So, you’ve got a welder lying around and you’re thinking, ‘Could I actually turn this into a 3D printer?’ Well, it’s not exactly like swapping out a printer head for a hot glue gun, but people are actually doing it. It’s a pretty wild idea, taking something that melts metal and making it build things layer by layer. This whole concept of 3d printing with a welder is still pretty new, and honestly, a bit rough around the edges. But if you’re curious about how it works, what you’d need to do, and what kind of results you can expect, you’ve come to the right place. We’re going to break down how this whole thing works, the challenges involved, and what you might need to get started.

Key Takeaways

- Turning a welder into a 3D printer involves adapting existing 3D printer designs, like those from RepRap, to control a welding process, aiming for a low-cost metal 3D printing solution.

- Modifying your welder setup requires upgrading motor power, protecting components from heat and sparks, and ensuring electrical safety to handle molten metal.

- Key challenges in 3d printing with a welder include managing molten metal flow, preventing fires, controlling the welder’s duty cycle, and using shielding gases and enclosures for better results.

- Building your own welder 3D printer can be achieved for under $2000 by integrating gas metal arc welders with open-source microcontrollers and 3D printer stages.

- Achieving quality in welder 3D printing means understanding resolution limits, dealing with warping from heat, and often using subtractive milling to finish parts.

Understanding The Core Concept Of Welder 3D Printing

So, you’re probably familiar with those 3D printers that use plastic filament, right? They’re pretty neat for making trinkets or prototypes. But what if you want something a bit more… robust? That’s where the idea of turning a welder into a 3D printer comes in. Instead of melting plastic, we’re talking about melting metal, layer by layer, to build up a solid object.

From Plastic Printers To Metal Deposition

Think of it like this: a regular 3D printer has a nozzle that pushes out melted plastic. Our welder-based printer will have a welding torch that deposits molten metal. The process is similar – a computer controls the movement, telling the torch exactly where to go to build up the shape. It’s a big jump from plastic, which is generally easier to control. Metal, when it’s molten, is a whole different beast. It’s hotter, it flows differently, and it can be a lot more dangerous.

The Delft And Michigan Tech Approaches

People have been tinkering with this idea for a while. Researchers at Michigan Tech, for instance, experimented with laying down sheets of steel and then welding them together. That’s one way to do it. Then there’s the approach from Delft University. They took a different route, adapting a standard 3D printer design and integrating a wire-feed welder. Instead of just welding pre-made sheets, they feed a thin wire of metal directly into the welding arc, melting it and depositing it precisely where needed. This method is more akin to how plastic printers work, building up the object from a continuous stream of material.

Here’s a quick look at how the Delft approach differs:

| Feature | Standard Plastic Printer | Delft Welder Printer |

|---|---|---|

| Material | Plastic Filament | Metal Wire |

| Deposition Method | Extrusion | Arc Welding |

| Speed (typical) | ~10,000 mm/min | ~300 mm/min |

Bridging The Gap To Affordable Metal 3D Printing

Right now, industrial metal 3D printers can cost a fortune, often hundreds of thousands of dollars. The goal here is to bring that technology down to a more accessible level. By using common welding equipment and open-source 3D printer designs, the idea is to create a functional metal 3D printer for a fraction of the cost. It’s not going to be as fast or as precise as the high-end machines, at least not yet, but it opens up possibilities for makers, small businesses, and hobbyists who want to experiment with metal additive manufacturing without breaking the bank. This project is all about making metal 3D printing more practical and affordable for everyone.

Essential Modifications For Your Welder 3D Printer Setup

Alright, so you’ve got your welder, and you’re thinking about turning it into a metal 3D printer. That’s a big leap, and it’s not just a matter of plugging things in. You’re going to need to make some serious changes to get it working right and, more importantly, safely. Think of it like upgrading a basic car to a race car – you need more power, better control, and a whole lot of safety features.

Upgrading Motor Power And Drive Systems

Your standard 3D printer motors, like the NEMA 17s, are usually fine for plastic. But metal wire is thicker, heavier, and needs more force to push through the welder’s torch. You’ll likely need to step up to bigger, beefier motors, maybe NEMA 23s or even NEMA 34s. This gives you the muscle to feed the wire consistently without stalling. Another option is to add a gear reduction system or a robust belt drive. This multiplies the torque from your motor, making it easier to handle the resistance. It’s all about getting that smooth, steady wire feed, which is super important for consistent bead width and height. You can find some pretty neat solutions for motor upgrades that might fit the bill.

Implementing Protective Measures For Components

Welding creates a lot of heat and sparks, and your 3D printer parts aren’t exactly built for that. You need to shield everything that’s sensitive. Think about covering threaded rods or lead screws with something fireproof, like a flexible ceramic sleeve. This stops molten metal droplets and sparks from landing on them and causing damage or, worse, a fire. The arms of your printer’s gantry might also need an upgrade. Instead of plastic or weaker materials, consider metal or composite arms that can handle the heat without softening or becoming a fire hazard themselves. Heat rises, after all, and you don’t want your printer’s structure to become part of the problem.

Ensuring Electrical Isolation And Safety

This is probably the most critical part. Your welder operates at high voltages and currents, and you absolutely do not want that electricity interfering with your delicate microcontroller or motors. You need to make sure there’s complete electrical isolation between the welder’s ground circuit and your printer’s electronics. This often involves using optocouplers or dedicated isolation boards. A stalled wire feed, for instance, could lead to a massive pool of molten metal building up, which is a huge fire risk and can ruin your print. Proper isolation and safety checks are non-negotiable. It’s better to be safe than sorry when you’re dealing with this much power.

Addressing The Challenges Of Metal Deposition

So, you’ve got your welder all set up, ready to lay down some metal. But before you get too excited, let’s talk about the messy bits. Working with molten metal isn’t like extruding plastic; it’s a whole different ballgame, and frankly, it can be pretty dangerous if you’re not careful. The biggest hurdle is managing that hot, flowing metal. It wants to go where it wants to go, and if you’re not controlling it, you’re going to have a mess, or worse, a fire. Keeping that molten metal contained and directed is the primary goal.

Managing Molten Metal Flow And Fire Hazards

This is where things get serious. Molten metal is, well, molten. It’s incredibly hot and can easily ignite surrounding materials or cause severe burns. You’ve got to think about containment. Simple gravity can be your enemy here, causing drips and uncontrolled blobs. Some designs try to use capillary action to help control the flow, which is pretty neat, but it’s not foolproof. You also need to consider the environment around your printer. Is it clear of anything flammable? Do you have a fire extinguisher rated for metal fires (Class D) handy? It’s not just about the print itself; it’s about safety.

Controlling The Duty Cycle Of Your Welder

Your standard welder isn’t designed to run continuously for hours on end like a typical 3D printer. They have a ‘duty cycle,’ which is basically the percentage of time they can operate at a given amperage within a 10-minute period before needing to cool down. For example, a welder might have a 60% duty cycle at 100 amps. This means it can run for 6 minutes and needs to rest for 4 minutes. Trying to push it beyond this limit will cause it to overheat and potentially fail. You’ll need to plan your prints around these cooling periods, which can significantly increase print times. It’s a trade-off for using a readily available power source.

The Importance Of Shielding Gases And Enclosures

When you’re melting metal, it reacts with the air. Oxygen and nitrogen can get into the molten pool, causing defects like porosity and embrittlement in your final part. That’s why shielding gases are so important. They displace the air around the weld pool, protecting it. For MIG welding, this is usually a mix of argon and CO2, or pure argon. For TIG, it’s typically pure argon. You’ll need a reliable gas supply and a way to direct the gas precisely where it’s needed. Beyond just gas, a full enclosure can help maintain a stable atmosphere, control drafts, and contain any sparks or splatter. It also helps keep the heat in, which can be beneficial for reducing thermal gradients, though it adds complexity and cost. Research into controlled atmospheres is ongoing, with some methods like rod-leading potentially causing issues with tungsten carbide decomposition [da4a].

Building Your Own Welder 3D Printer: Key Components

So, you’re thinking about building your own metal 3D printer using a welder? That’s pretty ambitious, but totally doable if you’re handy. It’s not like printing plastic; we’re dealing with molten metal here, so safety and the right parts are super important. The goal is to get something functional without breaking the bank, ideally under $2000.

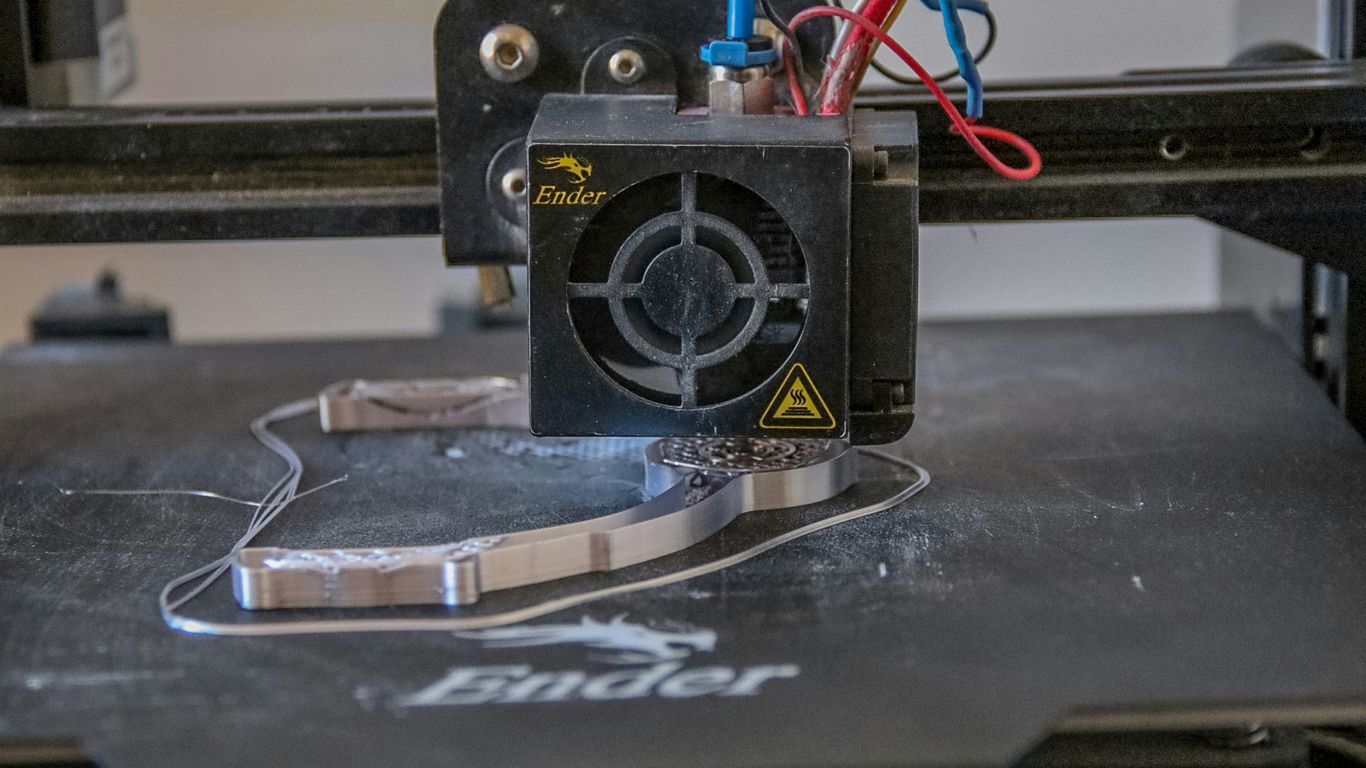

Leveraging Open-Source Microcontrollers And RepRap Designs

This is where the magic starts. You’ll want to use an open-source microcontroller, like an Arduino or something similar, to control the whole operation. Think of it as the brain. These microcontrollers are great because they’re cheap and there’s a huge community around them. You can also adapt designs from existing RepRap 3D printers. These are the printers that really kicked off the DIY 3D printing movement. Many of the mechanical parts and the general structure can be modified for metal deposition. It’s all about repurposing and adapting what’s already out there. You can find a lot of these designs and instructions freely available online, which is a big help when you’re trying to keep costs down. This approach makes metal 3D printing more accessible than ever before.

Integrating Gas Metal Arc Welders

The heart of your metal 3D printer will be a gas metal arc welder, commonly known as a MIG welder. You’re essentially replacing the typical 3D printer hotend with a welding torch. The welder needs to be controlled by your microcontroller. This means you’ll need to figure out how to trigger the welder’s arc and control the wire feed rate precisely. Some projects have replaced the standard trigger with a CNC-controlled switch, allowing the microcontroller to manage when welding starts and stops. This is a key modification for metal printing [7ad1]. The wire feed system needs to be robust enough to handle the metal wire you’ll be depositing.

Cost-Effective Solutions Under $2000

Keeping the cost below $2000 is a challenge, but it’s achievable. Here’s a breakdown of where your money might go:

- Microcontroller & Electronics: $50 – $150 (Arduino, stepper drivers, power supplies)

- Welder (MIG): $300 – $800 (Look for used or entry-level models)

- 3D Printer Mechanics: $200 – $500 (Modified RepRap parts, stepper motors, frame materials)

- Wire Feeder System: $100 – $300 (Custom or adapted parts)

- Safety Equipment & Enclosure: $100 – $300 (Crucial for safe operation)

The total cost can definitely stay under $2000 if you’re resourceful and willing to put in the work. You might need to reinforce the frame with steel or other strong materials to handle the heat and weight. Finding used parts for the 3D printer stage can also save a lot of money. It’s a project that requires patience and a willingness to experiment, but the payoff is a unique piece of technology you built yourself.

Achieving Quality And Precision In Welder 3D Printing

So, you’ve got your welder humming and spitting out metal. That’s awesome! But let’s be real, the first few prints might look more like abstract art than functional parts. Getting good quality and precision with this setup is where the real challenge lies. It’s not quite like printing with plastic, where you can get super fine details.

Understanding Resolution Limitations

One of the biggest hurdles is resolution. Unlike plastic printers that can extrude tiny filaments, molten metal droplets from a welder are naturally bigger. This means your prints will have a coarser finish. Think of it like building with LEGOs versus sculpting with clay – you get different levels of detail.

- Droplet Size: The size of the molten metal droplets directly impacts the surface finish and the smallest features you can create.

- Wire Feed Rate: A slower wire feed rate can sometimes lead to finer control, but it also drastically slows down the printing process.

- Nozzle Design: The design of the welding nozzle plays a role in how the metal is deposited, affecting the bead width and consistency.

Mitigating Warping And Thermal Gradients

Metal expands when it’s hot and shrinks when it cools. This simple fact causes a lot of headaches in the form of warping. As you build layer upon layer, the heat from the new metal interacts with the cooling metal below, creating stress. This is way more intense than with plastics.

- Preheating: Warming up the build plate and the part as it prints can help reduce the temperature difference, lessening the stress.

- Controlled Cooling: Slow, even cooling is key. Avoid drafts or sudden temperature changes.

- Support Structures: Just like with plastic printing, you might need supports for overhangs, but these also need to be designed carefully to avoid adding more stress during removal.

The Role Of Subtractive Milling For Final Parts

Because of these resolution and warping issues, you’ll often find that your welder 3D printed part is more of a starting point. For high-precision applications, a finishing step using subtractive milling is usually necessary. This means taking your rough, 3D printed metal shape and then using a CNC machine to mill away excess material, refining the shape and achieving the final dimensions and surface finish you need. It’s a hybrid approach, combining the speed of additive manufacturing with the accuracy of traditional machining. It’s not a perfect solution for every part, but for many, it’s the most practical way to get a usable metal component from your welder setup.

Exploring Substrate And Material Considerations

Alright, so you’ve got your welder humming and you’re ready to start laying down some metal. But wait, where are you building this thing? The surface you print on, the substrate, is a pretty big deal. It’s not just a flat piece of metal holding your creation; it plays a role in how well your print sticks and, importantly, how easily you can get it off when you’re done.

Ideal Substrate Properties for Adhesion and Release

Think of it like this: you want your molten metal to stick just enough to build up, but not so much that it fuses permanently to your build plate. This is where material science gets interesting. Ideally, you’re looking for a substrate that:

- Conducts electricity: This is key for initiating the welding process. You need a good ground connection.

- Reduces warping: Metal expands and contracts with heat, and this can cause your print to warp or even detach. A substrate that can handle heat well or help dissipate it evenly can make a difference.

- Releases easily: You don’t want to be chiseling your finished part off the build plate. A non-stick surface is the dream, but often a balance has to be struck.

Some materials that have been tried or suggested include graphite, certain types of clay, refractory cements, and even just a simple steel plate. Each has its pros and cons when it comes to adhesion, heat management, and reusability.

Preheating Techniques to Reduce Warping

Warping is the bane of metal printing, just like it is with plastic, but often much worse. When you’re laying down hot metal, the area that’s just been printed cools and shrinks, pulling on the still-hot metal below it. This tension is what causes the warping. Preheating your substrate and the surrounding area can significantly reduce this thermal stress.

Think of it like tempering steel. By bringing the whole build up to a certain temperature before you even start printing, you minimize the temperature difference between the newly deposited metal and the existing structure. This means less dramatic expansion and contraction, leading to flatter, more stable parts. You can achieve this with heating elements under the build plate or even by enclosing the whole setup in a heated chamber. It adds complexity, sure, but it’s often necessary for decent results.

Alternative Substrate Materials for Metal Printing

While a simple steel plate might seem like the go-to, it’s not always the best. For one, metal-on-metal adhesion can be too strong, making part removal a nightmare. Plus, steel can warp itself. This is why people have explored other options:

- Graphite: It’s relatively inert, can handle high temperatures, and often provides a good release surface.

- Ceramics and Refractory Materials: Think fire bricks or specialized cements. These can handle extreme heat and offer good insulation or controlled heat dissipation.

- Composite Materials: Mixing things like iron particles, graphite, and cement can create custom substrates with tailored thermal properties.

Choosing the right substrate isn’t just about what you’re printing on, but also about what you’re printing with. The properties of the metal itself, like its melting point, viscosity when molten, and thermal expansion rate, all interact with the substrate. It’s a whole system, and getting the substrate right is a big piece of that puzzle.

Advanced Techniques And Future Possibilities

So, we’ve talked about the basics and how to get your welder set up for 3D printing metal. Now, let’s look at what’s next. The technology is still growing, and there are some really interesting ideas out there.

Globular Deposition Modeling Of Metals (GDMm)

This is a newer way to think about metal 3D printing. Instead of trying to get a super fine, continuous stream of metal like some other methods, GDMm focuses on depositing larger, "globular" droplets of molten metal. Think of it like a really precise, automated version of hand-welding, but with much better control. This approach can lead to faster build times for certain applications. It’s not about super fine detail, but more about building up bulk material quickly. It’s still being explored, but it could be a game-changer for making larger, less intricate metal parts.

Exploring Additive Lathe Capabilities

What if you could combine 3D printing with a lathe? That’s the idea behind an "additive lathe." Imagine a machine that can both add material layer by layer and also spin a part to shape it precisely. This could be amazing for making things like custom medical implants, parts for wheelchairs, or even rebuilding worn-out engine components. You could print a rough shape and then immediately machine it to its final form, all in one go. This kind of multi-process machine could really speed up production and open up new design possibilities.

Potential Applications In Manufacturing And Art

The future here is pretty wide open. We’re talking about making custom car parts, unique bike frames, or even specialized farm equipment. Think about creating complex artistic sculptures that would be impossible to make with traditional methods. Even things like cookware or custom hardware for your home could be produced. The ability to create complex metal shapes on demand could really shake things up in many industries. It’s not just about making functional parts; it’s also about enabling new forms of creative expression.

Wrapping It Up

So, there you have it. Turning your welder into a metal 3D printer isn’t exactly a weekend project for the faint of heart, but it’s definitely something you can tackle. We’ve gone over the basics, talked about some of the tricky bits, and pointed out where you might need to get a little creative. It’s not going to be perfect right out of the gate, and there are definitely safety things to keep in mind. But the idea of making metal parts this way, especially when you can do it without breaking the bank, is pretty exciting. Keep tinkering, keep learning, and who knows what you’ll build next.