Keeping up with the world of chip manufacturing news can feel like a full-time job. It’s a fast-paced industry, always buzzing with new ideas and changes. From the tiny components that power our phones to the massive systems running data centers, it’s all happening in chip fabrication. This article will give you a rundown of what’s new, what’s coming, and why it all matters.

Key Takeaways

- The chip manufacturing world is constantly moving forward, with companies pushing for smaller and better chips. Think 3nm, 2nm, and even smaller. This means more power in smaller packages, which is great for all our gadgets.

- It’s not just about making chips smaller; it’s also about putting different pieces together, like chiplets. This approach helps create super-powerful chips without always needing the absolute smallest manufacturing process.

- Geopolitics and where chips are made are becoming a bigger deal. Countries want to make more chips at home for security reasons, leading to big investments in new factories.

- Building these advanced factories costs a ton of money, and there’s a real shortage of skilled people to run them. This makes it tough for new companies to get into the game.

- The industry is looking at how to be more eco-friendly, and there’s a growing demand for custom-designed chips, like ASICs, for specific jobs, especially for AI and other advanced tech.

Navigating the Evolving Landscape of Chip Manufacturing News

Keeping up with chip manufacturing news feels like trying to catch a speeding bullet train sometimes. It’s a field that’s always on the move, with new developments popping up faster than you can say "silicon wafer." The whole industry is basically a high-stakes game of technological one-upmanship, balancing who can make the best chips with making sure we actually have enough of them, all while keeping an eye on what’s happening globally.

Key Trends Shaping the Semiconductor Industry

So, what’s actually changing on the factory floor and in the labs? For starters, everyone’s chasing smaller and smaller process nodes. We’re talking 3 nanometers (nm), 2nm, and even whispers of 1.4nm. Why bother? Because smaller means more power efficiency and better performance, which is a big deal for everything from your smartphone to supercomputers. Companies like TSMC and Samsung are really pushing the limits here, using fancy techniques like Extreme Ultraviolet (EUV) lithography to cram more transistors onto a single chip.

Then there’s this whole "chiplet" thing. Instead of one giant, complex chip, manufacturers are starting to package smaller, specialized pieces (chiplets) together. It’s like building with LEGOs, but for incredibly advanced electronics. This approach, often called heterogeneous integration, gives designers more flexibility and can boost performance without needing to shrink the manufacturing process even further.

We’re also seeing a big push for "onshoring" or regionalizing chip production. Governments are getting involved, pouring money into building more fabs domestically. This is largely driven by concerns about supply chain security and international trade issues. It means more countries want to be able to make their own chips, reducing reliance on a few key players.

Finally, the demand for Application-Specific Integrated Circuits (ASICs) is booming. These are custom-designed chips built for very specific tasks, like powering AI algorithms or handling blockchain transactions. Fabless design firms are really benefiting from this, as they can focus on designing these specialized chips without needing their own massive manufacturing plants.

Market Dynamics and Competitive Models

The way companies compete in this space is getting pretty interesting. We’re seeing a mix of the traditional foundry model (where companies like TSMC make chips for others) and the integrated device manufacturer (IDM) model (where companies design and make their own chips, like Intel). Some companies are even blending these approaches.

It’s not just about who has the most advanced tech, though. The sheer cost and complexity of building and running these cutting-edge fabs mean that partnerships and strategic alliances are becoming super important. Companies are collaborating to share the massive costs and risks involved in developing new manufacturing processes and building new facilities.

Geopolitical Influences on Chip Production

You can’t talk about chips without talking about politics. Global trade tensions and national security concerns are having a huge impact. Countries are investing billions to build up their own semiconductor industries, trying to ensure they have a stable supply of these critical components. This has led to a lot of government incentives and subsidies, which can really shape where new factories get built and which companies get a leg up. It’s a complex web, and what happens in international relations can directly affect chip availability and pricing.

Here’s a quick look at some of the market projections:

| Region | Market Share (2024) | Projected CAGR (2025-2035) |

|---|---|---|

| Asia Pacific | 51.5% | Moderate |

| North America | Growing | Significant |

And in terms of chip types:

| Chip Type | Market Share (2024) |

|---|---|

| Memory Devices | 25.2% |

| Networking & Comms | 30.1% |

Innovations Driving the Next Generation of Semiconductors

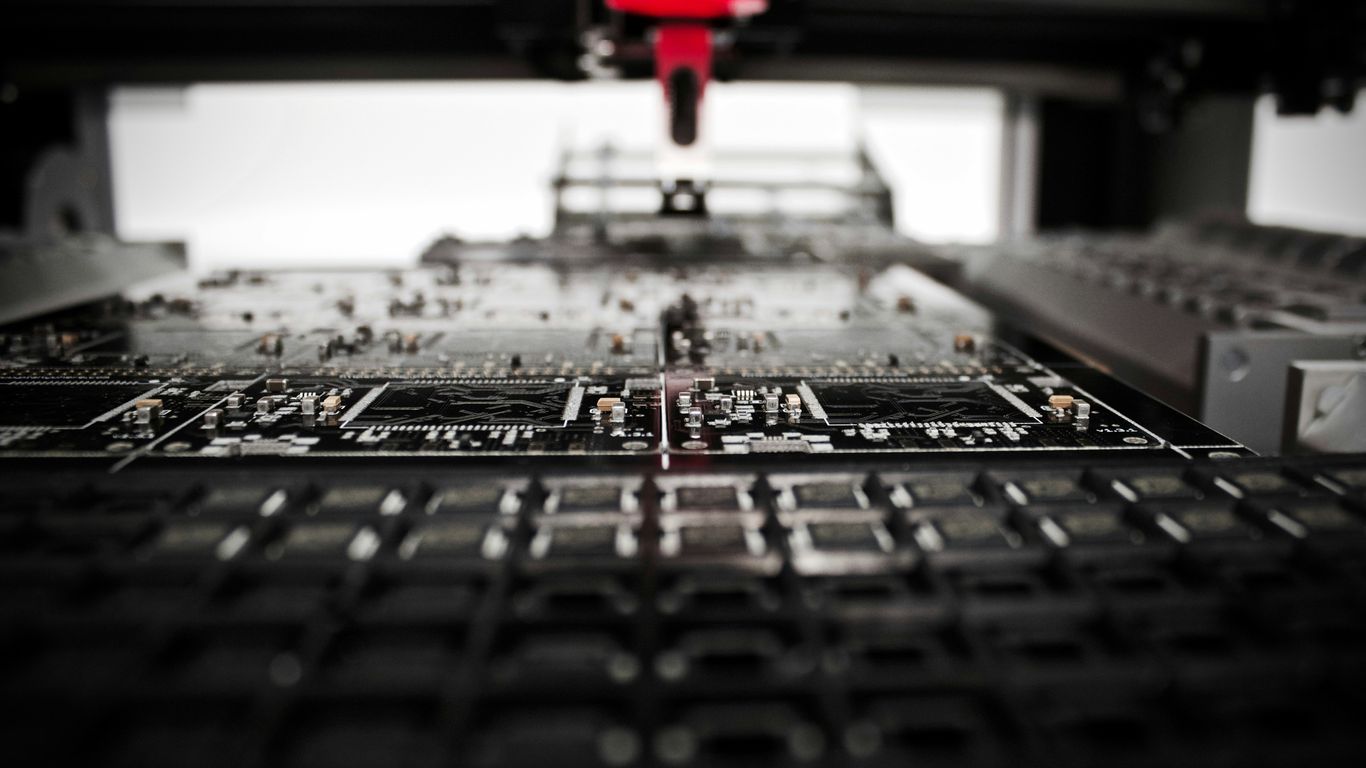

Advancements in Process Nodes and Lithography

Things are getting seriously small in the chip world. We’re talking about shrinking transistors down to sizes that are almost unbelievable. The race to get to smaller process nodes, like 2nm and even below, is heating up. This isn’t just about making chips tinier; it’s about packing more power and efficiency into the same space. Think about Intel’s 18A process, aiming for big gains in performance and power usage, or TSMC pushing towards their N2 and A16 nodes. These advancements are key for everything from super-fast AI processors to more capable smartphones. The technology behind making these tiny features, like Extreme Ultraviolet (EUV) lithography, is also getting more sophisticated. ASML is pretty much the only game in town for EUV, and they’re constantly refining it to make these incredibly complex manufacturing steps possible.

The Rise of Heterogeneous Integration and Chiplets

Instead of trying to cram everything onto one giant piece of silicon, the industry is moving towards a modular approach. This is where chiplets come in. Basically, you design smaller, specialized chips (the chiplets) and then put them together in a single package. It’s like building with LEGOs, but for electronics. This method, often called heterogeneous integration, allows companies to mix and match different types of silicon, like CPUs, GPUs, and memory, from various sources. It’s a big deal for performance and cost. Companies are investing heavily in advanced packaging techniques to make these chiplet systems work. We’re seeing aggressive expansion in things like CoWoS packaging, which is crucial for high-end AI chips. This approach helps overcome some of the limitations of traditional monolithic chip design, especially as we push the boundaries of what’s possible.

Emerging Materials and Their Impact

Silicon has been the king of semiconductors for decades, but its limits are starting to show. That’s why researchers are exploring new materials. Gallium Nitride (GaN) and Silicon Carbide (SiC) are already making waves, especially in power electronics. They handle electricity much more efficiently and can operate at higher temperatures than silicon. This makes them perfect for things like electric vehicle chargers, renewable energy systems, and faster power adapters. Beyond that, there’s a lot of interest in materials like graphene. While still in earlier stages for widespread chip production, its unique properties could lead to even faster and more energy-efficient devices down the line. The development of these new materials is opening doors to entirely new types of semiconductors and applications we haven’t even thought of yet.

Market Insights and Growth Opportunities in Chip Manufacturing

Projected Market Growth and Regional Dominance

The chip manufacturing market is really taking off. We’re looking at a global market valued at around $571.3 billion in 2024, and it’s expected to hit a massive $1.18 trillion by 2035. That’s a pretty steady growth rate, about 6.9% each year. It’s no surprise, really, when you think about how chips are the brains behind everything digital these days – from your phone to self-driving cars and all that AI stuff.

Right now, Asia Pacific is leading the pack, bringing in over half of the market’s revenue. But don’t count out North America; it’s set for some serious growth too. Governments everywhere are pouring money into chip production, trying to build up their own capabilities. This means more opportunities are popping up, especially for companies that can focus on specific areas like specialized sensors or power chips.

Key Applications Fueling Demand

So, what’s driving all this demand? A few big things come to mind. First off, data processing is huge. Think about all the servers in data centers and the cloud – they need tons of chips. Then there’s networking and communications; 5G, and soon 6G, require advanced chips to handle all that faster data. Consumer electronics are always a big player, but we’re also seeing massive growth in:

- Automotive: Electric vehicles and advanced driver-assistance systems (ADAS) are becoming chip-hungry.

- Industrial: Smart factories and automation rely heavily on sophisticated chips.

- Artificial Intelligence (AI) and Machine Learning (ML): These fields are exploding, and they need specialized processors.

- Internet of Things (IoT): Billions of connected devices, from smart home gadgets to industrial sensors, all need chips.

Investment Trends and R&D Focus

Because of this booming demand and the strategic importance of semiconductors, there’s a lot of money flowing into the industry. We’re seeing huge investments in building new fabrication plants, or ‘fabs’, which cost billions of dollars. Research and development is also a major focus. Companies and governments are pouring resources into developing smaller, faster, and more efficient chips. There’s also a growing interest in:

- Advanced Packaging: Techniques like chiplets, where smaller specialized chips are combined, are gaining traction. This allows for more flexibility and better performance without always needing to shrink the manufacturing process.

- New Materials: Researchers are exploring materials beyond silicon to create even better chips.

- Open-Source Hardware: Projects like RISC-V are making chip design more accessible, potentially lowering costs and speeding up innovation, especially for startups and academic institutions.

Addressing Challenges in Modern Chip Fabrication

Building the tiny, powerful chips we rely on every day isn’t easy. It’s a field packed with hurdles that companies have to jump over. Let’s break down some of the biggest ones.

Capital Intensity and Entry Barriers

First off, making chips is incredibly expensive. We’re talking billions of dollars just to build a single factory, a "fab," capable of producing the latest technology. Think about it: a state-of-the-art facility can cost over $20 billion. This massive price tag makes it really tough for new companies, especially those in developing countries or smaller players, to even get a foot in the door. It’s not like starting a small business in your garage; this requires serious, serious cash.

Talent Shortages and Workforce Development

Then there’s the people problem. The industry needs highly skilled engineers and technicians, folks who really know their stuff when it comes to things like photolithography, semiconductor physics, and designing complex chips. But there just aren’t enough of them to go around. Finding and keeping these experts is a constant struggle. Companies are trying to fix this by working with universities and creating special training programs, but it’s a long road to build up that skilled workforce.

Supply Chain Risks and Geopolitical Tensions

Finally, the global situation adds another layer of complexity. Chip manufacturing is spread all over the world, and that makes it vulnerable. Trade disputes, political instability, and national security concerns can all disrupt the flow of materials and finished chips. For example, reliance on specific regions for key components or manufacturing processes creates a big risk if something goes wrong there. Companies are trying to spread things out, building factories in different places to avoid putting all their eggs in one basket, but it’s a tricky balancing act.

The Future of Chip Manufacturing: Sustainability and Specialization

Looking ahead, the chip manufacturing world is really starting to focus on two big things: being kinder to the planet and making chips that are super specialized for specific jobs. It’s not just about making things smaller and faster anymore; it’s about doing it responsibly and with purpose.

Sustainability Initiatives in Fabs

Making chips takes a ton of energy and water, and let’s be honest, it creates waste. Companies are feeling the heat, both from governments and from us consumers, to clean up their act. We’re seeing more fabs powered by renewable energy sources, like solar and wind. There’s also a big push to cut down on water usage, with some places experimenting with waterless etching techniques. Recycling is becoming standard practice, and there’s a growing interest in developing new materials that are less harmful to the environment. The goal is to make the entire process greener, from the raw materials to the finished product. It’s a complex challenge, but it’s becoming a major part of how companies compete and get contracts these days. It’s not just good for the planet; it’s becoming good for business too, especially with global demand for advanced technologies like artificial intelligence [13b2].

The Growing Demand for Custom Silicon and ASICs

Remember when one chip did a bit of everything? Those days are fading fast. Now, there’s a huge demand for Application-Specific Integrated Circuits, or ASICs. These are chips designed from the ground up for one particular task, like running AI algorithms, handling blockchain transactions, or managing high-speed networking. This means fabless design companies can get exactly what they need, leading to more efficient and powerful devices. It’s a shift away from general-purpose chips towards highly optimized solutions.

The Role of Open-Source Hardware

This is a really interesting development. Open-source hardware, like the RISC-V architecture, is making waves. It means the designs for chips are freely available, which can dramatically lower development costs. This is a game-changer, especially for startups, researchers, and even developing countries. It democratizes access to chip design and manufacturing, allowing more people to innovate and create specialized hardware without massive upfront investment. Think of it like the open-source software movement, but for the physical chips themselves.

Looking Ahead

So, where does all this leave us? The chip manufacturing world is moving fast, that’s for sure. We’re seeing smaller, more powerful chips being made, and companies are trying to build them closer to home. It’s a complex dance between new tech, global politics, and just plain old supply and demand. Keeping up with these changes isn’t just for the big players; it affects everyone using electronics. Staying informed about these trends means understanding the future of everything from our phones to our cars. It’s a wild ride, and it’s only just getting started.

Frequently Asked Questions

What are the main trends happening in chip making right now?

Chip making is getting super fast! Companies are making chips smaller and smaller, like 3nm and 2nm, to make devices work better and use less power. They’re also putting different chip pieces together, called chiplets, to create powerful new chips. Plus, countries are trying to make more chips in their own borders to avoid relying too much on others.

What’s new in how chips are made?

New ways of making chips are popping up all the time. Scientists are figuring out how to use new materials, not just silicon, to make chips even better. They’re also getting really good at putting tiny pieces, called chiplets, together to build one big, super-smart chip. This helps make computers and phones faster and more powerful.

How much is the chip market expected to grow?

The market for making chips is growing a lot! It’s expected to be worth over a trillion dollars by 2035. This is because we need more chips for things like smart phones, cars, AI, and the internet of things (IoT).

Why is it so hard and expensive to build chip factories?

Building a factory that makes the latest chips is incredibly expensive, costing billions of dollars. This makes it really hard for new companies to get started. Also, there aren’t enough skilled workers who know how to design and build these advanced chips, which is another big hurdle.

Are countries trying to make more chips at home?

Yes, many countries are investing a lot of money to build their own chip factories. This is because chips are so important for technology and national security. They want to make sure they have enough chips and aren’t too dependent on other countries for them.

What does ‘sustainability’ mean for chip factories?

Sustainability means making chip factories in ways that are better for the environment. This includes using less water and energy, and trying to reduce pollution. Companies that are more eco-friendly might get more business in the future as people care more about the planet.