The United States is a major player in ethanol production, and understanding how it all works is pretty interesting. We’re talking about a fuel made from plants, mostly corn, that gets mixed with gasoline. It’s a big industry, driven by policies and the need for cleaner fuels. This article looks at what’s happening in us ethanol production right now, what’s pushing it forward, and what challenges it faces.

Key Takeaways

- US ethanol production is strongly supported by government rules like the Renewable Fuel Standard and a growing desire for cleaner gas in cars.

- Corn is the main ingredient for US ethanol because there’s a lot of it grown here, the supply chain is well-established, and processing it in large amounts is cost-effective.

- The market for US ethanol is expected to grow, with more use of higher ethanol blends like E15 and chances to sell it to other countries.

- Challenges include unpredictable corn prices, environmental worries about growing corn, and issues with the equipment needed to use ethanol fuels.

- New ideas like making ethanol from things other than corn (cellulosic ethanol) and capturing carbon are being explored to make production more sustainable and efficient.

US Ethanol Production: Market Dynamics and Growth Drivers

The US ethanol market is a pretty interesting space, shaped by a bunch of different forces. It’s not just about making fuel; it’s about how policies, demand for cleaner options, and new tech all come together. This renewable fuel is a big deal for transportation, and its role is only expected to grow.

Renewable Fuel Standard And Policy Support

The Renewable Fuel Standard (RFS) is a major player here. It’s a government mandate that requires a certain amount of renewable fuel, like ethanol, to be blended into the nation’s fuel supply. Think of it as a baseline requirement that keeps demand steady. Beyond the RFS, other government programs and trade agreements can also give ethanol a boost. For instance, if other countries have mandates for biofuels, it can open up export markets for US ethanol. On the flip side, changes in trade policies or tariffs can create uncertainty.

Growing Demand For Cleaner Transportation Fuels

People are more aware of environmental issues these days, and that’s pushing demand for cleaner ways to power our cars and trucks. Ethanol burns cleaner than traditional gasoline, which helps reduce greenhouse gas emissions. This trend is a big reason why ethanol is becoming more popular. As more people and companies look for ways to lower their carbon footprint, the demand for biofuels like ethanol naturally goes up. It’s a simple equation: more environmental concern equals more demand for cleaner fuels.

Technological Advancements In Production

It’s not just about policy and demand; technology plays a huge part too. Over the years, we’ve gotten much better at producing ethanol. The processes are more efficient, meaning we can make more ethanol with less energy and fewer resources. This includes improvements in how we convert plant matter into usable sugars and then ferment them. These advancements help lower production costs and can even make it possible to use different types of plant materials, not just corn. This ongoing innovation is key to keeping ethanol competitive and sustainable.

Corn’s Dominance In US Ethanol Production

Abundant Domestic Production Capacity

When you look at US ethanol production, corn is the big player. It’s not even close. We’ve got a massive amount of corn grown right here in the States, and that makes it a really convenient and cost-effective choice for making ethanol. Think about it – the farms are already there, the infrastructure to get the corn to the plants is pretty well-established, and the plants themselves are built to handle it. It’s like a perfect storm of availability.

Mature Supply Chain Networks

This isn’t something that just popped up overnight. The whole system for getting corn from the field to the ethanol plant has been around for a long time. We’re talking about established routes, storage facilities, and relationships between farmers and producers. This mature network means fewer hiccups and more predictable operations. It’s a well-oiled machine, so to speak, that keeps the ethanol flowing without too much fuss.

Economies Of Scale In Processing

Because so much ethanol is made from corn, the plants that do it are often huge. These big operations can process massive amounts of corn, which brings down the cost per gallon of ethanol. It’s all about efficiency. When you’re making millions of gallons, even small savings add up. This is why corn-based ethanol is usually cheaper to produce than ethanol made from other stuff. It’s a numbers game, and corn wins.

Here’s a quick look at why corn is king:

- Availability: Billions of bushels of corn are harvested annually in the U.S.

- Infrastructure: Existing transportation and storage systems are already in place.

- Technology: Processing technologies are highly developed and efficient for corn.

This established system makes corn the go-to feedstock for the vast majority of U.S. ethanol production.

Market Trends And Future Outlook For US Ethanol

So, what’s the deal with US ethanol these days? It looks like things are pretty busy in this sector. We’re seeing a steady climb in how much ethanol is being made and used, and that’s expected to keep going. The market is projected to grow significantly, with estimates suggesting it could reach around $60.66 billion by 2032. That’s a pretty big jump from where it is now.

Several things are pushing this growth. For starters, there’s a bigger push for cleaner ways to fuel our cars and trucks. Ethanol, being a renewable option, fits right into that. Plus, government rules and incentives are still playing a big role in making sure ethanol gets blended into our gasoline.

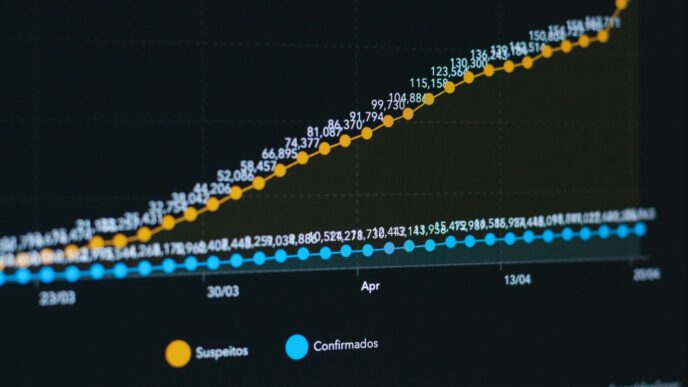

Projected Market Size And CAGR

Let’s look at some numbers. The US ethanol market was valued at about $32.76 billion in 2025. From 2025 to 2032, it’s expected to grow at a compound annual growth rate (CAGR) of about 9.20%. This means we’re looking at a pretty consistent expansion over the next several years.

Increasing Adoption Of Higher Ethanol Blends

One of the really interesting trends is how more gas stations are starting to offer higher ethanol blends, like E15 (which is 15% ethanol). It’s not just a little bit more, either. Sales of E15 hit a record over a billion gallons in 2024, showing a solid increase from the year before. This means more cars can use these blends, and it’s becoming a more common sight at the pump.

Here’s a quick rundown of why this is happening:

- More Stations Offering E15: Retailers are investing in the equipment needed to sell these higher blends.

- Consumer Awareness: People are becoming more aware of the benefits of using fuels with more ethanol.

- Policy Support: Government programs are helping to make these higher blends more accessible.

Emerging Export Opportunities

Beyond our borders, there’s also a growing interest in ethanol. As other countries look for ways to reduce their own carbon footprints and meet biofuel targets, the US is well-positioned to export its ethanol. This could open up new markets and further boost production here at home. However, it’s not always straightforward, as global trade policies and demand in other countries can shift, impacting how much we can sell overseas.

Challenges And Restraints In The Ethanol Sector

Even with all the positive momentum, the ethanol industry isn’t without its hurdles. It’s not always smooth sailing, and several factors can slow things down or make production tougher.

Feedstock Supply And Price Volatility

Corn is king when it comes to U.S. ethanol, and that’s a double-edged sword. While we grow a ton of it, the supply can get shaky. Weather events like droughts or floods can mess with harvests, leading to less corn available. Plus, ethanol producers aren’t the only ones buying corn; livestock feed and food industries are big customers too. This competition means prices can swing wildly.

- Weather impacts: A bad growing season can really tighten supply.

- Competing demands: Other industries also rely on corn, driving up prices when demand is high.

- Global markets: International trade and demand for corn can also affect domestic prices.

This unpredictability makes it hard for ethanol plants to budget and plan, impacting their profit margins. When corn prices spike, it directly eats into how much money ethanol producers can make.

Environmental Concerns And Sustainability

While ethanol is seen as a greener fuel, its production isn’t entirely without environmental questions. Growing all that corn takes a lot of resources. We’re talking about water for irrigation and fertilizers, which can sometimes run off into waterways. There’s also the land use aspect – is that land better used for food crops? These are ongoing discussions that put pressure on producers to find more sustainable farming and production methods.

Infrastructure And Compatibility Issues

Getting ethanol into the hands of consumers also presents some logistical headaches. Most cars on the road today are designed for traditional gasoline. While many can handle blends like E10 (10% ethanol), higher blends like E15 or E85 require specific engine technology and, importantly, compatible fueling infrastructure. Not all gas stations have the pumps needed for these higher blends, which limits their availability. Plus, there are ongoing debates and research about the long-term effects of higher ethanol blends on vehicle components and the existing pipeline systems.

Regional Landscape Of US Ethanol Production

Midwest: The Traditional Corn Belt Hub

The Midwest is pretty much the heartland of US ethanol production. Think states like Iowa, Illinois, Nebraska, and Minnesota – they’ve been growing corn and making ethanol for ages. It just makes sense, right? You’ve got tons of corn right there, and the infrastructure to process it is already in place. This region benefits from established supply chains and a long history with the biofuel industry, making it the go-to spot for most of the country’s ethanol.

Southern Region’s Growing Influence

While the Midwest is the old guard, the South is definitely stepping up its game. States like Texas and Louisiana are seeing more ethanol plants pop up. This growth is partly because of the demand for cleaner fuels in these areas and the federal rules that encourage blending ethanol into gasoline. It’s becoming a pretty significant player in the ethanol scene.

Western Region’s Focus On Alternative Fuels

The West is a bit different. States like California, for example, are really pushing for alternative fuels to tackle environmental issues. While they might not produce as much ethanol as the Midwest, their focus is on using it and exploring other renewable fuel options. The amount of ethanol used and produced here can really depend on what the individual states decide to do with their own rules and incentives.

Innovations Shaping The Future Of Ethanol

The ethanol industry isn’t just sticking with what works; it’s constantly looking for ways to do things better, cleaner, and more efficiently. Think of it like upgrading your old phone – sure, the old one still makes calls, but the new one does so much more. That’s what’s happening with ethanol production right now.

Cellulosic Ethanol Development

This is a big one. For years, most ethanol came from corn. But what about all the other plant stuff – the stalks, leaves, and husks? That’s where cellulosic ethanol comes in. It uses non-food parts of plants, like corn stover or switchgrass, as the raw material. The trick is breaking down these tough fibers, called cellulose, into sugars that yeast can ferment. Scientists have been working hard on better enzymes and microbes to make this process more practical and affordable. The goal is to use more of the plant and avoid the whole "food versus fuel" debate. It’s still a bit more expensive than corn ethanol, but it’s getting there.

Carbon Capture and Sequestration Initiatives

Ethanol production, like many industrial processes, releases carbon dioxide (CO2). Now, companies are looking at ways to capture that CO2 before it goes into the atmosphere and store it underground. This is called carbon capture and sequestration, or CCS. Why bother? Well, it significantly lowers the carbon footprint of the ethanol, making it a much cleaner fuel. Plus, there are tax credits, like the 45Z credit, that reward producers for making lower-carbon fuels. This is a major shift, encouraging investment in new technology and partnerships to build the necessary infrastructure. It’s complex, for sure, but it’s seen as a key way to make ethanol a truly low-carbon option for the future.

Advanced Fermentation Technologies

Even within traditional corn ethanol, there’s innovation happening. Companies are developing special yeast strains and microbes that are better at fermenting sugars. Some can handle a wider range of sugars, and others work faster or at different temperatures, which can save energy. Think of it as having super-powered yeast that can get the job done more effectively. Enzyme technology is also improving, making the process of converting starches to sugars quicker and cheaper. These aren’t flashy, headline-grabbing changes, but they add up to make the whole production process more efficient and less costly.

Wrapping It Up

So, looking at everything, the U.S. ethanol scene is pretty active. Government rules are still a big deal, pushing for more renewable fuels, and folks are using more E15 blends, which is good for business. Corn is still king for making ethanol, especially out in the Midwest, but there’s always talk about new ways to make it, like using different plants. Prices can jump around because of corn costs and global stuff, but overall, the market is expected to keep growing. Plus, new ideas like capturing carbon are popping up, which could make ethanol even more appealing down the road. It’s a complex picture, for sure, but it seems like ethanol is set to stick around as a key player in our fuel mix.

Frequently Asked Questions

What is ethanol and why is it important in the U.S.?

Ethanol is a type of alcohol made from plants, like corn. In the U.S., it’s mostly used as a fuel additive for cars. It helps make gasoline burn cleaner and reduces pollution. It’s a renewable fuel, meaning we can make more of it from crops.

Why is corn used so much to make ethanol?

Corn is used a lot because the U.S. grows a huge amount of it easily. There are already many factories set up to turn corn into ethanol, and the system for getting corn to these factories is well-established. This makes it cheaper and simpler to produce ethanol from corn compared to other plants.

What are the main reasons ethanol production is growing?

Several things are pushing ethanol production forward. Government rules, like the Renewable Fuel Standard, require a certain amount of ethanol to be mixed with gasoline. Also, people want cleaner fuels for their cars, and new technologies are making ethanol production more efficient and sometimes even using different plant parts.

What challenges does the ethanol industry face?

The ethanol industry deals with a few hurdles. The price of corn can change a lot, making production costs unpredictable. There are also worries about how growing so much corn affects the environment, like water use. Sometimes, the equipment in cars or gas stations isn’t ready for higher amounts of ethanol.

Where is most ethanol produced in the U.S.?

The Midwest, known as the ‘Corn Belt,’ is where most ethanol is made. States like Iowa, Illinois, and Nebraska are big players. However, other regions like the South are also starting to produce more ethanol.

Are there new ways ethanol is being made or used?

Yes, scientists are working on making ethanol from things other than corn, like leftover plant stalks and leaves, which is called cellulosic ethanol. Another exciting development is capturing the carbon dioxide released during production and storing it underground. This makes ethanol even cleaner.