So, General Motors and NVIDIA are teaming up, and it sounds like a pretty big deal for cars and how they’re made. It’s not just about building cars faster, but also about making them smarter, like, really smarter. They’re using some fancy tech to create digital copies of factories and to power the brains inside future cars. This nvidia gm partnership seems like it could change a lot of things in the auto world.

Key Takeaways

- The nvidia gm partnership is using NVIDIA’s Omniverse to make digital models of car factories. This helps them plan and test things out virtually before building them for real, which should make production smoother and safer.

- GM is putting NVIDIA’s DRIVE AGX platform, powered by the new Blackwell architecture, into its next generation of vehicles. This gives the cars a lot of computing power for advanced features and eventually, self-driving.

- This collaboration isn’t about GM becoming a computer chip maker. Instead, they’re focusing on what they do best – building cars – and using NVIDIA’s top-tier AI tech to get there faster.

- The partnership aims to improve the car experience for drivers and passengers with smarter driver assistance and cool in-cabin AI features.

- NVIDIA’s powerful GPUs will be used to train GM’s own AI models, and they’ll work together to build custom AI systems specifically for making cars and robots in factories.

Revolutionizing Automotive Manufacturing With AI

While a lot of the buzz around AI in the car world focuses on what’s happening inside the vehicle, General Motors is quietly building a huge advantage by putting AI to work on the factory floor. They’re not just looking for small tweaks; they’re aiming to completely remake their manufacturing and supply chain into something smarter, more predictive, and way more resilient. This focus on industrial AI is a smart move, creating a strong foundation that’s tough for newer companies to copy and freeing up resources for those exciting in-car AI projects.

Leveraging NVIDIA Omniverse For Digital Twins

At the heart of GM’s smart factory plan is the use of digital twins. Think of a digital twin as a living, breathing virtual copy of a physical thing – like a whole assembly line or even an entire factory. This virtual model gets updated constantly with real-world data. GM is using this to create detailed virtual blueprints of their production lines before they’re even built. It’s a "simulate before you build" approach, and it’s changing how they plan and run things.

Working with NVIDIA and its Omniverse platform is key here. Omniverse lets GM engineers build and test entire factories, production lines, and specific work areas in a super realistic virtual space that acts like the real world. This means they can try out different layouts, see how robots will move, check if the workflow makes sense, and spot potential problems or awkward spots for workers way before any money is spent on actual construction. The payoff is pretty big:

- Less downtime when launching new models.

- Faster ramp-up of production.

- Significant cost savings.

- Better ways for employees to find and fix issues.

Optimizing Factory Planning And Robotics

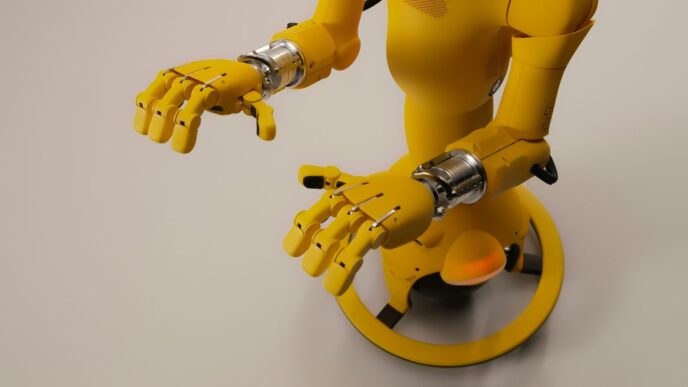

This digital twin technology isn’t just for show; it’s a practical tool for making factories run better. By simulating different scenarios in Omniverse, GM can figure out the most efficient way to arrange equipment and robots. They can test out different automation strategies and see how they’ll perform in a virtual environment. This helps them avoid costly mistakes and optimize the flow of work before anything is physically set up.

Imagine testing out a new robotic arm installation. Instead of physically moving heavy equipment and risking damage or delays, engineers can simulate the entire process. They can check for clearance issues, program the robot’s movements, and even train workers on the new setup – all within the digital twin. This drastically cuts down on the time and expense associated with physical prototyping and testing.

Enhancing Manufacturing Safety And Efficiency

Beyond just planning and robotics, digital twins and AI are making factories safer and more efficient. By simulating workflows, GM can identify potential hazards for workers and design processes to minimize risks. For instance, they can simulate how materials will move through a plant to prevent congestion or identify areas where workers might be exposed to repetitive strain.

Here’s a look at some of the benefits:

- Reduced Accidents: Identifying potential safety risks in virtual simulations before they occur on the factory floor.

- Improved Ergonomics: Designing workstations and processes that are more comfortable and less strenuous for employees.

- Streamlined Operations: Optimizing the flow of materials and vehicles to minimize bottlenecks and keep production moving smoothly.

- Predictive Maintenance: AI can analyze data from factory equipment to predict when maintenance will be needed, preventing unexpected breakdowns and costly downtime.

Advancing Autonomous Vehicle Technology

So, getting self-driving cars to work reliably is a huge challenge, right? It’s not just about making a car that can steer itself; it’s about making it safe, dependable, and able to handle pretty much anything the road throws at it. This is where NVIDIA’s tech really comes into play. They’ve built a whole system designed to tackle these complex problems.

The Power Of NVIDIA DRIVE AGX Platform

At the heart of this is the NVIDIA DRIVE AGX platform. Think of it as the brain and nervous system for autonomous vehicles. It’s a powerful computer system that can process all the data coming from sensors like cameras, radar, and lidar in real-time. This allows the car to ‘see’ its surroundings, understand what’s happening, and make decisions. GM is really leaning on this platform to build out its future autonomous capabilities. It’s designed to be scalable, meaning it can handle everything from advanced driver-assistance systems (ADAS) today to fully self-driving cars down the road. This flexibility is key because the technology is always evolving, and you need a system that can keep up. It’s all about having the right compute power to handle the massive amounts of data needed for safe autonomous operation.

Blackwell Architecture For Unprecedented Performance

Now, to process all that data, you need serious horsepower. That’s where NVIDIA’s Blackwell architecture comes in. It’s the latest generation of their GPU technology, built for AI and high-performance computing. For autonomous driving, this means faster processing, more complex AI models can be run, and the system can react quicker. Imagine trying to play a video game on an old computer versus a new one – the difference is night and day. Blackwell provides that leap in performance, allowing for more sophisticated perception and decision-making algorithms. This is what enables features like smoother automatic lane changes and better handling of tricky traffic situations. It’s the engine that powers the advanced AI needed for safe self-driving.

Safety-Certified NVIDIA DriveOS For Reliability

But what good is all that power if the software isn’t safe and reliable? NVIDIA addresses this with DriveOS. This is the operating system specifically built for autonomous vehicles. It’s not just about making things run; it’s designed with safety certifications in mind. This means it meets strict industry standards for reliability and security. Think of it like the operating system on your phone, but built for a car and with a much higher bar for safety. It manages all the complex software components, from sensor input to vehicle control, in a way that’s predictable and secure. This focus on safety is super important for building public trust in autonomous technology. GM is working to integrate these systems, aiming for a future where personally owned vehicles can offer advanced driver assistance and eventually, full autonomy. The recent changes in federal regulations, like the new AV Framework from NHTSA, are also helping to streamline the path for companies like GM to test and deploy these advanced systems more effectively.

The NVIDIA GM Partnership: A Strategic Alliance

This partnership between NVIDIA and General Motors (GM) is a big deal, really changing how cars get made and how they work. It’s not about GM trying to build computer chips themselves, which would be a huge headache and cost a fortune. Instead, they’re teaming up with NVIDIA, who are the pros in AI and computing power. Think of it like GM saying, "Hey NVIDIA, you’re awesome at this AI stuff, let’s work together." This way, GM can focus on what they do best: designing and building cars.

A Partnership-Driven Path To Scale

GM decided to partner with NVIDIA instead of trying to do everything in-house. This makes a lot of sense. Building all that AI tech from scratch would take forever and cost billions. By working with NVIDIA, GM gets access to the latest and greatest AI tools and computing power without all the upfront investment and risk. It’s a smart way to get ahead.

Here’s a quick look at how this partnership helps GM scale up:

- Access to Advanced AI Compute: GM gets to use NVIDIA’s top-tier GPUs and platforms for training their AI models. This is like having a super-powered brain for their AI development.

- Focus on Core Business: By letting NVIDIA handle the heavy lifting on AI infrastructure, GM can concentrate on vehicle design, engineering, and manufacturing.

- Faster Development Cycles: Working with a specialized partner speeds up the process of bringing new AI features and manufacturing improvements to market.

Leveraging Best-In-Class AI Compute

At the heart of this collaboration is NVIDIA’s powerful technology. GM is using NVIDIA’s Omniverse platform to create digital copies of their factories. This lets them test and fix things in a virtual world before they even touch the real factory floor. It’s a huge time and money saver, especially when setting up new production lines for electric vehicles.

On the vehicle side, GM is building its next generation of cars around the NVIDIA DRIVE AGX platform. This system is incredibly powerful, capable of handling complex tasks needed for advanced driver assistance and eventually, fully autonomous driving. It’s built on NVIDIA’s Blackwell architecture, which is designed for massive performance.

Focusing On Core Competencies In Vehicle Manufacturing

This partnership lets GM really double down on what makes them a car company. They’re not trying to become a tech company that also makes cars; they’re a car company that’s using the best tech available. This means they can put more resources into vehicle design, improving the driving experience, and making sure their manufacturing processes are top-notch. It’s about using AI to make better cars and build them more efficiently, all while staying true to their automotive roots.

Transforming The Vehicle Experience

AI For Advanced Driver-Assistance Systems

It’s not just about self-driving cars anymore, though that’s a big part of it. Think about the driver-assistance features we’re seeing pop up everywhere. These systems use AI to help drivers out, making things safer and a bit less stressful. We’re talking about things like adaptive cruise control that actually adjusts to traffic, lane-keeping assist that gently nudges you back into your lane if you drift, and automatic emergency braking that can stop the car before you even react. These aren’t just fancy gadgets; they’re becoming standard because they genuinely help prevent accidents. The NVIDIA DRIVE platform is a big player here, providing the computing power needed for these complex systems to work in real-time. It’s all about making driving safer, whether you’re on a long highway trip or stuck in city traffic. This technology is constantly getting better, learning from more data to anticipate what might happen on the road.

Sophisticated In-Cabin AI Experiences

Beyond just driving, AI is changing what it’s like to be inside the car. Imagine an assistant that understands you perfectly, not just simple commands. GM is looking into AI that can handle complex, natural language questions, kind of like a super-smart chatbot. This could mean asking your car to find the best route with specific criteria, adjust the climate control based on who’s in the car, or even suggest nearby points of interest based on your conversation. They’re working with Google Cloud on this, aiming to make these interactions feel natural and helpful. This moves beyond basic voice control to a truly conversational experience. The goal is to make the car feel more like a personal assistant and less like a machine. This also extends to personalization, where the car learns your preferences over time, from music to seating position.

The Future Of Personal Autonomous Vehicles

While the road to fully autonomous vehicles has had its bumps – remember the issues with Cruise? – the vision for personal autonomous vehicles is still very much alive. It’s a complex journey, involving massive investment and overcoming technical and regulatory hurdles. However, the potential is huge. We’re looking at a future where cars can handle most of the driving, freeing up your time. This could mean working, relaxing, or entertaining yourself during your commute. The NVIDIA DRIVE AGX platform and its associated software are key to making this a reality, providing the necessary compute power and safety certifications for these advanced systems. It’s about creating vehicles that are not just modes of transport but intelligent, evolving platforms that offer new possibilities for how we travel and interact with our vehicles.

AI Model Training And Custom Systems

When we talk about making cars smarter, a big part of that is the "brain" inside – the AI models. General Motors isn’t just buying off-the-shelf AI; they’re actively building and training their own specialized systems. This means they can create AI that’s perfectly suited for what they need, whether it’s for the factory floor or the car itself.

Utilizing NVIDIA GPUs For Proprietary Models

Think of NVIDIA’s GPUs as the super-powered engines that make AI training possible. For GM, these aren’t just for gaming; they’re essential for crunching massive amounts of data needed to teach AI. This is how they develop unique AI capabilities that give them an edge.

- Training complex models: GPUs speed up the process of teaching AI to recognize patterns, make predictions, and control systems.

- Handling large datasets: Automotive AI needs to learn from vast amounts of information, from sensor data to manufacturing logs. GPUs can manage this scale.

- Developing custom algorithms: GM can fine-tune AI algorithms specifically for their vehicles and manufacturing processes, something you can’t always do with pre-built solutions.

Co-Developing Custom AI Systems

It’s not just about the hardware; it’s about the software and the know-how too. GM is working with partners like NVIDIA to build AI systems from the ground up. This collaborative approach means they can:

- Integrate AI deeply: Ensure the AI works smoothly with existing vehicle hardware and software.

- Tailor performance: Adjust the AI’s behavior and capabilities to meet specific automotive requirements, like real-time decision-making for autonomous driving.

- Future-proof development: Build systems that can be updated and improved over time as AI technology advances.

Specialized Models For Manufacturing And Robotics

Beyond the car itself, AI is transforming how vehicles are made. GM is using custom AI models to make factories smarter and more efficient. For instance, AI can be trained to:

- Optimize robotic movements: Teach robots to perform complex tasks with greater precision and speed on the assembly line.

- Predict maintenance needs: Analyze data from factory equipment to know when a machine might break down before it happens, preventing costly downtime.

- Improve quality control: Train AI vision systems to spot tiny defects in paint or welds that a human eye might miss, leading to better quality vehicles.

Looking Ahead

So, what does all this mean for the future? This partnership between NVIDIA and GM is a pretty big deal. They’re not just talking about making cars drive themselves better, but also about making the whole process of building cars smarter and faster. By using NVIDIA’s tech, GM is setting itself up to be a major player in the AI-driven automotive world. It’s like they’re building the brains for the cars and the factories all at once. While there will be bumps in the road, like making sure all this new tech works together smoothly and figuring out the costs, the potential is huge. This collaboration really shows how companies are working together to shape what driving and car manufacturing will look like down the line.

Frequently Asked Questions

What is the main goal of the partnership between NVIDIA and GM?

The main goal is to use smart computer technology, called AI, to make car factories work better and to build smarter cars for the future. They want to make cars that can drive themselves and create cool features inside the car using AI.

How will NVIDIA’s technology help GM’s factories?

GM is using a special NVIDIA tool called Omniverse to create a digital copy of its factories. This lets them test out new ideas and fix problems in a virtual world before changing the real factory. It helps make the factories run smoother, faster, and safer, especially when building electric cars.

What is NVIDIA DRIVE AGX, and why is it important for GM’s cars?

NVIDIA DRIVE AGX is like a super-smart computer for cars. It’s powerful enough to help cars understand what’s happening around them, which is needed for features like advanced cruise control and eventually, cars that can drive themselves. It also helps create cool digital experiences for people inside the car.

Does this mean GM will start making computer chips like NVIDIA?

No, GM isn’t trying to become a chip maker. Instead, they are working with NVIDIA, who is great at making these AI computer parts and software. GM is using its expertise in building cars to combine with NVIDIA’s technology, making it a smart way to get the best of both worlds.

How does this partnership help make cars safer?

NVIDIA’s technology, like the DRIVE AGX platform and its safety-tested software called DriveOS, is designed to be very reliable. This helps build advanced safety features and systems for self-driving cars that people can trust.

What are ‘digital twins’ in this partnership?

Digital twins are like virtual copies of real things. In this case, GM is creating digital copies of its car factories using NVIDIA’s Omniverse software. This allows them to experiment, train robots, and plan production in a computer simulation, which helps avoid mistakes and improve how things are made in the actual factory.