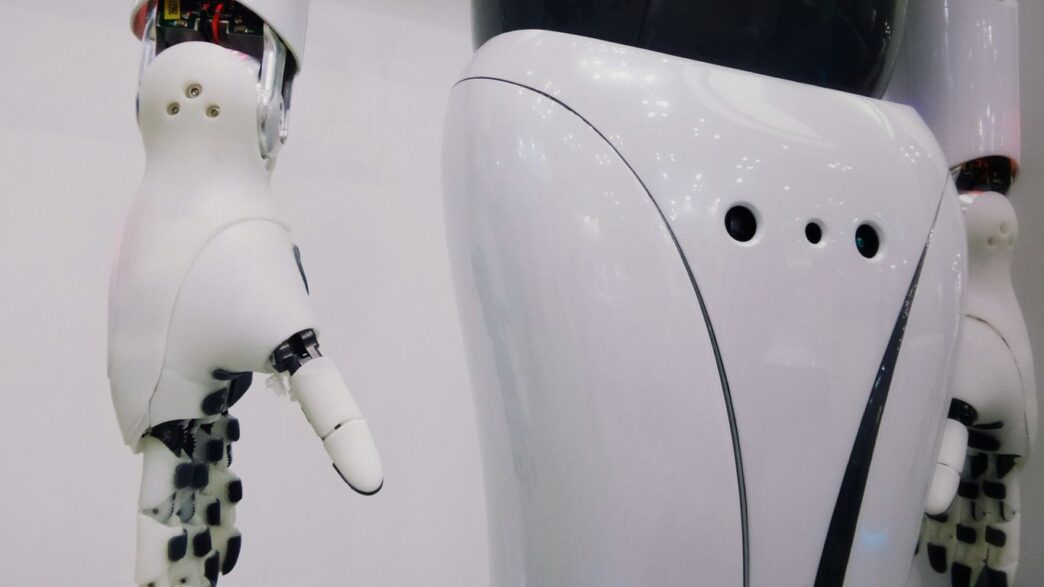

The Transformative Power Of Composite Materials For Robots

Robots are getting a serious upgrade, and a big part of that is thanks to new materials. We’re talking about composites, which are basically materials made from two or more different components. Think of it like a sandwich: you’ve got your strong stuff, like carbon fibers, and then you bind it all together with a resin. This combination gives you something that’s often way better than the sum of its parts.

Understanding Composite Materials In Robotics

So, what exactly are these composites we’re hearing so much about in the robotics world? At their core, they’re engineered materials. They combine a reinforcing agent, usually fibers, with a matrix material, often a polymer. The fibers provide the strength and stiffness, while the matrix holds them in place and transfers loads. This isn’t just about making things lighter; it’s about making them smarter and stronger in specific ways.

Key Advantages Of Composites For Robot Design

Why are engineers so excited about using composites for robots? Well, there are a few big reasons:

- Lighter Weight: This is a huge one. Lighter robots use less energy, which means longer battery life or more work done on a single charge. Plus, they can move faster and more efficiently.

- Higher Strength-to-Weight Ratio: Composites can be incredibly strong without being heavy. This is perfect for robot parts that need to withstand a lot of force, like joints or structural supports.

- Customizable Properties: You can actually tailor how a composite behaves. By changing the type of fiber, the resin, or how the fibers are arranged, you can make parts that are stiff in one direction and flexible in another, much like our own bodies.

- Corrosion Resistance: Unlike metals, composites don’t rust or corrode, which is a big plus for robots working in tough environments.

Continuous Fiber Composites In Robotic Applications

When we talk about composites in robotics, continuous fiber composites are often the stars of the show. These use long, unbroken fibers, which give the material incredible strength along the length of the fiber. This is where things get really interesting for robot design. Imagine robot arms that can lift more, legs that can handle rough terrain, or even entire robot bodies that are both tough and light. The ability to precisely control fiber placement allows for designs that mimic the directional strength found in biological systems, leading to more efficient and capable robots. This precision is often achieved through advanced manufacturing techniques, which we’ll explore further.

Advanced Manufacturing Techniques For Robot Components

Automated Fiber Placement For Precision

Making robot parts with composite materials used to be a real headache. Think of it like trying to build something intricate with sticky, stringy stuff – it’s messy and takes forever. But now, we’ve got Automated Fiber Placement (AFP). Basically, it’s a robot arm that precisely lays down carbon fiber or other composite fibers exactly where they need to go. This isn’t just about making things look neat; it’s about building parts that are incredibly strong but also super light. AFP systems can follow complex curves and angles, which is a big deal for creating custom robot shapes that weren’t possible before. It’s a huge step up from manual labor, cutting down on mistakes and making sure each part is built to spec, every single time. This precision is key for robots that need to be both agile and tough.

Continuous Fiber 3D Printing Innovations

Then there’s the whole world of 3D printing, but with a twist: continuous fiber. Imagine a 3D printer that doesn’t just lay down plastic, but also embeds long, strong fibers right into the print. This is a game-changer for robot components. Instead of printing a solid block that’s then reinforced, you’re printing the reinforcement into the structure from the start. This means we can create parts that are incredibly strong in specific directions, just like muscles in a human arm are stronger along their length. It allows for a level of customization that’s mind-blowing. Need a joint that can take a lot of torque in one direction but needs to be flexible in another? Continuous fiber 3D printing can handle that. It’s opening doors to making robots that are not only lighter and stronger but also much more adaptable to different tasks.

Overcoming Manufacturing Challenges With Modern Solutions

Let’s be real, making advanced materials work for robots hasn’t always been easy. Historically, composite manufacturing was expensive, time-consuming, and frankly, a bit dangerous. The materials themselves cost a lot, and the processes were complicated, often leading to wasted material or parts that weren’t quite right. Plus, dealing with fibers and resins isn’t exactly a walk in the park health-wise. But the new tech is changing all that. Systems like AFP-XS are making the process way more affordable and easier to integrate with existing equipment. And when you combine AFP with continuous fiber 3D printing, you get a powerful one-two punch. These modern solutions are tackling the old problems head-on, making it possible to produce complex, high-performance robot parts more efficiently and safely than ever before. It’s about making advanced manufacturing accessible, so we can build better robots without breaking the bank or the environment.

Mimicking Human Strength With Advanced Materials

Think about how our own bodies work. Muscles aren’t just strong; they’re strong in specific directions. Your bicep is great for pulling, but not so much for pushing sideways. This directional strength, or anisotropy, is something engineers are now trying to replicate in robots using advanced materials, especially composites.

Customizable Fiber Orientation For Directional Strength

Composites, particularly those made with long, continuous fibers like carbon fiber, have this neat trick up their sleeve: their strength can be tailored by how you lay down those fibers. It’s a bit like how wood grain gives wood its strength. By carefully controlling the orientation of these fibers during manufacturing, we can create robot parts that are incredibly strong along one axis but perhaps more flexible along another. This is a huge step towards making robots move more like us, with joints that bend and flex in natural ways.

- Tailored Strength: Fibers can be aligned to match the specific stresses a robot part will face. For example, a robot’s leg might need to be super strong vertically but allow for some sideways give.

- Mimicking Tendons: This directional strength is key to mimicking the way human muscles and tendons work, allowing for more nuanced and efficient movements.

- Material Choice: Different fiber types (carbon, glass, aramid) and matrix materials (resins) can be combined to fine-tune the properties even further.

Implications For Robot Movement And Efficiency

So, what does this mean for robots? Well, it’s pretty significant. When a robot can move more like a human, it opens up a whole new world of possibilities. Imagine robots that can navigate cluttered environments with greater agility or perform delicate tasks that require precise, controlled movements. This isn’t just about looking more human; it’s about becoming more capable.

- Agility Boost: Robots can react faster and move more smoothly, making them better suited for dynamic tasks.

- Energy Savings: By moving more efficiently, robots can use less power. This means longer operating times on a single charge, which is a big deal for mobile robots.

- Reduced Wear and Tear: More natural movements can also mean less stress on the robot’s internal components, leading to greater durability and less need for repairs.

Enhancing Load-Bearing Capacity And Durability

Beyond just movement, this ability to engineer strength in specific directions is a game-changer for how much weight a robot can handle. Think about a robot arm lifting heavy objects. By orienting the composite fibers correctly within the arm’s structure, engineers can make it incredibly strong in the directions needed to support and move those loads, without adding unnecessary bulk. This makes robots more robust and reliable for demanding industrial applications. Plus, composites are generally quite resistant to corrosion and fatigue, meaning these robots could last a lot longer in tough environments.

The Future Outlook For Materials In Robotics

So, where are we headed with all these cool new materials in robotics? It’s pretty exciting, honestly. We’re seeing a big push towards making these advanced materials, especially composites, way more accessible. Think less super-specialized labs and more practical, everyday manufacturing. Costs are dropping, and the tools to work with them are getting simpler, which means more companies can actually start using them.

Potential For Wider Adoption Of Composite Manufacturing

This isn’t just a pipe dream. The technology is maturing fast. Automated fiber placement and continuous fiber 3D printing are getting really good, really quickly. They’re bridging that gap between needing super-precise, custom parts and being able to churn them out in decent numbers. It’s like going from a tailor-made suit to a high-quality, off-the-rack option that still fits great. This trend is going to make robots lighter, stronger, and more efficient across the board.

Innovations Driving The Next Generation Of Robots

What’s next? Well, expect robots that can do even more. We’re talking about materials that can sense their environment, self-heal minor damage, or even change their properties on the fly. Imagine a robot arm that can adjust its stiffness depending on the task – super rigid for heavy lifting, but more flexible for delicate assembly. This kind of adaptability is key.

Here’s a quick look at what’s coming:

- Smarter Materials: Composites with embedded sensors for better situational awareness and structural health monitoring.

- Self-Repair: Materials that can fix small cracks or damage automatically, reducing downtime.

- Adaptive Properties: Materials that can change their stiffness, conductivity, or other characteristics based on commands or environmental cues.

- Bio-inspired Designs: Mimicking natural structures for even greater strength and flexibility.

Broader Applications Across Industries

With these advancements, robots won’t just be stuck in factories. We’re going to see them pop up everywhere. Think about healthcare, where robots could perform more intricate surgeries or assist with patient care using gentle, adaptable materials. Or in agriculture, helping with delicate harvesting. Even in our homes, robots might become more common, handling tasks that require a lighter touch. The possibilities really are expanding beyond what we might have imagined even a few years ago.

Revolutionizing Robot Design With Advanced Materials

So, we’ve talked about how composites are strong and light, but what does that actually mean for building robots? It means we can rethink how robots are made from the ground up. This isn’t just about making robots lighter; it’s about making them smarter, more capable, and frankly, more like us in how they move and handle things.

Weight Reduction For Enhanced Performance

Think about it: a lighter robot needs less energy to move. That’s a big deal for battery life, letting robots work longer. Plus, being lighter means they can move faster and more smoothly. Imagine a robot arm that can zip around without a lot of heavy motors – that’s the kind of performance boost we’re talking about. It’s like swapping out a heavy steel frame for something much lighter but just as strong, maybe even stronger in specific ways.

Customization And Functional Integration

One of the coolest parts is how we can tailor these materials. We can arrange the fibers inside a composite part to give it strength exactly where it’s needed. This is how we can start to mimic the way human muscles work, with different strengths in different directions. It also opens doors to embedding other things right into the robot’s structure. We could put sensors directly into the material itself, so the robot can ‘feel’ its environment or monitor its own structural health without needing extra add-on parts. This makes the robot more compact and efficient.

Multifunctionality Through Material Design

This idea of embedding functions is where things get really interesting. Instead of bolting on sensors or extra components, we can design the material to be the sensor. For example, a composite panel could detect stress or strain, telling the robot if it’s being pushed too hard. Or, conductive fibers could be woven in to act as wiring. This approach leads to robots that are not only lighter and stronger but also more integrated and aware. It’s a big step towards robots that can adapt and perform a wider range of tasks more effectively.

Wrapping It Up

So, we’ve looked at how new materials, especially composites, are changing the game for robots like Tesla’s. These materials make robots lighter, stronger, and more adaptable, which is pretty neat. Think about robots that can move more like us or handle delicate tasks without breaking a sweat. It’s not just about making robots better; it’s about opening up totally new jobs for them. While there are still hurdles to clear, like figuring out the best ways to make these parts and keeping costs down, the path forward looks really promising. We’re heading towards a future where robots are even more capable and integrated into our lives, thanks to these material science breakthroughs.