So, we’re talking about ATE semiconductor stuff today. You know, those machines that test all the tiny computer chips that go into pretty much everything we use. It’s kind of a big deal because if these chips aren’t right, the whole product can be a mess. We’ll look at why these ATE systems are so important, how they help make sure things work, and what’s coming next in the world of testing.

Key Takeaways

- ATE systems are super important for testing computer chips, making sure they work right before they go into your phone or car.

- Testing happens at different stages, from checking the whole wafer to individual chips and even stressing them out to see if they’ll last.

- Using ATE helps manufacturers make more good chips, fix their processes, and avoid sending out bad ones.

- These machines aren’t just for chips; they’re used in cars, planes, and all sorts of electronics.

- The future of ATE involves smarter testing with AI, connecting more devices, and thinking about the environment.

The Indispensable Role of ATE in Semiconductor Manufacturing

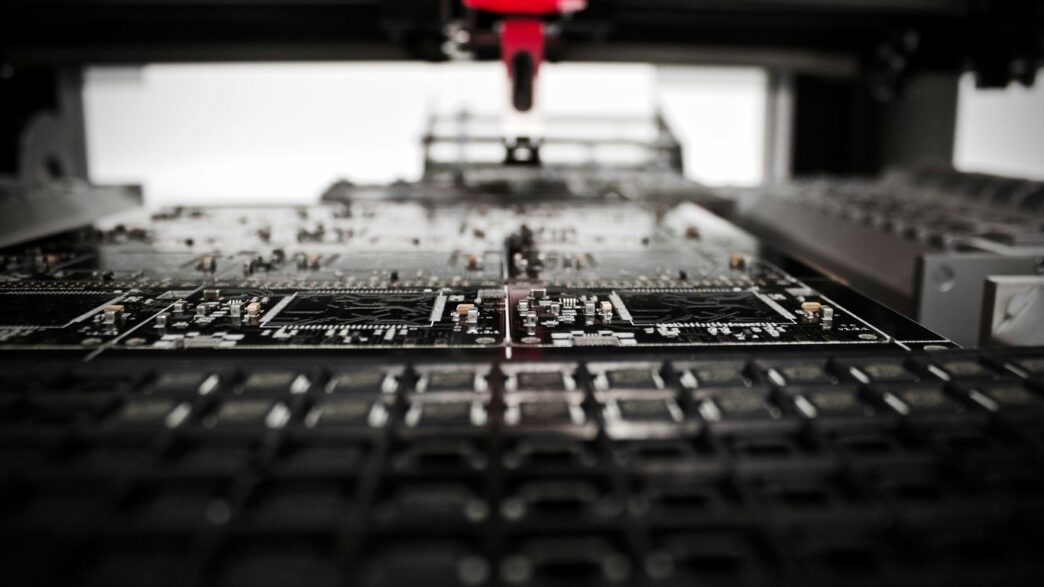

Semiconductor manufacturing is a pretty intense business. You’ve got these tiny, complex chips that power everything from your phone to your car, and they absolutely have to work perfectly. That’s where Automated Test Equipment, or ATE, comes in. It’s not just a nice-to-have; it’s really the backbone of making sure these components are up to snuff before they get anywhere near a final product. Without ATE, the whole process would be way slower, way more expensive, and frankly, a lot less reliable.

Testing Integrated Circuits (ICs) with ATE

At its core, ATE is all about testing. For Integrated Circuits (ICs), which are the brains of most electronics, this means putting them through their paces. Think of it like a super-detailed check-up. ATE systems run through a series of tests to measure all sorts of things – how much power they use, how fast they respond, if the signals they send out are clean. They compare these measurements against a strict set of requirements. If an IC doesn’t hit the mark on even one test, it’s flagged. This early detection is key to preventing faulty parts from causing bigger headaches down the line. It’s a big part of why we can trust the devices we use every day.

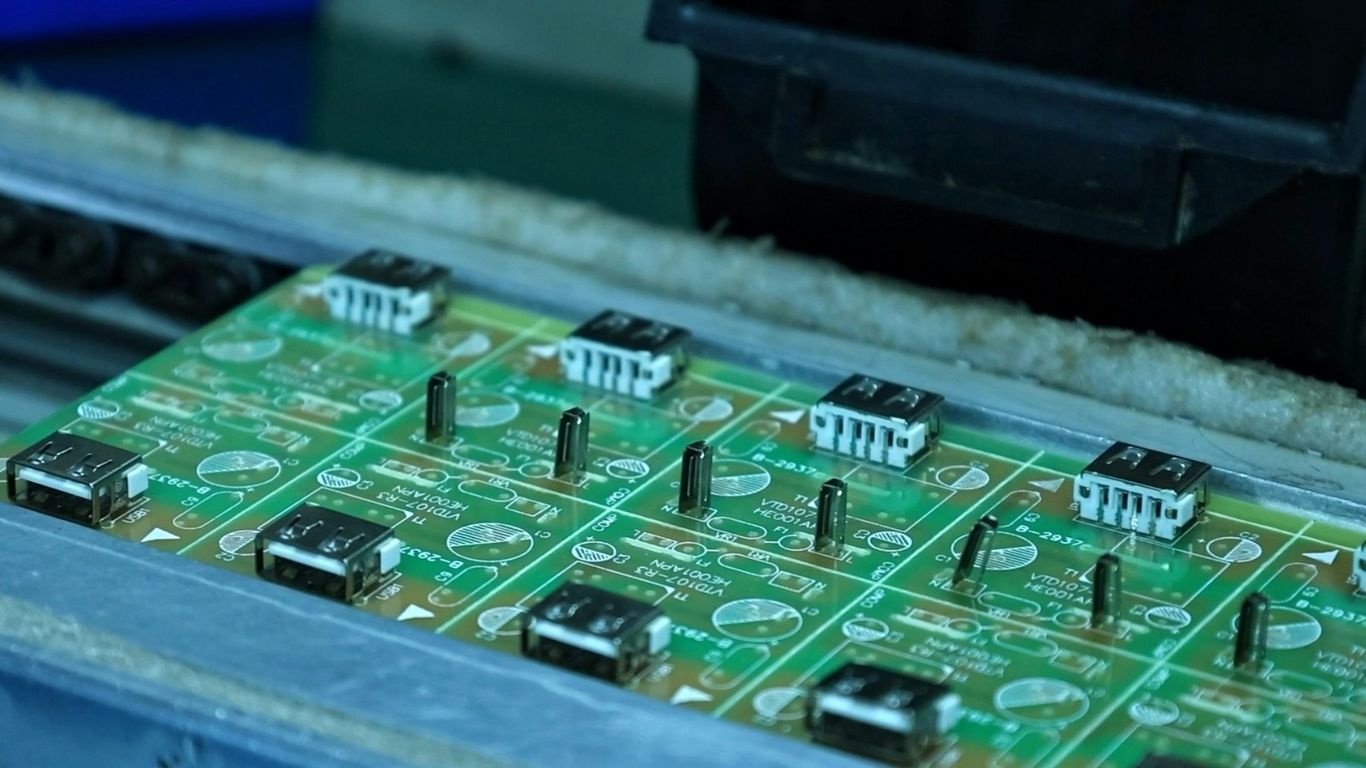

Wafer-Level Testing and ATE Systems

Before those ICs get cut into individual pieces, they live on a silicon wafer. ATE plays a big part here too, with wafer-level testing. Imagine a whole pizza, and you need to check every single slice before you serve it. ATE systems use special probes to test each tiny chip right there on the wafer. This is super important because it catches problems early. If a whole section of the wafer is bad, you know it right away. This saves a ton of money and resources because you’re not wasting time and materials assembling bad chips. It’s all about catching issues when they’re easiest and cheapest to fix. You can find out more about how these systems are vital across various industries here.

Burn-In Testing for Enhanced Reliability

Then there’s burn-in testing. This is where ATE really shines in making sure chips last. For burn-in, the ICs are put under stress – usually higher temperatures and more electrical activity than they’d normally see. The idea is to force any weak components or hidden flaws to show themselves early on. ATE systems monitor the chips during this intense period. If a chip fails during burn-in, it means it likely wouldn’t have lasted long in the real world anyway. By filtering these out, manufacturers can significantly improve the long-term reliability of their products. It’s a tough test, but it means the chips that pass are built to endure.

Ensuring Semiconductor Quality Through Advanced ATE

When it comes to making the tiny, complex chips that power everything from our phones to our cars, quality is king. You can’t just slap them together and hope for the best. That’s where Automated Test Equipment, or ATE, really steps in. These machines are like the ultimate quality control inspectors for semiconductors, making sure each little chip works exactly as it should before it ever gets put into a product.

ATE for Yield Improvement and Process Optimization

Think of ATE as a super-smart detective for the manufacturing line. It doesn’t just check if a chip is working; it gathers tons of data about how the whole process is going. By looking at this data, manufacturers can spot where things might be going wrong, even before a lot of bad chips are made. This helps them tweak their machines and processes, leading to more good chips – what they call ‘yield’ – and less wasted material. It’s all about making the production smarter and more efficient.

Here’s a quick look at what ATE helps with:

- Spotting Trends: ATE systems can track test results over time, showing if a particular test is failing more often or if a certain batch of chips isn’t performing well.

- Pinpointing Problems: If a chip fails, ATE can often tell you exactly which test it failed and under what conditions, giving engineers a clear starting point for figuring out the root cause.

- Fine-Tuning: The information gathered helps engineers adjust things like temperature, voltage, or the timing of signals during manufacturing to get better results.

Parametric Testing and Specification Verification

Every chip has a list of specifications – basically, what it’s supposed to do and how well it’s supposed to do it. Parametric testing is all about checking these basic electrical characteristics. ATE systems precisely measure things like voltage levels, current draw, and resistance. They make sure these values fall within the tight ranges the chip designer set. This detailed electrical check is fundamental to verifying that the chip meets its design blueprint. It’s like checking if all the ingredients in a recipe are exactly the right amount before you start baking.

Functional Testing of Semiconductor Devices

Beyond just checking the basic electrical properties, ATE also puts the chips through their paces to see if they actually perform their intended functions. This is where the chip is asked to do the jobs it was designed for. For a processor, this might mean running complex calculations; for a memory chip, it means storing and retrieving data correctly. ATE systems simulate real-world operations, sending signals and checking the outputs to confirm the chip behaves as expected. This ensures that when the chip is finally used in a device, it won’t let anyone down.

ATE Systems: Driving Efficiency in Production

Automated Test Equipment (ATE) systems are the backbone of efficient manufacturing, especially when it comes to electronics. They’re not just about checking boxes; they’re about making the whole production line run smoother, faster, and with fewer mistakes. Think of them as the highly skilled inspectors who never get tired or distracted.

Reducing Costs with Automated Testing

One of the biggest wins with ATE is how it cuts down on expenses. Manual testing takes a lot of time and requires a skilled workforce, which adds up. ATE systems can test components much faster and more consistently than people can. This means fewer workers are needed for repetitive testing tasks, and the ones you do have can focus on more complex issues. Plus, catching defects early with ATE stops faulty products from moving down the line, saving a ton of money on rework or scrapped items. It’s a smart way to keep your budget in check while still getting top-notch quality. The Semiconductor Automated Test Equipment Market is growing because of these cost-saving benefits.

Accelerating Time-to-Market

In today’s fast-paced world, getting products out the door quickly is key. ATE systems significantly speed up the testing phase, which is often a bottleneck. Instead of waiting days for test results, you can get them in hours or even minutes. This rapid feedback loop allows engineers to identify and fix problems much faster, shortening the entire product development cycle. Being able to bring new products to market ahead of the competition can make a huge difference for any company.

Minimizing Human Error in Testing

Let’s be honest, humans make mistakes. It’s just part of being human. When it comes to testing sensitive electronic components, even small errors can lead to big problems down the road, like product recalls or customer dissatisfaction. ATE systems perform tests with incredible precision and repeatability, every single time. They follow programmed procedures exactly, removing the variability that comes with manual testing. This consistency is vital for producing reliable devices, especially in industries where failure isn’t an option, like automotive or aerospace.

Here’s a quick look at how ATE helps:

- Consistency: Every test is performed the same way, every time.

- Speed: Tests are completed much faster than manual methods.

- Accuracy: Reduces the chance of misinterpreting results or missing defects.

- Data Logging: Automatically records test results for traceability and analysis.

The Evolving Landscape of ATE Technology

Things are changing fast in the world of electronics, and ATE systems have to keep up. It’s not just about making more chips; it’s about making them more complicated and packing more features into smaller spaces. This means the way we test them has to get smarter too.

Adapting to Rapid Technological Advancements

New technologies pop up all the time, and ATE needs to be ready. Think about faster processors, more memory, and new types of sensors. ATE systems have to be able to test all these new things accurately. This constant need for upgrades means ATE manufacturers are always working on new equipment. The semiconductor test equipment market is expected to grow quite a bit, showing just how important this is semiconductor test equipment market.

Addressing Increased Product Complexity

Products today are way more complex than they used to be. Chips have more pins, run at higher speeds, and need to handle more power. Testing these intricate designs requires ATE that can handle a lot of different signals and parameters. For example, devices used in cars or planes often need to work in really wide temperature ranges, from very cold to very hot, which adds another layer of testing difficulty.

Leveraging Data Analytics and Machine Learning

Modern ATE isn’t just about running tests; it’s about what we do with the results. These systems generate tons of data. By using data analytics and machine learning, manufacturers can get a better picture of what’s happening on the production line. This helps them:

- Find problems earlier in the design process.

- Figure out why certain parts might be failing.

- Make the manufacturing process itself more efficient.

- Predict when equipment might need maintenance.

This data-driven approach helps make sure products are reliable and that the manufacturing process runs smoothly.

ATE’s Impact Beyond Semiconductors

Automotive Industry Applications

Automated Test Equipment (ATE) isn’t just for the tiny chips inside our computers. Think about cars these days – they’re practically rolling supercomputers! Modern vehicles are packed with electronic control units (ECUs) that manage everything from the engine and transmission to safety features like airbags and anti-lock brakes. ATE systems are used to rigorously test these components. They check if the ECUs can handle different temperatures, resist electrical interference, and respond correctly to various inputs. This level of testing is absolutely vital for keeping drivers and passengers safe. It’s not just about performance; it’s about reliability when it matters most.

Aerospace and Defense Sector Needs

The aerospace and defense industries have some of the most demanding requirements for electronic components. Devices used in aircraft and military equipment must function perfectly, no matter the conditions – extreme temperatures, high altitudes, or intense vibrations. ATE plays a big role here by simulating these harsh environments during testing. This ensures that critical systems, like navigation, communication, and flight control electronics, won’t fail when lives are on the line. The integrity of these components is paramount, and ATE helps verify that they meet incredibly strict standards. It’s all about making sure the technology performs as expected, every single time.

Consumer Electronics Validation

And then there’s the stuff we use every day: smartphones, smart TVs, gaming consoles, and all sorts of connected gadgets. The sheer volume of these products means manufacturers need efficient ways to test them. ATE helps speed up the process of checking that all the different parts work together correctly. It verifies that your new phone’s camera takes great pictures, your TV displays a clear image, and your smart speaker understands your commands. By automating these checks, manufacturers can get more products out the door faster, while still making sure they work right out of the box. This helps build trust with consumers, knowing that the gadgets they buy are reliable.

Future Trends in Automated Test Equipment

Adapting to Rapid Technological Advancements

The world of electronics moves fast, and ATE has to keep up. Think about it, new chips and gadgets are coming out all the time, each one a bit more complicated than the last. This means the machines that test them need to get smarter and faster too. We’re seeing ATE systems that can handle more complex tests, sometimes even figuring out problems on their own. It’s like they’re learning as they go.

Addressing Increased Product Complexity

Modern products aren’t just simple circuits anymore. They’re packed with tiny parts and do all sorts of things. Testing these complex devices requires ATE that can check many different functions and signals at once. It’s not just about checking if a light turns on; it’s about making sure everything works together perfectly, like a well-oiled machine. This means ATE needs to be flexible and able to handle a wide range of tests without missing a beat.

Leveraging Data Analytics and Machine Learning

This is where things get really interesting. ATE systems are starting to use data analytics and machine learning. Basically, they collect tons of information from every test they run. Then, they use smart algorithms to find patterns, predict potential issues before they happen, and even suggest ways to make the manufacturing process better. This data-driven approach helps manufacturers catch problems early and improve their products over time. It’s moving testing from just a quality check to a tool for continuous improvement.

Wrapping Up

So, we’ve seen how important automatic test equipment, or ATE, really is. It’s not just a fancy piece of tech; it’s what helps make sure the electronic parts we rely on every day actually work the way they should. From the tiny chips inside our phones to the complicated systems in cars, ATE is there, checking everything. It makes manufacturing faster, cuts down on mistakes, and ultimately means we get better, more reliable products. As technology keeps changing, ATE will keep changing with it, staying a key player in making sure the gadgets and systems of tomorrow are built right.

Frequently Asked Questions

What exactly is ATE and why is it so important for making computer chips?

ATE stands for Automatic Test Equipment. Think of it as a super-smart robot that checks if computer chips (also called ICs) work correctly. It’s super important because chips are tiny and complex, and ATE makes sure they all work perfectly before they go into phones, computers, or cars. This stops bad chips from causing problems later.

How does ATE help test chips when they are still on a big round slice called a wafer?

Before chips are cut into small pieces, they are all made together on a big, round slice called a wafer. ATE systems can test each tiny chip on this wafer while it’s still whole. This is like checking all the cupcakes on a baking sheet before you cut them apart. If a chip on the wafer doesn’t work, ATE finds it early, saving money and effort.

What is ‘burn-in testing’ and how does ATE help with it?

Burn-in testing is like giving a chip a tough workout to see if it can handle stress. ATE systems put chips in a hot environment and make them work hard for a while. This helps find tiny flaws that might not show up right away but could cause problems later. ATE watches the chips during this tough test to make sure only the strong ones pass.

Can ATE help make more good chips and fewer bad ones?

Yes, absolutely! ATE systems collect lots of information about how chips are being made and tested. By looking at this information, engineers can figure out why some chips are failing and fix the manufacturing process. This means making more working chips and wasting fewer, which is called improving the ‘yield’.

Besides computer chips, what other things does ATE help test?

ATE is a superstar tester for many things! It’s used in cars to check engine computers and safety systems, in airplanes to test important flight equipment, and for all sorts of gadgets we use every day, like smartphones and TVs. Basically, if it’s an electronic device, ATE probably helps make sure it works right.

What’s new and exciting happening with ATE technology?

ATE is always getting smarter! It’s learning to test even more complicated devices, like those used in the Internet of Things (IoT) where many devices talk to each other. ATE is also using smart computer programs (like AI and machine learning) to find problems faster and help factories run more smoothly, almost like a super-smart assistant.