Simulation World 2024: Advancing Engineering Education

Simulation World 2024 is really shaking things up when it comes to how we teach and learn engineering. It’s not just about textbooks anymore; we’re seeing a big shift towards more hands-on, digital experiences that prepare students for the real world.

Immersive Learning Environments for Engineering

Think about learning complex engineering concepts not just by reading about them, but by actually being in them. Immersive learning environments, often using virtual reality (VR) or augmented reality (AR), let students interact with 3D models of machinery, explore intricate designs, or even conduct virtual experiments that would be too dangerous or expensive in a physical lab. This kind of active participation makes abstract ideas much easier to grasp. It’s like going from looking at a blueprint to walking through the building before it’s even constructed.

Virtual Reality in Vocational Training

For those learning a trade or specific technical skills, VR is a game-changer. Instead of just watching a demonstration, trainees can practice tasks repeatedly in a safe virtual space. This is particularly useful for skills that require precision or involve working with heavy equipment. Imagine a student learning to operate a complex piece of industrial machinery; VR allows them to get comfortable with the controls and procedures without any risk of damaging equipment or causing injury. Studies show this can really speed up the learning process and improve retention.

Metaverse Technologies for Enhanced Learning

The metaverse, in its broader sense, is opening up new avenues for collaborative learning. It’s not just about individual VR experiences; it’s about creating shared virtual spaces where students and instructors can meet, interact, and work together on projects. This can break down geographical barriers, allowing students from different parts of the world to collaborate on engineering challenges. It also provides a platform for educators to build more engaging and interactive learning modules, moving beyond traditional lecture formats. We’re seeing a move towards "edu-metaverse" ecosystems designed specifically for educational purposes.

Pioneering Virtual Engineering Frontiers

Simulation World 2024 is really pushing the boundaries of what we can do with virtual tools in engineering. It’s not just about making things look real; it’s about creating entirely new ways to interact with engineering concepts and processes.

Programmable Reality and Digital Twins

Think about programmable reality. This is where the digital world isn’t just a static model, but something that can change and adapt based on real-world data or user input. Digital twins are a big part of this. They’re basically virtual copies of physical things, like a machine or even a whole factory. These twins get live updates, so you can see exactly what the real thing is doing, predict problems, and test changes without touching the actual equipment. It’s like having a crystal ball for your engineering projects.

Spatial Computing and Interactive Environments

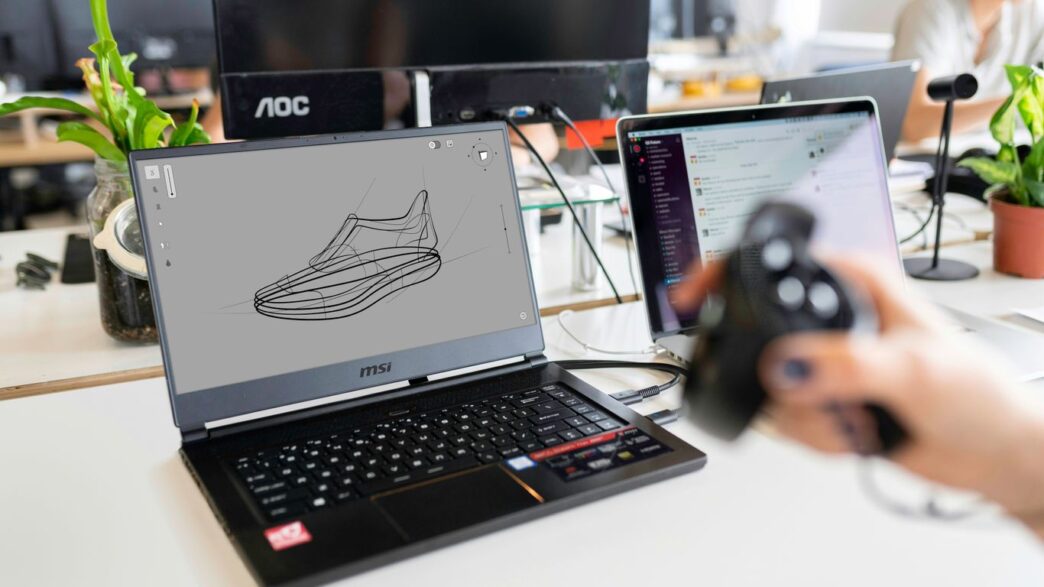

Then there’s spatial computing. This is all about how we interact with digital information in a 3D space. Instead of just looking at a flat screen, we can now walk around, manipulate, and understand complex designs in a way that feels more natural. Imagine being able to grab a 3D model of an engine and rotate it, zoom in on specific parts, or even see how different components fit together, all within a virtual space. This makes understanding intricate systems much easier.

Bridging Physical and Digital Engineering Workflows

What’s really exciting is how these technologies are starting to connect the physical and digital worlds. We’re moving beyond just using simulations for design. Now, engineers can use virtual environments to plan out physical tasks, train for complex procedures, or even collaborate on designs in real-time, no matter where they are. This blend means fewer mistakes on the factory floor and faster development cycles. It’s about making sure that what happens in the virtual world translates directly and effectively into the real world.

Innovations in Simulation and XR

Simulation World 2024 is really showing off some cool new ways we can mix the real world with digital stuff. It’s not just about VR headsets anymore; we’re seeing a lot more focus on how these technologies can actually work together.

Cross-Reality Learning Experiences

This is where things get interesting. Instead of just being in a fully virtual world or looking at an augmented overlay, cross-reality (XR) learning aims to blend these. Think about a lab class where some students are physically present, and others join from afar, but everyone interacts with the same virtual equipment. It’s like having a shared space that exists in both the physical and digital realms simultaneously. This approach is great because it allows for more flexible collaboration, letting people join in no matter where they are. It’s about making sure everyone feels like they’re in the same room, working on the same project, even if they’re miles apart. The goal is to make these blended experiences feel as natural as possible, breaking down the barriers between different realities.

Augmented Reality in Engineering Education

Augmented Reality (AR) is getting a lot more practical for engineering. We’re moving past simple 3D models floating in space. Now, AR is being used to overlay complex data directly onto physical equipment. Imagine a student working on a real engine, and their AR glasses show them real-time performance metrics, diagnostic information, or even step-by-step repair instructions directly on the parts they’re looking at. This kind of direct, contextual information can really speed up learning and reduce errors. It’s like having an expert guide right there with you, pointing out exactly what needs attention.

Designing Effective Edu-Metaverse Ecosystems

Building these virtual learning spaces, often called the ‘Edu-Metaverse,’ is more than just setting up a virtual classroom. It’s about creating a whole environment where learning can happen naturally. This involves:

- Content Creation Tools: Making it easy for educators to build and update learning modules within the metaverse.

- Interoperability: Ensuring different virtual tools and platforms can work together smoothly.

- User Experience Design: Focusing on how students and teachers actually interact within these spaces to make it intuitive and engaging.

- Assessment Methods: Developing new ways to measure learning that fit these immersive environments.

It’s a big undertaking, but the potential for creating deeply engaging and effective learning experiences is huge. We’re talking about virtual campuses, simulated industrial sites, and collaborative project spaces that feel incredibly real.

The Evolving Landscape of Virtual Engineering

It feels like every day there’s something new popping up in how we approach engineering, especially with all this virtual stuff. The way we learn and work is changing, and it’s not just about fancy gadgets anymore. We’re seeing a real shift towards integrating digital tools into the core of engineering practices.

Industrial Metaverse and Its Impact

The idea of an "industrial metaverse" is starting to take shape. Think of it as a persistent, shared digital space where engineers can design, test, and even manage physical systems before they’re built or while they’re in operation. This isn’t just a game; it’s about creating digital twins of real-world assets, allowing for simulations that are incredibly detailed. Companies are looking at this to cut down on physical prototyping costs and speed up development cycles. It’s a big change from just looking at blueprints on a screen.

Future Skills for Industry 4.0 Integration

So, what does this mean for the people actually doing the engineering? Well, the skills needed are changing too. We’re moving beyond just knowing how to use specific software. Now, it’s about being adaptable and understanding how to work within these complex digital environments.

Here are some key areas:

- Digital Fluency: Being comfortable with various simulation tools, VR/AR interfaces, and data analysis platforms.

- Problem-Solving in Virtual Spaces: Learning to identify and fix issues within digital models and simulations.

- Collaboration Across Digital Platforms: Working effectively with teams who might be physically distant but connected through these virtual environments.

- Understanding of AI Integration: Knowing how artificial intelligence can assist in simulations and design processes.

The ability to learn and adapt quickly to new virtual tools will be a major advantage.

Collaborative Learning in the Edu-Metaverse Era

This evolution isn’t limited to industry; it’s also making waves in education. The "edu-metaverse" is becoming a thing, where students can learn engineering concepts in interactive, virtual settings. Imagine dissecting a virtual engine or walking through a simulated factory floor to understand its layout. This kind of hands-on, albeit virtual, experience can really help solidify understanding. It’s a move towards more engaging and accessible learning, especially for complex subjects. The goal is to make learning more practical, even when physical resources are limited or dangerous to access.

Transforming Engineering Practices with Simulation World 2024

Simulation World 2024 is really shaking things up when it comes to how engineers learn and work. It’s not just about theory anymore; it’s about getting hands-on, even when the equipment is miles away or too expensive to use regularly. This event highlights how digital spaces are becoming just as important as physical labs.

Hands-On Learning in Digital Immersive Environments

Forget just reading textbooks. The future of engineering education involves stepping into virtual worlds. These digital environments let students build, test, and break things without real-world consequences. Think of it like a super-advanced sandbox where you can try out complex machinery or chemical reactions safely. This approach means more people can get practical experience, regardless of their location or access to physical resources. It’s a big step towards making engineering training more accessible and repeatable.

- Simulating complex scenarios: Students can practice troubleshooting intricate systems that would be difficult or dangerous to replicate in a traditional lab.

- Cost-effective training: Reduces the need for expensive physical equipment and materials, making advanced training more affordable.

- Repeatable practice: Allows students to practice tasks multiple times until they get them right, building confidence and skill.

- Global collaboration: Teams from different parts of the world can work together in the same virtual space on projects.

Virtual Worlds for Professional Skill Development

It’s not just for students, either. Professionals are using these virtual spaces to hone their skills too. Imagine a seasoned engineer practicing a new, complex procedure in a virtual replica of a plant before doing it for real. Or a team learning to coordinate during a simulated emergency. These virtual worlds are becoming training grounds for soft skills, like communication and teamwork, as well as technical abilities. Studies show that using virtual worlds can be quite effective for training engineers in areas like smart city development, helping them understand complex systems and how to manage them.

AI-Enhanced Educational Environments

Adding artificial intelligence into these virtual learning spaces is another game-changer. AI can act as a virtual tutor, providing instant feedback, adapting challenges to a student’s skill level, or even generating new problems to solve. This means learning can be more personalized. If you’re struggling with a particular concept, the AI can offer extra help or different explanations. This blend of immersive technology and smart AI is paving the way for a more effective and engaging way to train the next generation of engineers. It’s about creating learning experiences that are not only realistic but also intelligent and responsive to individual needs.

Looking Ahead

So, what’s the takeaway from Simulation World 2024? It’s pretty clear that virtual engineering isn’t just a buzzword anymore; it’s becoming a real thing. We saw a lot of cool tech that lets engineers build and test things in ways that just weren’t possible before. This means faster development, fewer mistakes, and maybe even some totally new kinds of products down the line. It feels like we’re on the edge of something big, where digital tools and the real world are going to blend together in some pretty interesting ways for how we design and make stuff. It’s going to be fascinating to see how this all plays out in the coming years.