Defining Robotics vs Robots: Core Concepts

Okay, so you hear the words ‘robotics’ and ‘automation’ thrown around a lot, and honestly, they can sound pretty similar. It’s easy to get them mixed up. But there’s a real difference, and understanding it helps a bunch when you’re trying to figure out what technology actually fits what job.

Understanding Automation as a Broad Category

Think of automation as the big umbrella. It’s all about using technology – be it software, machines, or other devices – to do tasks that people would normally do. This can be super simple, like a thermostat turning on your heat when it gets cold, or really complex, like software that handles customer service inquiries. It’s basically about making things happen automatically, without a person needing to be there every second.

- Software Automation: This is when programs handle repetitive digital tasks, like filling out forms or moving data between applications. Robotic Process Automation (RPA) is a type of this, where software ‘robots’ mimic human actions on a computer.

- Process Automation: This involves setting up systems to manage and control workflows, often in manufacturing or business operations, to improve efficiency.

- Hardware Automation: This is where machines or devices perform physical tasks automatically, like an assembly line machine.

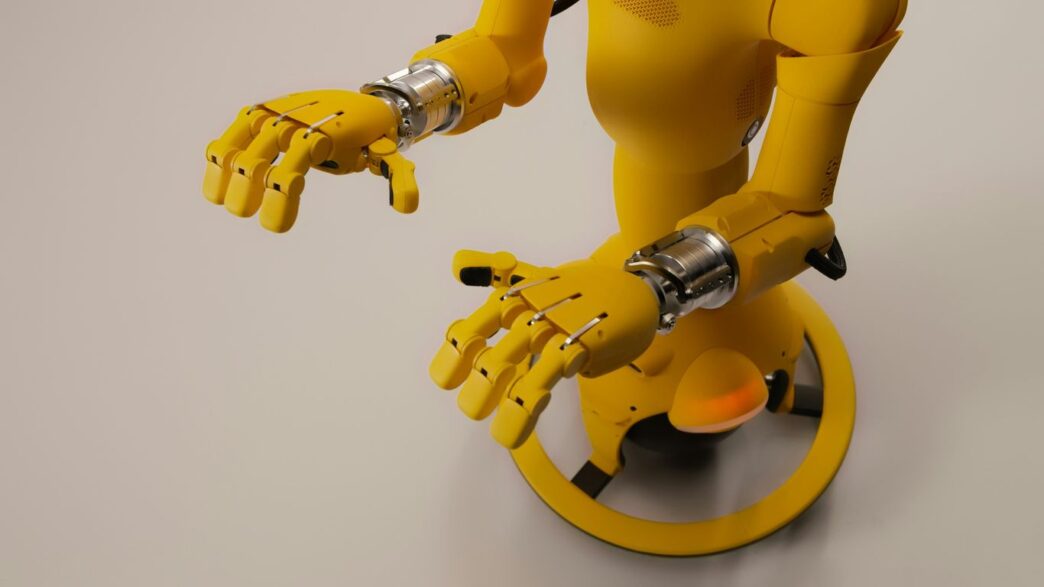

Robotics: The Realm of Physical Machines

Now, robotics is a bit more specific. It’s the field that deals with designing, building, and operating robots. And when we talk about robots in this context, we’re usually talking about physical machines. These aren’t just any machines; they’re typically programmable and can interact with the physical world. They can sense things, move, and perform actions. Robotics is essentially a specialized part of automation that focuses on creating these physical agents.

The Interdisciplinary Nature of Robotics

Robotics isn’t just about building a metal body. It’s a mix of different fields. You’ve got:

- Mechanical Engineering: For the physical structure, joints, and movement.

- Electrical Engineering: For the power, wiring, and control systems.

- Computer Science: For the programming, artificial intelligence, and decision-making.

- Sensors and Actuators: To allow the robot to perceive its environment and act upon it.

It’s this combination that allows a robot to do more than just follow a set path; it can potentially react to its surroundings, learn, and adapt. It’s pretty neat when you think about it.

Key Distinctions in Functionality and Scope

So, we’ve talked about what robotics and automation are, but how do they actually differ in what they do and what they can cover? It’s not just about whether it’s a physical machine or a computer program, though that’s a big part of it. Think of it like this: automation is the big picture goal, and robotics is one of the ways we achieve that goal, especially when physical work is involved.

Automation’s Focus on Task Execution

Automation, at its heart, is all about getting tasks done without a person having to do them. This can be anything from software automatically sending out emails based on a trigger, to a thermostat turning on the heat when it gets cold. It’s about setting up a system, whether it’s code or a simple device, to follow a set of rules and complete a job. The main point here is the task itself. Is it repetitive? Is it rule-based? Can we set it up so it just runs on its own?

- Digital Tasks: Think about processing invoices, moving data between spreadsheets, or managing customer service inquiries. Software bots, often called Robotic Process Automation (RPA), are great at this. They mimic human actions on a computer.

- Physical Tasks (Simple): Even simple physical actions can be automated. A timed sprinkler system for your lawn is a basic form of automation.

- Process Improvement: The goal is usually to speed things up, cut down on mistakes humans might make, and free up people for more complex work.

Robotics’ Emphasis on Design and Construction

Robotics, on the other hand, is more about the machine itself. It’s the engineering and computer science that go into creating a physical robot. This involves designing its body, figuring out how its parts move (actuators), giving it ways to sense the world (sensors, cameras), and programming its brain (processors, AI) to do something useful. A robot is a physical entity designed to interact with the physical world. While automation is about the ‘what’ (the task), robotics is heavily focused on the ‘how’ (the physical means to accomplish it).

- Physical Interaction: Robots are built to move, manipulate objects, and navigate spaces. This could be a robot arm on an assembly line or a drone inspecting a bridge.

- Complex Environments: Many robots are designed to work in places that are difficult, dangerous, or just plain tedious for humans.

- Adaptability: Advanced robots can sense their surroundings and adjust their actions, making them more flexible than simple automated systems.

The Spectrum of Automation: From Software to Hardware

It’s really helpful to see automation not as one thing, but as a wide range. On one end, you have pure software automation, like RPA, which handles digital tasks. It doesn’t need a physical body. On the other end, you have highly sophisticated robots that are physical machines, often using advanced AI to make decisions and act in the real world. Then, there’s a whole lot in between. Think of automated factory machines that aren’t necessarily ‘robots’ in the common sense but are definitely automated systems. The key is that automation is the umbrella term for using technology to do tasks, and robotics is a specific, often physical, way to achieve that automation.

Robots in Action: Types and Applications

So, we’ve talked about what robotics is and how it’s different from just automation. Now, let’s get down to the nitty-gritty: what do these robots actually do? It’s not just science fiction anymore; robots are out there, working in all sorts of places.

Industrial Robots and Manufacturing Processes

This is probably where most people picture robots. Think big factories, assembly lines, and heavy lifting. Traditional industrial robots are built for repetitive, high-precision tasks. They’re often caged off for safety because they’re powerful and move fast. They’ve been doing things like welding car parts, painting car bodies, and moving heavy stuff around warehouses for decades. They’re great at doing the same thing over and over without getting tired or making mistakes, which is a huge deal for mass production.

- Welding: Spot welding, arc welding – robots do it with incredible consistency.

- Painting: Applying paint evenly on complex shapes, like car exteriors.

- Assembly: Putting together components, especially in electronics manufacturing.

- Material Handling: Moving items from one place to another, like loading and unloading machines.

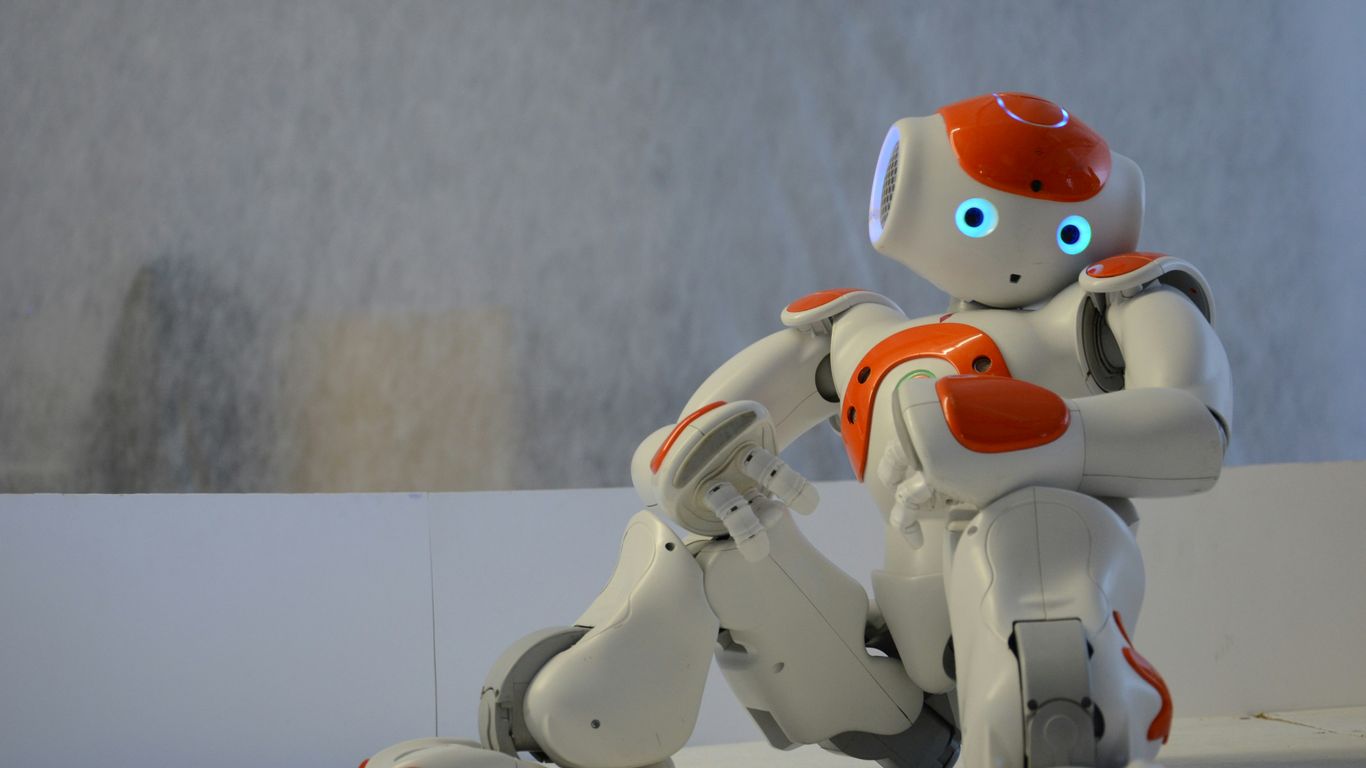

Collaborative Robots: A New Era

These are the ‘cobots,’ and they’re changing the game. Unlike their industrial cousins, cobots are designed to work alongside humans. They’re usually lighter, have built-in safety features that stop them if they bump into something, and are way easier to program. This means smaller businesses can use them, and they can be moved around to different jobs pretty quickly. They’re showing up in places where humans and robots can share tasks, making things more efficient without replacing people entirely.

Cobots are making automation accessible to a wider range of businesses.

Here’s a quick look at how they differ:

| Feature | Traditional Industrial Robots | Collaborative Robots (Cobots) |

|---|---|---|

| Safety | Often caged, requires safety zones | Built-in sensors, can work near humans |

| Programming | Complex, requires experts | Simpler, often intuitive |

| Flexibility | Fixed tasks, hard to reconfigure | Easily reprogrammed for new tasks |

| Footprint | Large, dedicated space | Smaller, can be mobile |

Autonomous Robots and Decision-Making Capabilities

Then you have the robots that can think for themselves, sort of. These are autonomous robots. They use sensors, cameras, and AI to understand their surroundings and make decisions on the fly. Think of robots that can navigate a warehouse on their own, inspect pipelines for damage, or even help with complex surgeries. They don’t need constant human control. They can adapt to changing situations, which is pretty amazing. They’re used in all sorts of fields, from exploring dangerous places to helping out in hospitals.

- Navigation: Moving through complex environments without bumping into things.

- Inspection: Using cameras and sensors to spot problems, like leaks or structural weaknesses.

- Logistics: Moving goods around in warehouses or even delivering items.

- Healthcare: Assisting in surgeries or providing patient care.

The Symbiotic Relationship: Robotics and Automation

It’s easy to get these two mixed up, but automation and robotics really work best when they’re together. Think of automation as the big idea – making things happen without a person doing every single step. Robotics is one of the main ways we make that happen, especially when we need a physical machine to do the work.

How Robotics Enhances Automation

Robots are the muscle and brains behind a lot of modern automation. They can do repetitive tasks faster and more accurately than humans, which is a huge win for efficiency. Plus, they can handle jobs that are dangerous or just plain unpleasant for people, like working with chemicals or in really hot environments. This frees up human workers to focus on more complex problem-solving or quality control.

- Increased Speed: Robots can perform tasks much faster than humans, leading to higher production output.

- Improved Accuracy: They maintain consistent precision, reducing errors and waste.

- Enhanced Safety: Robots take on hazardous jobs, protecting human workers.

- 24/7 Operation: Robots don’t need breaks, allowing for continuous production.

Complementary Roles in Modern Operations

Automation isn’t just about robots, though. It also includes software that manages processes, sensors that collect data, and systems that control everything. Robotics fits into this by providing the physical component that interacts with the world. For example, an automated warehouse might use software to track inventory, but it needs robots to actually pick and move the boxes.

| Area of Operation | Automation’s Role | Robotics’ Role |

|---|---|---|

| Manufacturing | Process control, scheduling, quality checks | Assembly, welding, painting, material handling |

| Logistics | Inventory management, order processing | Picking, packing, sorting, transport |

| Healthcare | Patient record management, appointment scheduling | Surgical assistance, lab sample handling |

Driving Innovation Through Integrated Systems

When you combine smart automation systems with advanced robots, you get something really powerful. We’re seeing robots that can learn and adapt, thanks to AI and better automation software. This means they can handle more varied tasks and even work alongside humans more safely and effectively, like those "cobots" we talked about. This integration is what’s really pushing the boundaries of what’s possible in almost every industry. It’s not just about doing things faster; it’s about doing them smarter and creating entirely new ways of working.

Navigating the Landscape of Robotics vs Robots

So, you’ve been hearing a lot about robotics and robots, and maybe the lines have gotten a little blurry. It’s totally understandable. Think of it like this: automation is the big umbrella, and robotics is a really important part of what fits under it. But knowing which piece you need for your specific situation is key. It’s not just about picking the fanciest tech; it’s about finding what actually makes sense for your business goals and what you want to achieve.

Choosing the Right Technology for Business Needs

When you’re looking at bringing in new tech, whether it’s a sophisticated robotic arm or a smart software automation tool, the first question should always be: what problem am I trying to solve? Are you trying to speed up a repetitive physical task on the factory floor? Or maybe you need to streamline a bunch of paperwork that’s bogging down your office staff?

Here’s a quick way to think about it:

- Robotics: Best for physical tasks that require movement, manipulation, or interaction with the real world. Think assembly lines, picking and packing, or even complex surgeries.

- Automation (Broader Sense): Great for repetitive digital tasks, process optimization, and data handling. This could be anything from scheduling appointments to managing customer service inquiries with chatbots.

- Software Robots (RPA): A specific type of automation that mimics human actions on a computer. Good for tasks like data entry, form filling, or processing invoices.

The most effective solutions often combine both robotics and software automation. For example, a robot might physically pick up an item, and then software automation might handle the inventory update and shipping notification.

Scalability and Future-Ready Solutions

It’s not enough to just solve today’s problem. You also need to think about tomorrow. Will the technology you choose grow with your business? Can it handle more work if your demand increases?

Consider these points:

- Modularity: Can you add more robots or automation modules later without a complete overhaul?

- Integration: How well does it play with your existing systems? You don’t want to create new silos.

- Adaptability: Can the system be reprogrammed or reconfigured for new tasks as your needs change? A robot that can only do one thing might become obsolete quickly.

Future-ready solutions are flexible. They aren’t rigid boxes that do one job. They are systems that can evolve alongside your company, adapting to new challenges and opportunities. This means looking beyond the initial setup cost and thinking about the long-term return on investment.

Maximizing Benefits Through Responsible Adoption

Bringing in robotics and automation isn’t just about efficiency; it’s also about how you implement it. A thoughtful approach leads to better outcomes for everyone involved. This means not just focusing on the technology itself, but also on the people who will work with it.

Think about:

- Training: Properly train your staff on how to operate, maintain, and work alongside the new systems. This builds confidence and competence.

- Safety: Always prioritize safety. Robots, especially in shared workspaces, need robust safety protocols.

- Ethical Considerations: Be mindful of job displacement. While these technologies create new roles, it’s important to manage the transition for your workforce responsibly, perhaps through reskilling programs.

When adopted thoughtfully, robotics and automation can significantly boost productivity, improve product quality, and create a safer, more engaging work environment. It’s about making smart choices that benefit your business, your employees, and your customers in the long run.

Wrapping It Up

So, we’ve talked about how automation is the big picture – using tech to get stuff done without people doing it all. Robotics is a part of that, specifically about building and using those physical machines, the robots themselves. They work together a lot, especially in factories and warehouses, making things faster and safer. Thinking about them separately helps us figure out what tools we really need. It’s not just about fancy machines; it’s about making work smarter, whether that’s with software or with robots doing the heavy lifting. As these technologies keep changing, understanding this difference will be key for businesses looking to keep up and get ahead.