For a while now, there’s been a lot of talk about silicon carbide, or SiC for short. It’s this special material that’s really good at handling electricity, way better than the regular silicon we’ve used for ages. Think of it like upgrading from an old flip phone to the latest smartphone – it just does things faster, handles more power, and doesn’t get as hot. This shift is a pretty big deal for electronics, especially for things like electric cars and renewable energy. We’re going to look at why SiC is so special and how it’s changing the game.

Key Takeaways

- Silicon carbide (SiC) semiconductors offer significant advantages over traditional silicon, including better performance, heat management, and high-voltage handling.

- SiC technology is driving major changes in industries like electric vehicles, renewable energy, and data centers.

- The development of SiC has evolved from its early abrasive uses to becoming a key material in advanced electronics.

- Key benefits of using SiC include higher energy efficiency, smaller and lighter designs, and greater reliability in tough conditions.

- The market for SiC semiconductors is growing rapidly, with significant investments in production and a projected surge in demand.

The Unparalleled Advantages of Sic Semiconductors

So, why all the fuss about Silicon Carbide (SiC) semiconductors? It really comes down to what they can do that traditional silicon just can’t. Think of it like upgrading from a basic flip phone to a smartphone – suddenly, you can do so much more, and it’s way more efficient.

Superior Performance Beyond Silicon’s Limits

Silicon carbide just handles things better. It has a wider bandgap, which is a fancy way of saying it can deal with much higher electric fields before it gives up. This means SiC devices can be smaller and still handle a lot of power. Plus, they don’t lose as much energy as heat compared to silicon. This efficiency is a game-changer for anything that uses a lot of power.

Here’s a quick look at how SiC stacks up:

- Bandgap: SiC’s bandgap is almost three times wider than silicon’s.

- Breakdown Voltage: SiC can handle way more voltage before breaking down.

- Thermal Conductivity: SiC is much better at moving heat away.

Enhanced Thermal Management Capabilities

Dealing with heat is a big deal in electronics. When components get too hot, they don’t work as well, and they can even fail. SiC is naturally good at handling high temperatures. Its thermal conductivity is significantly better than silicon, meaning it can dissipate heat more effectively. This allows electronic systems to run hotter, or to be designed with less bulky cooling systems, which is a huge plus for making things smaller and more reliable.

High Voltage Handling and Faster Switching

This is where SiC really shines. It can handle much higher voltages without breaking down. This is super important for things like electric cars and renewable energy systems that deal with a lot of power. On top of that, SiC can switch on and off incredibly fast. Faster switching means less energy is wasted during the switching process, leading to even greater efficiency. It’s like being able to flip a light switch on and off thousands of times a second without any lag – that speed translates directly into better performance and less wasted energy.

Sic Semiconductors: Driving Innovation Across Industries

Silicon carbide (SiC) isn’t just a fancy material; it’s actively changing how we power everything from our cars to our factories. Because SiC can handle way more power and heat than regular silicon, it’s a game-changer for industries that need serious electrical muscle.

Revolutionizing Electric Vehicle Powertrains

Electric vehicles (EVs) are a prime example. SiC components, like inverters and MOSFETs, make the whole power conversion process much more efficient. This means EVs can go further on a single charge, which is a big deal for drivers. Plus, less wasted energy means a smaller carbon footprint for these vehicles. It’s not just about performance; it’s about making EVs more practical and environmentally friendly.

Optimizing Renewable Energy Systems

Think about solar farms and wind turbines. These systems need to convert natural energy into usable electricity, and SiC is making that conversion much cleaner. Using SiC in inverters for solar power, for instance, means less energy gets lost during the conversion from sunlight to electricity. This translates to more clean energy being fed into the grid, powering our homes and businesses more sustainably.

Advancing Industrial Automation and Data Centers

In factories and data centers, where machines run constantly and servers hum away, efficiency and reliability are key. SiC devices are tough. They can handle the demanding conditions of industrial settings, meaning components last longer and need replacing less often. This not only saves money on maintenance but also reduces the environmental impact of manufacturing and disposing of parts. For data centers, this means more efficient power usage, which is a huge factor when you consider the massive energy demands of these facilities. SiC’s ability to operate reliably under extreme conditions is making industrial processes more robust and energy-smart.

Here’s a quick look at how SiC is making a difference:

- Electric Vehicles: Longer range, faster charging, and reduced emissions.

- Renewable Energy: More efficient conversion of solar and wind power, increasing the usable clean energy supply.

- Industrial Automation: Increased equipment lifespan, reduced energy consumption for heavy machinery, and more dependable operations.

- Data Centers: Lower energy bills and a smaller environmental footprint due to more efficient power management.

The Evolution and Future of Sic Semiconductor Technology

From Abrasive Origins to Advanced Electronics

Silicon carbide, or SiC, has a pretty interesting history. It wasn’t always about fancy electronics. Believe it or not, natural SiC, known as moissanite, is a rare mineral found in meteorites. On Earth, we started making it in super hot furnaces by mixing sand and carbon. For a long time, it was mostly used as an abrasive – think sandpaper and grinding wheels. It took decades of work to figure out how to make SiC pure and large enough for electronics. Early methods like the Lely process were big steps, allowing for the creation of crystals suitable for devices. It’s a long way from being a rough abrasive to powering the most advanced tech.

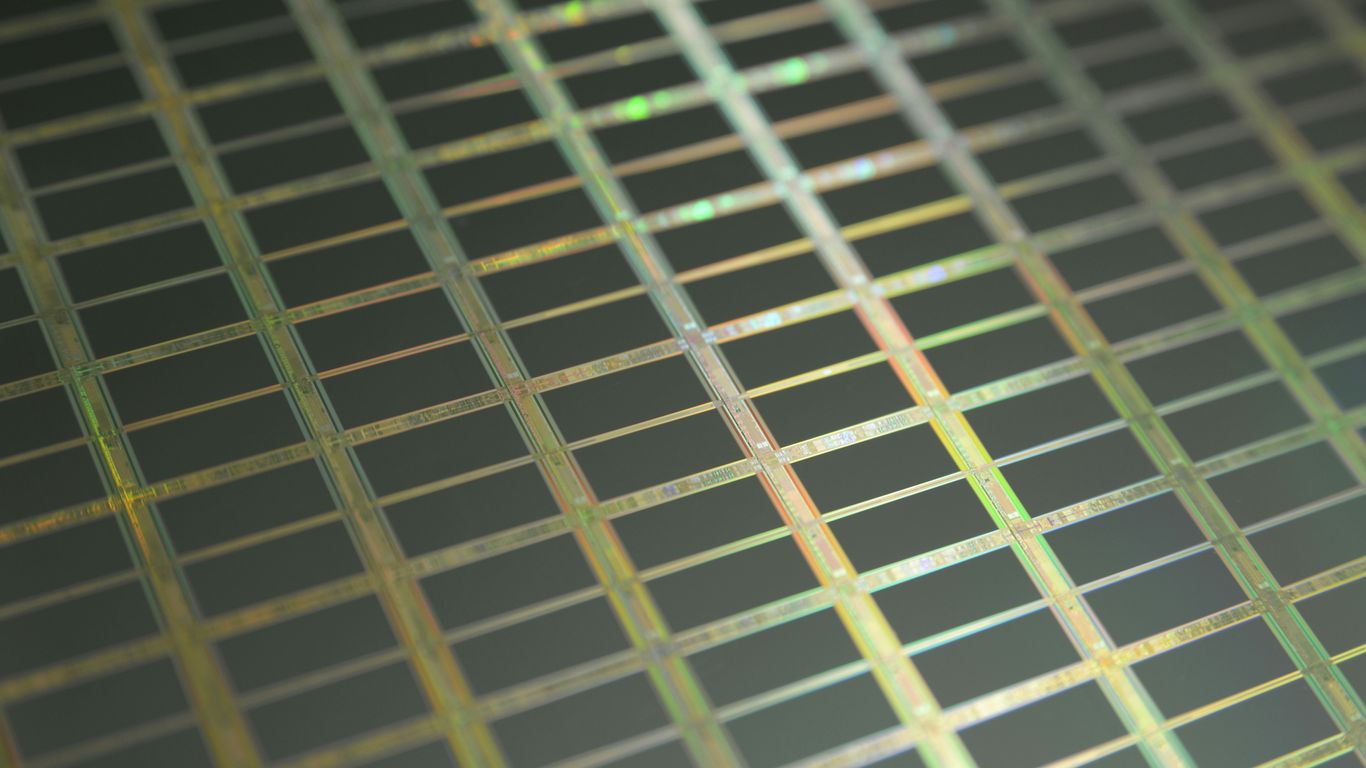

Scaling Production and Reducing Costs

For years, SiC was just too expensive and difficult to make in large quantities. The manufacturing process was complex, and yields weren’t great. But things have really changed recently. Companies have gotten much better at producing SiC wafers and chips, and the scale of production has gone way up. This increased output, along with process improvements, has started to bring prices down. It’s still more costly than regular silicon, but the gap is closing, making it a more realistic option for more products.

Here’s a look at how the market has been growing:

| Year | SiC Power Device Market Value (Approx.) |

|---|---|

| 2023 | $2.59 billion |

| 2032 | $21.27 billion (Projected) |

The Next Frontier in Power Electronics

So, what’s next for SiC? We’re seeing it move beyond just basic components. The focus is shifting towards more integrated systems where SiC plays a central role in managing energy more effectively. This means looking at how different parts of a system work together, not just individual power converters. Think about:

- Higher Power Density: Packing more power into smaller spaces.

- Improved System Efficiency: Reducing energy waste across the entire device or system.

- Advanced Packaging: Developing better ways to house SiC chips to handle heat and electrical stress, especially in tough environments.

The future looks like SiC being the backbone for new power electronics, enabling designs that were simply not possible before. It’s a big shift, and it’s happening now.

Key Benefits of Sic Semiconductors in Modern Electronics

Achieving Higher Energy Efficiency

So, why all the fuss about Silicon Carbide (SiC)? One of the biggest reasons is how much less energy these chips waste compared to their older silicon cousins. Think of it like this: when electricity flows through a component, some of it always turns into heat. SiC is just way better at letting that electricity pass through with minimal fuss. This means less energy is lost, which is a pretty big deal when you’re talking about big power systems. This improved efficiency directly translates to lower electricity bills and a smaller carbon footprint.

Here’s a quick look at why SiC is so good at this:

- Less Resistance: SiC materials naturally have lower electrical resistance, meaning electrons can move more freely.

- Better Heat Dissipation: While some heat is unavoidable, SiC handles it much better, allowing components to run cooler and more efficiently.

- Faster Switching: SiC devices can turn on and off much faster, reducing the time energy is being wasted during transitions.

Enabling Compact and Lightweight Designs

Because SiC components are so much more efficient and can handle more power in a smaller package, designers can make things a lot smaller and lighter. This is a game-changer, especially for things like electric cars. Imagine needing less space for the power electronics, or being able to make a charging station smaller and easier to install. It also means less need for bulky cooling systems, which further cuts down on size and weight.

Ensuring Reliability in Extreme Conditions

SiC isn’t just about efficiency and size; it’s also incredibly tough. These semiconductors can handle much higher temperatures than traditional silicon. They also have a higher breakdown voltage, meaning they can withstand bigger electrical stresses without failing. This makes them perfect for demanding environments where things can get pretty hot or where high voltages are common. Think about industrial machinery running non-stop or power grids dealing with fluctuating loads – SiC components are built to last in these tough spots, reducing the chances of unexpected breakdowns and keeping systems running smoothly.

Adoption Trends and Market Growth for Sic Semiconductors

Accelerating Market Penetration

The shift from traditional silicon to silicon carbide (SiC) isn’t just a slow trickle anymore; it’s becoming a noticeable wave. For years, SiC was talked about as the future, but it was tricky to make and pretty expensive. Now, though, things are changing. Companies are getting better at making SiC chips, and that’s bringing the costs down. This makes it way more practical for a lot of different products. We’re seeing SiC pop up in more places, especially where efficiency and handling tough conditions are a big deal. Think about electric cars – they really benefit from SiC’s ability to manage power better and last longer. The whole SiC wafer market is expected to grow a lot in the next few years.

Investment and Manufacturing Expansion

Because so many industries are starting to see the benefits of SiC, there’s a lot more money and effort going into making these chips. Companies are investing heavily in new factories and improving the ones they already have. It’s not just about making more chips, but also about making them more reliably and consistently. This is a big deal because SiC manufacturing is pretty complex. Building out this manufacturing capacity is key to meeting the growing demand. It’s a bit of a race to secure supply chains and develop the best production methods. This expansion is happening globally, with different regions focusing on different parts of the process.

Projected Market Surge by 2032

Looking ahead, the numbers for SiC are pretty impressive. Experts predict a massive jump in the SiC market value over the next decade. This growth is fueled by several big trends:

- Electric Vehicles (EVs): As more people buy EVs, the need for efficient and powerful components like SiC inverters and converters goes way up.

- Renewable Energy: Solar and wind power systems need to convert energy efficiently, and SiC helps make those systems better and less wasteful.

- Data Centers and AI: The massive amounts of data and processing power needed for AI and cloud computing require highly efficient power supplies, where SiC shines.

- Industrial Applications: From factory robots to power grids, SiC’s ability to handle high power and heat makes it a great choice for demanding industrial jobs.

All these factors are pushing the market forward. The global SiC power device market, which was around $2.59 billion in 2023, is expected to reach about $21.27 billion by 2032. That’s a huge increase, showing just how important SiC is becoming for the future of electronics.

The Road Ahead with SiC

So, looking at everything, it’s pretty clear that silicon carbide isn’t just some passing trend. It’s really changing how we build electronics, especially when it comes to handling power. From making electric cars go further and charge faster to helping us use renewable energy more effectively, SiC is quietly making a big difference. It’s not always the easiest material to work with, and there’s still work to do on making it even better and cheaper, but the benefits are hard to ignore. We’re seeing it pop up everywhere, and it feels like we’re just at the beginning of what SiC can do. It’s definitely something to keep an eye on as our world keeps needing more efficient and powerful tech.

Frequently Asked Questions

What is Silicon Carbide (SiC) and why is it better than regular silicon?

Silicon Carbide, or SiC, is a special material made from silicon and carbon. Think of it like a super-powered version of the silicon used in most electronics today. SiC can handle much higher temperatures, voltages, and switch on and off way faster than regular silicon. This means devices made with SiC can be more efficient, smaller, and last longer, especially in tough jobs.

How is SiC used in electric cars?

Electric cars use a lot of power, and SiC helps make them work better. SiC chips are used in the car’s inverter, which changes the battery’s power to run the motor. Because SiC is so efficient, it means less energy is wasted as heat. This can help electric cars go further on a single charge and charge up faster, making them more practical for everyone.

Does SiC help with renewable energy like solar and wind power?

Yes, absolutely! Solar panels and wind turbines generate electricity, but it needs to be converted into a usable form. SiC is great for the equipment that does this conversion because it loses very little energy. This means more of the power generated by the sun or wind actually makes it to your home or the grid, making renewable energy sources more effective.

Is SiC technology expensive?

In the past, making SiC was quite costly, which made it harder to use. But, as more companies have learned how to make it and more people are buying it, the price has been coming down. It’s still often more expensive than regular silicon, but the benefits in performance and efficiency can make it worth the extra cost for many important applications.

What are the biggest challenges in using SiC?

One challenge is making SiC wafers perfectly without any tiny flaws, as these can affect how well the electronic parts work. Another is figuring out the best ways to package SiC chips so they can handle the extreme heat and power they’re designed for. Engineers are constantly working on solutions for these issues.

What does the future look like for SiC semiconductors?

The future for SiC looks very bright! As we need more efficient ways to use energy for things like electric cars, faster internet, and smarter factories, SiC will become even more important. Experts predict that the market for SiC chips will grow a lot in the next few years, making them a key part of many new technologies.