The Evolution of Industrial Automation

It’s pretty wild to think about how much manufacturing has changed over the years, right? Automation didn’t just pop up yesterday; it’s been a slow burn, evolving through different stages. We’re talking about a journey that really kicked off with the First Industrial Revolution.

Mechanization in Early Industrial Revolutions

Back in the late 1700s and into the 1800s, things started getting mechanized. Think steam power and water wheels doing the heavy lifting. This was a huge deal for productivity, letting factories churn out more goods than ever before. Then, the Second Industrial Revolution rolled around, bringing electricity into the mix. This meant more complex machines and the start of assembly lines, which really sped things up. It was all about replacing manual labor with machines, making things faster and, well, more mechanical.

The Dawn of Modern Automation and Robotics

The real shift towards what we think of as automation today started happening in the mid-20th century. A big moment was the invention of the Programmable Logic Controller (PLC) in 1969. These things are like the brains of automated systems, controlling repetitive tasks without needing a person to flip switches constantly. And then, of course, there were robots. The first industrial robot, Unimate, showed up in 1961. Initially, these robots were pretty basic, mostly doing one job over and over, but they were the start of something big. These early robots and PLCs laid the groundwork for the smart factories we see emerging today.

Industry 4.0 and Connected Manufacturing

Now we’re in what people call the Fourth Industrial Revolution, or Industry 4.0. This isn’t just about individual machines being automated; it’s about everything being connected. We’re talking about smart factories where machines, systems, and even people communicate with each other in real-time. Data is flowing everywhere, allowing for much smarter decisions and more flexible production. It’s a whole new level where digital technology and the physical world of manufacturing merge. This interconnectedness is what’s driving the next wave of automation, making factories more efficient and responsive than ever before.

Key Technologies Driving Industrial Automation

So, what’s actually making all this automation happen on the factory floor? It’s not just one magic bullet, but a few really smart technologies working together. Think of them as the engines powering the future of making stuff.

Artificial Intelligence and Machine Learning

This is where machines start to get "smart." Artificial Intelligence (AI) and its buddy Machine Learning (ML) let systems look at tons of data, find patterns, and then make decisions. It’s like teaching a computer to learn from experience, but way faster. For manufacturers, this means predicting when a machine might break down before it actually does, or spotting tiny flaws in products that a person might overlook. ML models can also help figure out the best way to schedule production or manage inventory, cutting down on waste and saving money. It’s all about making smarter choices based on real information.

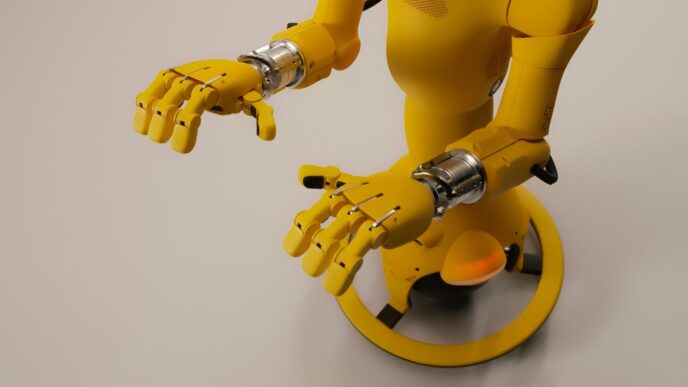

Advanced Robotics and Collaborative Robots

Robots aren’t new to factories, but they’re getting a serious upgrade. We’re talking about robots that are faster, more precise, and can do a wider range of tasks. Then there are the "cobots," or collaborative robots. These guys are designed to work right alongside people, making jobs safer and more efficient. Imagine a cobot helping an assembly line worker lift heavy parts or performing repetitive tasks so the human can focus on more complex steps. They’re not just replacing people; they’re teaming up.

The Industrial Internet of Things (IIoT)

This is basically connecting all the machines, sensors, and equipment in a factory to the internet. It creates a huge network where everything can talk to everything else. Sensors on machines can report their status in real-time, sending data about temperature, vibration, or output. This constant stream of information allows factories to be super responsive. If one part of the line slows down, the system can adjust automatically. It also helps track materials and products throughout the entire process, from raw materials to the finished good. It’s like giving the factory a central nervous system.

Transformative Benefits of Industrial Automation

So, why are so many factories jumping on the automation train? It’s not just about looking high-tech; there are some really solid reasons why it’s changing the game. Think about it: when a machine does the same job over and over, it doesn’t get tired or distracted like we do. This means the products coming off the line are pretty much identical, every single time. That consistency is a big deal, especially for things like medical equipment or airplane parts where even a tiny mistake can be a huge problem. It cuts down on defects and saves a ton of money on fixing mistakes.

Ensuring Consistent Product Quality

This is probably the most obvious win. Automated systems are built for repetition. They follow precise instructions without fail, leading to a level of uniformity that’s hard for humans to match, especially over long shifts. This means fewer faulty items, less waste, and happier customers who get what they expect.

Scaling Production Capacity and Agility

Demand for products can go up and down like a roller coaster. Automation lets factories keep up. Need to make more widgets for the holidays? Automated lines can often just run longer or faster. This ability to ramp up or down quickly without a massive increase in staff or complex scheduling makes businesses much more flexible. They can react to market changes way faster than before.

Optimizing Resource Utilization and Sustainability

When machines are running efficiently, they don’t waste materials or energy. Automation can help pinpoint exactly where resources are being used and where there might be leaks or inefficiencies. This not only saves money but also helps companies be kinder to the planet by reducing waste and energy consumption. It’s a win-win, really.

Reducing Operational Costs

While setting up automation can cost a pretty penny upfront, the long-term savings are significant. Machines can often do the work of several people, and they don’t need breaks or benefits. Plus, by reducing errors and waste, you’re cutting down on expenses related to rework and scrap. Over time, these savings can really add up, making the initial investment seem small.

Emerging Trends in Automation

Things are really moving fast in the world of factory automation. It feels like every week there’s some new tech making waves. We’re not just talking about robots doing the same old thing anymore. The focus is shifting towards smarter, more adaptable systems that can really change how things are made.

Predictive Maintenance for Equipment Uptime

Breakdowns are a huge headache, right? They stop everything and cost a ton of money. Predictive maintenance is changing the game. Instead of waiting for a machine to break, we’re using sensors and data to spot problems before they happen. Think of it like a doctor checking your vitals to catch an illness early. Sensors on machines can pick up on weird vibrations, temperature spikes, or changes in how they’re running. This info gets sent off for analysis, and if something looks off, the maintenance crew gets a heads-up. This means they can fix a small issue before it turns into a big, costly shutdown. This proactive approach keeps production lines running smoothly and avoids those dreaded unexpected stops.

Digital Twins for Process Simulation

Imagine having a perfect virtual copy of your entire factory, or even just one machine. That’s a digital twin. It’s a computer model that acts just like the real thing. We can use these twins to test out new ideas or changes without actually messing with the live production. Want to see if changing a setting on a conveyor belt will speed things up? Run it on the digital twin first. Worried about how a new material will affect a machine? Simulate it. This lets engineers and managers figure out the best way to do things, find bottlenecks, and improve processes all in a safe, virtual space. It saves time, cuts down on waste, and reduces the risk of making a mistake on the actual factory floor.

Enhanced Human-Machine Collaboration

There’s a lot of talk about robots taking jobs, but the reality is often more about teamwork. The new wave of automation isn’t just about replacing people; it’s about giving them better tools. Collaborative robots, or ‘cobots’, are designed to work safely alongside humans. They can handle the repetitive, heavy, or precise tasks that might be tough or boring for a person. Meanwhile, humans can focus on the problem-solving, decision-making, and quality checks that still need a human touch. This partnership means that tasks can be done faster, more accurately, and often more safely than before. It’s about making people’s jobs easier and more productive, not making them obsolete.

Navigating the Challenges of Automation Implementation

So, you’re thinking about bringing more automation into your factory. That’s great! It can really change things for the better. But let’s be real, it’s not always a walk in the park. There are definitely some hurdles to jump over.

Addressing High Upfront Capital Investment

Okay, first off, getting new automated systems costs a pretty penny. We’re talking about buying the machines, the software, and then paying people to get it all set up. It’s a big chunk of change right at the start. For smaller companies, this can feel like a mountain to climb. A smart way to handle this is to not try and do everything at once. Instead, you can add automation piece by piece, upgrading one process at a time. Think of it like fixing up your house – you don’t do it all in a weekend. Plus, sometimes there are government programs or tax breaks that can help ease the financial load.

Integrating New Technologies with Legacy Systems

Then there’s the issue of hooking up all this shiny new tech with your older machines and systems. It’s not always a smooth connection. You want everything to work together without causing a bunch of downtime or errors. This is where working with companies that really know their stuff about automation integration can make a huge difference. They can help make sure the transition is as smooth as possible and that your new setup can grow with your business.

Bridging Skill Gaps Through Workforce Development

Now, about your team. As you bring in more advanced machines and software, your employees will need new skills. They’ll have to learn how to run the new equipment, fix it when it acts up, and understand the data it spits out. Investing in training and upskilling your current workers is super important. It not only helps them adapt but also makes them feel more valued. Whether it’s sending them to a class or setting up on-the-job training, helping your staff learn these new skills means they can keep your automated factory running smoothly.

Securing Industrial Automation Systems from Cyber Threats

With all these connected machines and sensors, your factory becomes a bigger target for hackers. The more things that are online, the more ways someone could try to get in. If you’re using cloud services or letting people monitor things remotely, you need really strong security. This means using good encryption, setting up firewalls, and keeping an eye out for any suspicious activity. Thinking about cybersecurity from the very beginning of your automation project can save you a lot of headaches and money down the road. You don’t want a cyberattack to shut down your production or steal your company’s secrets.

The Future Landscape of Industrial Automation

So, where is all this automation stuff heading? It’s not just about robots doing repetitive tasks anymore. We’re looking at a future where factories are way more connected and smart. Think about it: automation is spreading everywhere, not just in the big car factories. Smaller businesses are getting in on it too, which is pretty cool.

Wider Adoption Across All Manufacturing Sectors

Automation used to be mostly for the giants in industries like cars or electronics. But now, even places making food or medicines are using it. Why? To speed things up, make sure everything is just right, and save some cash. It’s becoming a must-have for companies of all sizes that want to keep up. Smaller companies can now get their hands on automation without breaking the bank. This means more businesses can make things with the same quality and react faster when people want to buy more.

Connected Factories and End-to-End Automation

This is where the Industrial Internet of Things (IIoT) really shines. Imagine machines, sensors, and computers all talking to each other in real-time. This lets factories adjust on the fly. It’s not just about one machine; it’s about the whole system, from the raw materials coming in to the finished product going out. Data from the factory floor, suppliers, and even what customers are buying can all be used to make things run smoother. This connected approach helps companies use their resources better and avoid costly shutdowns.

AI-Driven Autonomous Systems

This is where things get really interesting. We’re talking about machines that don’t just spot problems but can figure out why they happened and fix them. These aren’t just replacing people; they’re working alongside them. Think of robots that can inspect products, adjust settings on the fly, or even self-driving forklifts moving materials around without anyone telling them what to do. These systems are getting more reliable and faster all the time, making the whole production process more efficient.

Looking Ahead

So, where does all this leave us? It’s pretty clear that automation isn’t just a passing trend in manufacturing; it’s the way things are going. We’ve seen how it’s already changing factories, making them faster and more efficient. Sure, there are hurdles to jump, like figuring out the costs and making sure people have the right skills for these new jobs. But the companies that are ready to adapt and embrace these changes, from smarter machines to connected systems, are the ones that will really do well. The future of making things is here, and it’s automated.