So, you’re looking to buy silicon carbide wafers in 2025? It’s a bit of a maze out there, with lots of different companies making them and even more ways to get them. We’ll break down what you need to know, from understanding the market itself to picking the right supplier and making sure you get what you actually need. It’s not just about the price, though that’s a big part of it. We’ll cover what makes these wafers special, how to avoid common headaches, and even touch on the greener side of things. Basically, let’s get you up to speed on silicon carbide wafer manufacturers so you can make smart choices.

Key Takeaways

- The silicon carbide wafer market is growing fast, mostly because of electric cars and renewable energy needing better chips.

- When picking a supplier, think about working with them long-term and check if they really make good quality stuff consistently.

- There are different kinds of silicon carbide wafers, like 4H-SiC and 6H-SiC, and you need to match them to what you’re using them for, like power electronics or LEDs.

- Be ready for problems like supply chain delays and confusing technical specs; knowing what to ask and who to talk to can help a lot.

- More and more, companies are looking at how eco-friendly and ethically sourced the materials are when they buy silicon carbide wafers.

Understanding the Silicon Carbide Wafer Market Landscape

The silicon carbide (SiC) wafer market is really taking off right now. It’s not just a small niche anymore; it’s growing fast, and a lot of that has to do with electric vehicles (EVs) and renewable energy. Think about it: SiC wafers make power electronics in EVs work better and more efficiently, which means longer range and faster charging. Plus, solar inverters and wind turbines are using more SiC because it handles heat better and is more efficient than older materials. It’s projected that this market will jump from about $2.27 billion in 2025 to over $8 billion by 2032, growing at a rate of more than 20% each year. That’s a pretty big jump!

Key Market Dynamics and Growth Drivers

So, what’s really pushing this growth? Well, besides EVs and green energy, there’s also the constant demand for better consumer electronics. As our phones, laptops, and even smartwatches get more advanced, they need more sophisticated chips, and SiC is playing a bigger role there. The need for faster, more efficient semiconductors is pretty much everywhere. We’re seeing this demand reflected in how companies are trying to ramp up production, like GlobalWafers Co. adding thousands of advanced wafers monthly. It’s a busy time for wafer makers.

Emerging Trends in B2B Sourcing

When businesses are looking to buy these wafers, they’re not just looking at the cheapest option anymore. There’s a big trend towards spreading out where they buy from, not putting all their eggs in one basket. This means looking at suppliers in different countries and trying to build longer-term relationships. It’s all about making sure they can get the wafers they need, even if something unexpected happens, like political issues or shipping delays. Buyers are also looking for suppliers who use newer tech, like automation, to make things faster and more reliable. It’s a shift towards more stable, predictable supply chains.

Geographical Sourcing Considerations

Where you get your SiC wafers from matters. Buyers from places like Europe, the Middle East, and South America are looking closely at suppliers not just for price, but for reliability and quality. Some are even looking closer to home for faster delivery. It’s a global market, but local factors and international relations can really influence where companies decide to source their materials from. Finding the right balance between global reach and local availability is key for many businesses these days.

Navigating Supplier Selection for Silicon Carbide Wafers

Establishing Strategic Partnerships

Finding the right silicon carbide wafer supplier isn’t just about getting a good price; it’s about building a relationship that lasts. Think of it like finding a reliable partner for your business. You want someone who understands your needs, can consistently deliver quality, and is willing to work with you as your requirements change. Start by looking for manufacturers with a solid reputation in the industry. Check out what other companies are saying about them, maybe at trade shows or through industry contacts. It’s also a good idea to see if they’re open to long-term agreements, which can often lead to better pricing and a more stable supply chain. Remember, a strong partnership means they’re invested in your success, not just making a quick sale.

Evaluating Supplier Reliability and Quality Assurance

When you’re looking at potential suppliers, you really need to dig into how reliable they are and what they do to make sure their wafers are top-notch. Don’t just take their word for it. Ask for proof of their quality control processes. Things like ISO certifications are a good starting point, but it’s even better if they have specific certifications for semiconductor manufacturing. You should also ask for samples of their wafers to test yourself. This lets you see firsthand if the material meets your technical specs, like crystal orientation and purity. It’s also smart to ask about their defect rates and how they handle any quality issues that pop up. A supplier that’s transparent about their quality assurance is usually a good sign.

Understanding Minimum Order Quantities and Trade Terms

Before you commit to anything, make sure you’re clear on the supplier’s minimum order quantities (MOQs) and their trade terms. Some suppliers might have very high MOQs, which could be a problem if you’re just starting out or don’t need huge volumes right away. It’s important to find a supplier whose MOQs align with your purchasing capacity. Also, pay close attention to the payment terms, delivery schedules, and any warranty information. Understanding these details upfront can prevent a lot of headaches down the road and help you manage your budget effectively. Don’t be afraid to negotiate these terms to find something that works for both parties. Getting the ideal silicon carbide manufacturer often comes down to these practical details.

Key Silicon Carbide Wafer Types and Applications

When you’re looking for silicon carbide (SiC) wafers, it’s not just a one-size-fits-all situation. There are different kinds, and knowing which one you need really depends on what you’re trying to build. It’s a bit like picking the right tool for a job; you wouldn’t use a hammer to screw in a bolt, right?

Exploring Different Silicon Carbide Wafer Variations

There are a few main types of SiC wafers that buyers usually come across. Each has its own quirks and best uses:

- 4H-SiC Wafers: These are pretty popular, especially for power electronics. They’ve got great thermal conductivity, meaning they can handle heat really well, and they’re good for high-power stuff. Think of them as the workhorses for demanding applications. The downside? They can be a bit pricier than other options.

- 6H-SiC Wafers: These offer a decent mix of properties and tend to have fewer defects. They’re often used in things like automotive electronics and even some LED technology. They’re a solid, versatile choice if you don’t need the absolute highest thermal performance.

- Semi-Insulating SiC Wafers: If you’re dealing with high-frequency devices, these are the ones to look at. They have reduced electrical conductivity, which helps cut down on unwanted electrical interference. They’re great for RF and microwave applications, but they can be harder to find.

- Epitaxial SiC Wafers: These aren’t just plain wafers; they have a thin layer of SiC grown on top of a base wafer. This extra layer really boosts performance, making them ideal for advanced power devices and transistors where every bit of efficiency counts. The trade-off is a more complicated manufacturing process and, you guessed it, a higher cost.

- SiC Substrates: These are the basic building blocks. You can get them and then process them further for whatever you need. They’re a good, cost-effective option for general use or research, but if you need top-tier performance for advanced tech, you might need to do more work on them.

Matching Wafer Types to Industrial Applications

So, where do these different wafers actually get used? It’s pretty widespread:

| Industry/Sector | Specific Application of Silicon Carbide Wafers | Value/Benefit for the Business |

|---|---|---|

| Power Electronics | High-Power MOSFETs and IGBTs | Better efficiency and thermal performance in devices. |

| Automotive | Electric Vehicle (EV) Power Modules | Increased EV range and performance, lighter vehicles. |

| Renewable Energy | Solar Inverters and Wind Turbine Converters | Higher energy conversion efficiency, lower operating costs. |

| Telecommunications | RF and Microwave Devices | Improved signal quality and less power loss. |

| Aerospace and Defense | High-Temperature Components | Reliability in extreme conditions. |

Understanding the Pros and Cons for Buyers

When you’re making a purchase, it’s always good to know the good and the not-so-good:

- 4H-SiC: Pros: Top-notch performance in tough conditions. Cons: Can be more expensive.

- 6H-SiC: Pros: Very adaptable for different uses. Cons: Thermal performance isn’t quite as high as 4H-SiC.

- Semi-Insulating SiC: Pros: Helps reduce unwanted electrical signals. Cons: Availability can be an issue.

- Epitaxial SiC: Pros: Boosts device performance significantly. Cons: More complex to make, so they cost more.

- SiC Substrates: Pros: Cost-effective for general use. Cons: Might need extra processing for advanced applications.

Choosing the right wafer is a big deal for your project’s success. It’s worth spending time to figure out what your application truly needs. If you’re looking into advanced filtering, you might find technologies like Leaky Surface Acoustic Wave (LLSAW) worth exploring as alternatives.

Addressing Common Challenges in Silicon Carbide Wafer Procurement

Buying silicon carbide (SiC) wafers can feel like a puzzle sometimes, right? There are a few common hurdles that pop up, and knowing how to get around them makes a big difference. Let’s break down some of these issues and how to tackle them.

Mitigating Supply Chain Disruptions

It’s a real headache when you can’t get the SiC wafers you need because something went wrong somewhere else in the world. Think about things like political issues, bad weather, or even unexpected factory shutdowns. These things can stop production lines dead in their tracks. To deal with this, it’s smart to not put all your eggs in one basket. Try finding suppliers in different places. Also, making longer-term deals can help lock in your supply. Sometimes, looking for suppliers closer to home can speed things up too. Keeping a close eye on your stock levels with good software helps you plan better for those “just in case” moments. It’s all about being prepared.

Deciphering Technical Specifications for Optimal Selection

Okay, so SiC wafers have all sorts of technical details – diameter, thickness, how the crystals are lined up, and what kind of impurities are in them. It can get pretty confusing if you’re not deep in the tech weeds. Picking the wrong specs means your parts might not work as well as they should, costing you time and money. To get this right, it’s a good idea to really learn about what you need. Talk to your engineers, make a list of the must-have features for your specific use, and don’t be shy about asking suppliers for detailed info. They often have people who can help explain things. Understanding these details is key to getting the right SiC wafer for your needs.

Managing Cost Considerations and Budgetary Constraints

Let’s face it, SiC wafers aren’t cheap. Their advanced performance comes with a higher price tag, which can be tough for budgets, especially for newer companies or those in regions with tighter finances. The cost breaks down into a few main areas:

- Materials: The raw silicon carbide itself can be pricey, and its cost changes with demand.

- Labor: You need skilled people to make these wafers, and that expertise costs money.

- Manufacturing Overhead: This covers the factory, the machines, and keeping everything running.

- Tooling: Special tools are needed, and custom ones add to the bill.

Balancing the need for top-notch materials with what you can afford is a constant juggling act. It’s about finding that sweet spot where performance meets your budget.

The Role of Sustainability in Silicon Carbide Wafer Sourcing

It’s becoming pretty clear that how we get our silicon carbide (SiC) wafers matters. We’re not just looking at price and specs anymore; the whole sustainability picture is coming into play. Think about it – the semiconductor industry, including SiC production, uses a lot of energy and resources. So, companies are starting to ask more questions about where their materials come from and how they’re made.

Environmental Impact of Semiconductor Manufacturing

Making these wafers isn’t exactly a low-impact process. There are energy demands, chemical usage, and waste streams to consider. Many manufacturers are now looking at ways to reduce their carbon footprint, like using cleaner energy sources for their factories or finding more efficient ways to process materials. It’s a big shift, and it means buyers need to be aware of these environmental considerations when they’re choosing who to buy from. We’re seeing more interest in suppliers who can show they’re actively working to minimize their environmental footprint.

Ethical Sourcing of Raw Materials

Beyond the factory floor, there’s also the question of the raw materials themselves. Where does the silicon carbide come from? Are the mining and processing practices fair and responsible? This is where ethical sourcing comes in. Buyers are increasingly interested in knowing that the materials they’re using aren’t tied to any questionable labor practices or environmental damage at the source. It’s about building a supply chain that’s not just efficient but also responsible.

Meeting Regulatory Standards and Consumer Expectations

All of this ties into bigger picture stuff, like government regulations and what consumers expect. As environmental awareness grows, so does the pressure on companies to be more sustainable. Holding certifications like ISO 14001, which shows a commitment to environmental management, is becoming a real plus. Buyers are looking for suppliers who can help them meet these growing demands, not just for compliance but also to build a better brand image. It’s about aligning your sourcing with broader societal goals, and that’s a trend that’s only going to get bigger. You can find more information on market dynamics and sourcing trends in the silicon carbide wafers sector.

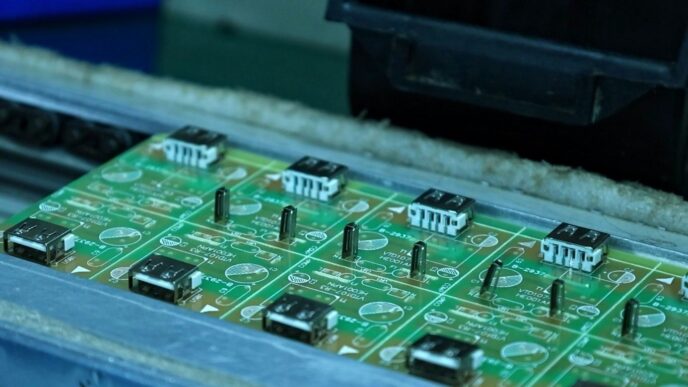

Manufacturing Processes and Quality Control for Silicon Carbide

Making silicon carbide (SiC) wafers isn’t like baking cookies; it’s a really involved process. You start with super pure SiC crystals, often made using something called the Lely method. These crystals then get purified to get rid of anything that might mess with how the wafer works electrically. After that, they’re sliced into wafers, usually 4, 6, or even 8 inches across, using special diamond saws. This slicing step is pretty important for getting the thickness and flatness just right.

Key Stages in Silicon Carbide Wafer Production

The journey from raw crystal to a usable wafer has a few main stops:

- Material Preparation: This is where the high-purity SiC crystals are selected and purified. Think of it as getting the best ingredients before you start cooking.

- Wafer Formation: The purified crystals are sliced into thin wafers. Precision is key here to get the right dimensions.

- Cleaning and Inspection: After slicing, the wafers get a thorough cleaning to remove any dust or residue. Then, they’re checked for tiny flaws like cracks or surface issues.

- Finishing: The final step is polishing the wafer surface. This is usually done with a technique called chemical-mechanical polishing (CMP) to make it super smooth and flat, ready for the next steps in making electronic parts.

Ensuring High-Quality Substrates for Advanced Applications

To make sure these wafers are good enough for advanced tech, several techniques are used. Epitaxial growth, often done with Chemical Vapor Deposition (CVD), adds thin layers to the wafer to improve its electrical performance. Doping is also done during this stage to adjust the wafer’s conductivity for specific uses. It’s all about tailoring the material.

The Importance of Purity and Crystal Orientation

Quality control is a big deal throughout this whole process. Buyers often look for certifications like ISO 9001 to know the manufacturer has good quality systems in place. They might also ask for test results from different batches.

- Testing Methods: Common tests include checking the wafer’s electrical properties, like how well it conducts electricity (resistivity) and how much voltage it can handle before breaking down. Surface analysis tools, like scanning electron microscopes (SEM), are used to look for any surface imperfections.

- Supplier Verification: For international buyers, checking a supplier’s quality control is really important. This can involve site visits to see the factory or asking for detailed quality reports.

- Logistics: When importing, things like shipping methods and customs rules matter. Making sure the wafers are packed well for transit is also part of quality assurance. The industry is moving towards larger wafer sizes, like 8-inch wafers, which is a big step for production efficiency.

Strategic Sourcing and Future Outlook for Silicon Carbide

So, you’ve got your eye on silicon carbide (SiC) wafers, which is smart. These things are becoming super important for all sorts of tech, especially with electric cars and renewable energy really taking off. But just buying them isn’t enough; you need to think about how you’re going to get them reliably and at a good price. That’s where strategic sourcing comes in. It’s all about building solid relationships with the companies that make these wafers, not just looking at the cheapest option available.

Optimizing Supply Chains for Silicon Carbide Wafers

When you’re trying to get your hands on SiC wafers, thinking about your supply chain is a big deal. You don’t want to get caught with your pants down if something goes wrong, right? This means looking at where your suppliers are located, how stable their own supply lines are, and if they have backup plans. It’s also about making sure you’re not putting all your eggs in one basket. Spreading out your suppliers, maybe even across different countries, can really help avoid problems if one region faces issues. We’re seeing a lot of companies looking into this more closely now, especially with all the global ups and downs we’ve had lately. It’s about making sure you can always get what you need, when you need it.

Securing Competitive Pricing and Reliable Supply

Getting a good price for SiC wafers is definitely a challenge, but it’s not impossible. You have to do your homework. This involves understanding the market really well, knowing what a fair price looks like, and being ready to negotiate. Sometimes, buying in larger quantities can get you a better deal, or maybe teaming up with other businesses to buy together. It’s also about looking at the total cost, not just the sticker price. A slightly more expensive wafer that lasts longer or performs better might actually save you money in the long run. Building trust with your suppliers is key here; they’re more likely to work with you on pricing if you’re a consistent, reliable customer. It’s a give and take, really.

Positioning for Future Growth in the Technology Sector

Looking ahead, the demand for SiC wafers is only going to get bigger. Think about how much electric vehicles are growing, or how much we need to improve our energy systems. SiC is right in the middle of all that. So, if you can get your sourcing sorted now, you’re setting yourself up for success down the road. It means staying on top of new developments, understanding what new types of SiC wafers might be coming out, and working with suppliers who are also innovating. This way, you’re not just keeping up; you’re actually getting ahead of the curve. It’s about making sure your business can handle whatever the future throws at it, especially in the fast-paced world of advanced power electronics.

Looking Ahead: Your SiC Wafer Sourcing Strategy

So, we’ve covered a lot about silicon carbide wafers, from what they are to how to find the right suppliers. It’s clear this material is a big deal for things like electric cars and cleaner energy. For businesses, especially those in places like Africa, South America, or Europe, getting the right wafers is key. It’s not just about the price, but also about making sure your supplier is reliable and up-to-date with new tech. The market is changing fast, with new factories popping up and competition getting tougher. Thinking about where you get your wafers from now is a smart move. Building good relationships with suppliers who can grow with your needs will help your business down the road. It’s about staying ahead in a world that needs better, more efficient electronics.

Frequently Asked Questions

What exactly are silicon carbide wafers and why are they a big deal?

Silicon carbide (SiC) wafers are super important for making advanced electronics. Think of them like the foundation for powerful computer chips. They’re used in things like electric cars because they help make the car’s electronics work better and last longer. They’re also great for renewable energy stuff, like solar panels and wind turbines, because they can handle high heat and electricity really well.

What’s happening in the silicon carbide wafer market right now?

The market for these wafers is growing fast! A lot of this is because electric cars are becoming more popular. SiC wafers make the electronic parts in these cars more efficient. Also, the world wants more clean energy, so things like solar power systems are using more SiC. Companies are also looking to buy from different places and work closely with suppliers to make sure they always have enough wafers, even if something unexpected happens.

Does being eco-friendly matter when buying silicon carbide wafers?

Yes, it’s becoming really important! Making computer chips can have an effect on the environment, so companies want to use materials that are made in a way that’s kinder to the planet. This means looking at how the raw materials are gathered and making sure the factories are using clean methods. Customers also want to know that the companies they buy from are being responsible.

How are silicon carbide wafers actually made?

Making SiC wafers is a tricky process. It starts with getting really pure silicon carbide crystals. Then, these crystals are sliced very carefully into thin wafers. After that, they go through cleaning and other steps to make sure they’re perfect for use in electronics. It’s all about making sure the wafers are super clean and have the right structure for the job.

What are some common problems buyers face when choosing silicon carbide wafers, and how can they fix them?

It can be tough to understand all the technical terms, like wafer thickness or how the crystals are lined up. These details are super important for how well the final electronic part will work. To get it right, it’s good to learn about SiC technology, talk to your company’s tech experts, and ask the suppliers for detailed information. They can often help you pick the best wafers for what you need.

Why are silicon carbide wafers so expensive, and how can buyers manage the costs?

The cost of SiC wafers can be high, which is a challenge, especially for businesses with limited money. Because these wafers are so good at handling tough conditions, they cost more than regular silicon. Buyers need to find a balance between getting the best performance and staying within their budget. Sometimes, this means looking for suppliers who offer good prices or making long-term deals.