Advancements in Applied Materials Semiconductor Manufacturing Equipment

Applied Materials has been busy rolling out new gear that’s pushing the boundaries of what’s possible in chip making. They recently showed off a few things that caught my eye, especially if you’re into the nitty-gritty of how these tiny circuits get made.

Integrated Die-to-Wafer Hybrid Bonding Systems

This is a pretty big deal for putting chips together. Hybrid bonding lets you connect chips directly, face-to-face, which is way more efficient than the old way of connecting them side-by-side. Applied Materials’ new integrated system aims to make this process smoother and more reliable. The goal is to pack more computing power into smaller spaces, which is exactly what we need for everything from your phone to supercomputers. It’s all about getting those connections just right, with incredibly tight tolerances.

Selective Epitaxy Platforms for Enhanced Performance

Epitaxy is basically growing a crystal layer on top of another crystal. Applied Materials’ new selective epitaxy platforms are designed to do this with a lot more control. They can grow these layers only where they’re needed, which helps in creating more complex chip designs. This means chips can perform better and use less power. Think of it like being able to paint with atomic precision, building up the exact structures needed for top-tier performance.

E-Beam Metrology with Sub-Nanometer Resolution

Measuring things at the nanometer scale is tough. Applied Materials has developed an electron-beam (e-beam) metrology system that can see details smaller than a nanometer. This is super important for checking the quality of the tiny features on modern chips. If there’s a flaw you can’t see, it can ruin the whole chip. This new system helps catch those problems early, making sure the chips coming off the line are good to go. It’s like having a microscope that can spot imperfections invisible to the naked eye, or even standard microscopes.

Innovation Driving Semiconductor Production

The semiconductor industry is always pushing forward, and a lot of that push comes from new ideas in how we make chips. It’s not just about making them smaller; it’s about making them smarter and more efficient.

AI and Machine Learning in Process Optimization

Think about a giant factory making millions of tiny computer parts. Keeping everything running perfectly is a huge job. That’s where AI and machine learning come in. These technologies can look at tons of data from the manufacturing process – way more than a person ever could – and spot patterns. This helps find small problems before they become big ones, leading to fewer wasted chips and a smoother production line. It’s like having a super-smart assistant watching over every step.

Virtual Silicon Digital Twins for Yield Improvement

Another cool idea is creating a digital copy, or ‘digital twin,’ of the actual silicon wafers being made. This virtual model gets updated with real-time data from the factory floor. Engineers can then test out changes or new ideas on this digital twin without risking any real chips. It’s a safe way to experiment and figure out the best ways to get the most good chips out of each wafer. This approach is really helping to boost the number of usable chips, known as yield.

Advanced Test Systems for Power Semiconductors

Power semiconductors are a big deal, especially with electric cars and renewable energy systems. They handle a lot of electricity, so testing them thoroughly is super important. New test systems are being developed that can handle both the high volume of chips needed for everyday electronics and the more specialized, smaller batches required for niche applications. This means we can get reliable power chips out faster and more efficiently, no matter the production scale.

The Evolving Landscape of Chip Manufacturing

Global Fab Equipment Spending Projections

The semiconductor industry is seeing some big shifts. We’re looking at a significant increase in spending on fab equipment, especially for 300mm facilities. Projections show this spending climbing from around $107 billion in 2025 to an estimated $138 billion by 2028. This growth isn’t just random; it’s fueled by a couple of major trends. Companies are looking to build more fabs closer to home, a move often called regionalization. Plus, the demand for chips used in AI is just exploding, pushing the need for more advanced manufacturing capabilities.

Regionalization Trends in Fab Development

It feels like every country wants a piece of the chip-making pie these days. We’re seeing a definite push towards building more semiconductor factories in different regions around the world. This isn’t just about having more factories; it’s about making supply chains more secure and less dependent on just a few locations. For example, the US is investing heavily, with new research and development facilities popping up. Asia continues to be a major player, with significant investments in advanced packaging and new memory chip makers looking to go public. Even Europe has plans, though sometimes they get sidetracked by other needs, like infrastructure repairs. It’s a complex picture, with governments and companies trying to balance global needs with local production.

Surging Demand for AI-Specific Chips

Artificial intelligence is changing everything, and that includes the chips we need. The demand for chips specifically designed for AI tasks is through the roof. These aren’t your everyday processors; they need to handle massive amounts of data and complex calculations very quickly. This surge is a big reason why companies are investing so much in new equipment and expanding their manufacturing capacity. We’re talking about chips that power everything from self-driving cars to sophisticated data analysis tools. It’s a fast-moving area, and the chip industry is working hard to keep up with what AI needs.

Applied Materials’ Role in Industry Growth

Applied Materials is a big player when it comes to the machines that make computer chips. They’re not just building equipment; they’re really investing in the future of how chips get made. Think of them as a company that helps other companies figure out the best way to produce these tiny, complex parts.

Materials-to-Fab Research and Development Facilities

One of the cool things Applied Materials is doing is setting up these places where they can test out new ideas for chip making. They recently opened a big research center with Arizona State University. It’s a place to work on new materials and processes, all the way from the raw stuff to a finished chip. This kind of hands-on work is super important because the chip world changes so fast. They’re trying to get ahead of the curve by experimenting and finding better ways to do things.

Partnerships for Outstanding Equipment Performance

It’s not just about the machines themselves. Applied Materials works closely with other companies, like chip makers and even universities. This teamwork helps them make sure their equipment works really well for what people need. When you have strong partnerships, you can get feedback and make improvements that really matter. This collaboration is key to making sure the tools they provide help their customers succeed. It’s like a band working together to make great music – everyone plays their part.

Navigating Supply Chain Challenges

Making chips is complicated, and getting all the parts and materials needed for the machines can be tough. The past few years have shown us how easily supply chains can get messed up. Applied Materials has had to figure out how to keep their production going even when things are difficult. This means finding different suppliers, planning ahead, and being flexible. It’s a constant effort to make sure they can deliver the equipment their customers need, when they need it, despite global hiccups.

Key Technologies Supported by Applied Materials

Applied Materials is right in the thick of it when it comes to the technologies that are shaping the future of chips. They’re not just making machines; they’re building the tools that enable some pretty wild advancements.

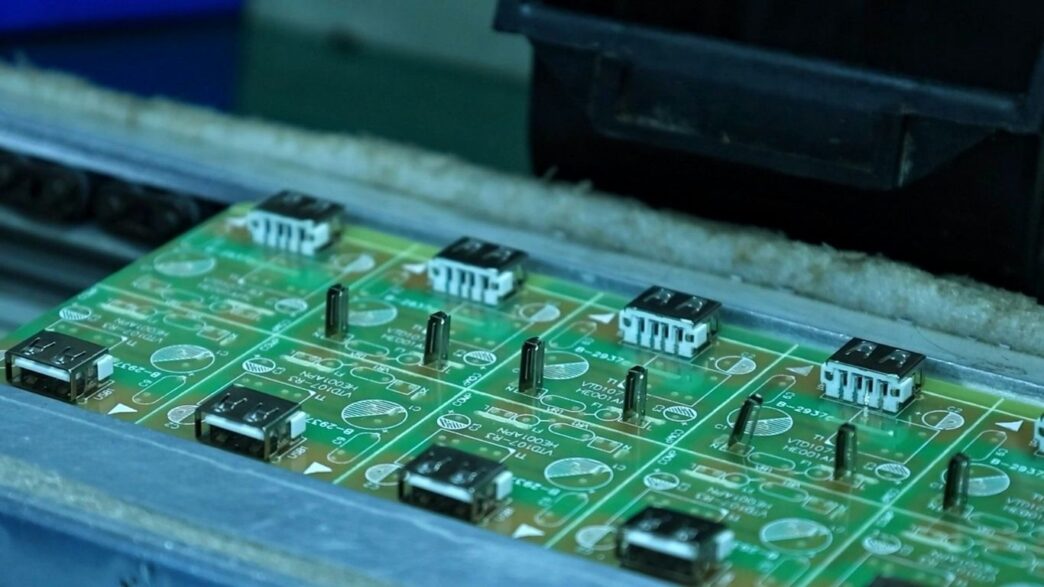

Heterogeneous Integration and Advanced Packaging

This is a big one. Instead of trying to cram everything onto one giant chip, heterogeneous integration is all about combining smaller, specialized chips, or ‘chiplets,’ into a single package. Think of it like building with LEGOs instead of trying to sculpt a whole toy from a single block of plastic. Applied Materials’ equipment plays a role in putting these chiplets together precisely. This approach allows for more flexibility, better performance, and can even reduce costs. It’s especially important for things like AI accelerators and high-performance computing where you need different types of processing power working together.

Next-Generation Processor Architectures

CPUs and GPUs are getting more complex, and the way they’re designed is changing. Applied Materials’ gear is involved in creating the advanced materials and structures needed for these new architectures. This includes things like new transistor designs and memory technologies that allow processors to work faster and use less power. They are helping to build the foundation for processors that can handle more data and more complex tasks than ever before.

Enabling Technologies for AI and High-Performance Computing

Artificial intelligence and high-performance computing (HPC) are hungry for more processing power and faster data handling. Applied Materials is developing equipment that supports the manufacturing of chips specifically designed for these demanding applications. This can involve creating specialized memory, like High Bandwidth Memory (HBM), or the intricate interconnects that allow different parts of an AI chip to communicate at lightning speed. Their work helps make the chips that power everything from self-driving cars to complex scientific simulations possible.

Future Outlook for Semiconductor Equipment

Looking ahead, the semiconductor equipment scene is definitely going to keep changing. A big thing is how global politics might mess with getting the gear we need. Countries are thinking more about making their own chips, which is good for some, but it also means supply chains could get complicated. We’re seeing more talk about where fabs get built, and that’s going to shape demand for equipment in different places.

The Impact of Geopolitics on Equipment Supply

It’s not just about building more fabs; it’s about where they get built and who supplies the machines. Governments are getting more involved, trying to secure their own chip-making capabilities. This can lead to some interesting situations where access to certain technologies or equipment might be restricted. It’s a bit of a balancing act, trying to keep innovation moving while also dealing with national interests. This push for regional self-sufficiency is a major driver for equipment manufacturers.

Sustainability Initiatives in Manufacturing

Companies are also starting to pay more attention to how their manufacturing processes affect the environment. Think about energy use in fabs, water consumption, and waste. There’s a growing pressure, from both consumers and regulators, to make chip production greener. This means equipment makers will need to come up with machines that are more energy-efficient and produce less waste. It’s a shift that’s already happening and will only get bigger.

The Importance of Capital Equipment Intelligence

Finally, the actual machines used to make chips – the capital equipment – are getting smarter. We’re talking about using data and AI to make these machines run better, predict when they might need maintenance, and generally improve the whole production process. It’s like giving the machines a brain so they can help optimize themselves. This kind of intelligence is going to be key for keeping up with the demand for more complex chips.

Looking Ahead

So, what does all this mean for the future of making chips? Applied Materials, along with others in the industry, is really pushing the boundaries. We’re seeing big investments in new facilities and research, like the one with Arizona State University. The demand for chips, especially for things like AI, isn’t slowing down, and companies are spending billions to keep up. It’s a complex world with lots of moving parts, from new equipment to global supply chains and even government policies. But one thing is clear: the drive to create smaller, faster, and more powerful chips is constant, and companies like Applied Materials are right in the middle of it, building the tools that make it all happen.