Introduction

In the world of precision engineering and quality control, temperature test chambers play a pivotal role in ensuring that products can withstand extreme environmental conditions. These chambers are indispensable tools for various industries, from electronics to pharmaceuticals, where the performance of materials and products needs to be rigorously evaluated. In this article, we will delve into the fascinating world of temperature test chambers, exploring their significance, applications, and how they contribute to product reliability.

Understanding Temperature Test Chambers

What Are Temperature Test Chambers?

Temperature test chambers, often referred to as environmental test chambers, are specially designed enclosures that simulate various environmental conditions, primarily temperature and humidity. These chambers allow engineers and researchers to subject their products, materials, or specimens to controlled temperature variations, replicating real-world scenarios.

The Importance of Precision

Precision is paramount when it comes to environmental testing. Temperature test chambers are engineered to maintain precise temperature and humidity levels, ensuring that test results are accurate and reliable. This precision is essential for industries such as aerospace, automotive, and electronics, where even minor deviations can lead to catastrophic failures or suboptimal performance.

Applications of Temperature Test Chambers

Electronics Testing

In the ever-evolving electronics industry, components and devices must endure extreme temperature fluctuations. Temperature test chambers help manufacturers assess the reliability of electronic components, from semiconductors to circuit boards, under varying conditions. This is crucial for producing electronics that can withstand the demands of consumer and industrial applications.

Pharmaceutical Research

Pharmaceutical companies rely on temperature test chambers to assess the stability of drugs and vaccines. These chambers mimic the temperature variations drugs might experience during storage and transportation, ensuring that they remain effective and safe for consumption.

Automotive Quality Control

The automotive industry uses temperature test chambers to evaluate the performance of vehicle components, including engines, brakes, and electronic systems. By subjecting these components to extreme temperature conditions, manufacturers can identify weaknesses and make necessary improvements, ultimately enhancing vehicle safety and reliability.

Types of Temperature Test Chambers

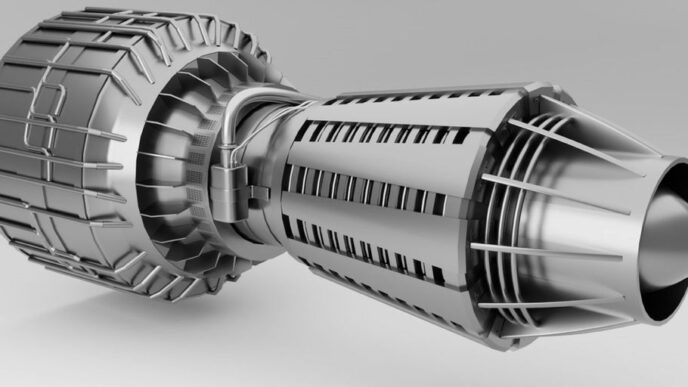

Climatic Chambers

Climatic chambers are designed to replicate a wide range of environmental conditions, including temperature, humidity, and sunlight exposure. These chambers are commonly used for testing products intended for outdoor use, such as solar panels and outdoor electronics.

Thermal Shock Chambers

Thermal shock chambers subject products to rapid temperature changes, simulating extreme conditions. These chambers are invaluable for assessing a product’s ability to withstand abrupt temperature transitions without structural damage.

Choosing the Right Temperature Test Chamber

Selecting the appropriate temperature test chamber is a critical decision for any industry. Factors such as the size of the chamber, temperature range, and humidity control must be carefully considered. It’s essential to match the chamber’s capabilities with the specific testing requirements to achieve accurate results.

Advancements in Temperature Test Chambers

With advancements in technology, temperature test chambers have become more sophisticated. Many now come equipped with touchscreen interfaces, remote monitoring capabilities, and data logging features, making them easier to operate and providing valuable insights during testing.

Conclusion

Temperature test chambers are indispensable tools in industries where product reliability and performance are paramount. Their ability to simulate extreme environmental conditions with precision ensures that products can withstand the rigors of the real world. As technology continues to advance, these chambers will play an even more significant role in ensuring the quality and durability of the products we rely on daily.