So, silicon carbide, or SiC for short, has been talked about for ages as this super material for electronics. It’s supposed to be way better than regular silicon, especially for things that need to handle a lot of power. But it feels like it’s only really starting to take off now. There’s a whole lot of buzz around SiC semiconductors, and it seems like they’re popping up everywhere, from electric cars to the power systems behind our internet. Let’s break down what’s making these SiC semiconductors so important right now.

Key Takeaways

- SiC semiconductors are gaining traction because they offer better performance than traditional silicon, handling higher voltages and temperatures with less energy loss.

- Electric vehicles are a major driver for SiC adoption, with these components helping to extend driving range and speed up charging times.

- Renewable energy systems and industrial automation also benefit greatly from SiC’s efficiency and reliability, leading to reduced energy waste and operational costs.

- Companies like onsemi are investing heavily in expanding SiC manufacturing to meet growing global demand, focusing on quality and scaling production.

- Despite challenges in production and supply chains, SiC semiconductors are seen as critical for future tech like AI and data centers, promising greater efficiency and sustainability.

The Strategic Rise Of Sic Semiconductors

It feels like silicon carbide, or SiC as everyone calls it, has been talked about for ages as the next big thing in electronics. And for good reason! It’s got these amazing qualities that silicon just can’t match, especially when it comes to handling power. Think higher efficiency, better performance even when things get really hot, and the ability to deal with way more voltage. So, why are we only really seeing it take off now? Well, it turns out making this stuff reliably and in big enough quantities was a real hurdle. But we’re finally past that point. The technology has matured, the manufacturing processes are more robust, and companies are building the confidence and the infrastructure to really use it.

Understanding The Unique Advantages Of Silicon Carbide

So, what makes SiC so special compared to the silicon we’ve used for decades? It really comes down to its material properties. Silicon has been pushed to its limits, and SiC offers a way to break through those barriers. It’s not just a small improvement; it’s a significant leap forward for power electronics.

Here’s a quick look at why SiC is different:

- Handles High Voltages: SiC can manage much higher voltages without breaking down. This is a big deal for things like electric cars and power grids.

- Faster Switching: SiC devices can switch on and off much faster. This means less energy is wasted as heat during operation, leading to greater efficiency.

- High-Temperature Operation: SiC can operate reliably at much higher temperatures than silicon. This reduces the need for bulky cooling systems and allows for more compact designs.

Key Benefits Driving Sic Adoption

The advantages of SiC translate directly into tangible benefits that are pushing industries to adopt it. It’s not just about having a better material; it’s about what that material enables.

- Higher Efficiency: This is probably the biggest draw. SiC power devices lose much less energy as heat compared to traditional silicon. For applications that use a lot of power, like electric vehicles or data centers, this efficiency gain means significant savings on energy consumption and lower operating costs. It’s a win for both the wallet and the planet.

- Improved Thermal Management: SiC has excellent thermal conductivity. This means it can handle extreme heat much better. Devices can operate at higher temperatures without performance dropping off, which is super useful in demanding environments and allows for smaller, lighter designs because you don’t need as much cooling.

- Smaller Size and Lighter Weight: Because SiC devices are more efficient and handle heat better, they often don’t need as many supporting components, like large heatsinks. This allows for much more compact and lighter end products. Think about how much difference that makes in an electric car or a piece of industrial equipment.

Sic’s Role In Next-Generation Power Management

As we look ahead, SiC is becoming the backbone for how we manage power in so many critical systems. It’s enabling designs and capabilities that just weren’t possible before.

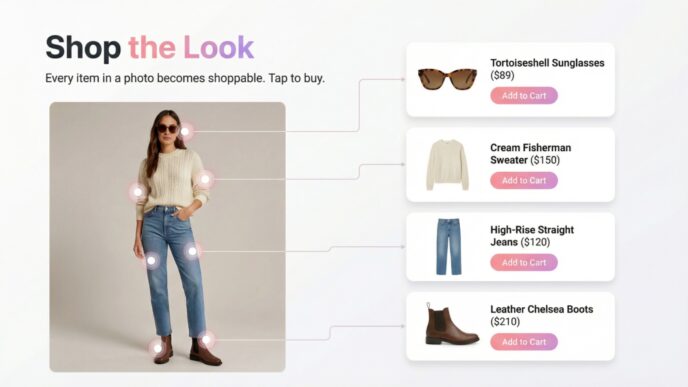

- Electric Vehicles (EVs): SiC is a game-changer for EVs. It helps make the power inverters more efficient, which means cars can go further on a single charge and charge up faster. The ability to handle high voltages and temperatures also means more power can be packed into smaller, lighter components, which is key for vehicle design.

- Renewable Energy: In solar and wind power systems, SiC helps make the inverters that convert energy from the panels or turbines into usable electricity much more efficient. This means less energy is lost in the conversion process, leading to more power generated and a better return on investment for these systems.

- Industrial Automation: For things like motor drives in factories, SiC’s robustness and efficiency are huge. Stable performance and energy savings can directly impact production costs and reliability. It means machines can run more consistently and use less electricity.

- 5G Infrastructure: The rollout of 5G requires components that can handle high frequencies and deliver power efficiently. SiC devices are well-suited for these demanding applications, helping to ensure the reliable, high-speed connectivity that 5G promises.

Sic Semiconductors Powering Key Industries

It’s pretty wild how silicon carbide (SiC) is popping up everywhere these days, especially in industries that really need to be smart about power. Think about electric cars – they’re a huge reason why SiC is getting so much attention. These cars need to be efficient to go further on a charge, and SiC helps with that. It means less energy wasted when the car converts battery power to move the wheels. This efficiency boost is a big deal for extending driving range and even speeding up charging times. SiC components are making electric vehicles more practical and appealing.

Then there’s the whole renewable energy scene. Solar panels and wind turbines generate power, but you need good electronics to convert that energy into something we can actually use in our homes and businesses. SiC is showing up in inverters for these systems, making the conversion process cleaner and reducing energy loss. So, more of that clean energy actually makes it to the grid. It’s a win-win for efficiency and for the environment.

Industrial automation is another area where SiC is making waves. Factories are using more robots and automated systems, and these often need a lot of power. SiC devices are tough and can handle high temperatures and voltages, which is great for keeping heavy machinery running smoothly. Plus, their efficiency means lower electricity bills for factories, and that adds up. It also means less frequent part replacements, which is good for reducing waste.

And let’s not forget about 5G. Building out those super-fast networks requires a lot of new infrastructure, and the components need to be top-notch. SiC power devices are good at handling the high frequencies and power demands of 5G equipment, helping to keep those connections reliable and speedy. It’s all about making sure the technology we rely on can perform without a hitch. The market for SiC power devices is growing fast, with projections showing a significant increase in value over the next few years, driven by these very industries SiC’s strategic rise.

Here’s a quick look at where SiC is making a difference:

- Electric Vehicles: Better range, faster charging, and more compact designs.

- Renewable Energy: More efficient conversion of solar and wind power to usable electricity.

- Industrial Automation: Reliable operation of machinery, reduced energy consumption, and longer component life.

- 5G Infrastructure: Supporting high-speed data transfer with efficient and reliable components.

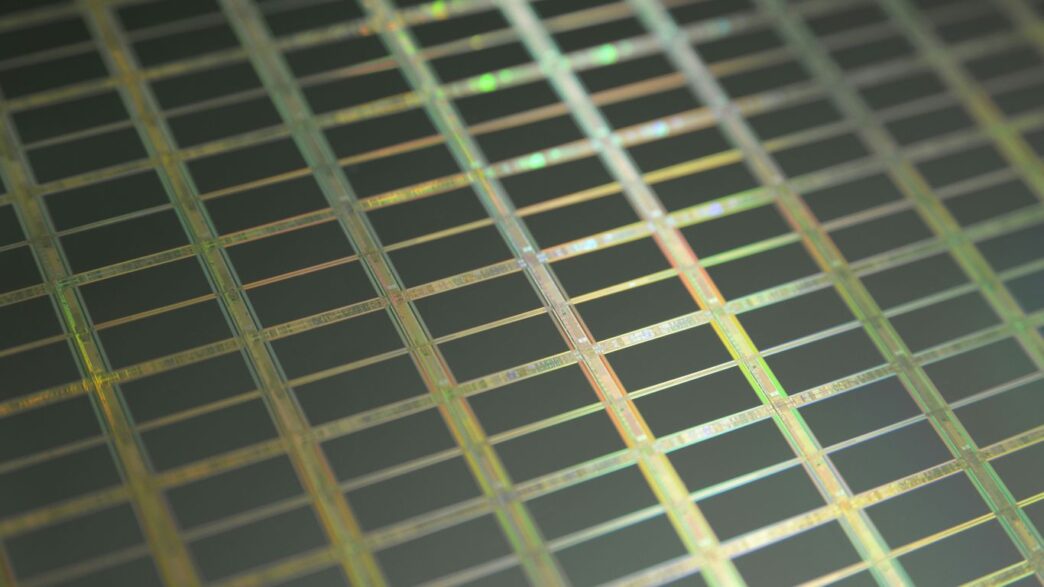

Manufacturing And Scaling Sic Semiconductor Production

Making silicon carbide (SiC) chips isn’t quite like making regular silicon ones. It’s a whole different ballgame, requiring special materials and super precise manufacturing. Think incredibly high temperatures and ultra-pure conditions. Companies like SGL Carbon are key here, providing the really tough graphite parts needed for furnaces that handle all this heat and keep things pure. These parts, like heat shields and crucibles, are pretty important for getting the SiC powder and growing the crystals that eventually become wafers.

Onsemi’s Strategy For Sic Manufacturing Expansion

Onsemi is really going big on SiC production. They know everyone wants these chips, especially for electric cars and renewable energy. So, they’ve been buying up factories and making sure they have their own wafer production. This way, they can control the quality and make sure they have enough SiC wafers to keep up with demand. It’s all about having a steady supply and not being stuck waiting on others. They’ve also been working on making their production processes better, trying to get more good chips out of each wafer and improve how reliable they are. Plus, they’re making smart partnerships to get the raw materials they need and stay on top of new manufacturing tech. It’s a big push to make sure they can supply the market now and in the future.

Innovations In Silicon Carbide Fabrication Processes

When it comes to making SiC chips, the fabrication process itself is getting a lot of attention. Companies are pouring money into research to figure out how to make the process smoother, get higher yields, and produce better quality wafers. This involves getting better at growing the SiC crystals and processing the wafers. The goal is to make devices that are not only more efficient but also last longer. Recent advancements in SiC device technology are exploring how to refine these fabrication steps even further, sometimes even looking at how machine learning can help optimize things.

Ensuring Quality And Consistency In Sic Devices

Getting SiC devices to be consistently good is a big deal. Because these chips are used in demanding applications, even small flaws can cause problems. So, manufacturers are using a lot of automation and strict quality checks throughout the whole process. This means keeping a close eye on everything from the raw materials to the final chip. They’re working hard to make sure every SiC power device meets the tough standards the industry expects. This focus on quality is what builds trust and makes sure these advanced components perform as they should, especially when reliability is non-negotiable.

Addressing Challenges In The Sic Semiconductor Market

Scaling Production to Meet Global Demand For Sic

So, silicon carbide (SiC) is pretty amazing, right? It lets devices handle more power, run hotter, and generally be way more efficient than old-school silicon. This is why everyone from electric car makers to folks building giant solar farms wants more of it. The problem? Making SiC chips isn’t like baking cookies. It needs special materials and super precise factories. Companies are trying to build more of these factories and get better at making the wafers, but it’s a slow process. It’s a real balancing act between keeping up with demand and making sure the quality stays top-notch.

Navigating Supply Chain Vulnerabilities For Sic Materials

Think about the whole world of making computer chips. It’s already a bit of a tangled mess, with parts coming from all over. For SiC, it’s even trickier because you need specific raw materials that aren’t always easy to get. Things like politics, natural events, or just plain old shortages can mess things up. Companies are trying to fix this by working more closely with their suppliers, sometimes even buying up the companies that provide the raw stuff, just to make sure they have what they need.

Maintaining Competitiveness Through Technological Advancements

This SiC market is getting crowded, and fast. To stay ahead, companies can’t just rest on their laurels. They’ve got to keep inventing new and better ways to make SiC chips and figure out what customers will need next. This means pouring money into research and development, trying out new manufacturing tricks, and always keeping an eye on what the competition is doing. It’s a constant race to be the first with the next big improvement.

The Future Of Sic Semiconductors And Innovation

Onsemi’s Product Roadmap For Sic Solutions

Onsemi isn’t just resting on its laurels with current SiC tech. They’ve got a pretty clear plan for what’s next, and it looks like they’re aiming for even more power packed into smaller spaces. Think next-gen devices that can handle more juice, are smaller, and just plain more reliable. They’re talking about SiC modules specifically designed for things that need a lot of power, like those super-fast EV chargers popping up everywhere, and the big motors that drive industrial machines. The goal here is to solve real problems for these industries, letting them handle more power without getting bogged down by inefficiency or breaking down.

They’re also looking at specialized stuff, like SiC components for 5G networks. You know, where things need to run fast and not hog a ton of electricity. It’s all about making sure their SiC products fit exactly what different industries need, which is pretty smart.

The Role Of Sic In Advancing AI And Data Centers

Artificial intelligence is a hungry beast, and data centers are its feeding grounds. These places use a massive amount of electricity, and that’s where SiC really starts to shine. Because SiC components are so much more efficient than older silicon ones, they can help cut down on the energy waste. This is a big deal when you’re talking about massive server farms that run 24/7. Less wasted energy means lower electricity bills and, importantly, a smaller carbon footprint. As AI gets more complex and data demands grow, the need for efficient power solutions in data centers will only get bigger. SiC is looking like a key player in making sure these AI hubs don’t become energy black holes.

Packaging Innovations For Unlocking Sic Potential

Even the best semiconductor material can be held back if it’s not packaged right. That’s where packaging innovations come in for SiC. It’s not just about putting the chip in a box; it’s about how that box handles heat, how it connects to everything else, and how it holds up over time. New packaging methods are being developed to get the most out of SiC’s high-temperature capabilities and its ability to switch power on and off really fast. Better packaging means SiC devices can perform at their peak, handle even tougher conditions, and last longer, which is exactly what you want when you’re pushing the limits in electric vehicles or industrial applications. Think of it like giving a high-performance engine the perfect chassis and cooling system – it lets the engine do what it was built to do, and then some.

Sic Semiconductors Driving Sustainability And Efficiency

Reducing Energy Waste With Sic Power Devices

It’s pretty wild how much energy gets wasted in electronics, especially in high-power stuff. That’s where silicon carbide (SiC) really starts to shine. Unlike regular silicon, SiC devices are just way better at handling power without losing as much as heat. Think about electric cars – using SiC inverters means they can go further on a charge because less energy is wasted during power conversion. It’s not just about making things go faster or last longer; it’s about making them use less power overall. This efficiency gain is a big deal for cutting down on electricity use across the board.

Supporting Eco-Friendly Initiatives Through Sic

When you look at renewable energy, like solar farms or wind turbines, SiC plays a huge part in making them more effective. By using SiC in the equipment that converts the energy from the sun or wind into usable electricity, we can reduce the amount of energy lost in that process. This means more clean energy actually makes it to our homes and businesses. It’s a pretty direct way SiC helps us move towards greener solutions. Plus, the fact that SiC components often last longer means fewer replacements are needed, which cuts down on manufacturing waste and the environmental impact of producing new parts. It’s a win-win for efficiency and the planet.

Long-Term Benefits Of Sic For Industrial Systems

In factories and industrial settings, where machines run constantly, efficiency and durability are key. SiC components are tough and don’t need replacing as often as older technologies. This not only saves money but also reduces the environmental footprint associated with manufacturing and disposing of industrial parts. Imagine heavy machinery that requires less energy to operate and whose components last for years instead of months. That’s the kind of change SiC brings. It helps industrial systems run more smoothly and with less environmental impact, supporting sustainability goals for businesses that rely on consistent, powerful operations.

The Road Ahead for SiC

So, it looks like silicon carbide is really starting to hit its stride. For a long time, it was all talk and not much action, but now, with electric cars, cleaner energy, and all that AI stuff needing more power, SiC is finally getting its moment. Companies are pouring money into making more of it, and the tech itself is getting better and cheaper. It’s not just about making things run faster; it’s about making them run smarter and use less energy. We’re seeing SiC pop up everywhere, from your car to the power grid, and that trend is only going to grow. It’s pretty clear that this material is going to be a big part of how we build our tech future, making things more efficient and sustainable along the way.

Frequently Asked Questions

What is Silicon Carbide (SiC) and why is it special?

Silicon Carbide, or SiC, is a special material used to make computer chips. It’s better than regular silicon because it can handle more power, work in hotter places, and switch on and off much faster. Think of it like a super-strong, super-fast version of the material in your current phone or computer.

Why are electric cars using SiC chips?

Electric cars use SiC chips to go farther on a single charge and charge up quicker. These chips help manage the car’s power more efficiently, meaning less energy is wasted as heat. This also allows car designers to make the power systems smaller and lighter.

How does SiC help with renewable energy like solar and wind power?

SiC chips make solar panels and wind turbines more efficient. They help convert the energy from the sun or wind into electricity with less loss. This means we can get more usable power from these clean energy sources and reduce waste.

Are SiC chips expensive compared to regular silicon chips?

SiC chips used to be much more expensive, but as more companies make them, the cost is coming down. While they might still cost a bit more upfront, their better performance and efficiency can save money in the long run through lower energy use and less need for cooling.

What are the biggest challenges in making SiC chips?

Making SiC chips is tricky! It needs special materials and very precise machines. Companies are working hard to make more of them (scaling up production) and make sure they all work perfectly every time. Also, getting the special materials needed can sometimes be difficult.

What’s next for SiC technology?

The future is bright for SiC! Companies are planning to make even better chips that are smaller, more powerful, and more efficient. They will be used in more advanced electric cars, bigger renewable energy projects, and even in the supercomputers that power artificial intelligence and big data centers.