1. ABB Robotics

ABB Robotics has been a major player in industrial automation for a long time, really since 1988. They’re based in Switzerland, but their reach is global, with operations in over 100 countries and a massive installed base of robots – we’re talking over 400,000 worldwide. They’re not just about building robots; they’re focused on integrating them with digital services to make factories run smoother and more efficiently.

ABB is involved in a few key areas:

- Electrification: Making power systems smarter and more reliable.

- Motion: Developing advanced drives and motors.

- Process Automation: Automating complex industrial processes.

- Robotics & Discrete Automation: This is where their core robot business sits, serving industries like automotive, electronics, and logistics.

They’ve been putting a lot of effort into AI lately. For instance, they held an AI Startup Challenge in 2024, giving money to companies working on generative AI for robots. This shows they’re serious about making robots smarter and more adaptable. Their YuMi cobot is a good example of this, designed to work alongside people more intuitively. ABB’s revenue from its robotics division was $3.21 billion in 2024, and they’re even planning to spin off this unit as a separate company in 2026, aiming for a valuation of around $3.5 billion. It seems like they’re really pushing to stay at the forefront of automation technology.

2. FANUC Corporation

FANUC Corporation, a name that’s practically synonymous with industrial automation, has been around since 1956. Based out of Yamanashi, Japan, they’re a huge player in factory automation, industrial robots, and those CNC control systems that keep a lot of manufacturing humming along. Their whole deal is "Service First," and they really mean it, offering what they call lifetime maintenance for their gear. This means factories can keep running with less worry about unexpected shutdowns.

FANUC organizes its work into four main areas: FA (Factory Automation), ROBOT, ROBOMACHINE, and IoT FIELD System. This setup lets them create integrated solutions that bridge the gap between what’s happening on the factory floor and the digital data that drives decisions. You might have heard about their Smart Digital Twin technology or their CRX series of collaborative robots – these show they’re serious about making automation smarter, safer, and more adaptable.

By early 2026, FANUC has a pretty extensive global network, with over 260 service locations spread across more than 100 countries. They serve a wide range of industries, from cars and electronics to making really precise parts. It’s no surprise they’ve snagged some top sustainability ratings, like EcoVadis Platinum and MSCI ESG AAA. They’re not just about building robots; they’re focused on making manufacturing more reliable and efficient for the long haul.

Key aspects of FANUC’s approach:

- Global Reach: Over 260 service locations in more than 100 countries.

- Product Focus: Industrial robots, CNC systems, and factory automation solutions.

- Service Philosophy: Commitment to lifetime maintenance for maximum uptime.

- Innovation: Development of smart digital twins and collaborative robots.

3. KUKA SE & Co. KGaA

KUKA, a name that’s been around since way back in 1898, is a big player in the automation world, based out of Augsburg, Germany. They’re known for making industrial robots, smart automation systems, and solutions for digital manufacturing. What’s really interesting is their push into collaborative robots – the ones that can safely work alongside people – and mobile robots that can zip around a factory floor.

KUKA’s whole vibe is about making automation simpler. They’ve got these platforms called iiQKA.OS and iiQKA.Works. Think of them as the brains and tools that tie together their robots, software, and entire production setups. This makes it easier for companies to build and control automated systems, whether it’s just a small part of a line or a whole factory. They’re really focused on making automation adaptable and driven by data.

KUKA’s reach is global, and they’ve got a knack for tailoring their systems to fit what different industries need. They’re involved in a bunch of sectors:

- Automotive

- Electronics

- Healthcare

- Logistics

- Construction

They’ve been putting out some neat stuff, like their iiQKA.OS operating system, which is pretty forward-thinking with its virtual robot controller and readiness for AI. Plus, they’re keeping an eye on the latest safety standards for robots. It seems like they’re trying to blend their long history in robotics with all the new AI tech out there, making robots smarter and more capable.

4. Yaskawa Electric Corporation

Yaskawa Electric Corporation, a name that’s been around since 1915, is a big deal in the world of automation. They’re the folks behind the Motoman robots, which you’ve probably seen doing all sorts of heavy lifting and precise work in factories. Their whole approach is built around something they call "i³-Mechatronics." Basically, it’s about blending smart mechanical systems with digital data to make factories run better and smarter.

They’ve got a massive lineup of robots, over 150 different models, really. You can find them doing everything from welding and assembly to packing and moving stuff around. It’s pretty impressive when you think about it.

Here’s a quick look at what they’ve shipped out:

- Robots: Over 540,000 Motoman robots

- Servos: Around 18 million servo systems

- Drives: About 30 million inverter drives

These robots are showing up everywhere, from car manufacturing to electronics and even logistics. They recently rolled out some new gear, the MOTOMAN-GP10 and Σ-X servo drive series, which are supposed to be even more precise and connected. Yaskawa has a presence in 28 countries, so they’re definitely a global player. They’ve been around for a century, and people seem to trust them for making reliable automation tech.

5. Universal Robots A/S

Universal Robots, or UR as they’re often called, has really made a name for itself in the world of collaborative robots, or cobots. They started up in Denmark back in 2005, and their whole thing is making automation something that even smaller businesses can get their hands on. It’s pretty neat how they’ve managed to create robots that can work right alongside people without needing a bunch of safety cages.

What’s cool about UR is their focus on making things easy. You don’t need to be a robotics engineer to get these things up and running. They’ve got this whole system called UR+ with tons of add-ons – like grippers and sensors – that just plug in. This means you can get automation set up way faster than with older, more complicated systems. They’ve got over 100,000 of these cobots out in the world now, doing all sorts of jobs from stacking boxes to helping with welding and assembly.

Their newer models, like the UR20 and UR30, can handle heavier loads and reach further, which is a big deal for a lot of manufacturing tasks. Plus, they’re incorporating AI to make the robots smarter, especially when it comes to vision systems and how they move. They even have this UR Academy to help people learn how to use their robots, which is a nice touch. It feels like they’re really pushing for a future where humans and robots work together, not just humans doing all the repetitive stuff.

Here’s a quick look at what makes them stand out:

- Focus on User-Friendliness: Designed for easy setup and operation, even for those new to robotics.

- Extensive UR+ Ecosystem: A wide range of compatible accessories and software for quick integration.

- Collaborative Design: Robots built to work safely alongside human operators.

- Global Reach and Support: A significant worldwide presence with training resources available.

It’s clear that Universal Robots isn’t just selling robots; they’re selling a way to make automation more accessible and practical for a lot more companies out there.

6. Doosan Robotics Inc.

Doosan Robotics, founded in 2015 and based in South Korea, is really making waves in the collaborative robot, or cobot, space. They’re part of the larger Doosan Group, and their main goal seems to be making automation easier for businesses, especially by using AI. They’ve got a pretty wide range of cobots, actually, covering different series like the P, H, M, A, and E. These aren’t just for factories either; they’re used in places like service industries and even for education.

What’s interesting is how many different jobs these robots can do. We’re talking about things like stacking pallets, welding, sanding down surfaces, tending to machines, and even helping with EV charging and food service. They really focus on making their robots safe and precise, which is obviously a big deal when humans are working alongside them. Doosan’s DART-Suite software platform is a key part of their strategy, pushing forward AI integration for smarter manufacturing.

It’s not just talk, either. Big names like LG Electronics, Dior, Hyundai, Toyota, and Samsung C&T are using their robots, and Doosan’s solutions are out there in over 50 countries. They’ve got a solid R&D setup in South Korea, with labs for research, innovation, and prototyping. It all points to their vision of using AI-powered robots to make life better.

Here’s a quick look at their setup:

- Founded: 2015

- Headquarters: Seongnam-si, Gyeonggi-do, South Korea

- Key Products: Collaborative robots (cobots), industrial automation solutions, AI-driven robotics, software platforms.

- Notable Clients: LG Electronics, Dior, Hyundai, Toyota, Samsung C&T.

- Certifications: ISO 9001, ISO 10218-1.

7. DENSO Corporation

DENSO Corporation, founded way back in 1947 and headquartered in Kariya, Japan, is a massive player in the automation and mobility tech scene. They’re a Fortune 500 company, which tells you something about their scale. For over 75 years, they’ve been building smart systems that power everything from cars to factories.

What’s really interesting is their dual focus on sustainability and user experience. They’re aiming for carbon neutrality by 2035, which is pretty ambitious, and they want their automation to make things safer and easier for people to work with. It’s not just about robots doing tasks; it’s about how those robots fit into the bigger picture of manufacturing and our environment.

DENSO’s robots are everywhere in industrial settings, handling assembly, checking quality, moving materials, and doing all sorts of precise manufacturing jobs. They’re known for being fast, accurate, and reliable – the kind of stuff you need when you’re running a factory 24/7.

Here’s a quick look at their operational principles:

- Green: Working towards carbon neutrality by 2035 through eco-friendly products and energy-saving processes.

- Peace of Mind: Making sure human-robot interactions are safe, comfortable, and smooth.

They’ve got a huge global presence, with over 158,000 employees spread across 35 countries. It’s clear they’re not just sticking to their automotive roots; they’re pushing hard into next-gen robotics and smart factory tech that fits right in with Industry 4.0. Their long history of innovation and focus on precision makes them a company you can count on in the robotics world.

8. Stäubli Robotics

Stäubli Robotics has been around for a while, starting way back in 1892 in Switzerland. They’re known for making really precise automation stuff, and it’s not just robots. They also do connectors and machinery for textiles, which is kind of interesting.

When it comes to robots, Stäubli makes a bunch of different kinds. They have the standard industrial arms, but also collaborative robots, or cobots, that can work alongside people. Plus, they’ve got these autonomous mobile robots that can move around a factory floor on their own. Their focus is on speed, accuracy, and keeping things clean, which is why you see their robots in places like drug manufacturing or food processing plants.

Here’s a quick look at what they offer:

- 4-axis and 6-axis robotic arms: Good for all sorts of tasks.

- Autonomous Mobile Robots (AMRs): For moving materials around without a fixed path.

- Cobots: Designed for safe interaction with human workers.

- Automation Systems: Complete solutions for production lines.

They’re also big on digital solutions for what they call Industry 4.0, so their robots can connect and share information. It’s all about making factories smarter and more efficient.

9. Boston Dynamics

Boston Dynamics, now part of Hyundai Motor Group since 2021, is a name that often comes up when you think about robots that can really move. They’re famous for robots like Spot, the four-legged one that can trot around pretty much anywhere, and Atlas, the humanoid robot that can do flips and parkour.

While their earlier demos were pretty wild, showing off what robots could do, the focus now seems to be shifting towards practical jobs. They’ve got this new Electric Atlas, which they showed off at CES 2026. It’s built for industrial work, like moving stuff around in factories or warehouses.

Here’s a quick look at the Electric Atlas:

- Height: 1.9 meters

- Weight: 90 kg

- Reach: 2.3 meters

- Primary Use: Industrial tasks, search and rescue, research

- Run time: Around 4 hours

It seems like Boston Dynamics is really trying to get their robots out into the real world, doing actual work. They’ve already got deployments lined up for 2026 with places like Hyundai’s own robotics center and Google DeepMind. It’s a big step from just showing off cool moves to actually being a part of everyday operations.

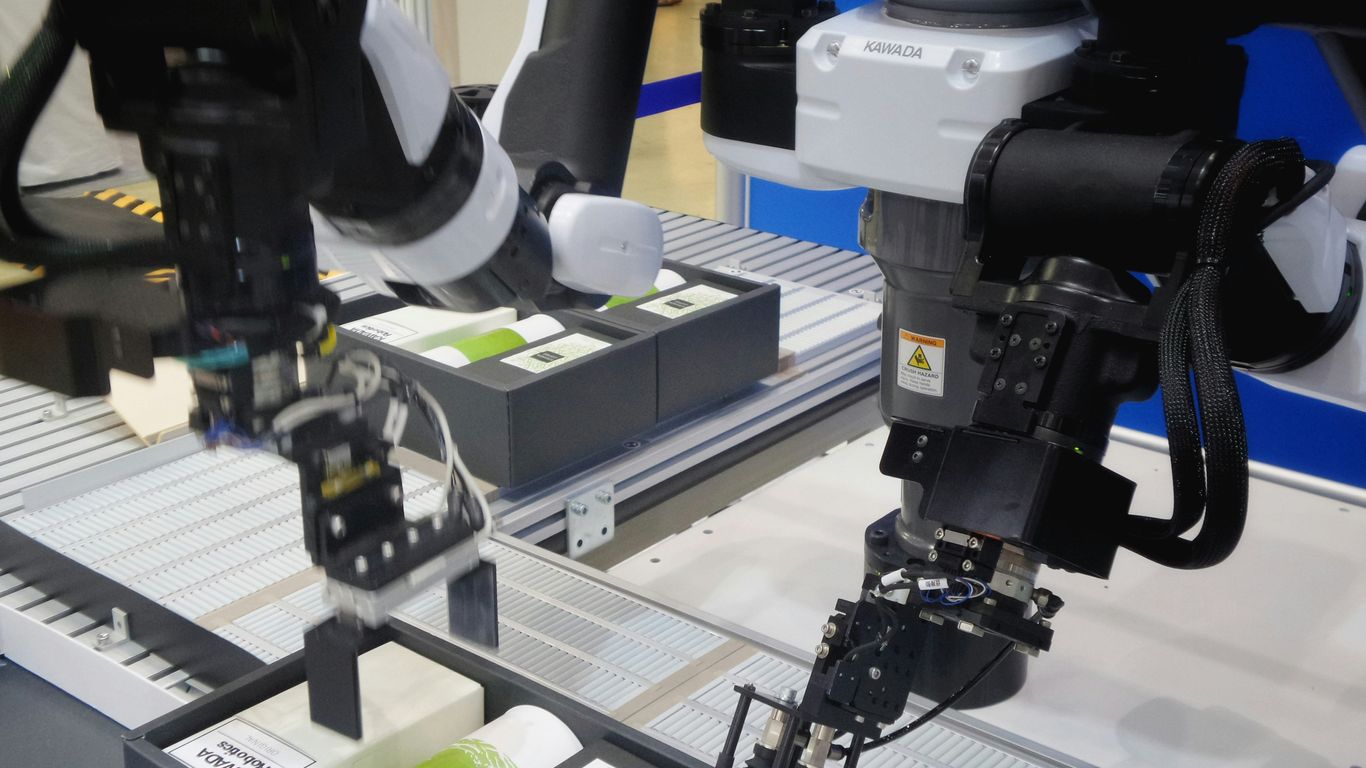

10. Kawasaki Robotics

Kawasaki Robotics, a name that’s been around for a while, is part of the larger Kawasaki Heavy Industries. They’ve been in the game since 1969, so they’ve seen a lot of changes in how factories work. They make all sorts of robots, from the big industrial arms you see in car factories to smaller, more nimble ones.

What’s interesting is how they’re blending their old-school engineering know-how with newer tech. They’re putting AI into their robots, which means things like robots being able to predict when they might need maintenance or figure out the best way to move around a busy workspace without bumping into anything. It’s all about making automation smarter and more adaptable.

They’ve also been pushing the envelope with their dual-arm robots, like the duAro. These are designed to handle more complex jobs, the kind that used to need a human touch. Think about putting together intricate parts or working alongside people on an assembly line. It’s a big step towards robots that can do more than just repetitive tasks.

Here’s a quick look at what they bring to the table:

- Decades of experience in building reliable industrial robots.

- Focus on dual-arm robots for more complex assembly and manipulation.

- Integration of AI for smarter decision-making and predictive capabilities.

- Development of collaborative systems to work safely with human employees.

With over 150,000 robots already out there in the world, Kawasaki isn’t just experimenting; they’re a major player making automation more capable.

What’s Next for Automation?

So, there you have it. These companies are really changing the game when it comes to automation. It’s pretty wild to think about how far robots have come, and honestly, it feels like we’re just getting started. From making factories run smoother to helping out in warehouses, these machines are becoming a bigger part of our world. It’s exciting to see what new ideas pop up next, and how these robots will keep getting smarter and more useful. One thing’s for sure: the future of how we work is definitely being shaped by these robotic innovators.