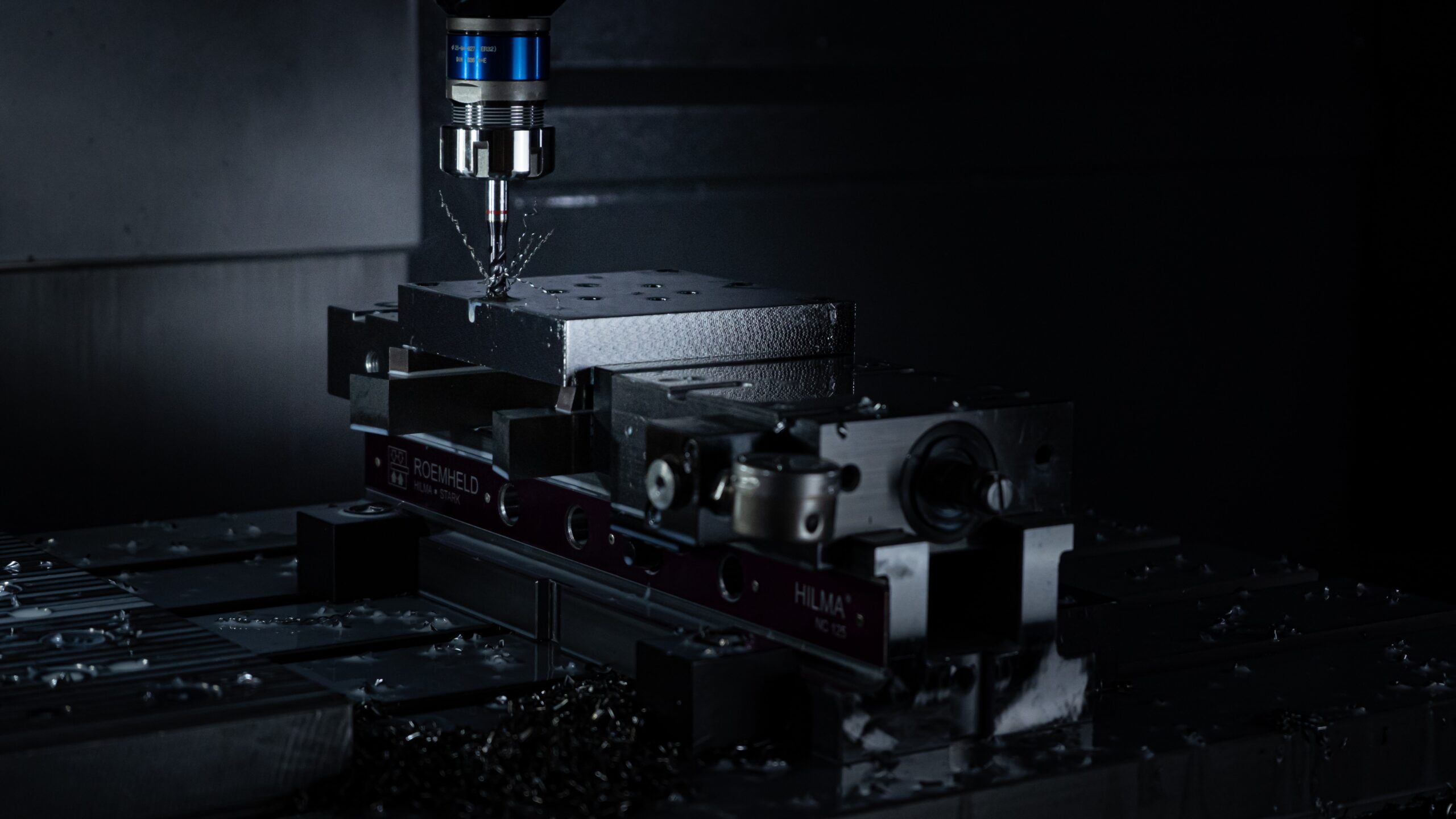

Let’s say you want to take advantage of cnc machining to create custom parts for your next production endeavor. That decision will likely bring you significant benefits, as cnc machining has a reputation for being able to produce precision parts with high efficiency.

You’ll need to take proactive measures with your designs if you don’t want the cost of your job to get out of hand, however, as cnc machining can also get expensive if you allow it to do so. This quick cnc machining guide will show you some simple (but not always well-known) techniques you can employ to cut costs and keep machining expenses manageable.

Watch Your Material Selection

Custom parts have to be made out of something, and the particular “something” that you choose is going to have a significant impact on final production costs. This is because different materials have different raw costs, that is to say, their inherent value varies, and more expensive materials will add a greater cost to your production process.

In addition to that, though, different materials can vary in cost because of their physical properties. Materials all have different thermal stabilities, hardnesses, chemical resistances, durability, malleability, etc. These physical characteristics determine how easy (or difficult) it is for machines to work. The more difficult it is to work, the more a material will end up costing.

Cut Down On Tool Changes

If your part design has a bunch of different complex idiosyncrasies going on, it’s often going to cost you more to produce. Why’s that? Because having a whole host of complexities will often require tool changes during the machining process, which adds time and thus money to the final tally. The antidote for this is to keep designs simple and consistent, and when you do need to add complexity to designs, do so in a measured fashion whenever possible.

Pay Attention To Tolerances

When you talk about “tight tolerances” in manufacturing custom parts, you’re most likely referring to the level of precision you’re going to need to replicate certain elements in the design. Tighter tolerances require special tools and more time to complete, thus, they will typically add to the cost of a job. Be sure you employ tight tolerances in the places where they are critical so that you’re not going overboard and driving up your costs unnecessarily.

Make Use Of 5-Axis Machining Where Applicable

Sometimes complexity is a necessity. In these situations, you’ll be doing yourself a favor by turning to 5-axis machining, which is capable of greater productivity and accuracy at reduced costs. Faster cutting speeds, improved drilling process, the ability to handle more complicated angles and shapes—these factors all come together to give 5-axis machines an advantage.

Slash Your Machining Time

As we alluded to earlier, total production time is linked to total production cost. If you want your custom part orders to cost less, you need to do what you can to reduce the time that machines need to run in order to complete production. The most obvious factors are controlling your design complexities, aiming for lower required tolerances, and watching your material selection (shooting for materials that are easy to work with an inexpensive to acquire).