So, you’re curious about windmill blades size, huh? It’s a pretty big deal, literally. These giant spinning arms are what grab the wind and turn it into electricity. We’re talking about blades that can be longer than a football field these days. It makes you wonder how they even build them, let alone get them to a windy spot. Let’s break down what goes into making these massive things and why their size matters so much for getting clean energy.

Key Takeaways

- Making windmill blades bigger means they catch more wind, but it also makes them way heavier and harder to build and move. Power goes up with the square of the length, but the weight and stress go up even faster.

- The shape of the blade is super important. Engineers have figured out how to make blades twist and bend in ways that help them last longer and catch more wind, even when it’s gusty.

- New blade designs, like those with a flatter back edge, are easier to make and still work really well. This helps keep the cost of wind energy down.

- The way a blade is shaped along its length, with twists and narrower tips, helps it grab the wind most effectively from root to tip, reducing drag and getting more power.

- Bigger blades capture more energy, especially in the outer part. Designing blades to be longer, lighter, and easier to manufacture is key to making wind power cheaper and more widespread.

Understanding Windmill Blades Size Dynamics

So, you want to talk about windmill blades, huh? It’s not just about making them bigger for more power, though that’s a big part of it. There’s a whole lot of science and engineering that goes into figuring out just how big these things can get and what happens when they do.

Blade Length Scaling Effects

Think about it: if you double the length of a blade, you’re not just doubling the power you can catch. Nope, the power output actually goes up with the square of the length. That sounds great, right? More power! But here’s the catch – the weight and the stress on the blade go up even faster, like with the cube of the length, or even more. This means that as blades get longer, the engineering gets way more complicated, and the materials needed become a bigger deal. We’re constantly trying to find that sweet spot where we get the most energy without the whole thing becoming too heavy or too stressed to be practical. It’s a balancing act, for sure.

Physical Constraints of Larger Blades

When blades get really long, gravity starts to pull them down a lot more, and the wind pushes them around with much more force. All this extra pressure is concentrated at the base of the blade, where it connects to the turbine. We need materials that are super strong but also really light to handle these forces. If blades get too long, they can start to wobble or shake in ways that are bad for the turbine. We’ve got to be careful about that, and sometimes we need fancy computer systems to keep everything steady.

Logistical Challenges of Oversized Components

Okay, so you’ve designed these giant blades. Now what? Getting them from the factory to where the wind farm will be is a whole other headache. These things are massive – hundreds of feet long and weighing tons. You need special trucks, sometimes you have to close roads, and you might even need to build temporary bridges or widen roads. It all adds up, making the whole project more expensive and taking more time. It’s not just about the blade itself, but the whole journey it has to take.

Evolution of Blade Design for Enhanced Performance

The Quest for More Energy at Lower Costs

Back in the day, wind power wasn’t exactly the cheapest way to get electricity. It was more expensive per kilowatt-hour than what you’d get from traditional power plants. The wind industry knew it needed to make turbines that could reliably churn out more power. The big idea was that bigger rotors, meaning longer blades, could grab more wind and thus lower the cost per kilowatt-hour. But here’s the catch: just making blades longer meant they got way heavier and more expensive, almost canceling out the benefits. Plus, even a little increase in blade length meant more wear and tear from wind gusts and turbulence.

Balancing Aerodynamic and Structural Engineering

This is where things got tricky. Aerodynamic folks wanted blades to be super thin, from the root all the way to the tip, to catch as much wind as possible. Thinner blades mean less drag, which is great for making power. On the flip side, structural engineers were pushing for thicker blades because they’re just stronger and can handle the stress better. Meanwhile, the manufacturing teams were having a tough time keeping quality consistent when layering materials like fiberglass to create these complex shapes with specific internal structures. It was a real balancing act.

Innovations in Blade Airfoils

To tackle these challenges, researchers started looking into some pretty neat ideas. Two that really made a difference were bend-twist-coupled blades and flatback airfoils. These concepts had been kicked around for airplanes before, but nobody had really given them a serious shot for wind turbines.

- Bend-Twist-Coupled Blades: Normally, blades just bend when the wind blows hard. But these special blades actually twist as they bend. When strong winds push them, this twisting action changes how the blade meets the wind, which reduces the stress on the blade. This means you can make blades longer without adding a ton of weight or cost.

- Flatback Airfoils: This was another game-changer for making blades lighter. Flatback airfoils are easier to build and actually make the blades stronger and better at catching wind.

These innovations, developed with support from places like the Department of Energy’s Wind Energy Technologies Office, national labs, universities, and manufacturers, really helped push wind energy forward. They allowed for longer, lighter, and cheaper blades, contributing to significant cost reductions in wind energy production. It’s a great example of how different engineering fields working together can lead to big improvements.

Key Innovations in Windmill Blade Technology

Bend-Twist-Coupled Blades Explained

So, you know how regular windmill blades bend when the wind really picks up? That’s normal, but sometimes strong gusts can make them bend too much, or the constant flexing from turbulence can wear them out faster. Bend-twist-coupled blades are pretty neat because they do something extra: they twist as they bend.

Think of it like this: when the wind pushes the blade, it also twists it a bit. This twist changes how the blade meets the wind, kind of like adjusting your grip on a steering wheel. This clever twist helps reduce the stress on the blade, making it last longer and allowing engineers to make blades even longer without adding a ton of weight or cost. It’s a smart way to handle those powerful wind forces.

The Role of Flatback Airfoils

Another big step forward came with what are called flatback airfoils. If you imagine the cross-section of a blade, most used to be really thin and curved all the way through. Flatback airfoils change that by having a flatter, or shorter, edge on one side.

Why is this a big deal? Well, these shapes are:

- Easier to make: Manufacturing complex, thin curves can be tricky. The flatback design simplifies some of the layering and structural work.

- Stronger: They can handle more load, which is important for those longer blades.

- More efficient in certain spots: While thinner airfoils are great for the outer parts of the blade where the wind moves fastest, the flatter, thicker design works really well closer to the hub where the structural demands are higher.

Impact of Innovations on Energy Cost

Putting these two ideas together – bend-twist-coupled blades and flatback airfoils – has had a pretty significant effect on how much wind energy costs. Before these innovations, making blades longer to capture more wind meant they got much heavier and more expensive, often canceling out the benefits.

But with these new designs, engineers can create blades that are longer, lighter, and cheaper to produce. This means each turbine can generate more electricity. Studies have shown that the combination of these technologies has helped bring down the cost of wind energy by a good chunk, making it a more competitive option for powering our homes and businesses. It’s a great example of how smart engineering can make renewable energy more accessible.

Aerodynamic Principles Guiding Blade Design

So, how do these giant blades actually grab wind and turn it into electricity? It all comes down to some pretty neat physics, mostly about how air moves around a shape. Think of a wind turbine blade like an airplane wing, but instead of flying through the air, it’s the air moving past the blade. The shape is key.

Optimizing Angle of Attack Along Blade Length

The "angle of attack" is basically the angle between the wind and the blade’s surface. Get it just right, and you get maximum "lift" – the force that pushes the blade to rotate. Too steep an angle, and the air gets messy, creating drag and reducing lift. Too shallow, and not enough wind is captured. The tricky part is that the tip of the blade moves much faster than the part near the center (the root). So, engineers design blades with a twist. Near the root, where the wind speed is slower, the angle of attack is steeper. As you move towards the tip, where the wind is zipping by, the blade twists to present a shallower angle of attack. This twist helps keep the angle of attack pretty much optimal all the way along the blade, grabbing as much energy as possible.

Lift Versus Drag Forces

When wind hits a blade, two main forces are at play: lift and drag. Lift is what we want; it’s the force that makes the blade spin. Drag is the resistance, the air pushing back against the blade, trying to slow it down. The curved shape of the blade is designed to create more lift than drag. It’s a constant balancing act. Engineers tweak the shape, the twist, and the taper to get the most lift possible while keeping drag to a minimum. It’s like trying to glide through water versus pushing through it – you want to slide, not fight.

The Benefits of Twisted and Tapered Blades

We’ve touched on twist, but tapering is also super important. Tapering means the blade gets narrower as it goes from the root to the tip. Why do this? Well, a wider blade at the root provides more strength to handle the bending forces. As the blade gets narrower towards the tip, it reduces weight and also helps manage drag. Combining this taper with the twist we talked about creates a blade that’s not only efficient at capturing wind energy across its entire length but is also structurally sound and lighter. It’s a smart way to get more power without making the blades ridiculously heavy or prone to breaking.

Manufacturing and Material Considerations

So, making these giant windmill blades isn’t exactly like baking a cake. As blades get longer, the amount of material needed goes up, and so does the complexity of putting them together. We’re talking about huge amounts of fiberglass and special glues, and then there’s the whole issue of what to do with them when they’re past their prime. It’s a big puzzle.

Production Processes for Longer Blades

Building longer blades means using more stuff, plain and simple. Think tons of fiberglass and epoxy resin. The process itself gets trickier too. Structural engineers want thicker blades for strength, while aerodynamic folks prefer thinner ones for better airflow. It’s a balancing act. Early on, getting the layers of fiberglass just right for these complex shapes was a real headache, leading to some quality control issues. The push is on to find ways to make these massive components more efficiently and with less waste.

Material Consumption and Waste Management

All this material use brings up a significant problem: what happens to old blades? They’re pretty hard to recycle right now. This is why researchers are looking into new ideas, like making blades in sections that can be put together on-site, or even using materials that are better for the environment. It’s all about trying to make wind energy as green as possible, from start to finish.

Advantages of Flatback Airfoils in Manufacturing

Here’s where things get interesting. The flatback airfoil design, which has a flatter back side, has been a game-changer for manufacturing. Instead of needing super precise, tapering layers for the main load-carrying part of the blade, you can often use a single piece of constant thickness. This makes the whole process simpler and helps keep the quality consistent. It’s a win-win: easier to build and still good for catching wind. It’s like finding a shortcut that actually works better.

The Impact of Blade Size on Energy Capture

So, how does the size of a windmill blade actually affect how much power we can get from the wind? It’s not just about making them bigger for the sake of it. There’s a whole science behind it, and it really boils down to a few key things.

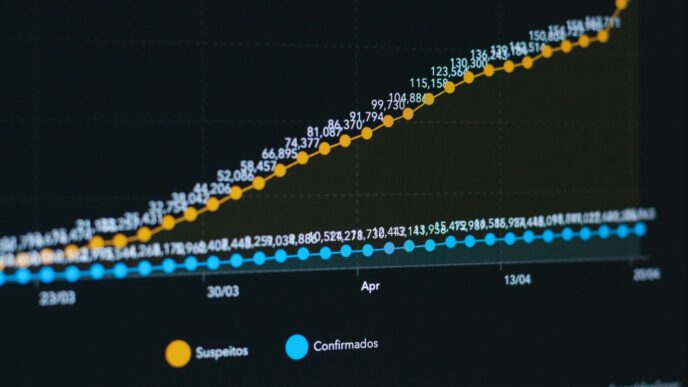

Rotor Diameter and Power Output

This is probably the most straightforward part. Think of a windmill blade like a giant scoop. The bigger the scoop, the more wind it can catch. The power a wind turbine can generate scales up pretty dramatically with the size of its rotor, which is basically the circle the blades sweep out. Specifically, the power output increases with the square of the rotor diameter. So, if you double the length of the blades, you’re not just getting double the power; you’re getting four times the power. That’s a huge jump! But, as you can imagine, making blades much longer also means they get a lot heavier and put more stress on the whole turbine structure. It’s a balancing act, for sure.

Energy Production Distribution Along the Blade

It might surprise you to learn that not all parts of the blade are doing the same amount of work. The real energy-grabbing happens mostly on the outer half of the blade. The inner part, closer to the hub, has a tougher job. It needs to be strong enough to handle all the forces from the outer sections and transfer that energy to the generator. This means the design needs to be smart: beefier and more structurally sound near the root, and more focused on catching wind efficiently further out. This is where innovations like using different airfoil shapes along the blade come into play, making the most of each section’s role.

Achieving Optimal Tip Speed Ratio

Ever watched a windmill spin? You might notice how fast the tips are moving compared to the wind speed. That relationship is called the Tip Speed Ratio (TSR). Getting this ratio just right is super important for getting the most energy out of the wind. If the blades spin too slowly, they’re not capturing enough wind. If they spin too fast, they can actually become less efficient and put too much strain on the turbine. The ideal TSR depends on the blade’s shape, how many blades there are, and even the design of the propeller itself. Engineers spend a lot of time tweaking blade designs to hit that sweet spot for maximum energy capture across different wind conditions.

Wrapping It Up

So, we’ve talked a lot about windmill blades, from how big they are to how they’re made and what makes them work. It’s pretty wild how something so big can be so finely tuned. We saw how making blades longer helps grab more wind, but it also brings a whole host of challenges, like needing stronger materials and figuring out how to move these giants around. Plus, the way they’re shaped, with twists and curves, is all about catching the wind just right to make electricity efficiently. Innovations like bend-twist blades and flatback airfoils show that engineers are always finding smarter ways to build them, making wind power more reliable and cheaper. It’s a constant process of figuring out the best balance between size, strength, cost, and how much power we can get. Pretty neat stuff, really.