The world of semiconductors is complex, and keeping up with all the rules and changes can feel overwhelming. Whether you’re dealing with new government regulations, making sure your tech is safe, or just trying to get your products made and delivered on time, there’s a lot to consider. As a semiconductor consultant, I’ve seen firsthand how important it is to get this right. It’s not just about avoiding trouble; it’s about making sure your business can grow and innovate.

Key Takeaways

- Staying on top of global rules and data protection is key in the semiconductor industry.

- Export controls and protecting your ideas are major concerns that affect business.

- Leaders need to align company goals with regulations to avoid problems and stay competitive.

- Getting the right people with the right skills is a big challenge for chip companies.

- Working with partners, especially in places like Taiwan, is important for making and moving chips.

The Evolving Semiconductor Regulatory Landscape

The world of semiconductors is getting more complicated, and not just on the tech side. Governments everywhere are stepping in with new rules and guidelines. It feels like every week there’s a new regulation to keep track of, whether it’s about where chips are made, how data is handled, or what technology can be sold to whom. This isn’t just a minor inconvenience; it’s changing how companies plan their production, where they invest, and how they innovate.

Navigating Global Standards and Data Protection

Keeping up with different countries’ rules for semiconductors is a big job. Each nation has its own ideas about what’s safe and acceptable, especially when it comes to protecting the information that chips help process. Companies need to be really careful to make sure their products meet all these varied requirements. This means understanding things like:

- Data Privacy Laws: Rules like GDPR in Europe or similar laws elsewhere dictate how personal data collected or processed by semiconductor-powered devices must be handled. This impacts chip design and the software that runs on them.

- Cybersecurity Standards: As chips become more integrated into critical infrastructure, governments are setting stricter cybersecurity standards to prevent breaches and ensure reliability.

- Cross-Border Data Flows: Regulations often govern how data can move between countries, which is a major consideration for global semiconductor companies.

The Impact of Export Controls and IP Safeguards

Export controls are a hot topic right now. Governments are using them to manage the flow of advanced technology, including sophisticated semiconductors, to certain countries. This can really shake up supply chains and affect who a company can sell to. On top of that, protecting intellectual property (IP) is always a concern. Companies spend a lot of time and money developing their chip designs, and they need to be sure those designs are safe from theft or misuse. This involves:

- Understanding Export Restrictions: Knowing which countries are subject to controls and what types of technology are restricted is vital. This can change quickly, so staying informed is key.

- Securing Intellectual Property: Implementing strong measures to protect patents, trade secrets, and design data is non-negotiable. This includes both physical security and digital safeguards.

- Navigating Licensing Requirements: For certain technologies or destinations, companies may need to obtain special licenses, adding another layer of complexity to international trade.

Balancing Compliance with Innovation Goals

This is the tricky part. Companies want to push the boundaries of what’s possible with new chip technology, but they also have to follow all these rules. It’s a constant balancing act. Sometimes, the effort to comply can slow down the pace of development. However, smart companies are finding ways to make compliance work for them. They see that meeting regulations can actually lead to better, more reliable products. It also builds trust with customers and partners. The goal is to integrate compliance from the start, not as an afterthought. This means:

- Early Integration: Building compliance checks into the research and development process from day one.

- Agile Adaptation: Developing processes that can quickly adapt to new or changing regulations.

- Strategic Advantage: Viewing compliance not just as a hurdle, but as an opportunity to differentiate and build a stronger, more reputable business.

Leadership’s Crucial Role in Semiconductor Compliance

It’s not just about knowing the rules; it’s about having the right people in charge to make sure those rules are followed. In the semiconductor world, where things move so fast and regulations change constantly, leadership really has to step up. Getting leaders who understand both the tech and the legal stuff is key to keeping things running smoothly and avoiding big problems.

Strategic Alignment with Regulatory Frameworks

Companies need leaders who can look ahead and see where regulations are going. It’s like trying to hit a moving target, but good leaders can anticipate these shifts. They need to make sure the company’s big plans line up with all the different rules out there, whether it’s about data protection or where we can sell our chips. This means:

- Understanding international policies and how they affect our business.

- Figuring out how new rules might change our production or sales.

- Making sure our company’s goals don’t clash with compliance requirements.

Fusing Technical Expertise with Ethical Governance

This is where it gets interesting. You need people who know how semiconductors are made, but also people who know right from wrong and can make tough calls. It’s about building a company culture where doing the right thing is just how we operate. This involves:

- Making sure that ethical considerations are part of every decision, from designing a new chip to shipping it out.

- Having leaders who can explain complex technical issues in a way that makes sense for compliance officers.

- Setting clear expectations for how everyone should behave, especially when dealing with sensitive information or international partners.

Building Resilient Teams for Audits and Certification

When the auditors show up, or when we need to get certified for something new, you don’t want a team that panics. Leaders need to build teams that are prepared, organized, and know exactly what to do. This means having good documentation, clear processes, and people who can confidently answer questions. It’s about creating a system that can handle scrutiny without falling apart. For example, having a solid traceability system is vital for supply chain visibility. This helps in:

- Gathering all the necessary paperwork and data ahead of time.

- Training staff on how to interact with auditors.

- Continuously improving processes based on feedback from audits and certifications.

Driving Innovation Through Responsible Semiconductor Governance

So, the semiconductor world is moving at lightning speed, right? New chips, new tech, it’s all happening. But with all this progress, there’s a growing need to make sure we’re doing things the right way. This isn’t just about following rules; it’s about building a stronger, more trustworthy industry for the long haul. Thinking about compliance early on can actually speed up how quickly we get new ideas out the door. It’s about being smart and responsible from the get-go.

Adhering to Environmental, Safety, and Trade Regulations

When you’re making tiny, complex pieces of technology, there are a lot of outside factors to consider. We’re talking about making sure our factories aren’t harming the environment, that our workers are safe, and that we’re playing fair in global trade. These aren’t just afterthoughts; they’re part of how we operate. Ignoring them can lead to big problems down the road, like fines or even losing the ability to sell our products in certain places. It’s about being a good global citizen, really. Plus, many countries are putting more focus on these areas, with some even establishing semiconductor funds and research initiatives to promote responsible development.

Integrating Compliance into R&D and Production Lifecycles

It makes a lot more sense to build compliance into our processes from the very beginning, rather than trying to bolt it on later. Think about it: when we’re designing new chips or setting up a new production line, we should be asking ourselves about the environmental impact, safety checks, and trade rules that apply. This means R&D teams and production managers need to be on the same page. It’s about creating a system where responsible practices are just part of the daily routine, not a separate task.

Here’s a quick look at how this integration can work:

- Design Phase: Consider material sourcing, energy efficiency, and potential disposal issues.

- Prototyping: Test for safety and environmental standards early.

- Manufacturing: Implement strict waste management and worker safety protocols.

- Distribution: Ensure all trade regulations are met for international shipping.

Leveraging Compliance as a Catalyst for Growth

It might sound counterintuitive, but following the rules can actually be a good thing for business. When companies are known for being compliant and responsible, it builds trust with customers, investors, and governments. This can open doors to new markets and partnerships. It shows that we’re a reliable player in the industry. Instead of seeing compliance as a burden, we can view it as a way to stand out and build a more sustainable business. It’s about being proactive and using these requirements to our advantage, making our company stronger and more competitive in the global market.

Understanding the Semiconductor Supply Chain Journey

The path a semiconductor takes from a raw idea to the device in your hand is pretty involved. It’s not just a single step; it’s a whole series of stages, each with its own set of challenges and requirements. Think of it like building a really complex model airplane – lots of tiny pieces, precise assembly, and careful handling.

From Manufacturing to End-Product Integration

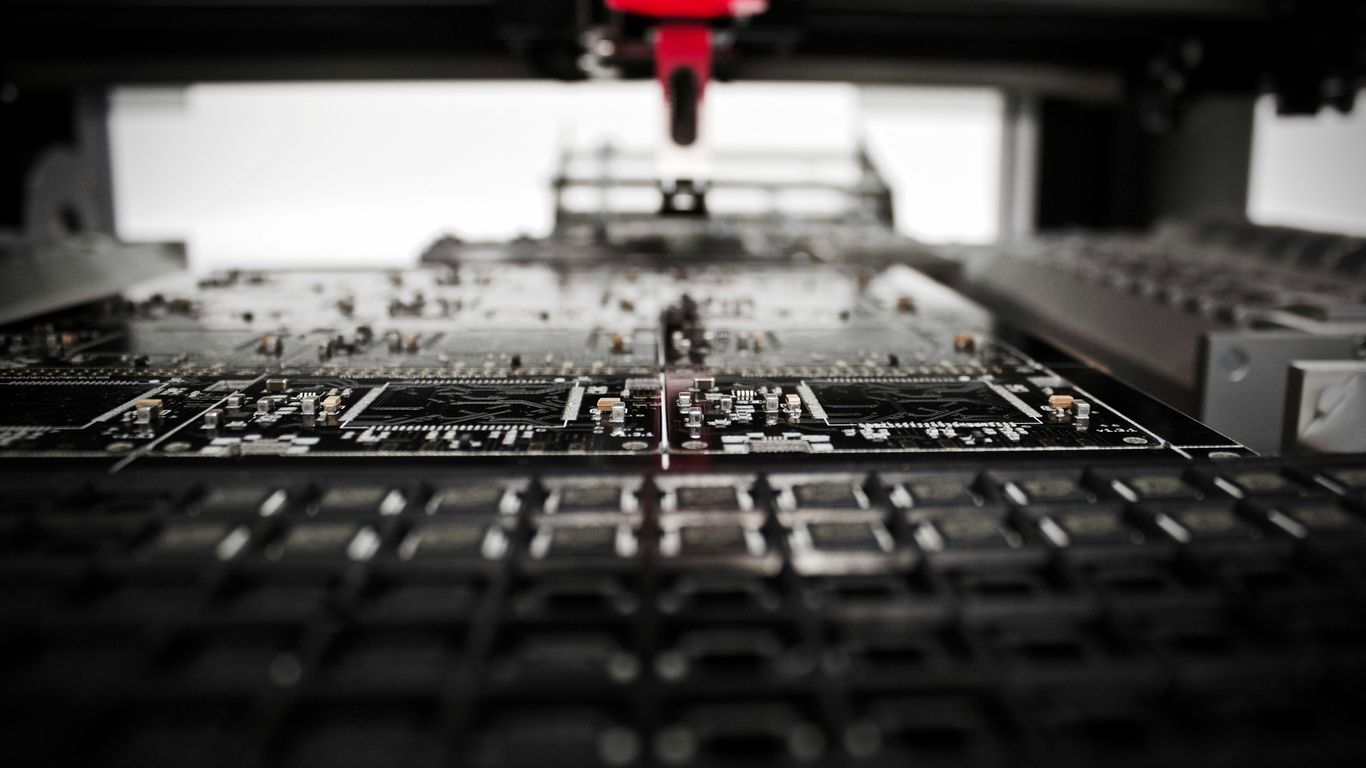

It all starts with the actual making of the chips. This happens in two main parts. First, there’s the ‘front end’ where designs are turned into physical circuits on silicon wafers. This involves super precise processes like photolithography. Then comes the ‘back end’. Here, those wafers are cut into individual chips, which are then put into protective packages. After that, they’re sent off for testing to make sure they work correctly. This testing phase is super important because faulty chips can cause big problems down the line. Once they pass, these packaged chips are ready to be put into the devices we use every day. This integration step involves working with companies that build the final products, like smartphones or computers, and getting the chips to them just when they need them to keep production lines moving smoothly.

The Critical Role of Logistics in Chip Assembly and Testing

Logistics isn’t just about getting things from point A to point B; in the semiconductor world, it’s about getting them there safely and on time, especially during assembly and testing. Chips, even after packaging, are still delicate. They need to be transported to specialized facilities, often called OSATs (Outsourced Semiconductor Assembly and Test), without getting damaged. This means careful handling, climate-controlled transport, and sometimes even special packaging to protect against shock and vibration. If a shipment of chips gets delayed or damaged, it can halt the assembly of entire product lines, leading to significant financial losses and missed market opportunities. It’s a high-stakes game where every move counts.

Ensuring Timely Delivery of Semiconductor-Powered Devices

After the chips are integrated into devices, the final leg of the journey begins: getting those finished products to consumers. This phase relies heavily on efficient logistics to make sure devices are available when and where people want them. This often involves a mix of shipping methods, from air freight for speed to ocean shipping for larger volumes. Warehousing strategically placed near major markets also plays a part, helping to reduce delivery times and manage inventory for fluctuating demand. The goal is to have the right product, in the right place, at the right time, without any hiccups.

Addressing the Semiconductor Talent Gap

It’s no secret that the semiconductor industry is facing a bit of a crunch when it comes to people. We’ve got a lot of experienced folks who have been doing this for years, and they’re starting to think about retirement. That’s totally normal, but it also means a whole lot of know-how could walk out the door with them.

The Aging Workforce and Knowledge Transfer Challenges

Think about it: a big chunk of the folks working in chip manufacturing and design have been around for a while. In the US, for example, a good number of the workforce is over 45, and in Europe, it’s even higher, with some countries expecting a significant portion to retire in the next decade. This isn’t just about losing bodies; it’s about losing decades of hands-on experience and institutional memory. We’re talking about the kind of knowledge that doesn’t always get written down in a manual. It’s the little tricks, the problem-solving approaches, the deep understanding of how complex systems really work. When these veterans leave, there’s a real risk of that knowledge just… disappearing. It makes it tough for companies to keep things running smoothly and to train the next generation effectively. We need better ways to capture and pass on this valuable information before it’s too late. It’s a big challenge for the semiconductor industry.

Recruiting New Talent to Adopt Institutional Knowledge

So, how do we get new people excited about working in semiconductors? For starters, the industry hasn’t always been the best at showing off what it does or why it’s cool. It’s not as flashy as some other tech fields, and that can make it harder to attract young talent. We need to do a better job of highlighting the impact semiconductors have on everything from our phones to advanced medical equipment. Beyond just getting them in the door, though, we need to make sure they’re learning from the experienced folks. This means creating structured programs for mentorship and knowledge sharing. It’s not enough to just put a new hire next to a senior engineer; there needs to be a deliberate effort to transfer that deep, practical knowledge. This could involve things like detailed documentation, hands-on training sessions, and even creating internal

Strategic Partnerships in the Semiconductor Ecosystem

So, let’s talk about how companies in the chip world work together. It’s not just one big company doing everything. Think of it more like a giant, interconnected puzzle where different pieces have to fit just right. This is especially true when you look at who’s doing what and where.

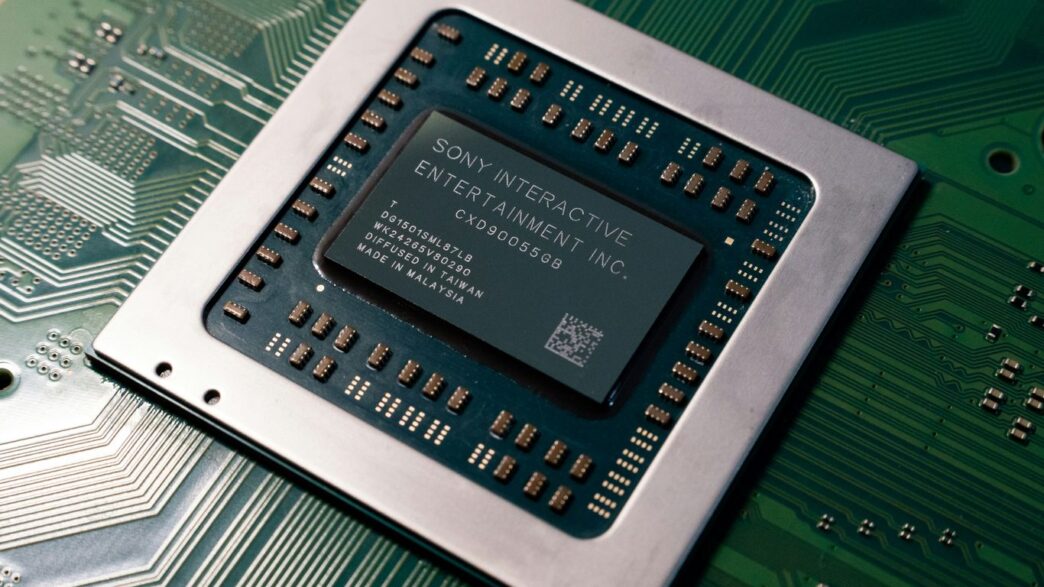

Taiwan’s Dominant Position in Global Chip Production

When you talk about making chips, you absolutely have to mention Taiwan. Seriously, they’re kind of a big deal. They produce a huge chunk of the world’s chips, like over 60% according to some reports. They’ve got these super advanced factories that handle all sorts of steps, from actually making the silicon wafers to putting them in their final packages and testing them out. It’s pretty impressive, and it means a lot of other companies rely on them to get their chips made. This concentration of manufacturing power means that stability and collaboration in Taiwan are key for the whole global tech industry. It’s why things like ICTC and CMC Microsystems are working to build up talent here, aiming for national resilience.

Collaborations Between IDMs, Foundries, and OSATs

Inside the industry, you have different types of players. There are Integrated Device Manufacturers (IDMs), which are companies that design and make their own chips. Then you have foundries, which are basically factories that just make chips for other companies based on their designs. And finally, there are Outsourced Semiconductor Assembly and Test (OSAT) companies, who handle the final steps of packaging and testing the chips. These three groups work together all the time. An IDM might use a foundry to make some of its chips, and then send those chips to an OSAT for packaging. It’s a complex dance, and good communication between them is vital to keep things moving smoothly and to make sure the final product is exactly what it should be.

The Advantage of Partnering with Specialized Logistics Providers

Now, getting these tiny, super-sensitive components from one place to another is a whole other ballgame. You can’t just throw them in a regular box and ship them. That’s where specialized logistics companies come in. These are the folks who know how to handle the delicate nature of semiconductor parts, manage international shipping rules, and get things where they need to be, on time. Having a logistics partner who really gets the semiconductor industry can save a company a lot of headaches and money. They understand the high stakes involved, especially when a critical part fails and production lines stop. They’re the unsung heroes making sure the global supply chain doesn’t break down.

Mitigating Risks in Semiconductor Spare Parts Logistics

When you’re in the business of making computer chips, downtime isn’t just an inconvenience; it’s a financial catastrophe. Imagine a key machine in your wafer fabrication plant grinding to a halt. Suddenly, production stops, and you’re looking at millions of dollars in lost revenue. That’s why having a solid plan for managing spare parts is so important. It’s not like ordering a replacement part for your car; semiconductor parts are incredibly delicate.

The High Cost of Downtime in Wafer Fabrication

Let’s be real, the semiconductor industry moves fast, and any interruption can be incredibly costly. A single piece of equipment failing can bring an entire production line to a standstill. This isn’t just about a few hours of lost work; we’re talking about significant financial hits that can impact a company’s bottom line for a long time. Having the right spare parts readily available is like having an insurance policy against these expensive production pauses.

Specialized Handling for Ultra-Sensitive Components

These aren’t your average electronic components. Semiconductor parts are super sensitive. They can be easily damaged by:

- Sudden shocks or vibrations during transit.

- Changes in temperature or humidity.

- Even static electricity.

Because of this, standard shipping methods just won’t cut it. We’re talking about specialized packaging, often using anti-static materials. Think custom crates, shock sensors that record any impacts, and temperature monitors that alert you if things get out of line. It’s all about protecting these high-value, delicate items from the moment they leave the warehouse until they’re installed.

Best Practices for Advanced Inventory Management

Managing spare parts effectively is a balancing act. You need enough parts on hand to avoid downtime, but you don’t want to be stuck with excess inventory that ties up capital. Here are some smart ways to handle it:

- Use data to predict needs: Look at past usage patterns and current production schedules to figure out what parts you’ll need and when. This helps avoid surprises.

- Spread out your stock: Instead of keeping all your spare parts in one place, consider having smaller stockrooms closer to your main production facilities. This way, if a part is needed urgently, it’s not stuck on a plane halfway across the world.

- Keep a close eye on everything: Implement a system that tracks every part, from when it arrives to when it’s used. This gives you a clear picture of your inventory levels and helps prevent parts from going missing or expiring.

By paying close attention to these details, companies can significantly reduce the risks associated with spare parts logistics and keep their chip production running smoothly.

Looking Ahead in the Semiconductor World

So, what’s the takeaway from all this? The semiconductor industry is a complex beast, constantly changing. Keeping up with new rules and making sure everything runs smoothly takes real effort. It’s not just about the tech itself, but also about having the right people and processes in place. As things keep moving fast, staying informed and adaptable will be key for anyone involved. It’s a challenging but exciting field, and the future looks pretty interesting.

Frequently Asked Questions

Why is it important for semiconductor companies to follow rules and regulations?

Following rules is super important for semiconductor companies because it helps keep things safe and fair. It’s like having rules in a game to make sure everyone plays nicely. These rules help protect people’s information, make sure products are made safely, and prevent bad stuff like stealing ideas. When companies follow the rules, they build trust and can keep making cool new technology without causing problems.

What are export controls and why do they affect semiconductor companies?

Export controls are like special permissions you need to send certain high-tech items, like advanced computer chips, to other countries. They are put in place to make sure these powerful technologies don’t end up in the wrong hands. For semiconductor companies, this means they have to be very careful about who they sell their chips to and where they are sent, as breaking these rules can lead to big trouble.

How can companies balance making new things with following all the rules?

It can be tricky, but companies can do this by thinking about the rules right from the start when they are designing new products. Instead of seeing rules as a roadblock, they can use them as a guide to make even better and safer products. This means having smart people who understand both technology and the rules working together to find clever solutions.

Why is Taiwan so important for making computer chips?

Taiwan is like a superstar in the world of making computer chips. They have built amazing factories with the latest technology and have lots of skilled workers who know exactly how to create these tiny, powerful components. Many of the world’s most advanced chips are made there, making Taiwan a crucial part of the global technology supply chain.

What is the ‘talent gap’ in the semiconductor industry?

The ‘talent gap’ means there aren’t enough skilled people to do all the jobs needed in the semiconductor industry. Many experienced workers are getting older and retiring, and not enough new, young people are entering the field. This makes it hard for companies to find the right people to design, build, and test the chips that power our technology.

What happens if a machine breaks down when making computer chips?

If a machine breaks down during the process of making computer chips, it’s a really big problem. This process, called wafer fabrication, is very delicate and expensive. A breakdown can stop everything, causing the company to lose a lot of money very quickly because they can’t make the chips that are in high demand.