactly where everything is, making it easier to deal with unexpected issues like trade problems or natural disasters.

What’s the deal with AI and chips?

AI, like the smart programs that can write stories or create pictures, needs powerful chips to work. Consultants help companies figure out how to use AI in making chips or how to design chips that are even better for AI. They also look into things like ‘digital twins,’ which are like virtual copies of real chip designs, to test ideas faster and cheaper before actually making them.

Are there enough people to make all the chips we need?

Nope, there’s a shortage of skilled workers! It’s like needing a lot of builders for new houses but not having enough trained people. Consultants help companies create programs to train new workers, connect schools with businesses so students learn what’s needed, and find ways to attract and keep the best talent. This is super important because we need lots of chips for all our gadgets.

How do consultants help companies be more eco-friendly?

Making chips uses a lot of energy. Consultants help companies find ways to use cleaner energy, like solar or wind power, instead of just relying on fuels that can be bad for the planet and cost a lot. They also help design chips and manufacturing processes that use less energy and create less waste, which is good for the environment and can save money in the long run.

Can consultants help my business plan for the future?

Absolutely! Consultants are like fortune tellers, but with data. They study the market to guess what kinds of chips people will want in the future and how many. They also help companies plan how to build and run their factories efficiently. By working together and using smart strategies, they help businesses get an edge over their competitors and make sure they’re ready for whatever comes next.