Semicon USA is a big deal when we talk about the future of computer chips. These tiny things are everywhere, powering everything from our phones to super-smart computers. This event brings together folks who are figuring out how to make these chips even better and what that means for all of us. It’s all about what’s next in tech and how the US stays in the game.

Key Takeaways

- Semicon USA highlights how chips are central to new tech like AI and faster internet.

- The way chips are put together, called advanced packaging, is changing chip design and making things more complicated but also more efficient.

- Cars are using way more chips now, especially with electric vehicles and smart features becoming common.

- Making chips uses a lot of power, and where they’re made matters for the environment. We need to think about how to make them with less impact.

- The US wants to keep its lead in chip making, but faces tough competition and needs smart plans to keep innovating.

Semicon USA: Driving Future Technologies

Semicon USA is really the place where the future gets built, you know? It’s all about the tiny chips that make everything else work. For decades, America has been at the forefront of this, giving us everything from the first computers to the smartphones in our pockets. Now, these same chips are the backbone of what’s next – think artificial intelligence, quantum computing, and super-fast wireless networks.

Enabling Artificial Intelligence and Quantum Computing

Artificial intelligence and quantum computing aren’t just buzzwords anymore; they’re becoming real, and semiconductors are the engine. AI needs massive amounts of processing power, and quantum computing is on a whole new level of complexity. The chips being developed today are designed to handle these incredible demands. It’s a race to create more powerful and efficient processors that can crunch data at speeds we could only dream of a few years ago. This push is what will define the next wave of technological breakthroughs.

Securing Leadership in Advanced Wireless Networks

We’re talking about 5G, 6G, and beyond. These advanced wireless networks need specialized chips to operate. They’re not just about faster downloads; they’re about connecting everything – cars, homes, industries – in ways that are more reliable and responsive. The innovation happening in semiconductor design is directly tied to how well these networks perform and how widely they can be deployed. It’s a complex ecosystem where chip performance dictates network capability.

The Critical Role of Semiconductors in National Security

It might not be the first thing you think of, but semiconductors are absolutely vital for national security. From defense systems to intelligence gathering, the technology that powers these operations relies heavily on advanced chips. Maintaining a strong domestic semiconductor industry means the U.S. can control the technology it needs for its security, rather than depending on other countries. This isn’t just about economic competition; it’s about safeguarding the nation.

Innovations Shaping the Semiconductor Landscape

It feels like every week there’s some new tech that just blows your mind, right? And behind all of it, you’ve got these tiny, super-complicated chips. They’re not just getting smaller; they’re doing way more. It’s pretty wild to think about how much they’ve changed things already, and we’re just getting started.

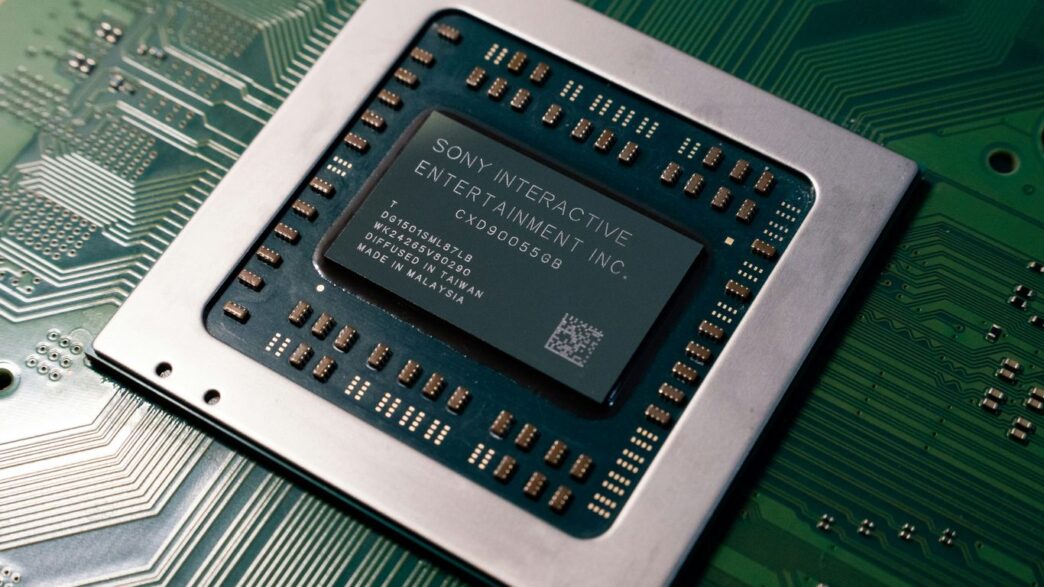

The Impact of Advanced Packaging on Chip Design

So, you know how they used to just make one big chip for everything? Well, that’s changing. They’re now putting multiple smaller chips together in clever ways, called advanced packaging. It’s like building with LEGOs, but for electronics. This lets them make devices that are smaller and can do more without needing a giant motherboard. Think about your smartphone – it’s packed with more power than a supercomputer from just a few decades ago, and packaging is a big reason why. It’s a tricky process, though, and uses a lot of energy, so it’s a bit of a balancing act between making things smaller and more efficient versus the energy it takes to make them.

Reshaping Automotive Electronics with Semiconductor Power

Cars are basically computers on wheels now. With all the talk about electric vehicles and self-driving features, the number of chips in a car is just going through the roof. It’s not just about the engine anymore; it’s about all the sensors, the screens, the safety systems. They need chips that can handle a lot of data, process it fast, and work reliably in tough conditions. This shift is pushing chipmakers to create new kinds of processors and memory that are specifically designed for the demands of the automotive world.

Meeting the Demand of Artificial Intelligence

Artificial intelligence is everywhere, and it’s hungry for computing power. Training AI models, especially the really big ones, takes an incredible amount of processing. This means we need specialized chips that are super good at the kinds of math AI relies on. It’s not just about having more chips; it’s about having the right kind of chips. This demand is driving a lot of the innovation we’re seeing today, pushing the boundaries of what’s possible in chip design and manufacturing. Plus, all these AI calculations happen in massive data centers, which also need a ton of power, adding another layer to the whole picture.

Sustainability in Semiconductor Manufacturing

Regional Differences in Chip Manufacturing Footprints

So, where chips get made really matters when we talk about their environmental impact. Think about it: if a factory is powered mostly by clean energy, like solar or wind, it’s going to have a much smaller carbon footprint than one running on coal. Some parts of the U.S. are getting better at this, using more renewables. But then you have other regions that still rely heavily on fossil fuels. This difference in energy sources means the same chip can have a wildly different environmental story depending on where it was produced. It’s not just about the factory itself, but the whole power grid it’s plugged into.

Balancing Energy Intensity with Chip Efficiency

Making semiconductors is a power-hungry business, no doubt about it. The newer, more complex chips, especially those for things like AI, need even more intricate manufacturing steps. Advanced packaging, for instance, is a big part of this. It allows us to cram more power into smaller spaces, which is great for performance and can even make the final product more energy-efficient when it’s running. But the manufacturing process itself? It uses a lot of energy and resources. The real trick is figuring out how to make these super-advanced chips without burning through an unsustainable amount of energy and materials during production. It’s a tough balancing act, trying to get the best tech while minimizing the environmental cost of making it.

Addressing Environmental Concerns of Data Centers

We all know AI is booming, and that means we need more and more powerful chips. But it’s not just the chips themselves; it’s also the massive data centers that house them. These places are huge energy consumers. And here’s the kicker: not all data centers are running on clean energy. Some are still powered by grids that rely on fossil fuels. So, while we’re getting excited about what AI can do, we also have to think about the environmental cost of keeping all those servers humming. It’s a big piece of the puzzle when we look at the overall sustainability picture of modern technology.

Navigating Challenges in the Semiconductor Sector

Look, the semiconductor industry is a big deal, and it’s not without its headaches. We’ve been at the forefront for decades, but keeping that lead is getting tougher. Other countries are making big moves, and frankly, keeping up with the pace of innovation while also dealing with global competition is a serious challenge. The United States needs a clear plan to stay ahead.

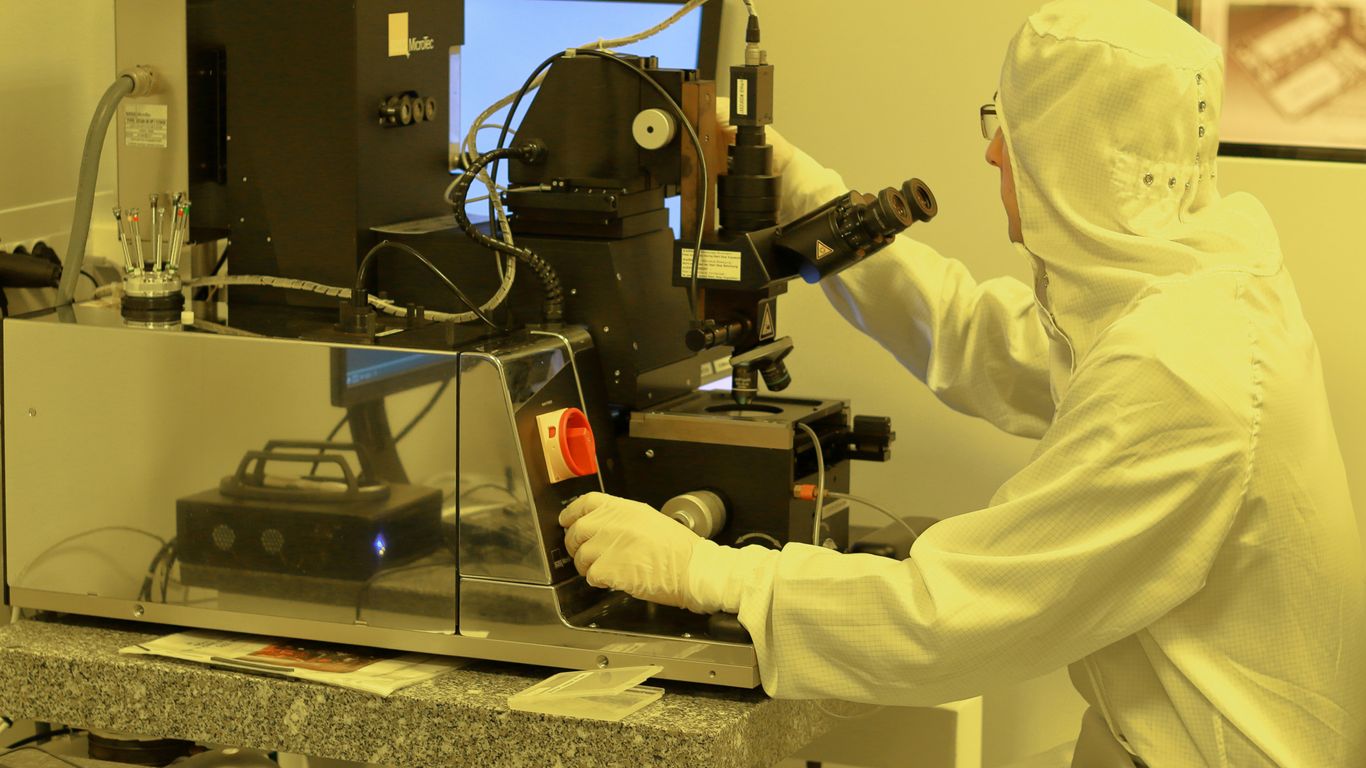

Confronting Technology Challenges and Foreign Competition

It feels like every week there’s a new tech hurdle to jump. Developing the next generation of chips requires massive investment and a lot of smart people. At the same time, we’re seeing other nations pour resources into their own semiconductor industries. This isn’t just about bragging rights; it’s about economic strength and national security. We need to make sure our research and development can keep pace, and that our manufacturing capabilities remain top-notch. It’s a constant race to stay ahead of the curve and fend off rivals who are also pushing hard.

Ensuring Continued Semiconductor Innovation

Innovation doesn’t just happen. It needs support. We’re talking about funding for basic research, training the next generation of engineers, and creating an environment where new ideas can actually take root and grow. Without a steady stream of new breakthroughs, we risk falling behind. This means looking at everything from materials science to chip architecture. It’s a complex puzzle, and every piece matters.

The Importance of Policy Actions for U.S. Leadership

Government policy plays a bigger role than you might think. Things like tax incentives, trade agreements, and investments in education can make a real difference. We need policies that encourage companies to build and innovate here at home, rather than looking elsewhere. It’s about creating a stable and supportive ecosystem. Think of it like this:

- Investing in R&D: Putting money into research labs and universities to explore new chip technologies.

- Workforce Development: Training programs to get more skilled workers into the field.

- Supply Chain Support: Making sure we have reliable access to the materials and equipment needed for manufacturing.

These aren’t just abstract ideas; they’re practical steps that can help secure our future in this vital industry.

Enhancing Transparency in the Industry

It feels like everywhere you look these days, there’s talk about sustainability and environmental impact. The semiconductor industry is no different, and honestly, it’s about time we got more open about what’s really going on. We need clear, consistent ways to talk about how chips are made and what that means for the planet. Without it, it’s hard to know who’s actually doing the work to be greener and who’s just talking a good game.

The Need for Standardized Sustainability Reporting

Right now, comparing sustainability efforts across different chip companies can be a real headache. Everyone reports things a little differently, making it tough to get a true picture. We need a common language, a set of standards, so we can actually compare apples to apples. This would push companies to be more honest and proactive about their environmental footprint. Think about it like this:

- Energy Use: How much power does manufacturing a chip really take, and where does that power come from?

- Water Consumption: How much water is used, and how is it managed afterward?

- Waste Generation: What kind of waste is produced, and how is it disposed of or recycled?

- Chemical Management: How are hazardous materials handled throughout the process?

Having these kinds of metrics standardized would make a huge difference. It would also help companies like those working with complex chemical regulations to better track their own impacts.

Improving Environmental Reporting Quality and Consistency

Beyond just having standards, we need the actual reporting to be good. That means making sure the data is accurate, reliable, and easy to understand. It’s not just about ticking boxes; it’s about providing information that can actually lead to change. This is especially important as we see the demand for chips grow for things like AI and advanced wireless networks. The more chips we make, the bigger the potential impact, so we need to be able to track it accurately. This kind of detailed reporting helps everyone understand the real environmental cost, from the energy intensity of chip manufacturing to the impact of large data centers.

Driving Industry-Wide Change Through Data

Ultimately, all this transparency is about driving real change. When companies are open about their environmental performance, it creates pressure to improve. It also allows for better collaboration and the sharing of best practices. Imagine if we had a public database showing the carbon footprint of different manufacturing processes or the water usage for various chip designs. That kind of data could really push the industry forward. It helps us see where the biggest challenges are, like balancing the energy needs of advanced packaging with the desire for more efficient chips, and then work together to find solutions. This open approach is key to making sure the semiconductor industry grows responsibly.

Looking Ahead

So, after checking out all the buzz at SEMICON USA, it’s pretty clear that the folks making these tiny chips are thinking hard about what’s next. We’re talking about chips for AI, for cars that drive themselves, and for all sorts of new tech. It’s not just about making them faster or smaller anymore; there’s a real focus on how these chips are made and where they come from, especially with energy use and the environment in mind. It feels like a big shift, and keeping America in the game means paying attention to research and making sure we can actually build these things here. It’s a lot to keep track of, but it’s definitely shaping up to be an interesting few years for the whole semiconductor world.

Frequently Asked Questions

What are semiconductors and why are they important for the U.S.?

Semiconductors are the tiny computer chips that power almost everything we use today, like phones and computers. They are super important for America because they help create new technologies, create jobs, and keep the country safe and ahead in technology.

How are semiconductors helping with new technologies like AI and faster internet?

These chips are the brains behind exciting new things like artificial intelligence (AI), which helps computers learn, and super-fast wireless networks. They are essential for making these future technologies work and for America to stay a leader in them.

What are some of the challenges the U.S. semiconductor industry faces?

The U.S. semiconductor industry faces tough competition from other countries and new technological hurdles. It’s a challenge to keep inventing and making the best chips when others are also working hard to do the same.

How does where chips are made affect the environment?

Making chips uses a lot of energy. If chips are made in places that get their power from clean sources like solar or wind, it’s better for the environment than places that rely heavily on coal. Also, the big computer centers needed for AI use a lot of power.

What is ‘advanced packaging’ in chip making, and is it good or bad for the environment?

Advanced packaging is a newer way to build chips that makes them smaller and work better. However, this process uses more energy, which can be tough on the environment. It’s like trying to make a smaller, more powerful gadget that needs more electricity to run.

Why is it important to have clear rules for reporting on sustainability in the chip industry?

Having standard ways for companies to report how environmentally friendly they are helps everyone understand the impact. It makes it easier to compare companies and encourages everyone to find better, cleaner ways to make chips, leading to positive changes across the whole industry.