It’s pretty wild how much 3D printing is changing things in the medical world. You know, the stuff that used to take ages or was super expensive is now becoming way more accessible. We’re talking about making things perfectly fit individual people, helping surgeons do their jobs better, and even changing how we get our medications. The whole field of 3D printing in the medical industry is really taking off, and it’s exciting to see what’s next.

Key Takeaways

- 3D printing allows for custom medical devices, like implants and prosthetics, made specifically for each patient.

- Surgeons can use 3D printed models to plan complex operations, leading to more precise procedures and better results.

- This technology is changing how drugs are made, allowing for personalized dosages and on-demand production.

- Manufacturing medical devices is getting faster and cheaper thanks to 3D printing, improving supply chains.

- While adoption is growing, challenges like regulations, costs, and training still need to be addressed for 3D printing to become even more widespread in healthcare.

Revolutionizing Patient Care with Personalized Solutions

It’s pretty amazing how 3D printing is changing things up in healthcare, especially when it comes to making treatments just for you. Gone are the days of a one-size-fits-all approach, which, let’s be honest, never really worked perfectly for everyone anyway. Now, we’re seeing a real shift towards care that’s tailored to each person’s unique needs.

Tailored Implants and Prosthetics

This is where 3D printing really shines. Imagine needing a prosthetic limb or a hip replacement. Instead of getting something off the shelf that might not fit quite right, doctors can now use scans of your body to print implants or prosthetics that are a perfect match. This means a better fit, more comfort, and often, faster recovery times. It’s like having a custom-made piece of your own body created just for you. This level of personalization can make a huge difference in someone’s quality of life.

Customized Surgical Instruments

Surgeons are also benefiting big time. For really tricky operations, having the right tools is everything. 3D printing allows for the creation of specialized surgical instruments designed for a specific procedure or even a specific patient’s anatomy. Think about a tool that needs to reach a very particular spot or has a unique curve to it. Printing these on demand means surgeons have exactly what they need, when they need it, which can lead to smoother surgeries. It’s a game-changer for complex cases.

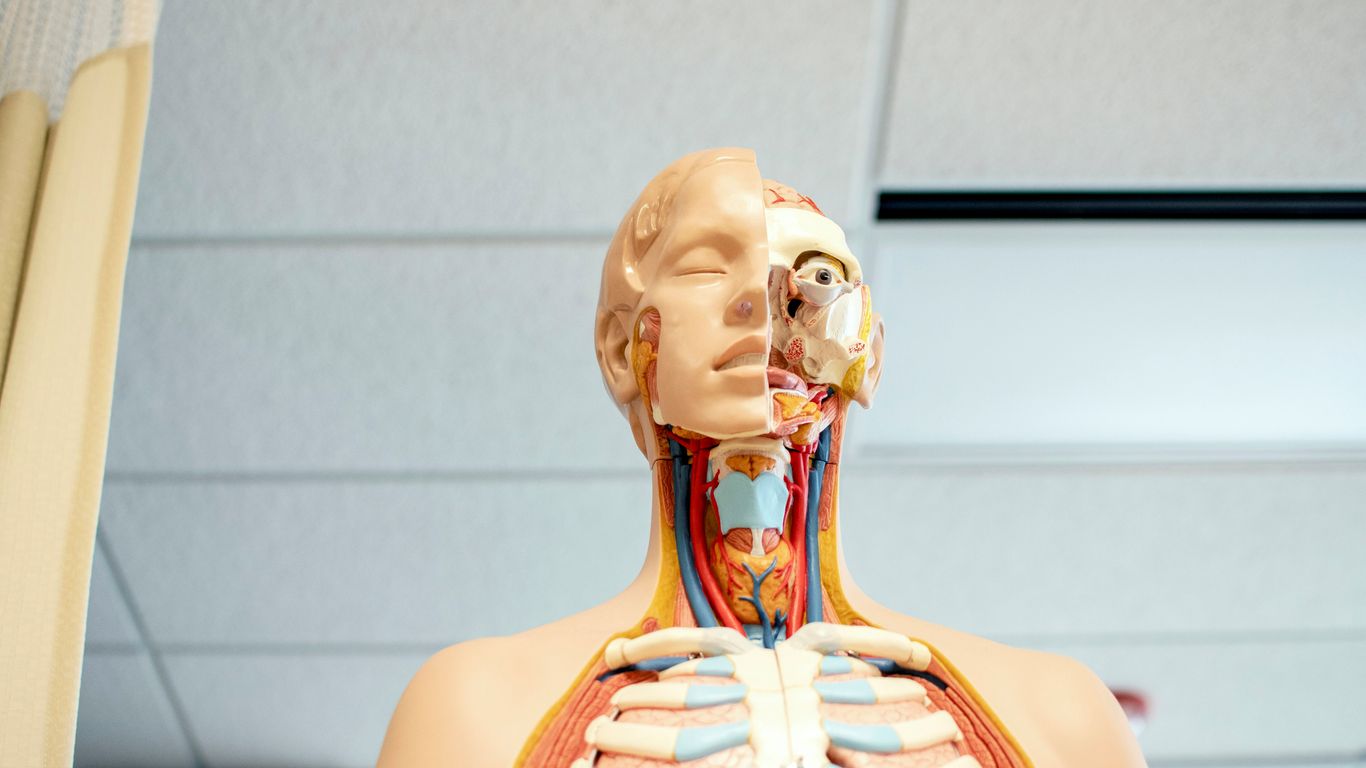

Patient-Specific Anatomical Models

Before a surgeon even steps into the operating room, they can now practice on a 3D-printed model of the patient’s actual anatomy. These models are incredibly detailed, showing tumors, blood vessels, and bone structures exactly as they appear in the patient. This allows surgeons to plan their approach meticulously, identify potential problems beforehand, and even rehearse the surgery. It’s like having a practice run that significantly reduces surprises during the actual operation. This preparation is key to improving patient outcomes and making medical 3D printing more accessible.

Advancing Surgical Precision and Outcomes

You know, before 3D printing really took off in medicine, surgeons often had to work with generic tools and models. It was like trying to build a custom piece of furniture with a one-size-fits-all wrench. But now? Things are changing, and it’s pretty amazing to see.

Pre-Surgical Planning with Realistic Models

Imagine a surgeon about to perform a really tricky operation. Instead of just looking at flat scans, they can now hold a perfect, life-size replica of the patient’s anatomy right in their hands. These aren’t just toys; they’re incredibly detailed models, printed from the patient’s own scans. This lets surgeons walk through the procedure beforehand, spotting potential problems and figuring out the best approach. It’s like having a dress rehearsal for surgery. Studies have shown that using these models can really cut down on the time spent in the operating room. For instance, some research indicates that using 3D printed anatomical models as guides can reduce surgery time by over an hour, saving a good chunk of money too.

Here’s a quick look at what these models can do:

- Visualize complex structures: See exactly where nerves, blood vessels, and organs are located.

- Practice difficult maneuvers: Rehearse tricky steps without any risk to the patient.

- Improve team communication: Everyone involved can see and understand the surgical plan.

Enhanced Accuracy in Complex Procedures

When you’re dealing with something as delicate as brain surgery or reconstructing a complex joint, precision is everything. 3D printing allows for the creation of custom surgical guides that fit perfectly onto the patient’s bone or tissue. These guides act like a stencil, directing the surgeon’s instruments with incredible accuracy. This means less guesswork and a much higher chance of getting it right the first time. It’s a big deal for procedures that require very specific angles or depths. Think about it: instead of relying on general measurements, you have a tool made just for that one patient, in that one spot. This level of customization is a game-changer.

Reduced Operative Times and Costs

So, how does all this precision and planning translate into real-world benefits? Well, when surgeons can plan better and have custom tools, they tend to work faster and more efficiently in the operating room. Less time under anesthesia is always a good thing for patients, and it also means hospitals can see more patients. Plus, by reducing the need for repeat surgeries due to errors or complications, the overall cost of care goes down. It’s a win-win situation. While the initial cost of printing might seem high, the savings from shorter procedures, fewer complications, and better patient outcomes often make it a worthwhile investment in the long run.

Transforming Pharmaceutical Development and Delivery

It’s pretty wild how 3D printing is shaking things up in the world of medicine, and the pharmaceutical industry is no exception. We’re moving away from that old ‘one-size-fits-all’ approach to making drugs, which, let’s be honest, never really worked perfectly for everyone. Now, we’re talking about making medications that are actually made for you.

Personalized Drug Dosages

This is a big one. Imagine getting a pill with exactly the right amount of medicine for your body, not just a standard dose. 3D printing lets us create tablets with incredibly precise dosages. This means fewer side effects and better results, especially for people with complex health issues or those who are sensitive to certain medications. It’s like having a custom-tailored suit, but for your health.

On-Demand Medication Production

Think about it: instead of massive factories churning out tons of pills that might expire or not be needed, we could print medications right where and when they’re needed. This cuts down on waste and makes sure that the drugs you get are fresh. It’s also a game-changer for rare diseases or for medications that have a short shelf life. Plus, it opens the door for making drugs that are easier to take, maybe even flavored for kids or people who have trouble swallowing pills. That could really help people stick to their treatment plans.

Controlled-Release Drug Systems

This is where things get really interesting. 3D printing allows for some seriously intricate designs within a single pill. We can create complex structures that release medication over a specific period, or even release different drugs at different times. This means you might not have to take as many pills throughout the day. For example, a single printed tablet could release a pain reliever immediately and then a different medication hours later. It’s all about making treatments more effective and way more convenient for patients.

Driving Innovation in Medical Device Manufacturing

When you think about making new medical gadgets, it used to take ages. You’d design something, then wait for expensive molds or tools to be made, and then hope it worked. It was a slow, costly process. But 3D printing, or additive manufacturing as it’s also called, has totally changed the game.

Accelerated Prototyping and Development

This is where 3D printing really shines. Instead of waiting weeks or months for a prototype, you can print one in a matter of days, or even hours. This means designers and engineers can test out ideas much faster. They can print a part, see how it fits, how it feels, and then tweak the design and print another one. This rapid iteration cycle is a huge deal for getting new devices from the drawing board to patients quicker. It also means less material is wasted compared to traditional methods, which is good for the wallet and the planet.

Cost-Effective Production Methods

For a long time, 3D printing was seen as just for making prototypes. But now, it’s becoming a real option for producing actual medical devices, especially for smaller batches or highly customized items. Think about specialized surgical tools or unique implants. Making a custom mold for just one or two of these would be incredibly expensive. With 3D printing, you don’t need those expensive molds. You just print what you need, when you need it. This makes it way more affordable to produce these kinds of specialized medical products.

Streamlined Supply Chain Efficiency

Another big win for 3D printing is how it helps with the supply chain. Instead of relying on a few big factories that might be far away, hospitals and medical companies can set up their own 3D printing facilities. This is called point-of-care manufacturing. It means they can make devices right there, on-site. This cuts down on shipping times and costs, and it’s super helpful if there’s a sudden shortage of a specific part or device. It makes the whole process more flexible and less prone to disruptions. Plus, it reduces the need to keep huge inventories of parts that might not get used.

The Growing Ecosystem of 3D Printing in Healthcare

It’s pretty wild how quickly 3D printing has become a regular part of hospitals and medical device companies. We’re not just talking about a few niche applications anymore; it’s a whole system that’s growing up fast. Think about it: back in 2010, only a handful of hospitals even had their own 3D printing setups. Now, that number has jumped to over a hundred, and it’s still climbing. This shift means that more and more medical professionals can get custom solutions made right there, on-site, when they need them. It’s a big change from waiting weeks for specialized parts or devices.

Rise of In-House Hospital Facilities

This move towards hospitals having their own 3D printing labs, often called "point-of-care" manufacturing, is a game-changer. It allows for really quick turnaround times on things like patient-specific surgical guides or anatomical models for pre-op planning. Imagine a surgeon needing a specific tool or model for a complex operation happening tomorrow – having it printed in-house makes that possible. It cuts down on shipping delays and makes the whole process more efficient. Plus, it gives medical teams more control over the design and production process, leading to better-tailored solutions for individual patients.

Key Players in Medical 3D Printing

The companies involved in this space are pretty diverse. You have the big names in 3D printer manufacturing, like Stratasys and HP, who are developing advanced machines specifically for medical use. Then there are specialized medical 3D printing companies that focus on creating patient-specific implants, prosthetics, and surgical instruments. These companies often work closely with hospitals and surgeons to bring innovative designs to life. We’re also seeing software companies developing the tools needed to design and prepare 3D models for printing, making the whole workflow smoother. It’s a collaborative effort, really, with everyone playing a part in pushing the technology forward.

Market Growth and Future Projections

The numbers here are pretty impressive. The medical 3D printing market is expanding rapidly, with projections showing significant growth over the next decade. We’re talking billions of dollars in market value. This growth isn’t just about more printers being sold; it’s about the increasing adoption of 3D-printed medical products across various fields, from orthopedics and dentistry to pharmaceuticals. As the technology matures and becomes more accessible, we can expect even more innovative applications to emerge, further solidifying 3D printing’s place in the future of healthcare. The trend points towards a future where personalized medicine, enabled by 3D printing, becomes the norm rather than the exception.

Addressing Challenges for Wider Adoption

Even though 3D printing is changing healthcare in some pretty amazing ways, it’s not exactly a walk in the park to get it everywhere. There are definitely some bumps in the road that we need to smooth out before it becomes totally normal.

Navigating Regulatory Frameworks

One of the biggest headaches is figuring out all the rules. Different countries and even different regions have their own ideas about what’s okay when it comes to making medical stuff with 3D printers, especially when it’s done right in the hospital. This uncertainty makes it tough for places to invest and feel secure about using these technologies. It’s like trying to build something when the building codes keep changing. We need clearer guidelines so everyone knows what’s expected, from the design all the way to the final product. This is especially true for things like point-of-care manufacturing, where a hospital prints a device on-site.

Overcoming Cost and Material Limitations

Let’s be real, the initial cost of some of these advanced 3D printers can be pretty steep. It’s a big investment for hospitals and clinics. Plus, the materials we can use aren’t always perfect. We’re still looking for more biocompatible options that are also affordable and, ideally, sustainable. Sometimes, the materials used for implants, for example, are much stiffer than bone, which can cause problems down the line. Finding materials that are both safe for the body and good for the planet is a big goal. We also need to think about how to recycle or reuse materials, moving towards a more circular economy in healthcare, which is a key part of sustainable healthcare.

Bridging the Skills Gap in Healthcare

Another thing is that not everyone in the medical field knows how to use this tech. We need more training programs that teach doctors, nurses, and technicians about 3D printing. It’s not just about hitting ‘print’; it involves understanding the design software, the printer itself, and how to make sure the final product is safe and works correctly. Think of it like learning a new language – it takes time and practice. Developing these skills is key to making sure 3D printing is used effectively and safely across the board.

Here’s a quick look at some of the hurdles:

- Regulatory Uncertainty: Lack of clear, consistent rules for 3D-printed medical devices.

- Financial Investment: High upfront costs for equipment and ongoing material expenses.

- Material Development: Need for more biocompatible, affordable, and sustainable materials.

- Workforce Training: Requirement for specialized skills among healthcare professionals.

- Cybersecurity Concerns: Protecting sensitive patient data and digital designs from breaches.

The Road Ahead

So, where does all this leave us? It’s pretty clear that 3D printing isn’t just a passing trend in medicine; it’s really changing things. From making custom implants that fit just right to creating models that help surgeons plan tricky operations, the benefits are huge. Plus, the idea of making things closer to where they’re needed cuts down on waste and shipping, which is good for the planet. Sure, there are still some bumps in the road, like figuring out all the rules, the cost of the machines, and making sure people know how to use them properly. But honestly, the potential is massive. As we work through these challenges, expect 3D printing to become even more common, making healthcare more personal, efficient, and maybe even a bit greener.

Frequently Asked Questions

What exactly is 3D printing in medicine?

Think of 3D printing like building with digital LEGOs. Instead of taking a big block and carving something out, a 3D printer builds an object, like a medical part, layer by layer from a computer design. It’s like printing a toy, but for important medical uses!

How does 3D printing help patients get better care?

It helps doctors make things perfectly fit each person. For example, they can print custom-made body parts, like artificial hips or hands, that are exactly the right size and shape for one patient. This means they work better and feel more comfortable.

Can 3D printing make surgeries safer?

Yes! Doctors can print realistic models of a patient’s body parts, like a heart or a bone, before surgery. This lets them practice the operation beforehand, figure out the best way to do it, and avoid surprises during the actual surgery, making it more precise.

Is 3D printing used for medicines?

It’s starting to be! Imagine getting medicine made just for you, with the exact amount you need. 3D printing can create pills with special layers that release medicine slowly over time, or even make doses perfectly matched to a person’s needs.

Are hospitals starting to use 3D printers themselves?

Many hospitals are now getting their own 3D printers. This means they can create needed medical tools or models right there on-site, instead of waiting for them to be shipped. It makes getting custom medical items much faster.

Are there any problems with using 3D printing in medicine?

There are a few challenges. Sometimes the special materials needed can be expensive, and rules about using these printed items need to be clear. Also, people need to learn how to use these new printers, so there’s a need for training.