It’s pretty wild how much things are changing in hospitals and doctor’s offices these days, right? One of the biggest game-changers is this thing called 3D printing. You might think of it for making toys or little gadgets, but it’s actually becoming a really big deal in medicine. We’re talking about making things that fit people perfectly, helping surgeons practice tricky operations, and even creating new ways to make medicines. It’s kind of amazing to see how this technology is shaking things up and making patient care better. This article looks at how 3D printing in the medical industry is making all this happen.

Key Takeaways

- 3D printing allows for custom medical devices, like prosthetics and implants, that are made to fit each person exactly.

- Surgeons can use 3D printed models of body parts to plan and practice complex surgeries before they operate, which can lead to better results.

- The technology is being used to create new tissues and even organs, opening doors for regenerative medicine and reducing transplant wait times.

- 3D printing can speed up the production of medical supplies and devices, and also lower costs by making things on-demand, right where they are needed.

- As 3D printing advances, it’s expected to lead to more personalized medicines and new ways to treat patients, making healthcare more efficient and effective.

Revolutionizing Patient Care Through 3D Printing

It’s pretty wild how much 3D printing is changing things in hospitals and clinics these days. We’re talking about a technology that used to be mostly for hobbyists now creating actual medical solutions. The global market for 3D printing in healthcare was already worth a good chunk of change in 2023, and it’s projected to grow a lot more in the next few years. This isn’t just about making cool gadgets; it’s about making patient care more personal and effective.

Personalized Medical Solutions

Think about it – everyone’s body is different, right? So why should medical treatments and devices be one-size-fits-all? 3D printing lets us create things that are made just for one person. This means better fits, better results, and generally happier patients. It’s like going from off-the-rack clothes to a custom-tailored suit, but for your health.

Customized Prosthetics and Implants

This is one of the areas where 3D printing has really made a splash. For people who need prosthetic limbs, getting something that fits perfectly and feels natural can be a game-changer. 3D printing allows for incredibly precise customization, matching a patient’s unique anatomy. It’s not just about prosthetics, either. We’re also seeing custom implants, like hip replacements or cranial plates, designed specifically for a patient’s needs. This level of personalization can lead to quicker recovery times and a better overall experience.

Here’s a quick look at how it works:

- Scanning: A patient’s body part is scanned using technologies like CT or MRI.

- Designing: A digital 3D model is created based on the scan, allowing for precise adjustments.

- Printing: The custom device is then printed layer by layer using biocompatible materials.

- Fitting: The final product is a perfectly fitted prosthetic or implant.

Tailored Pharmaceuticals

This is still a bit more on the cutting edge, but the idea of 3D printing medications is really interesting. Imagine getting a pill printed with the exact dosage you need, or even one that releases the medicine into your body at a specific rate. This could mean fewer side effects and treatments that work much better for individuals. It’s a step towards truly personalized medicine, where your prescription is as unique as you are.

Advancements in Surgical Planning and Training

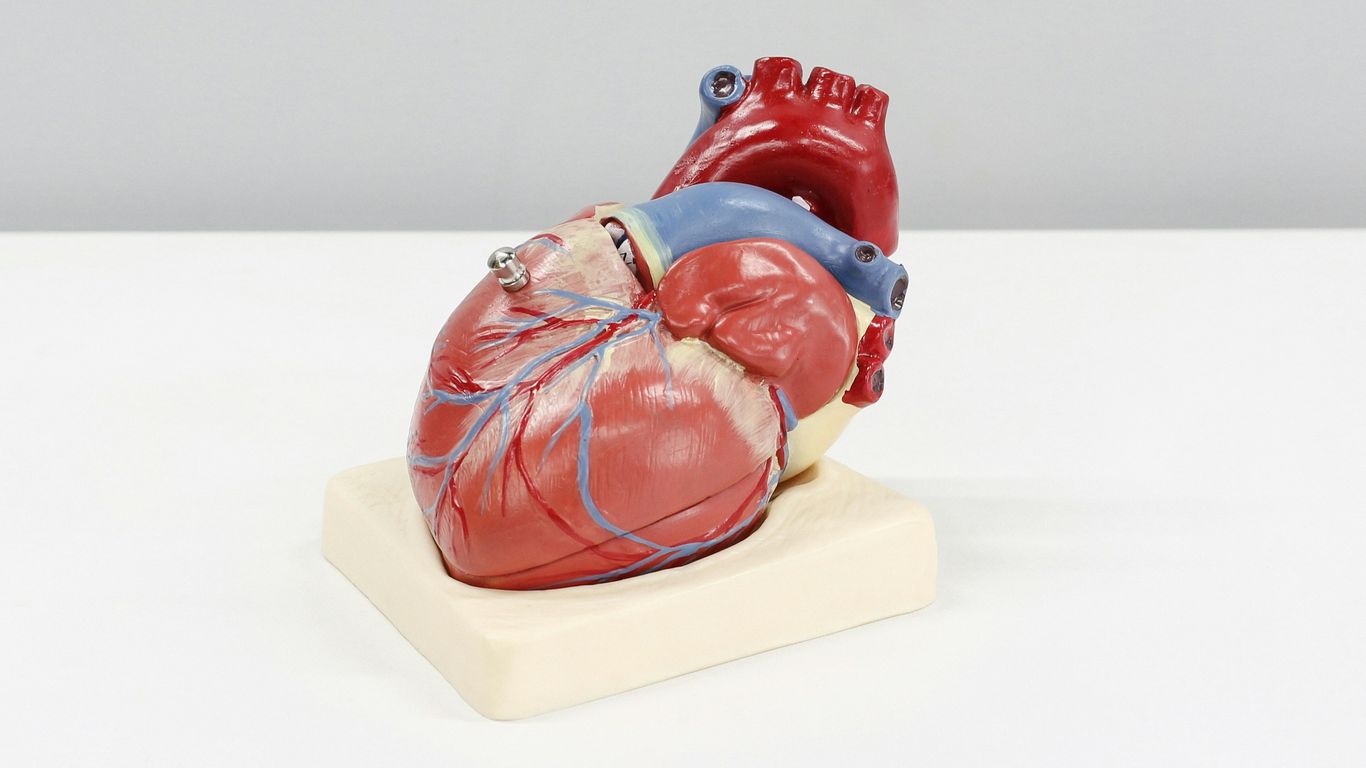

It’s pretty amazing how 3D printing is changing the game when it comes to planning surgeries and teaching new doctors. Before, surgeons had to rely mostly on flat scans and their own experience to figure out tricky operations. Now, they can actually hold a physical model of a patient’s specific anatomy in their hands. Think about it – a perfectly replicated kidney, a complex bone fracture, or even a delicate heart valve, all printed out from a patient’s own scan data. This lets surgeons walk through the procedure step-by-step before they even enter the operating room.

Anatomical Models for Pre-Surgical Rehearsal

These aren’t just rough models; they can be incredibly detailed. Surgeons can use them to identify potential problems, figure out the best approach, and even practice difficult maneuvers. This kind of hands-on preparation can really cut down on surprises during the actual surgery. It’s like having a dress rehearsal for the most important performance of all – saving a life. This practice can lead to shorter surgery times and fewer complications, which is a win-win for everyone involved.

Enhanced Understanding of Complex Cases

Sometimes, looking at a 2D scan just doesn’t cut it, especially with really complicated issues. A 3D printed model gives a much clearer picture. Doctors can see how different parts relate to each other in space, which is super helpful for things like tumor removal or reconstructive surgery. It also makes it easier to explain what’s going on to the patient and their family. Showing someone a physical model of their own body part can make a huge difference in how well they understand the proposed treatment.

Improved Surgical Outcomes

When surgeons can plan and practice extensively using these models, the results in the operating room tend to be better. They go in more confident and prepared. Studies have shown that using 3D printed models can reduce the time spent in surgery by a significant amount, sometimes by over an hour. This not only saves costs but also reduces the patient’s exposure to anesthesia and the risks associated with long procedures. It’s a clear example of how technology is directly leading to better patient care and recovery.

Real-World Impact of 3D Printing in Healthcare

It’s pretty amazing to see how 3D printing is actually being used right now to help people. We’re not just talking about futuristic ideas anymore; this technology is making a difference today.

Case Studies in Surgical Planning

Think about a surgeon getting ready for a really tricky operation. Instead of just looking at flat scans, they can now hold a physical, 3D model of the patient’s specific anatomy. The Mayo Clinic, for example, has used this to plan complex surgeries, like separating conjoined twins. Being able to practice on a replica beforehand means less time in the operating room and, hopefully, better results for the patient. It’s like having a dress rehearsal for surgery.

Tissue Engineering and Regenerative Medicine

This is where things get really wild. Researchers are using 3D printing to create scaffolds that can help grow new tissues. Northwestern University has done some incredible work, even printing an ovary that, when put into mice, allowed them to have babies. While we’re a long way from human applications, it shows the potential for fixing damaged organs or even creating new ones down the line. It’s a huge step for medicine.

Custom Prosthetics for Veterans

For veterans who need prosthetic limbs, getting a good fit can be a long and expensive process. The Veterans Health Administration is using 3D printing to make custom prosthetics that are tailored exactly to each person’s body. This means a better fit, more comfort, and often, a much quicker turnaround time. It’s not just about replacing a limb; it’s about improving someone’s quality of life and giving them back their confidence.

The Expanding Scope of 3D Printing Applications

It’s pretty wild how much 3D printing is changing things in medicine, isn’t it? We’re not just talking about a few niche uses anymore; the applications are really spreading out into all sorts of areas. It feels like every week there’s some new way this technology is being used to help people.

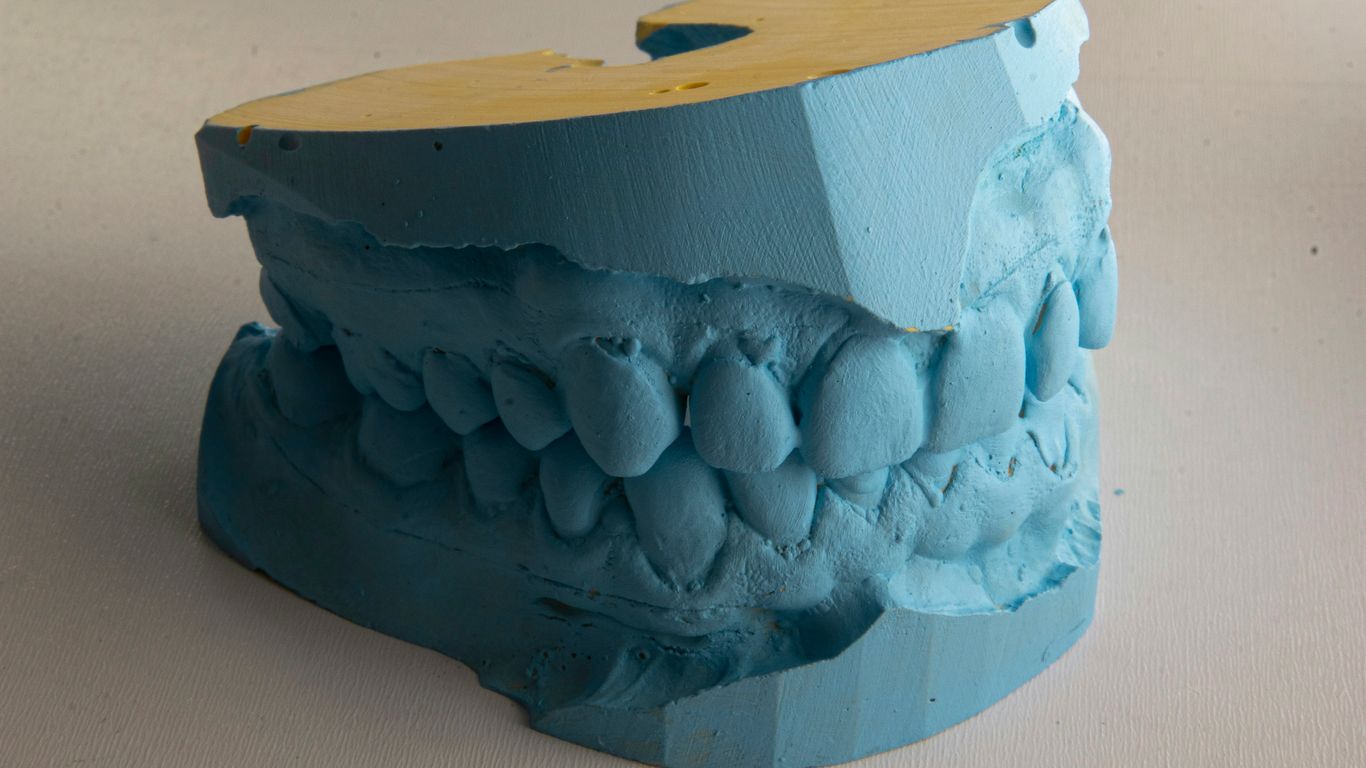

Dental Applications and Medical Devices

Think about your last trip to the dentist. Remember waiting for that crown or having to come back for another appointment? Well, 3D printing is shaking that up. Dentists can now print custom crowns, aligners, and even detailed models of your teeth right there in the office. This means less waiting around and a more personalized fit for whatever you need. It’s not just teeth, either. We’re seeing all sorts of medical devices being made this way, from specialized tools to parts for existing equipment. It makes getting what you need much faster and more precise.

Bioprinting of Tissues and Organs

This is where things get really sci-fi, but it’s happening. Researchers are working on printing actual human tissues using living cells. Imagine needing a skin graft and having it printed specifically for you, or even, down the line, printing replacement organs. There have been some pretty amazing experiments, like printing ovaries that actually worked in mice. It’s still early days for printing complex organs for humans, but the progress is undeniable. The idea is to reduce transplant waiting lists and the chance of rejection because the tissue is made from the patient’s own cells.

On-Demand Drug Manufacturing

This one might surprise you, but 3D printing could change how we get our medications. Instead of mass-producing pills that might not be the perfect dose for everyone, imagine printing your prescription right at the pharmacy, or even at home. This allows for incredibly precise dosages and customized release times, meaning the medicine works exactly how it should for each individual. It could make treatments much more effective and reduce side effects. It’s a big step towards truly personalized medicine.

Operational Benefits of 3D Printing in Medical Facilities

It’s pretty amazing how 3D printing is changing things in hospitals and clinics. Think about it – instead of waiting weeks for a custom part or device, you can often make it right there, on-site, in a matter of hours or days. This speed is a huge deal, especially when time is critical.

Speed and Efficiency in Device Production

This is probably the most obvious win. Traditional manufacturing for specialized medical items can be a slow process. You have to design it, send it off to a factory, wait for production, and then ship it. With an in-house 3D printer, that whole chain gets drastically shortened. For things like patient-specific surgical guides or even replacement parts for equipment, being able to print them quickly means less downtime and faster treatment for patients. It’s like going from sending a letter to instant messaging for device creation.

Cost Reduction and Waste Minimization

While setting up a 3D printing station might cost something upfront, the long-term savings can be pretty significant. You’re not stocking massive inventories of parts that might never get used. You print what you need, when you need it. This on-demand approach cuts down on storage costs and, importantly, reduces waste. Less material is wasted, and fewer old, unused devices end up in the trash. Plus, you save on shipping and handling fees associated with ordering from external suppliers.

Point-of-Care Manufacturing

This is where things get really interesting. ‘Point-of-care’ just means making things right where the patient is being treated. So, imagine a surgeon needing a specific tool or model during a complex operation. With 3D printing capabilities in the hospital, that tool or model can be printed in the very same building, sometimes even on the same floor. This immediate access is a game-changer for:

- Urgent repairs: Fixing broken medical equipment quickly.

- Customized surgical aids: Printing patient-specific guides or implants just before a procedure.

- Rapid prototyping: Quickly testing new device designs without lengthy external processes.

- Emergency supplies: Producing essential items during unexpected shortages, like we saw with PPE during the pandemic.

Navigating the Future of 3D Printing in Medicine

So, where is all this 3D printing in medicine headed? It’s a big question, and honestly, the possibilities seem pretty wild. We’re talking about a future where treatments are super personalized, and the technology is becoming more integrated into everyday hospital life. But, like anything new and exciting, there are definitely some hurdles to jump over.

Regulatory Considerations and Safety Factors

First off, we’ve got to talk about the rules. When you’re printing something that’s going inside a person or being used to plan their surgery, it has to be safe. Really safe. Regulatory bodies like the FDA are working on figuring out the best ways to approve these custom-made medical devices. It’s not as simple as approving a mass-produced item because each 3D-printed piece is unique.

- Ensuring material biocompatibility: The plastics, metals, or even cells used must be safe for the human body.

- Validating print accuracy and consistency: Every layer needs to be just right, every time.

- Establishing clear approval pathways: Making it easier for innovative designs to get the green light.

The goal is to make sure that while we embrace new tech, patient safety remains the absolute top priority.

Implementation and Management Strategies

Getting 3D printers into hospitals isn’t just a matter of buying a machine. It requires a whole plan. Think about:

- Training staff: Doctors, nurses, and technicians need to know how to use the printers and the software.

- Setting up workflows: How does a patient’s scan turn into a printed model or device? Who manages that process?

- Maintaining equipment: Just like any other medical device, these printers need regular upkeep.

Many hospitals are starting to set up their own in-house printing labs, sometimes called ‘point-of-care’ manufacturing. This means they can create what they need right there, on-site, which is way faster than ordering from an external company. It’s a big shift from just a few years ago when only a handful of hospitals had these facilities.

Emerging Technologies and Future Potential

This is where things get really futuristic. We’re already seeing incredible progress in areas like:

- Bioprinting: Imagine printing living tissues, maybe even simple organs, using a patient’s own cells. This could eventually mean no more waiting lists for transplants and fewer rejection issues.

- Custom Pharmaceuticals: Printing pills with exact dosages tailored to an individual’s needs, or even drugs that release their medication over a specific time. This could make treatments much more effective.

- Advanced Materials: New materials are being developed that are stronger, more flexible, and even more biocompatible than what we have now.

The market for 3D printing in healthcare is growing fast, and it’s expected to keep expanding significantly over the next several years. It feels like we’re just scratching the surface of what’s possible, and the impact on patient care could be enormous.

The Road Ahead

So, where does all this leave us? It’s pretty clear that 3D printing isn’t just a passing trend in medicine; it’s really changing things. We’ve seen how it helps surgeons plan tricky operations, how it makes custom parts for people who need them, and even how it’s starting to help with things like tissue and drug creation. It’s not perfect yet, and there are still some hurdles to jump over, like figuring out all the rules and making sure everything is safe. But the momentum is undeniable. As the technology gets better and more affordable, expect to see even more amazing uses pop up, making healthcare more personal and effective for everyone.

Frequently Asked Questions

What exactly is 3D printing in medicine?

Think of it like a super-advanced printer that doesn’t just put ink on paper. Instead, it builds real, solid objects, layer by layer, from a digital design. In medicine, this means we can create custom body parts, like fake limbs or even models of organs, that are perfectly shaped for each person. It uses special materials that are safe for the body.

How does 3D printing help doctors plan surgeries?

Doctors can take scans of a patient, like X-rays or MRIs, and use them to print an exact copy of the part of the body they need to operate on. This lets them practice the surgery beforehand on the 3D model, like rehearsing a play. It helps them see exactly what to do and avoid surprises, making the real surgery safer and quicker.

Can 3D printing make fake limbs (prosthetics) better?

Yes, definitely! Instead of making a generic fake limb that might not fit quite right, 3D printing allows doctors to make one that’s custom-made for each person’s body. This means it can be more comfortable, fit better, and work more naturally, helping people move around and live their lives more easily.

Is 3D printing used for anything besides body parts?

It’s used for a lot of things! For example, dentists can print custom crowns or braces. Researchers are even working on printing simple tissues or parts of organs that could one day be used in transplants. Plus, they can print medicines that are made just for one person with the exact right amount of medicine needed.

Does 3D printing save hospitals money or time?

It can do both! Making custom medical items the old way can take a long time and be expensive. With 3D printing, hospitals can often make what they need much faster, sometimes in just a day or two, and it can reduce waste because they only make what’s needed. This means less waiting for patients and potentially lower costs.

Are there any rules or safety concerns with 3D-printed medical items?

Yes, there are rules. Just like any medical device, things made with 3D printers need to be tested and approved to make sure they are safe and work correctly for patients. Experts are working hard to make sure these technologies are used safely and effectively in hospitals.